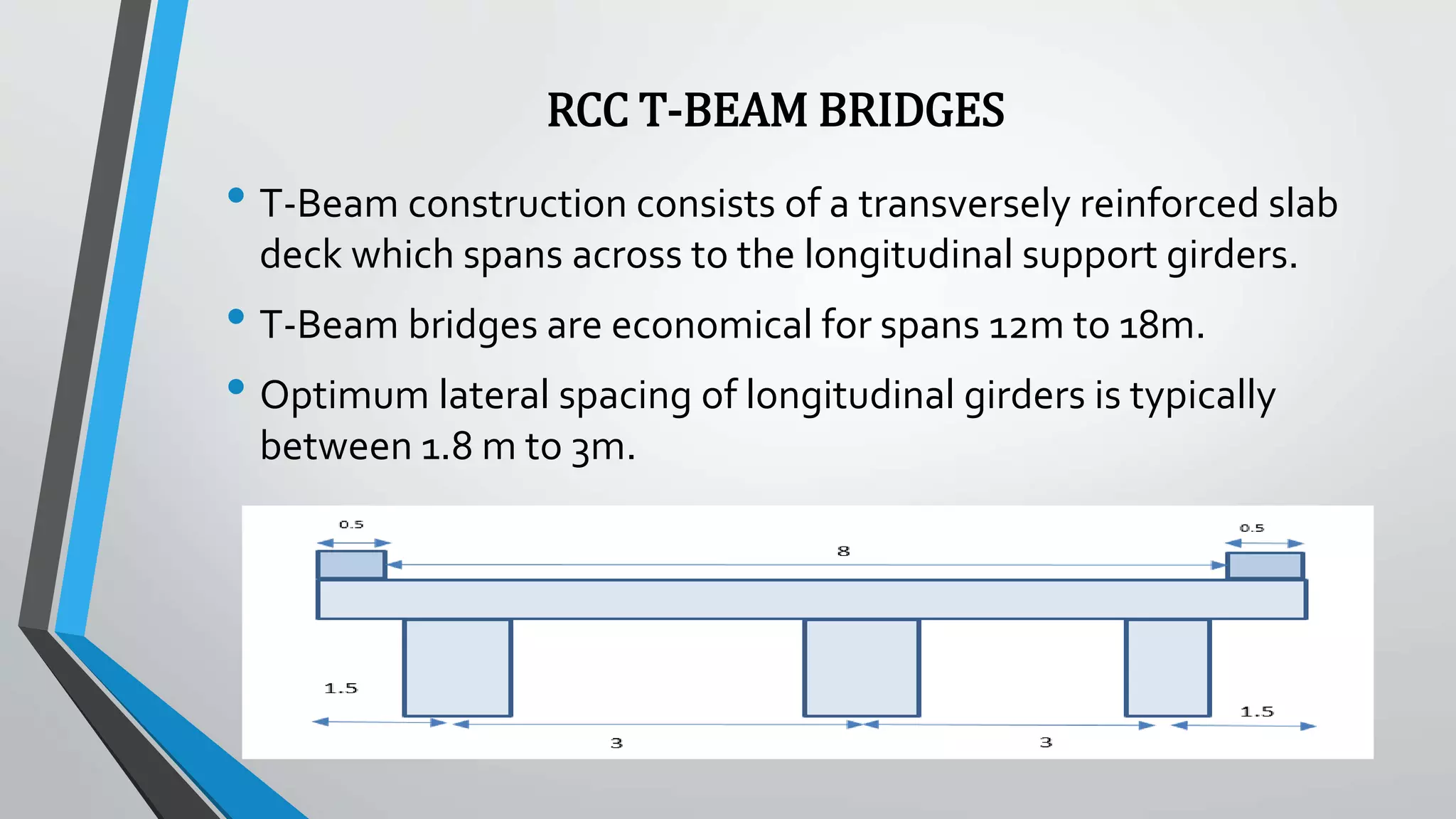

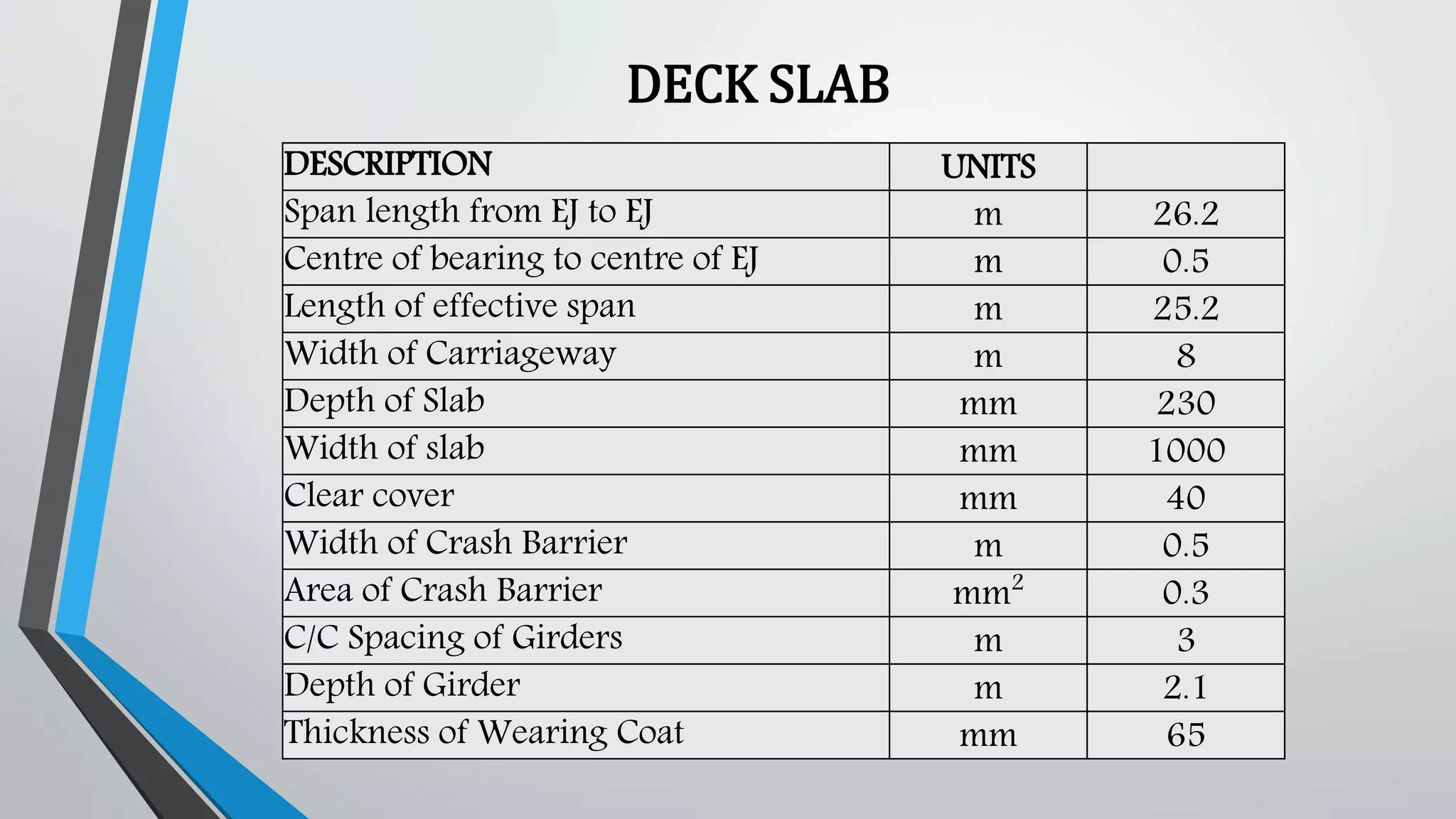

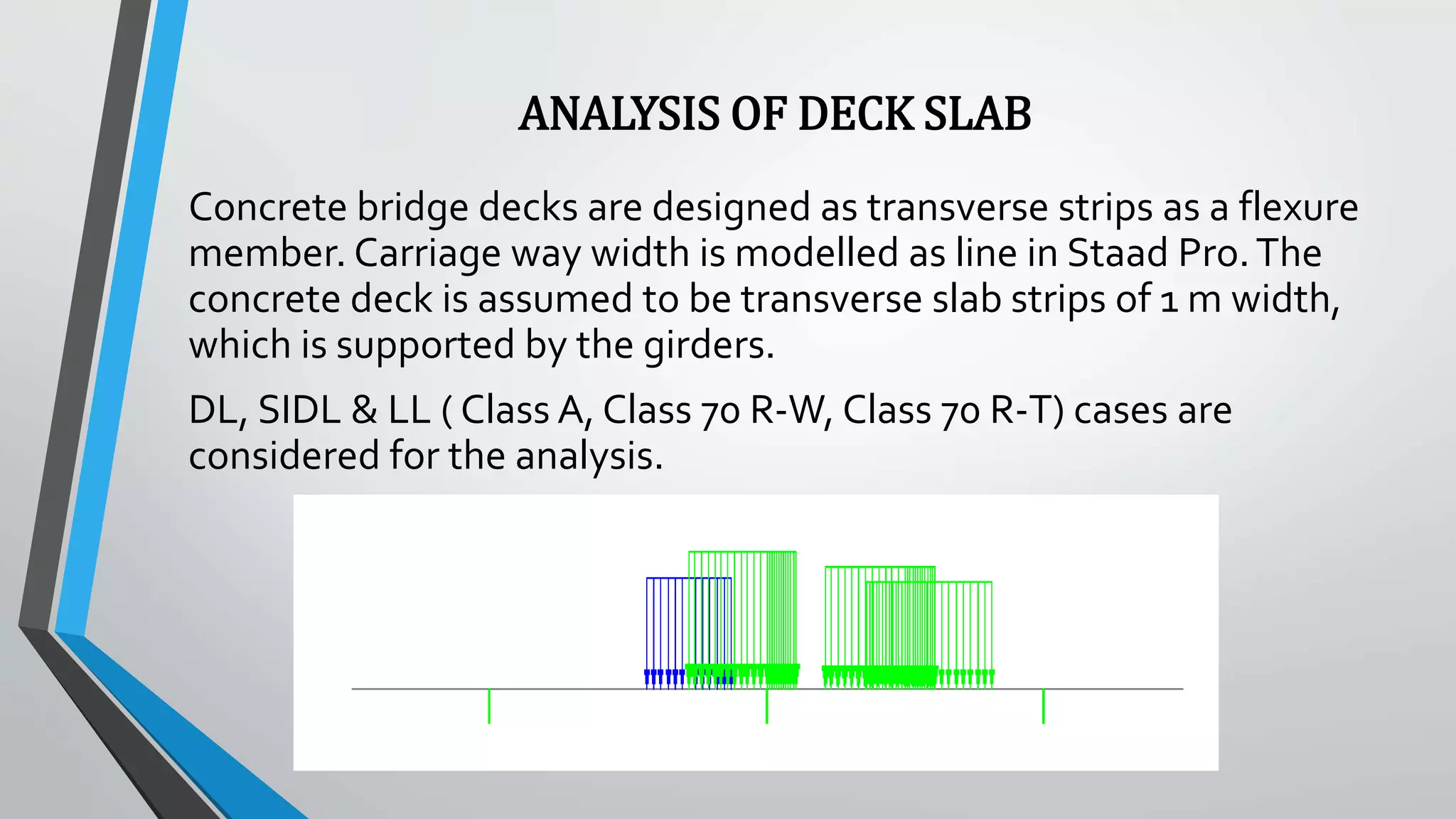

