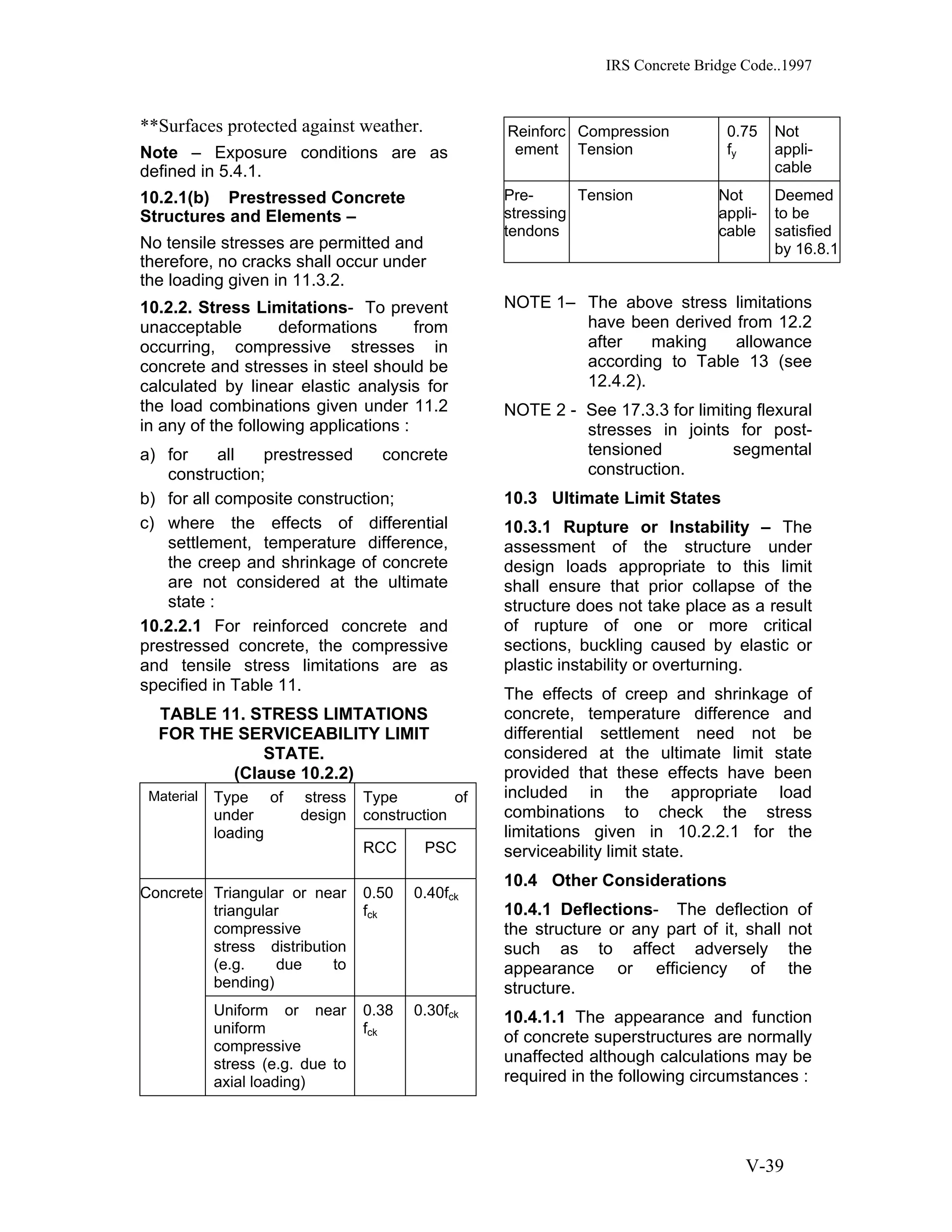

This document is the Indian Railway Standard Code of Practice for plain, reinforced and prestressed concrete for general bridge construction from 1997. It provides definitions for terminology used, specifies materials and workmanship for concrete, reinforcement and prestressing tendons. It defines loads, load combinations and requirements for limit state design. It provides recommendations for the design and construction of plain concrete, reinforced concrete and prestressed concrete bridges. The document covers topics such as concrete mix design, formwork, reinforcement, transportation and curing of concrete, prestressing, precast construction, and load testing.

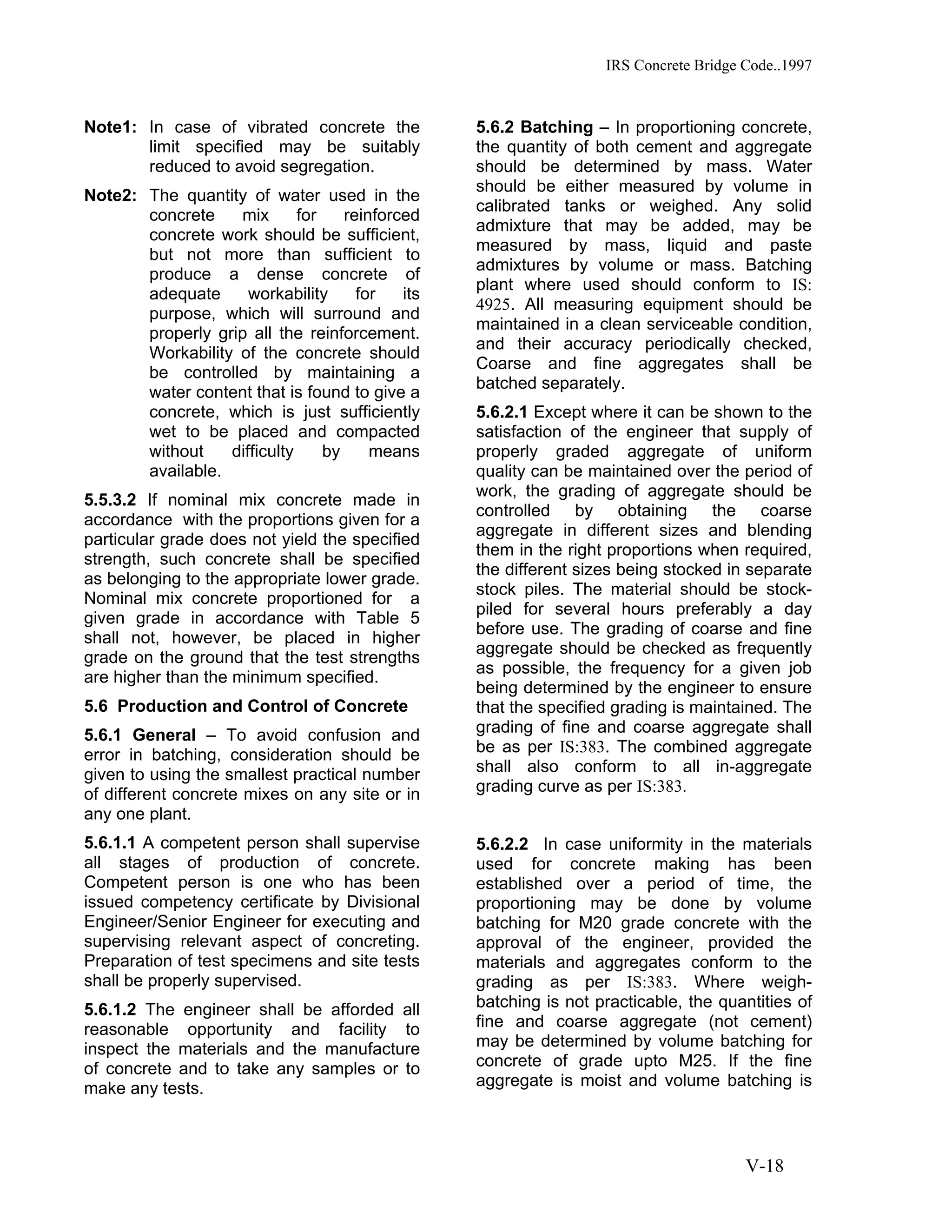

![IRS Concrete Bridge Code..1997

V-38

Effective pumping range is upto 300m

horizontally and 90m vertically.

8.9.3 Proportioning Pumpable

Concrete

8.9.3.1 Basic Consideration- More

emphasis on quality control is essential

to the proportioning and use of a

dependable pump mix. Concrete mixes

for pumping must be plastic. Particular

attention must be given to the mortar

and to the amounts and sizes of coarse

aggregates.

8.9.3.2 The maximum size of angular

coarse aggregate is limited to one-third

of smallest inside diameter of the hose

or pipe. Provisions should be made for

elimination of oversized particles in the

concrete by finish screening or by

careful selection of aggregates.

