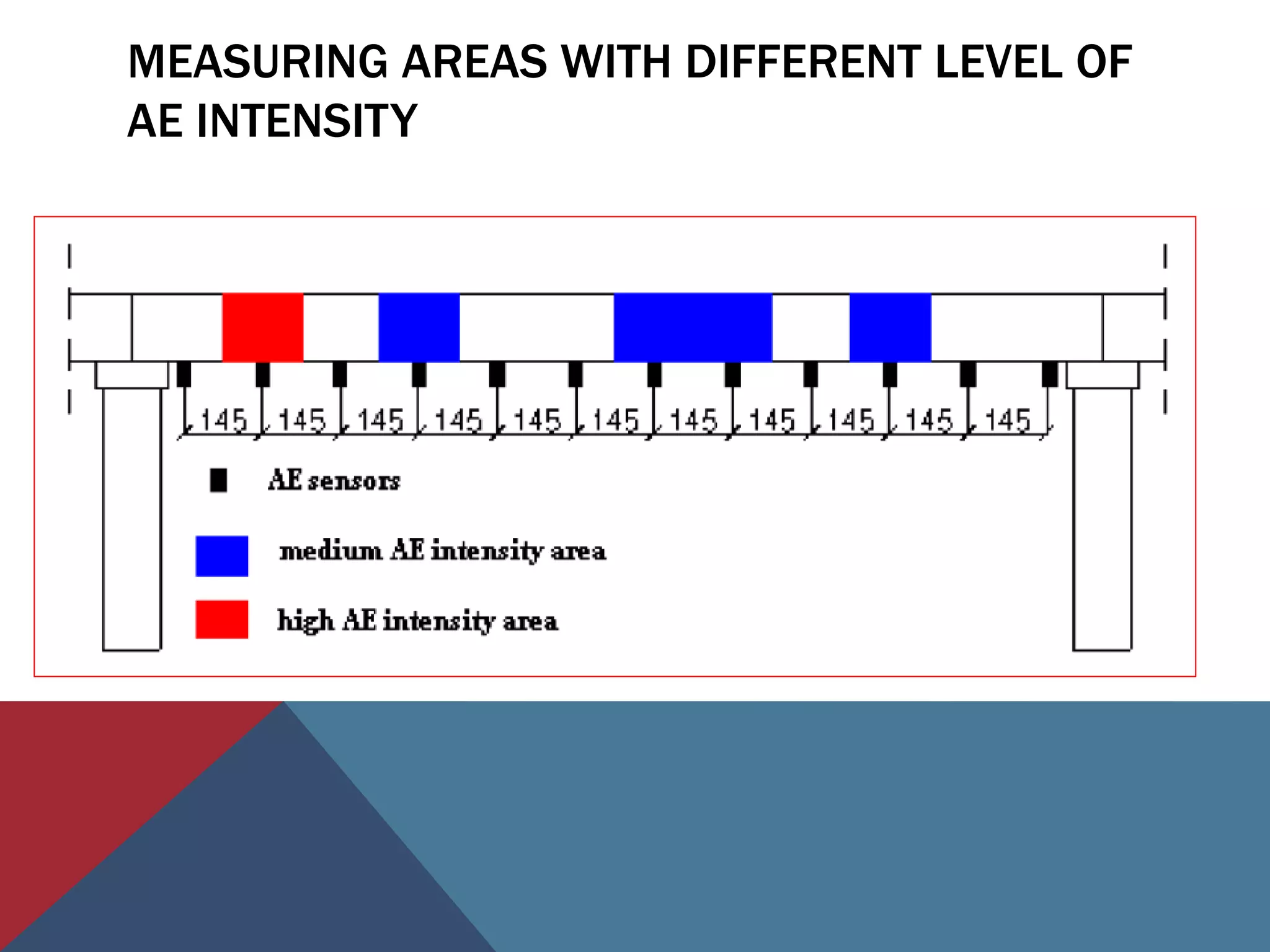

This document discusses bridge defects and maintenance. It covers topics like acoustic emission testing of concrete bridges, common bridge defects like corrosion, and methods to protect bridges. Bridge deck waterproofing is also discussed, noting the two main types of waterproofing systems used are sheet and liquid sprayed systems. The document emphasizes the importance of maintenance to enhance bridge durability and extend lifespan.