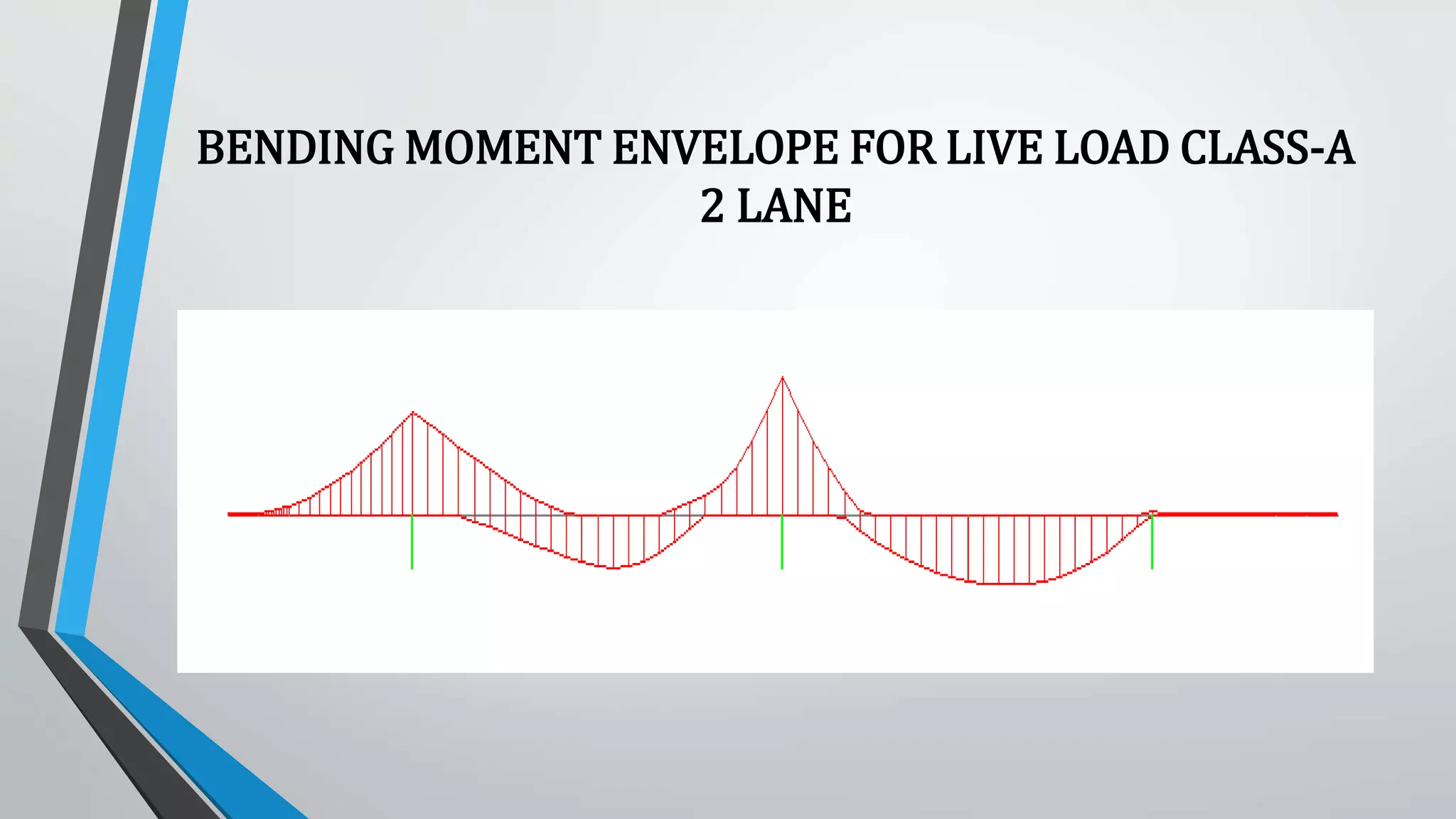

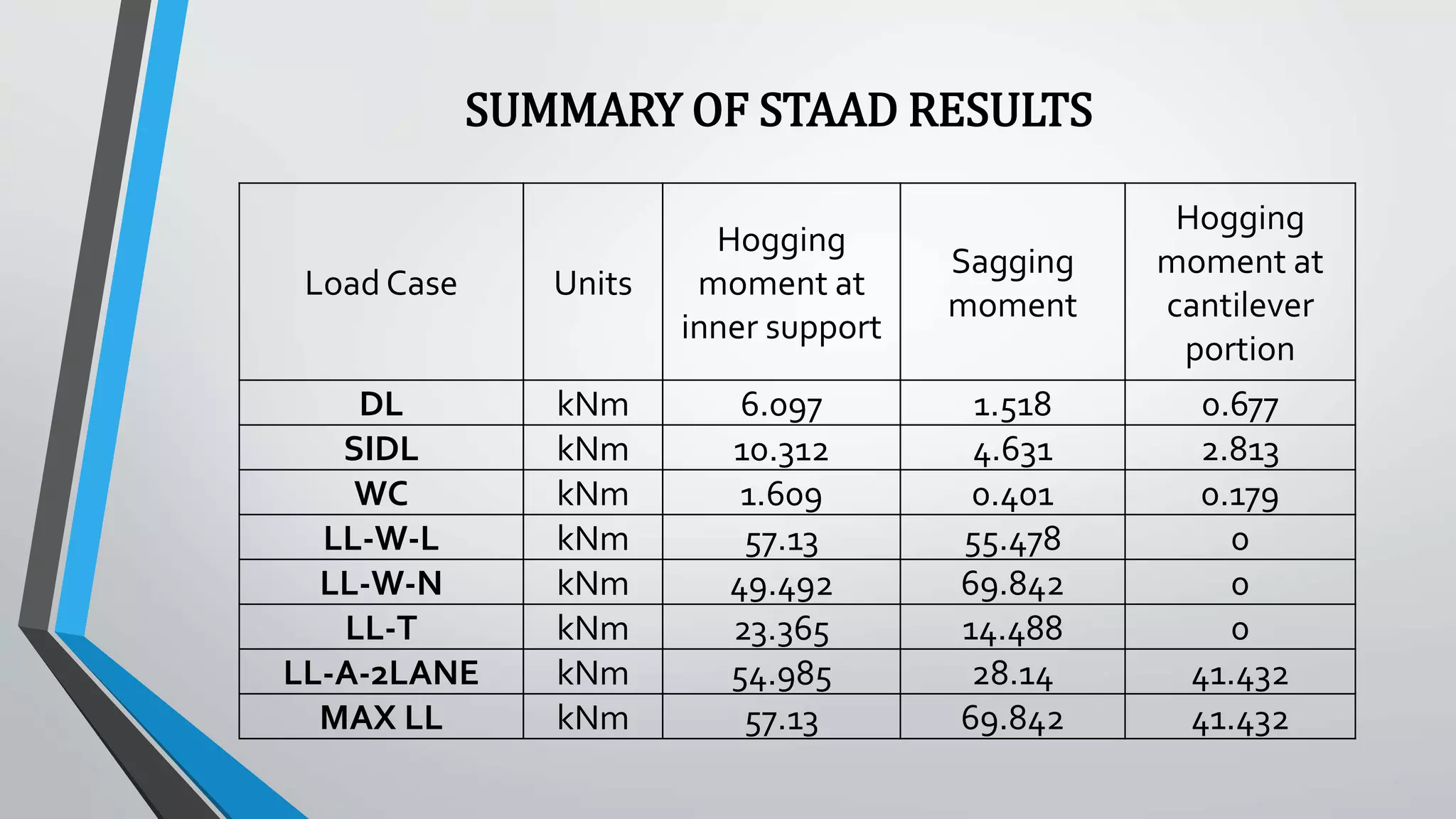

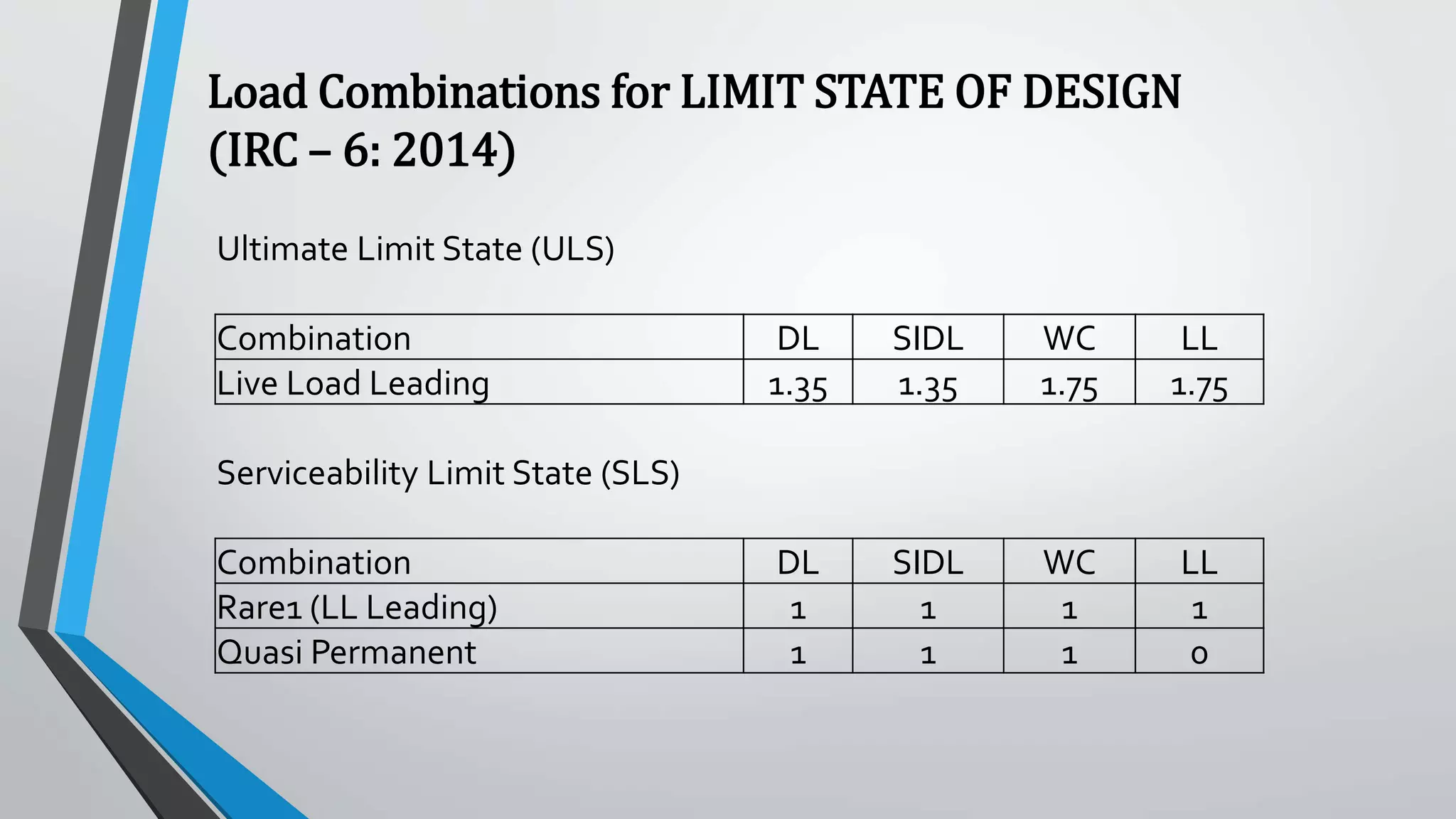