8.9.4 Pumping Concrete – Proper

planning of concrete supply, pump

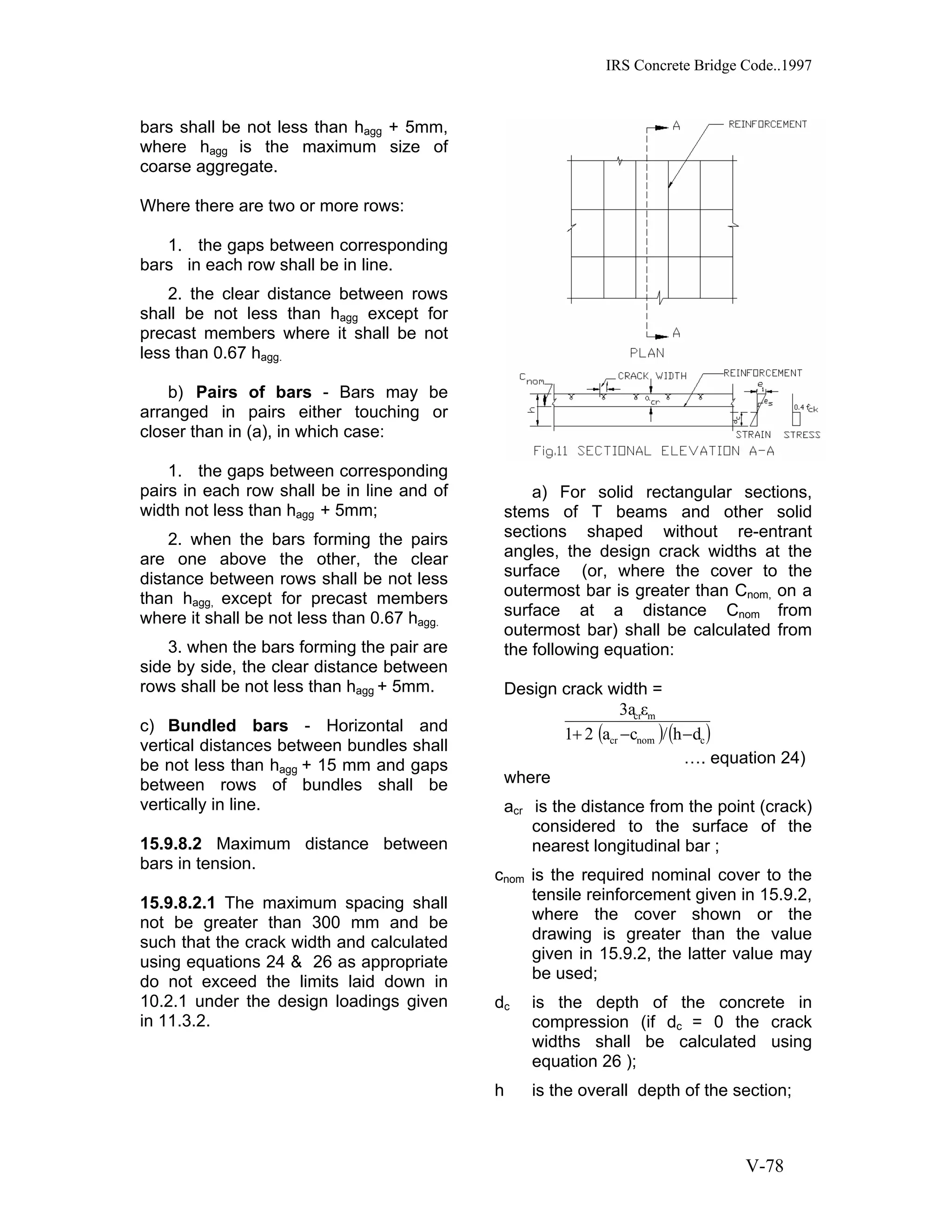

locations, line layout, placing sequences

and the entire pumping operation will

result in saving of cost and time. The

pump should be placed as near the

placing area as practicable and the

entire surrounding area must have

adequate bearing strength. Lines from

the pump to the placing area should be

laid out with a minimum of bends. The

pipe line shall be rigidly supported.

8.9.4.1 While pumping downward 15m

or more, it is desirable to provide an air

release valve at the middle of the top

bend to prevent vacuum or air build-up.

When pumping upward, it is desirable to

have a valve near the pump to prevent

reverse flow.

9 GROUTING OF PRE-STRESSING

CABLES.

9.1 A recommended practice for

grouting of cables is given at

Appendix D.

10. LIMIT STATE REQUIREMENTS

10.1 General – In the method of design

based on limit state concept, the

structure shall be designed so as to

ensure an adequate degree of safety

and serviceability. The acceptable limit

for each of the safety and serviceability

requirements is called a ‘Limit State’.

For this purpose the limit states of 10.2

and 10.3 shall be considered. The

usual approach will be to design on the

basis of the limit state expected to be

most critical and then to check that the

remaining limit states will not be

reached and that all other requirements

will be met.

Consideration of other factors, such as,

deflection, fatigue and durability, will

need to be made as referred to in 10.4.

10.2 Serviceability Limit States –

The design shall be such that the

structure will not suffer local damage

which would shorten its intended life or

incur expensive maintenance costs. In

particular, calculated crack widths shall

not exceed those permitted in 10.2.1.

10.2.1 Cracking- Cracking of concrete

shall not adversely affect the

appearance of durability of the structure.

The engineer should satisfy himself that

any cracking will not be excessive,

having regard to the requirements of the

particular structure and the conditions of

exposure. In the absence of special

investigations, the following limit shall be

adopted.

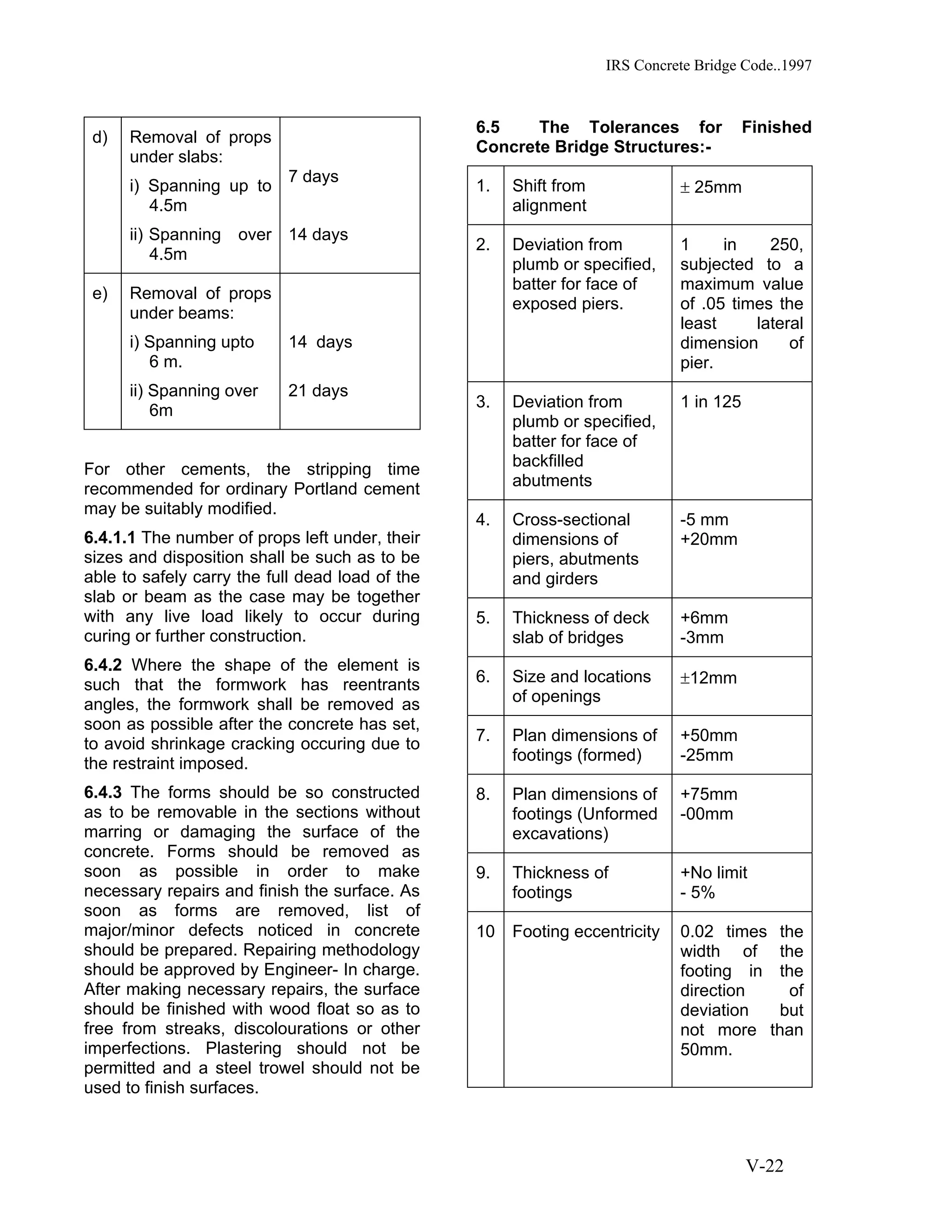

10.2.1(a) Reinforced concrete –

Design crack widths, as calculated in

accordance with 15.9.8.2, shall not

exceed the values given in Table 10

under the loading given in 11.3.2 :

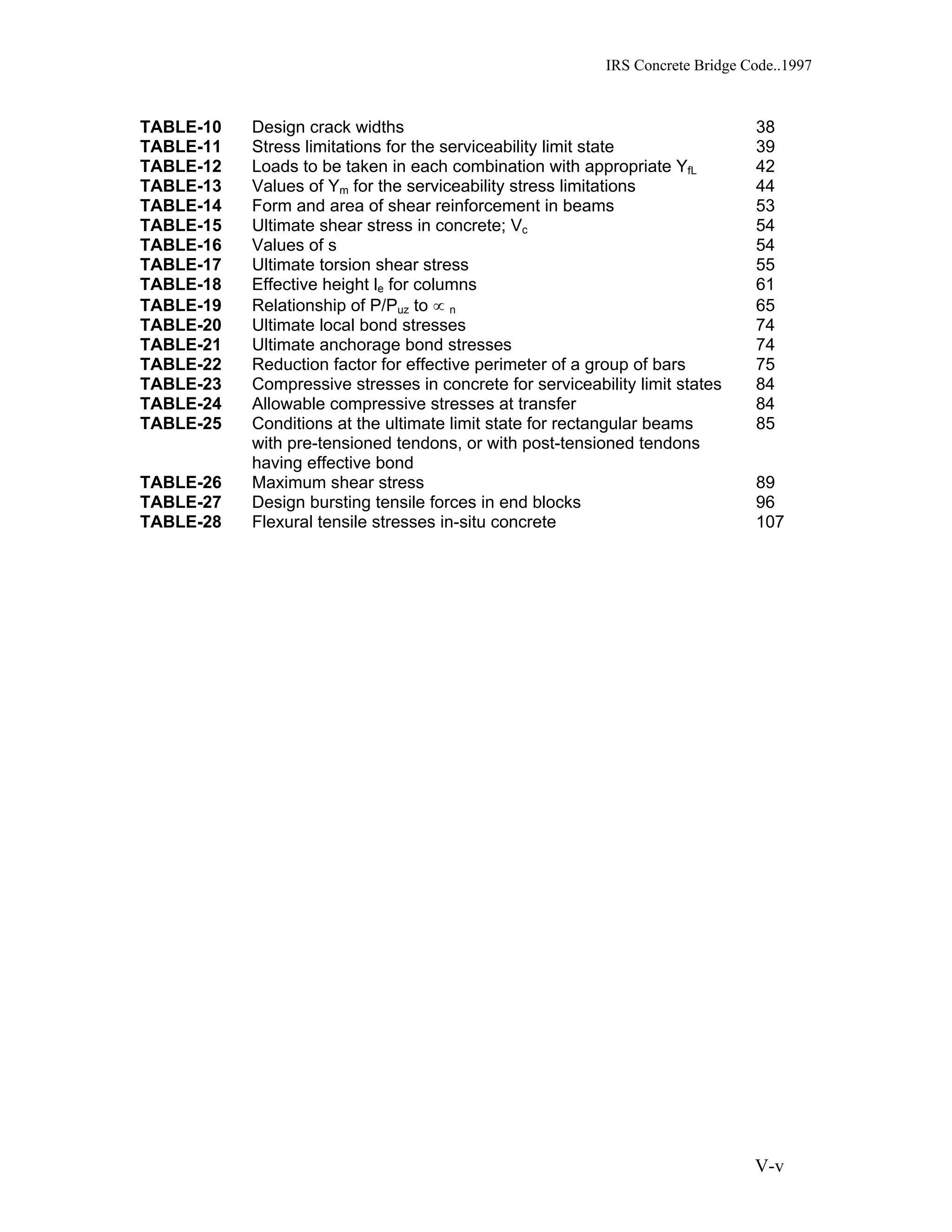

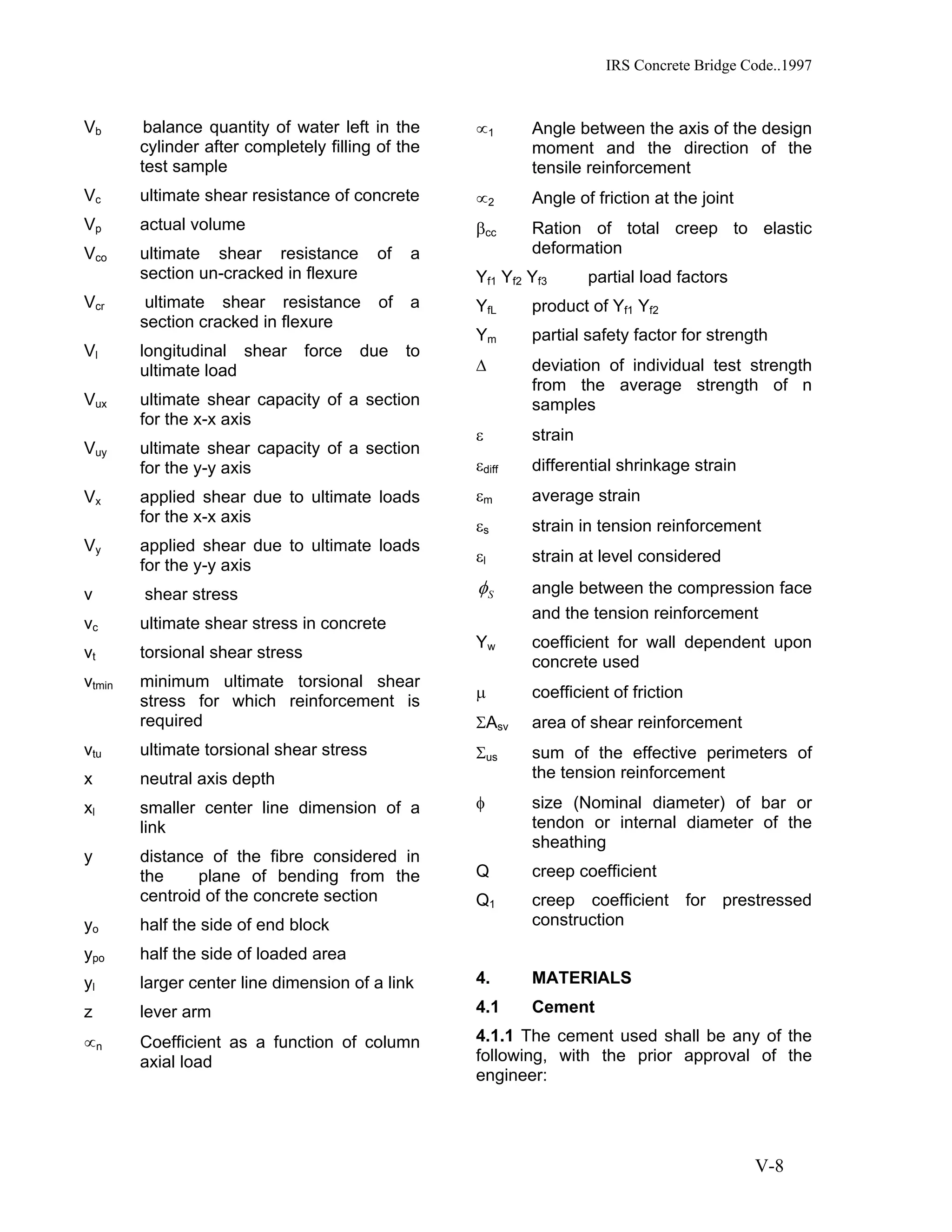

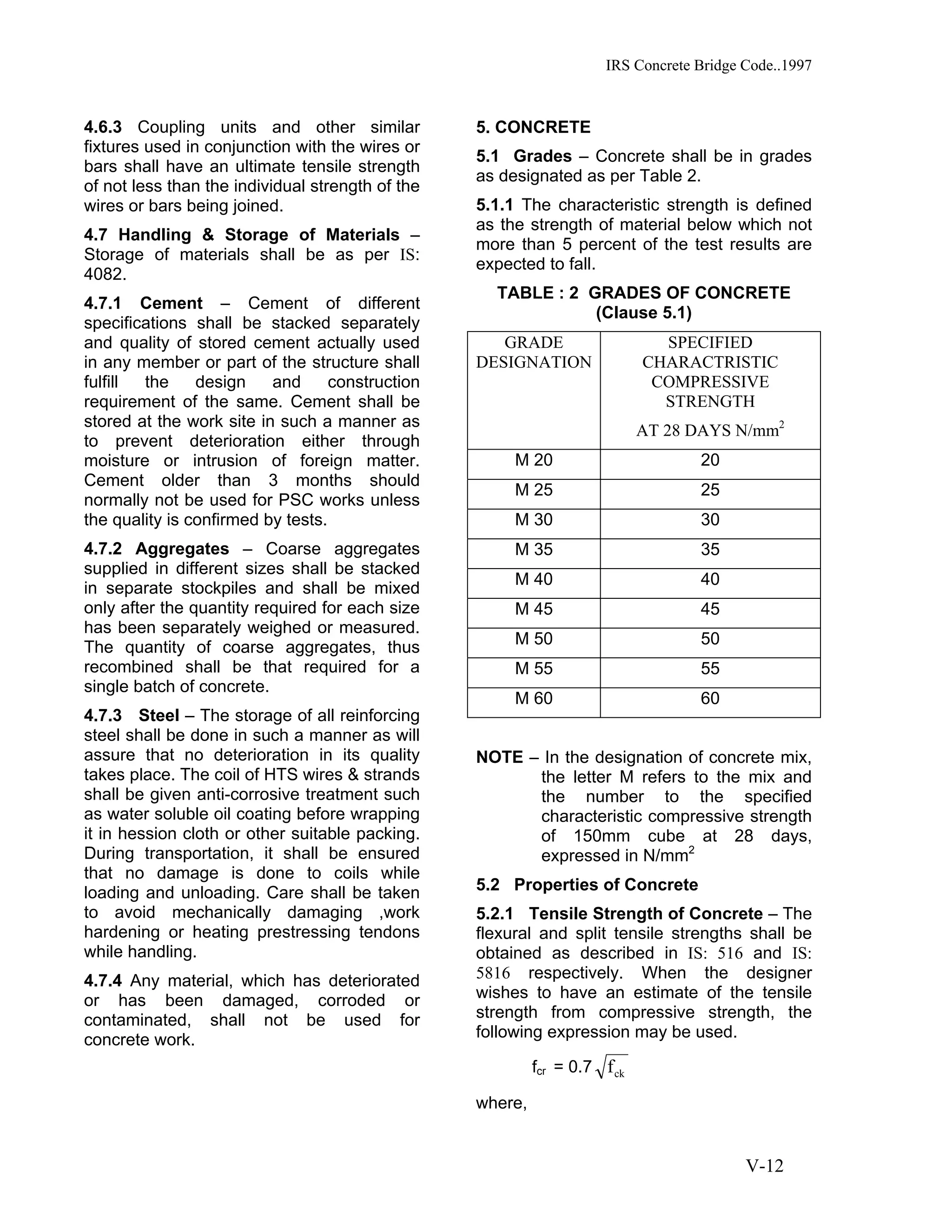

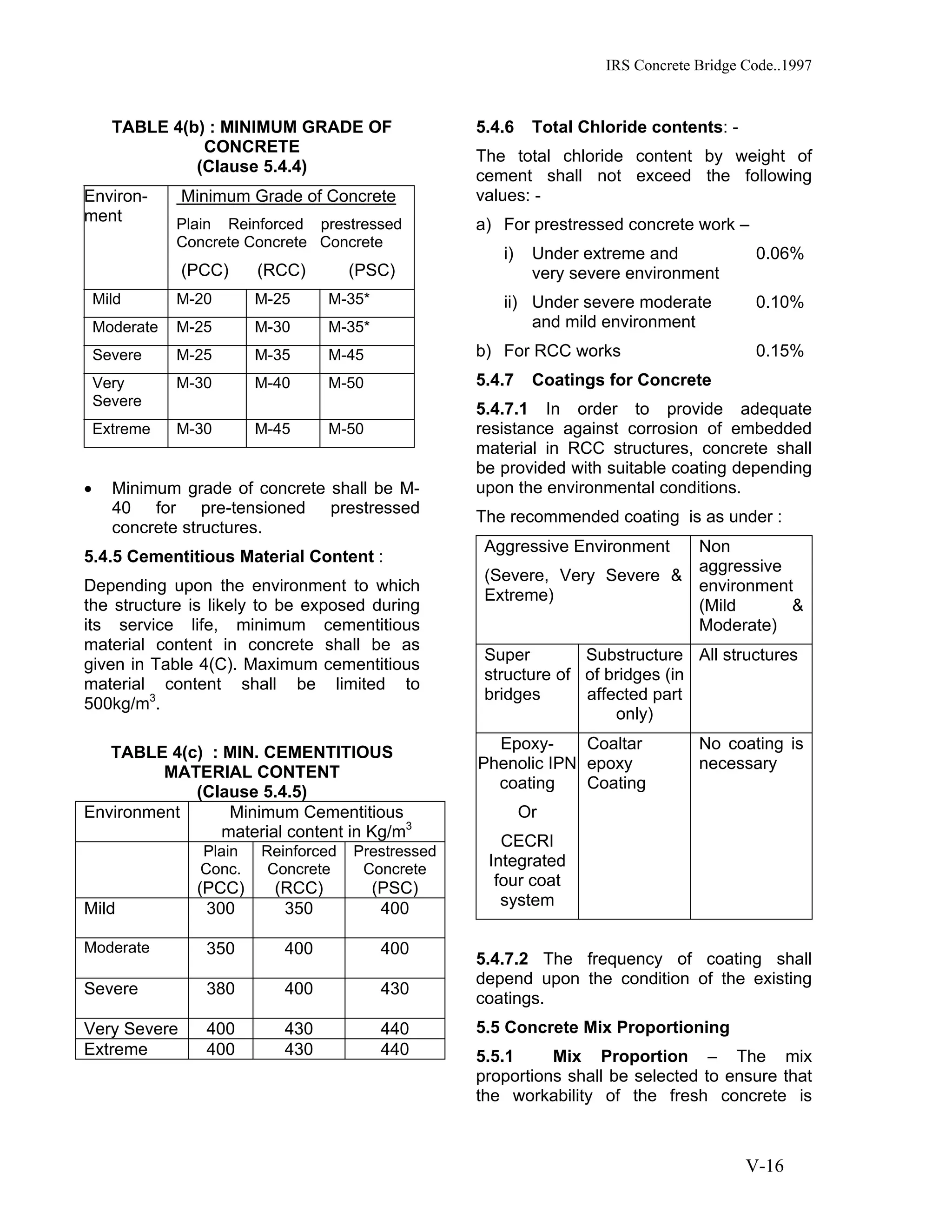