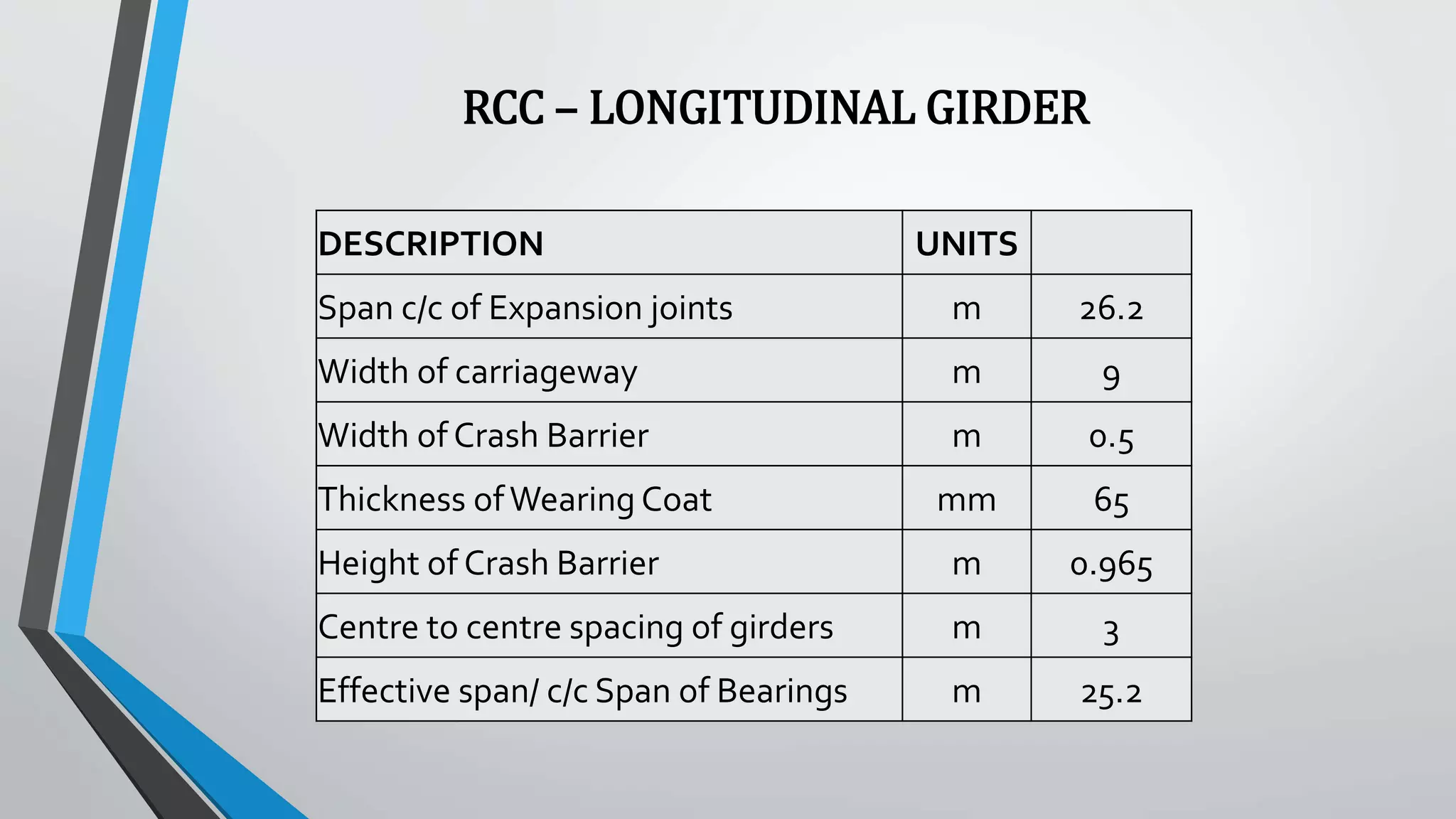

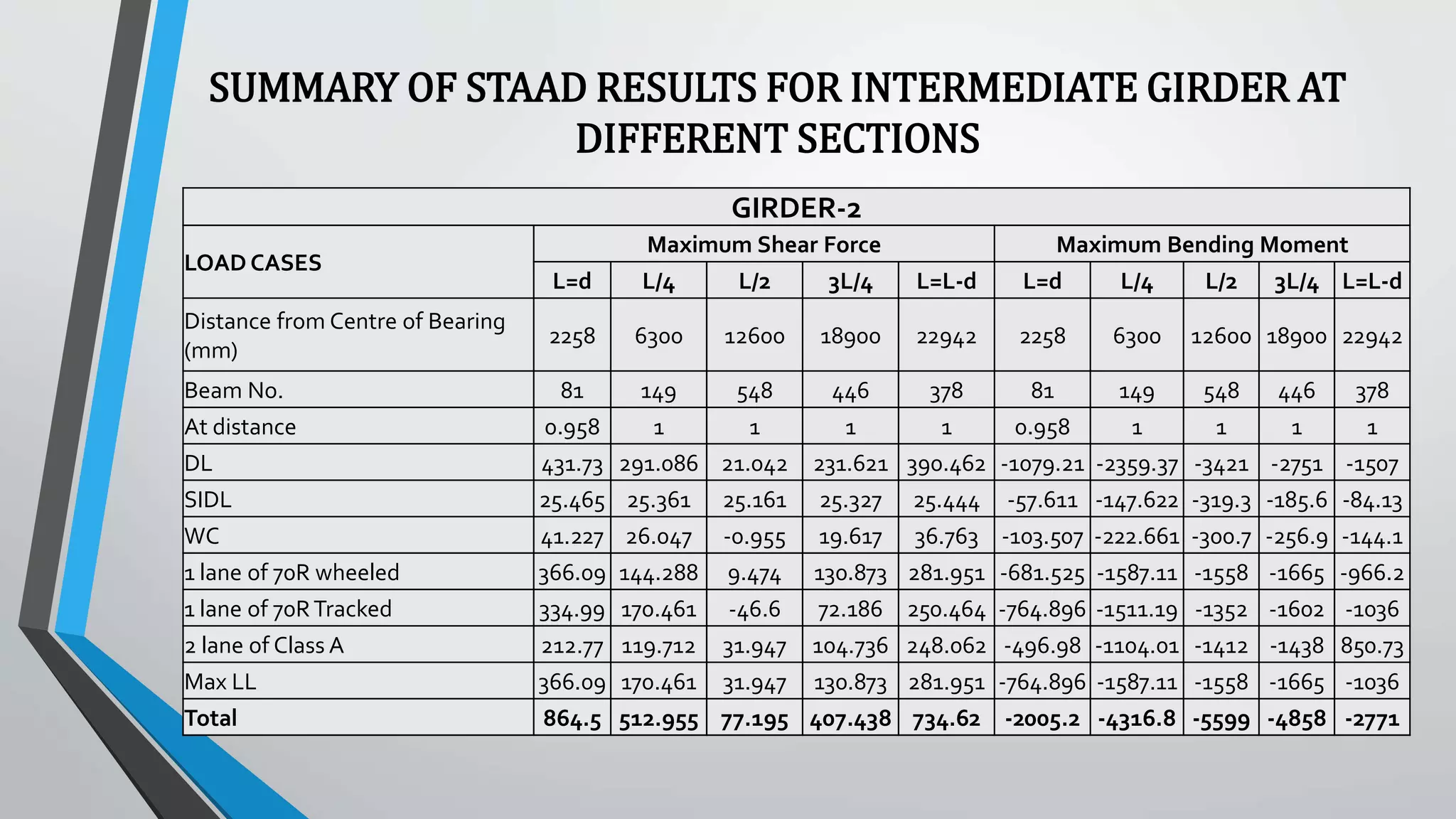

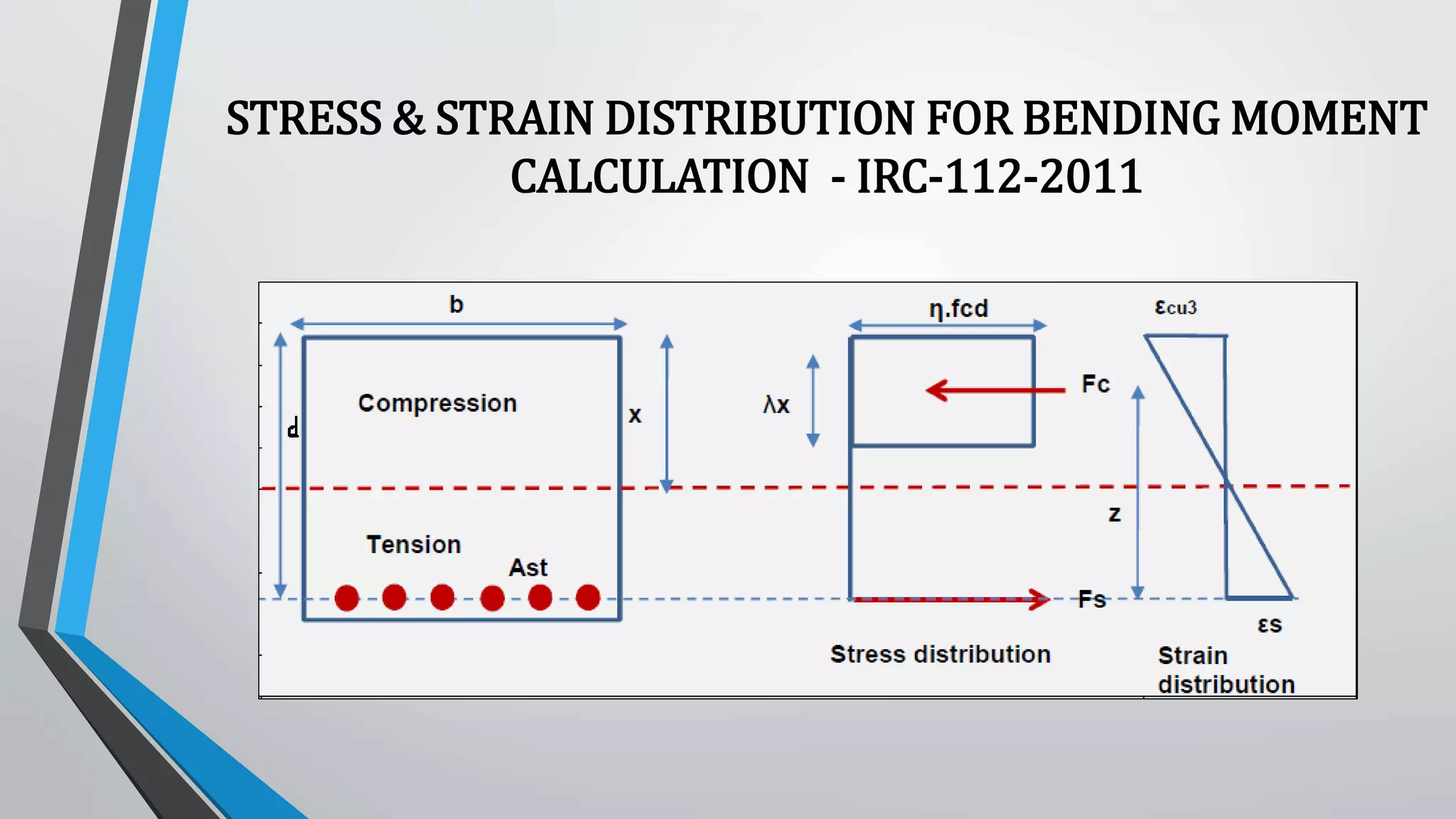