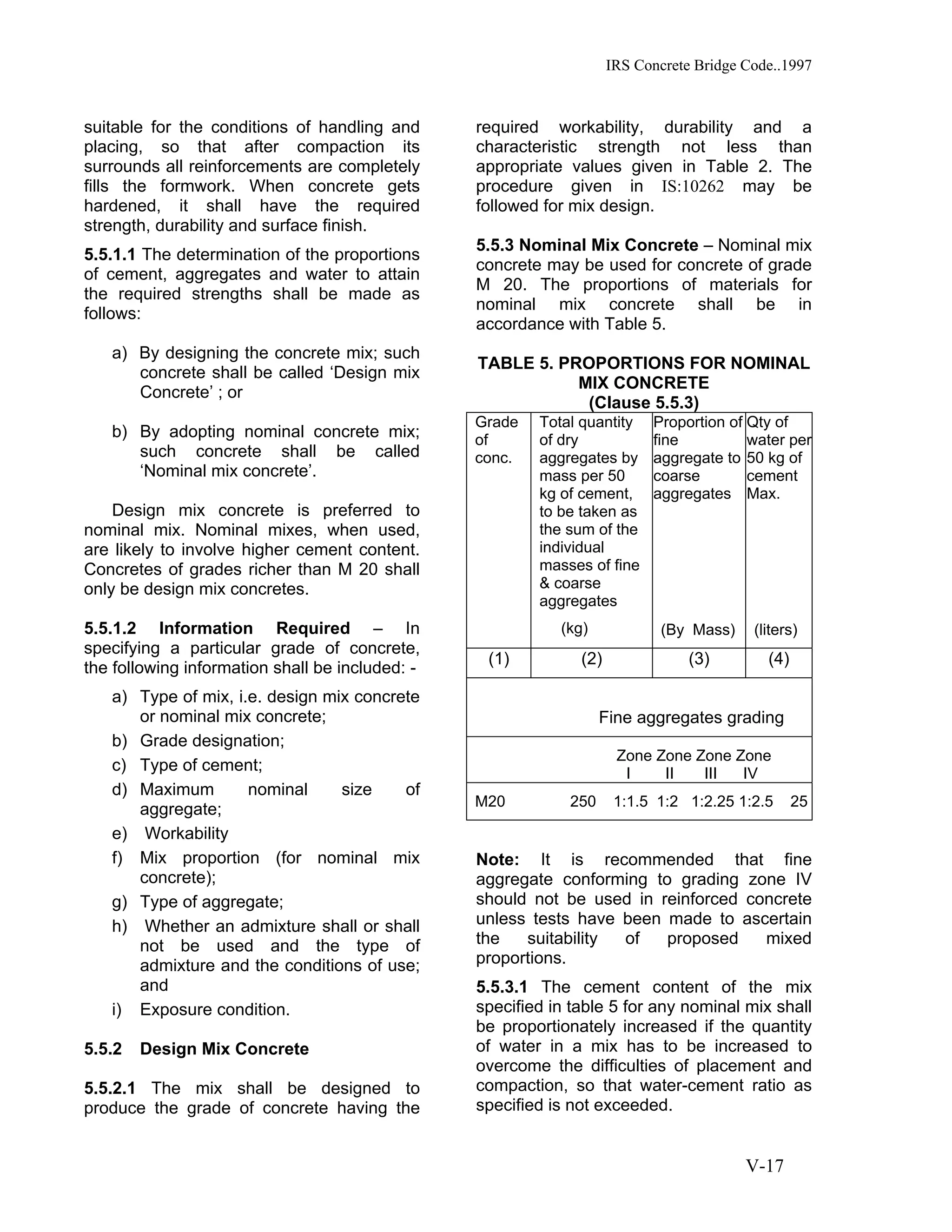

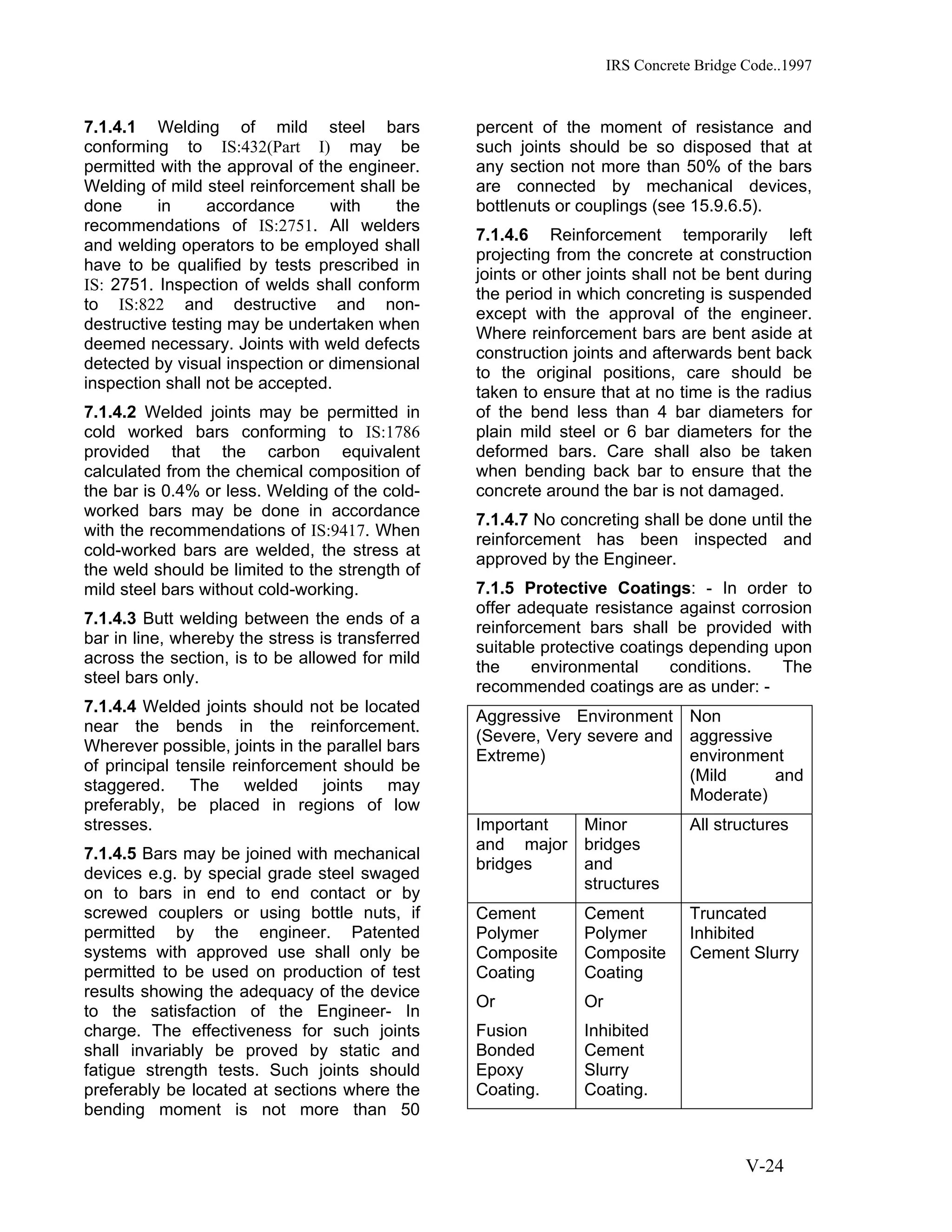

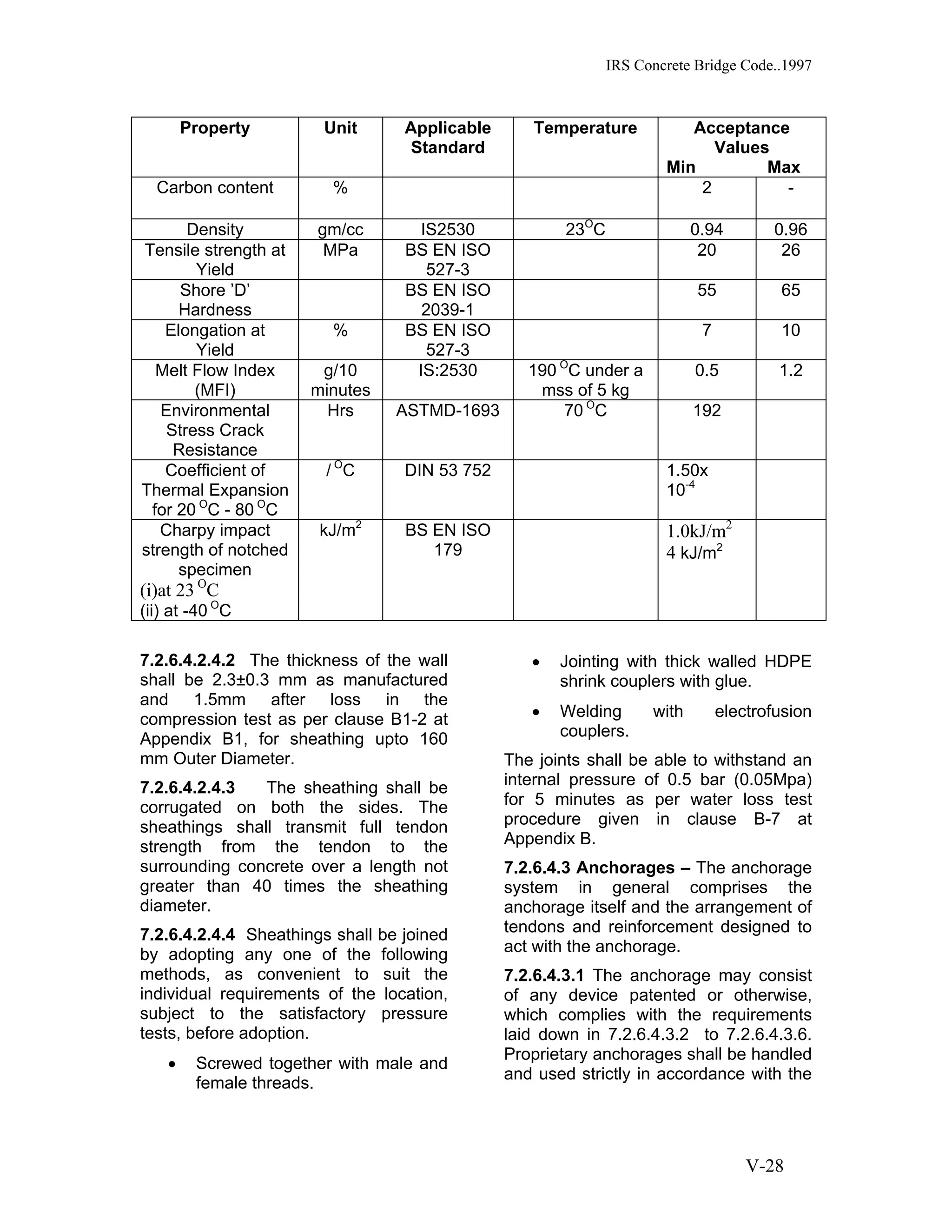

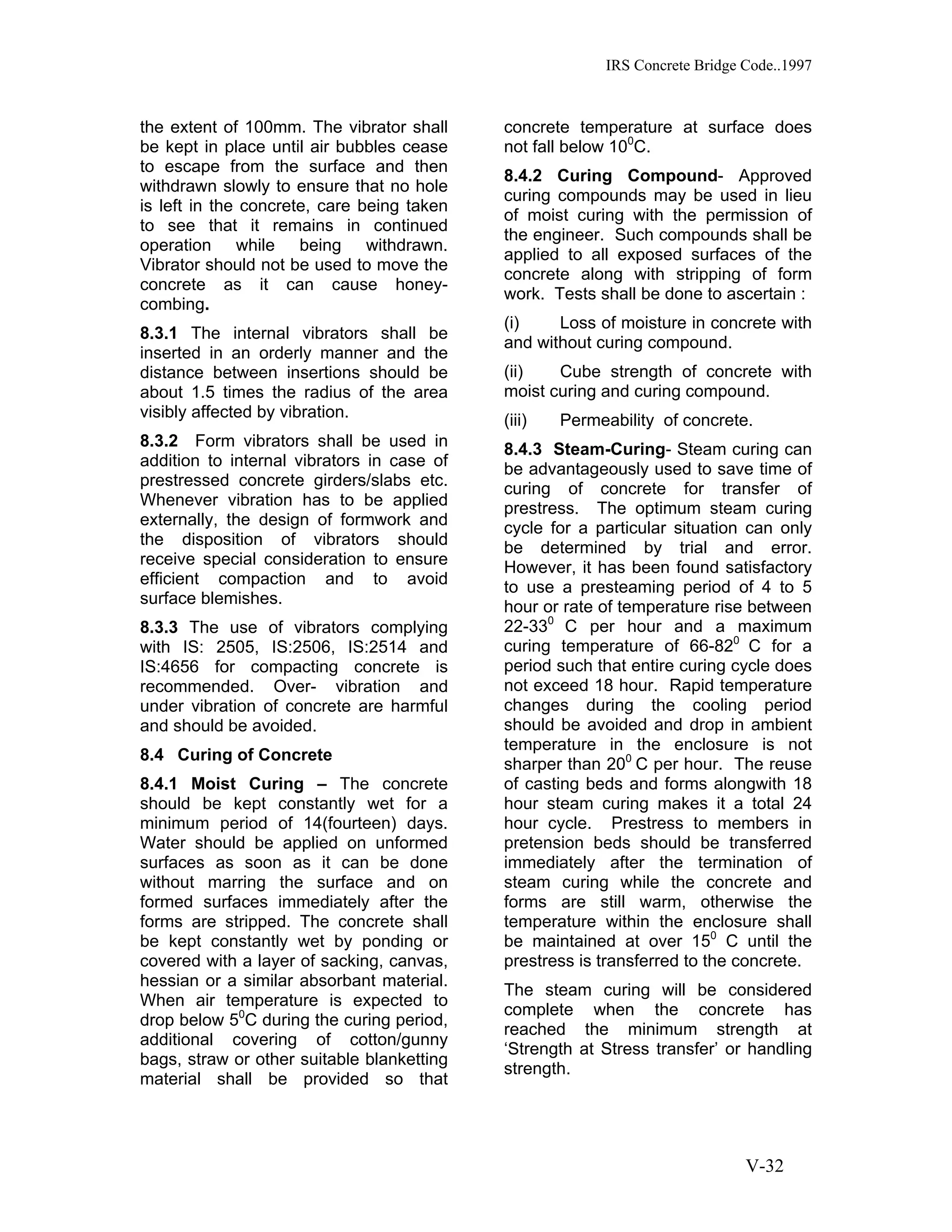

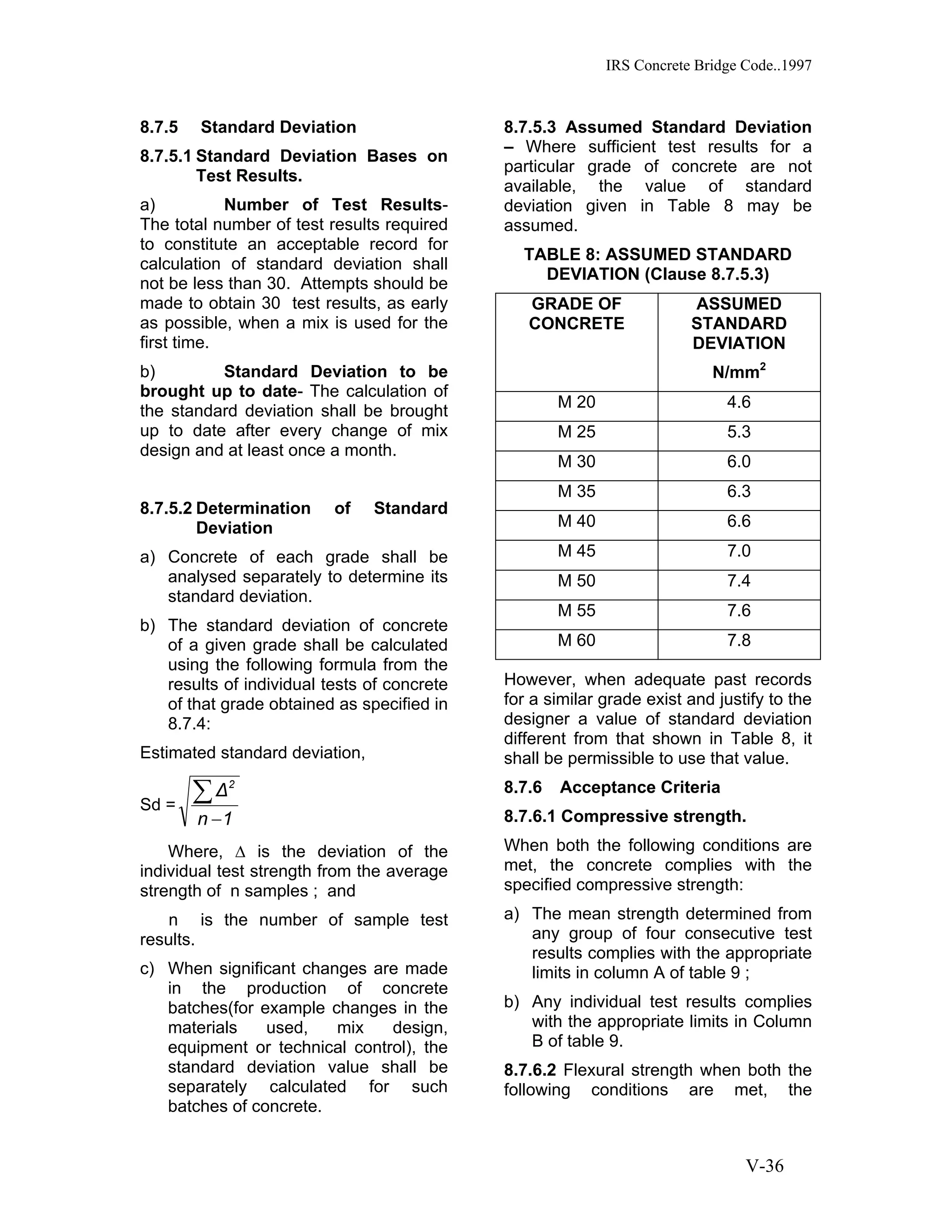

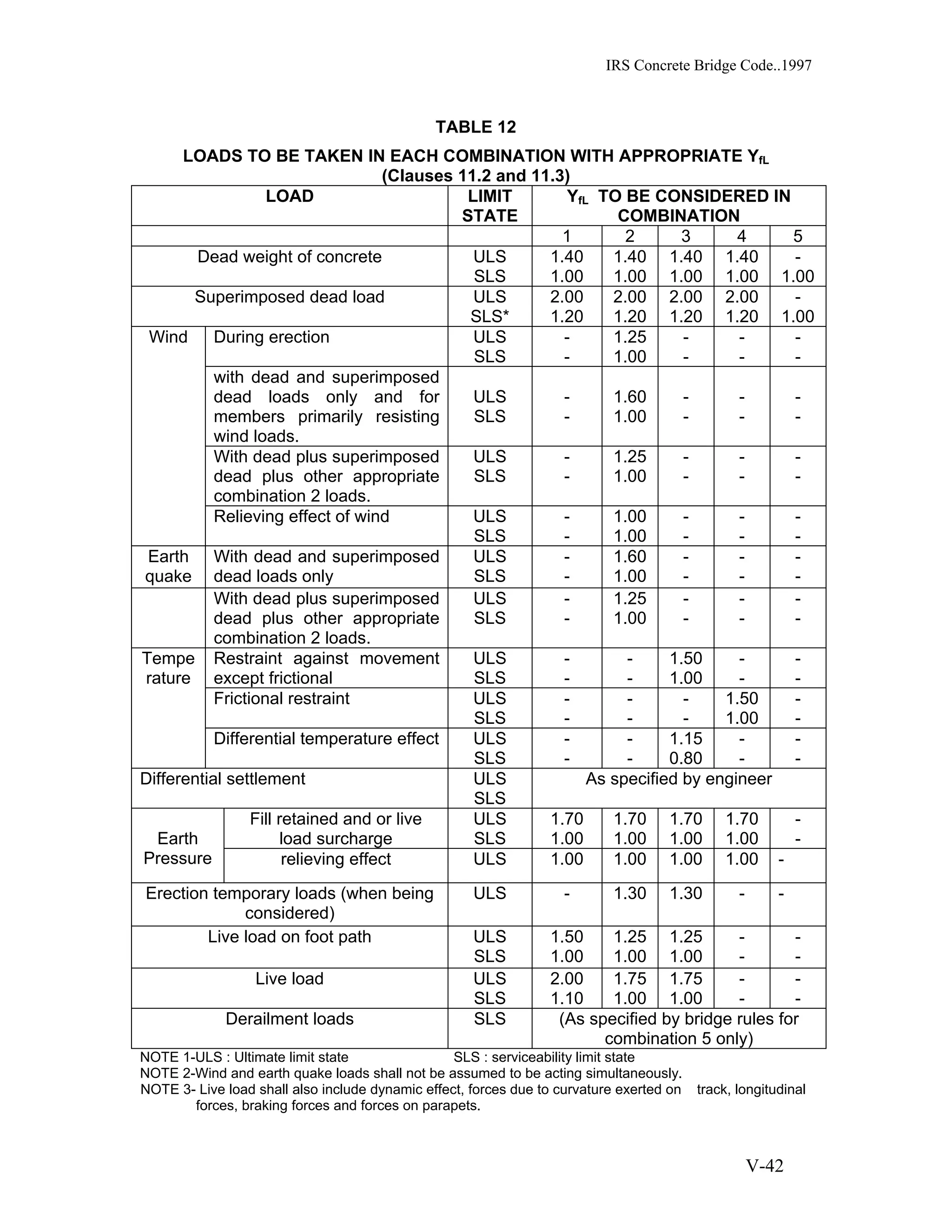

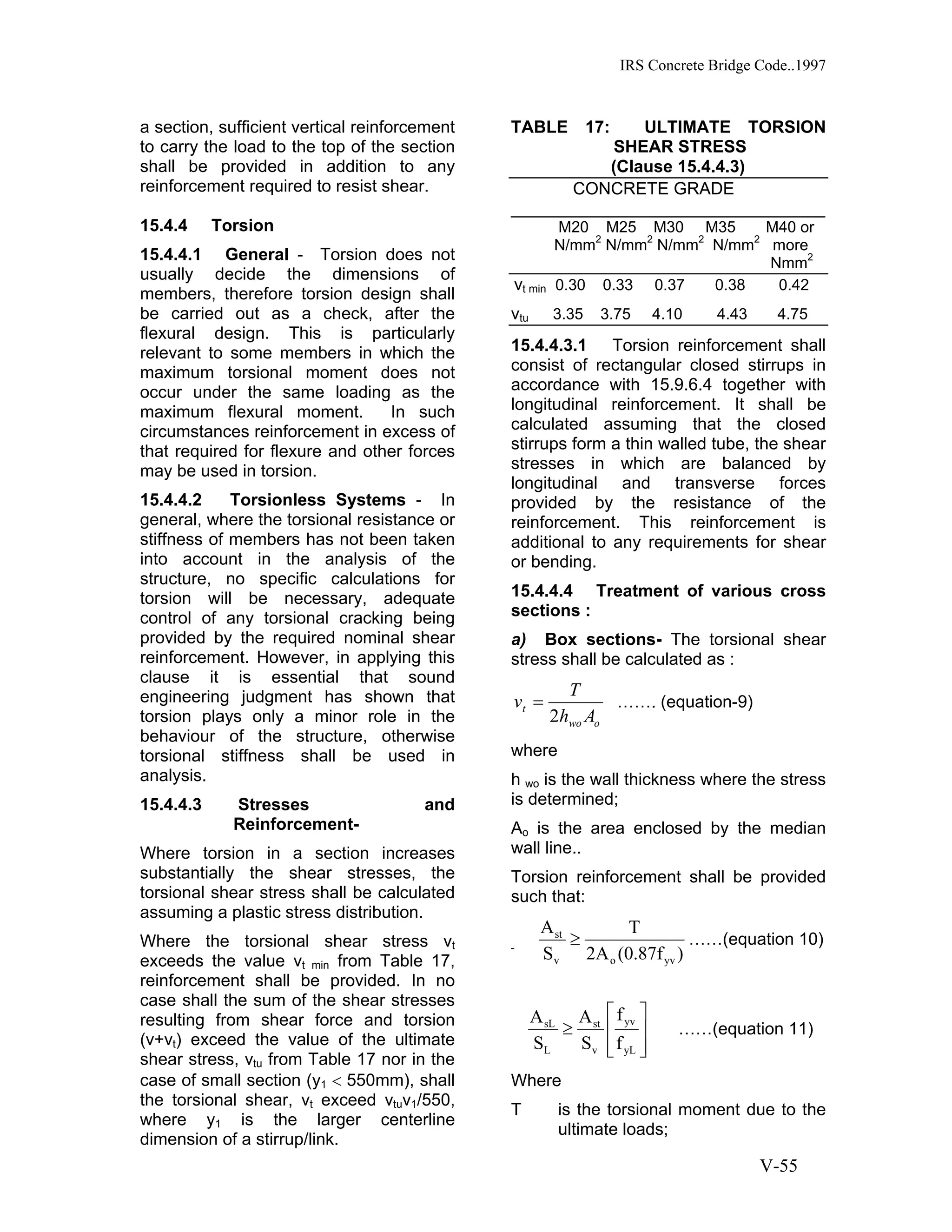

TABLE 10: DESIGN CRACK WIDTHS

[Cl. 10.2.1 (a) ]

Environment Design crack width

in mm

Mild 0.20

Moderate 0.20

Severe 0.10*

0.20**

Very severe 0.10*

0.20**

Extreme 0.10*

0.20**

*Surfaces exposed to weather.](https://image.slidesharecdn.com/irsconcretebridgecode-151106083454-lva1-app6891/75/Irs-concrete-bridge-code-43-2048.jpg)