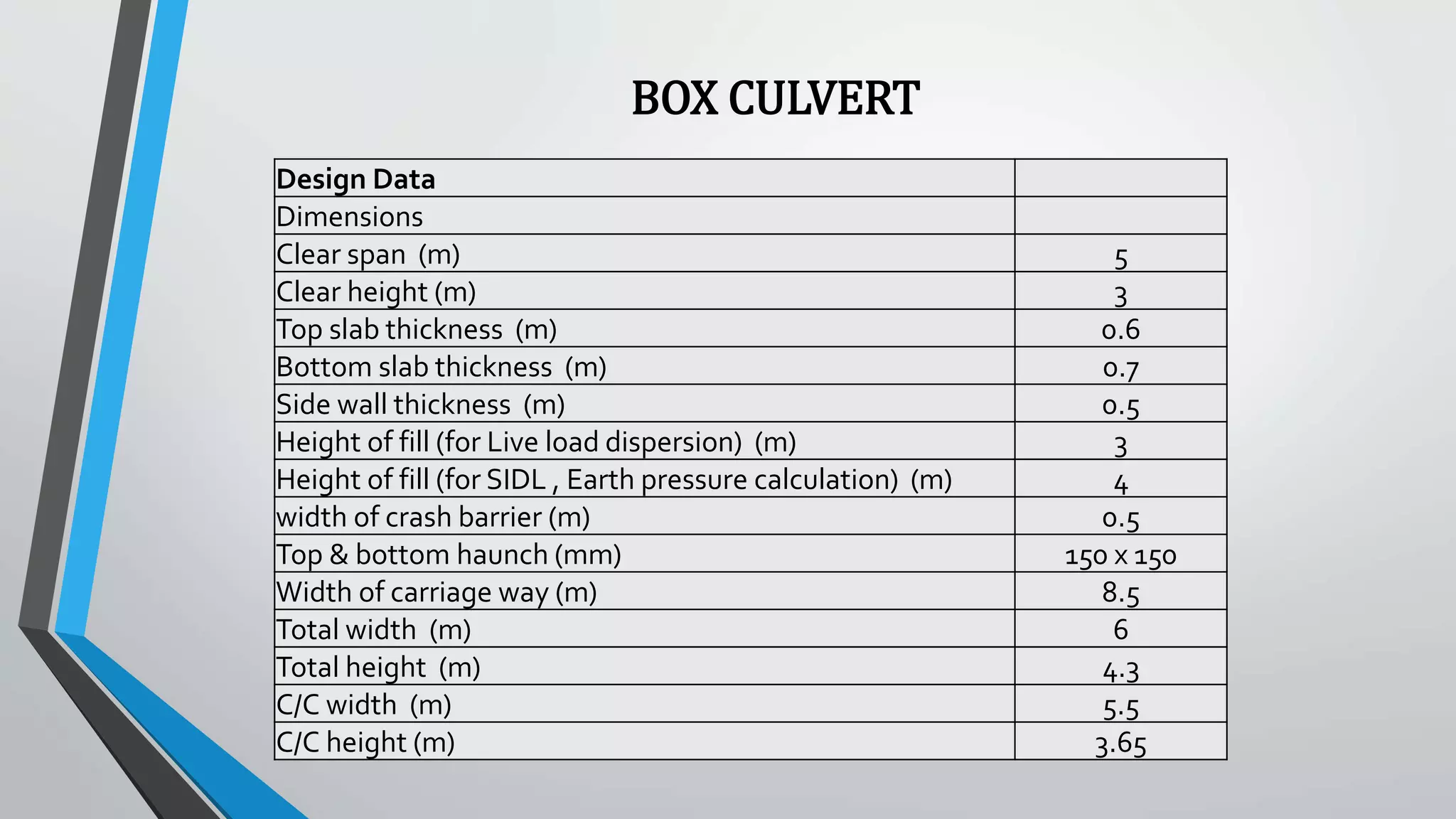

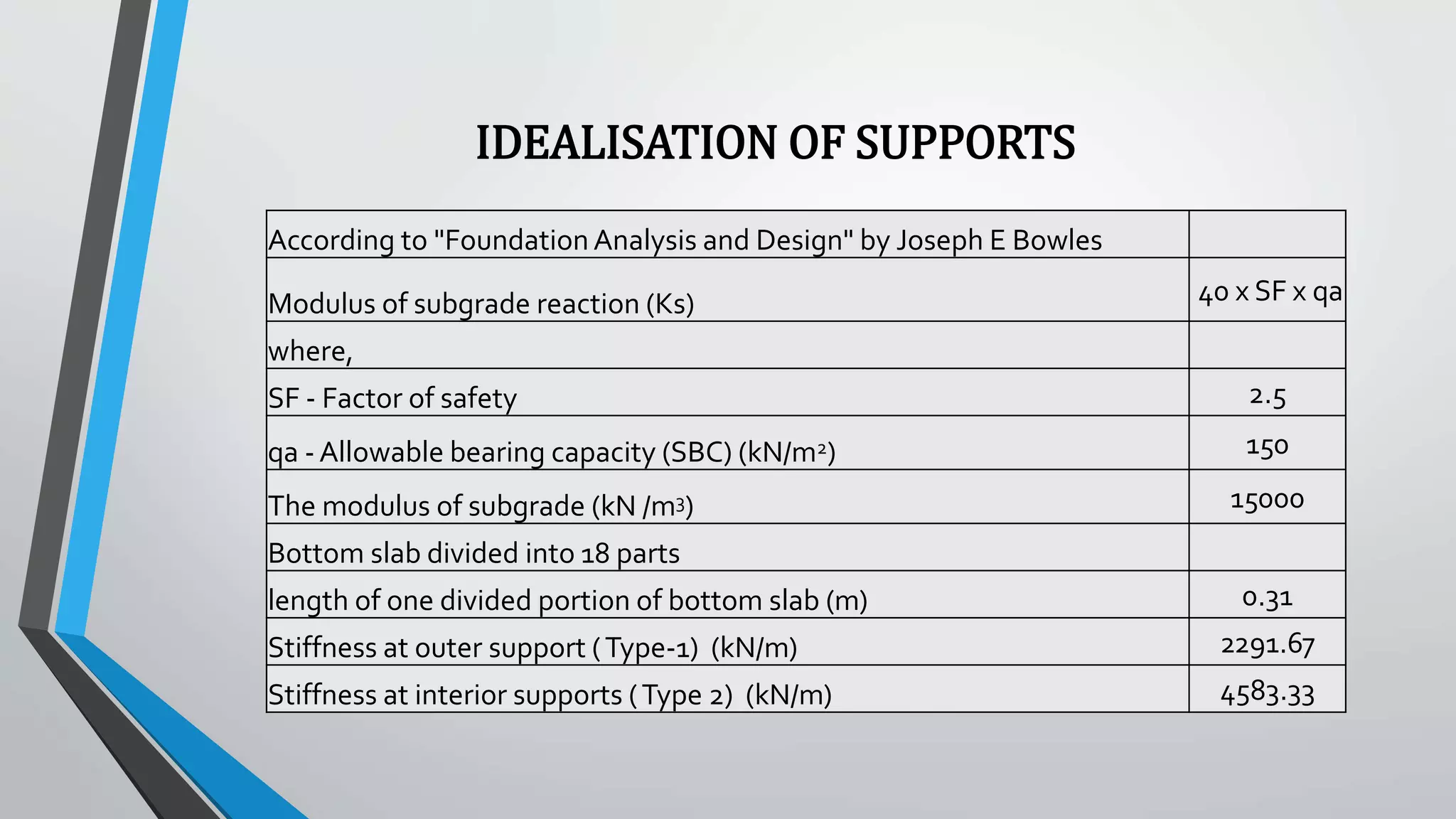

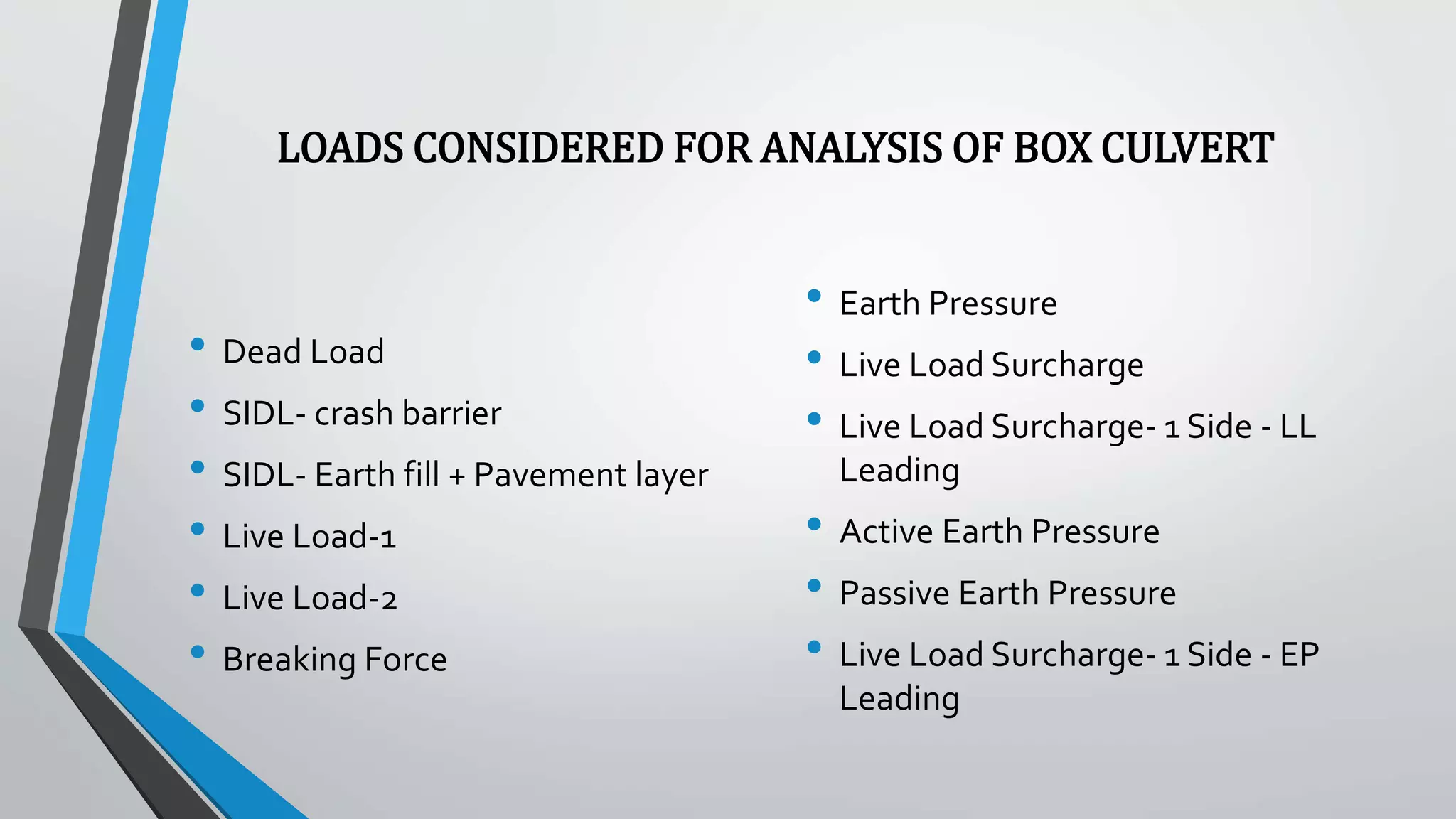

The document details an internship report on bridge superstructure analysis and design, focusing on T-beam bridges, structural design requirements, load considerations, and the limit state method for analysis. It emphasizes the various components of bridges, including decking, bearings, and foundations while outlining the essential calculations and structural checks for determining strength, stability, and serviceability. The report concludes with references to relevant Indian Road Congress codes and literature on concrete bridge practice.