![IRS Concrete Bridge Code..1997

V-95

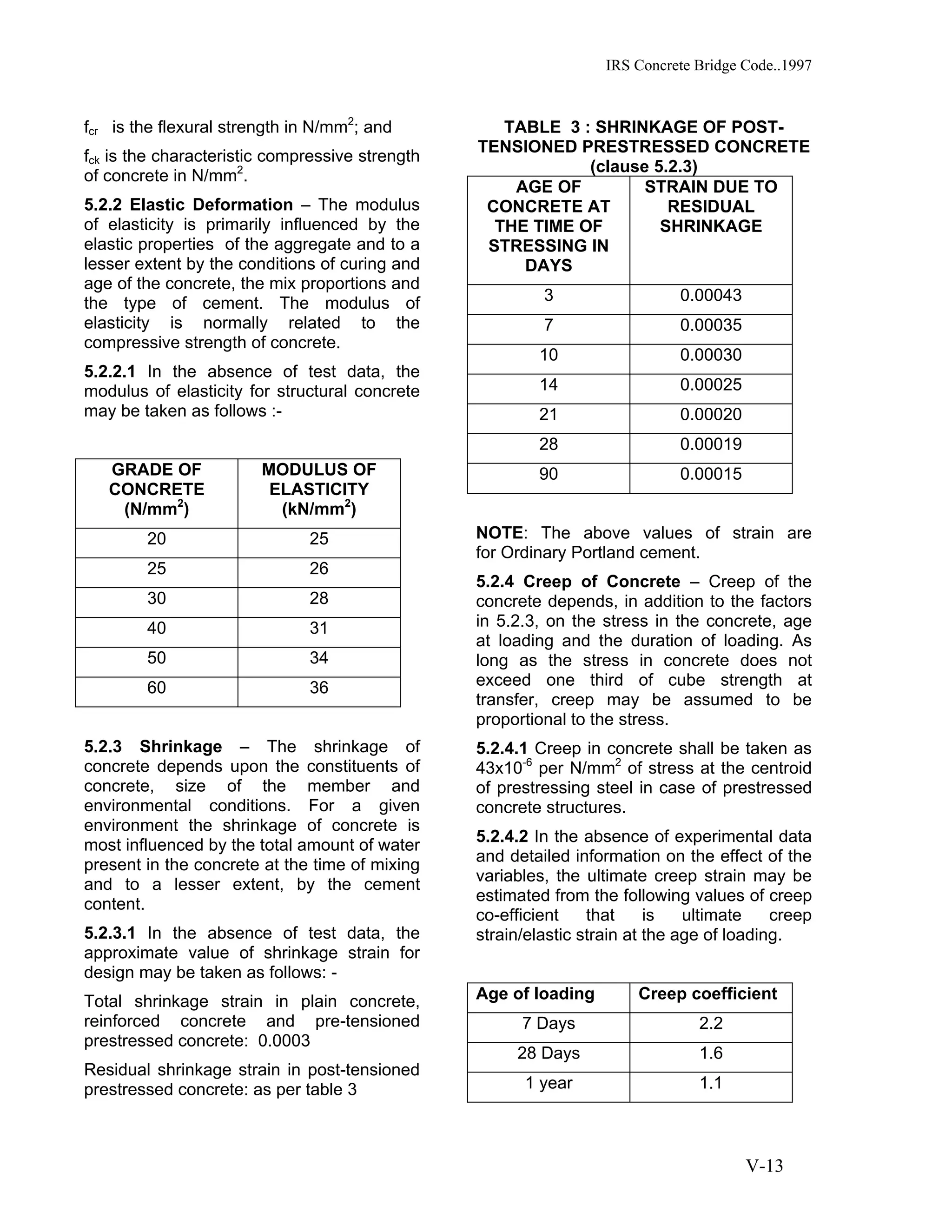

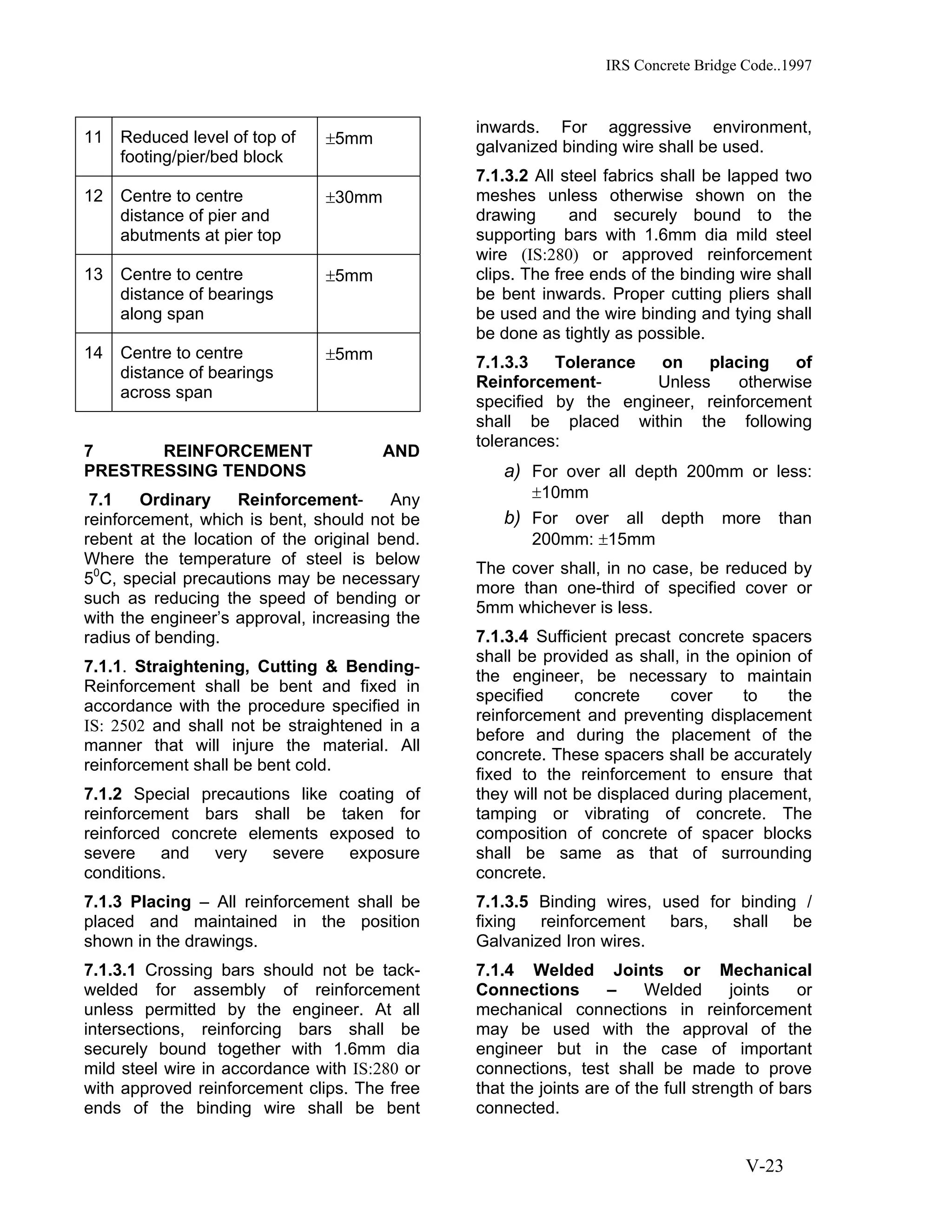

16.8.4.3 If the tendons are prevented

from bonding to the concrete near the

ends of the units by the use of sleeves

or tape, the transmission lengths shall

be taken from the ends of the de-

bonded portions.

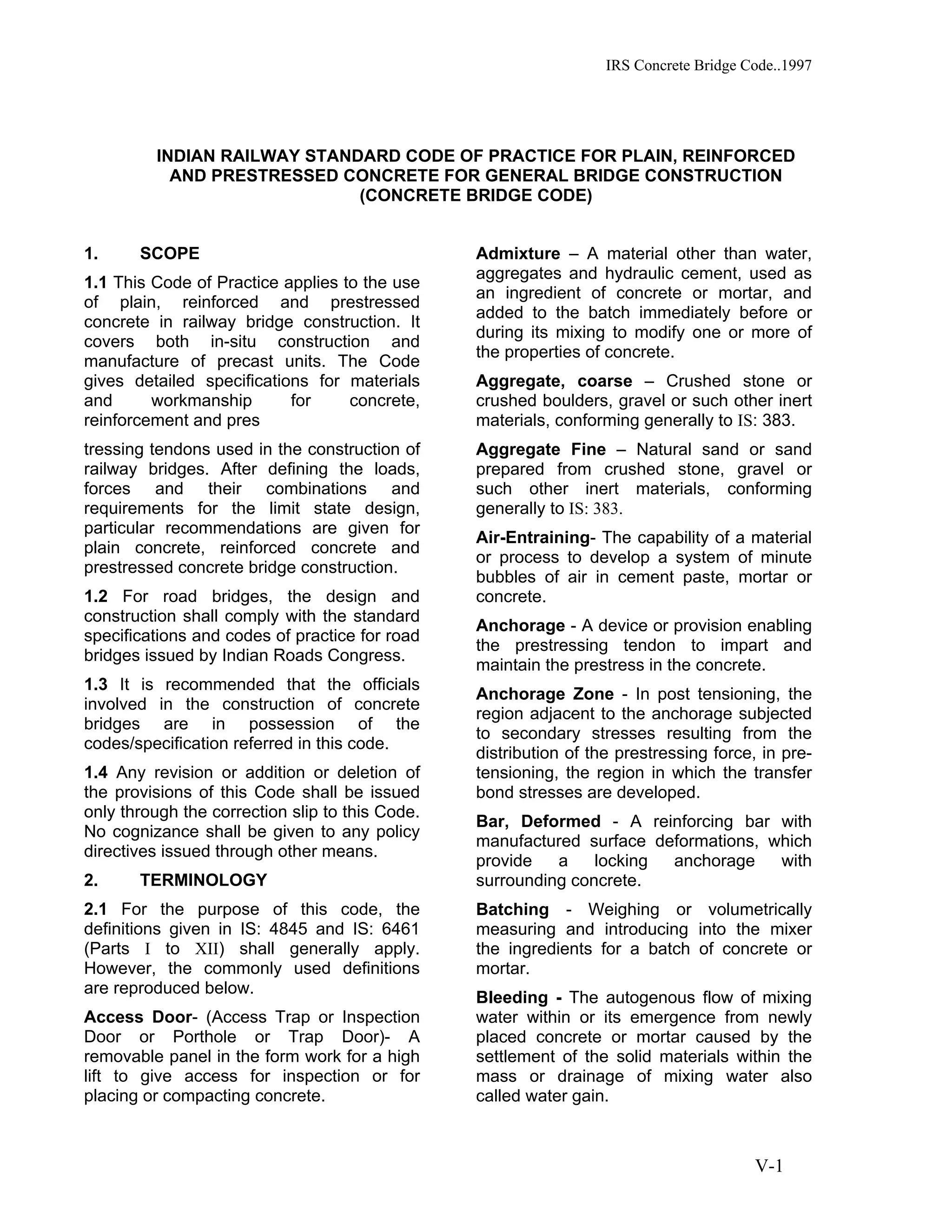

16.8.5 End Blocks - The end block

(also known as the anchor block or end

zone) is defined as the highly stressed

zone of concrete around the termination

points of a pre or post tensioned

prestressing tendon. It extends from the

points of application of prestress (i.e. the

end of the bonded part of the tendon in

pre tensioned construction or the

anchorage in post-tensioned

construction) to that section of the

member at which linear distribution of

stress is assumed to occur over the

whole cross-section.

16.8.5.1 The following aspects of

design shall be considered in assessing

the strength of end blocks:

(a) bursting forces around individual

anchorages;

(b) overall equilibrium of the end

block;

(c) spalling of the concrete form the

loaded face around anchorages.

16.8.5.1.1 In considering each of these

aspects, particular attention shall be

given to factor such as the following:

(1) shape, dimensions and position

of anchor plates relative to the

cross-section of the end block:

(2) the magnitude of the

prestressing forces and the

sequence of prestressing;

(3) shape of the end block relative to

the general shape of the

member;

(4) layout of anchorages including

asymmetry group effects and

edge distances;

(5) influence of the support reaction;

(6) forces due to curved or divergent

tendons.]

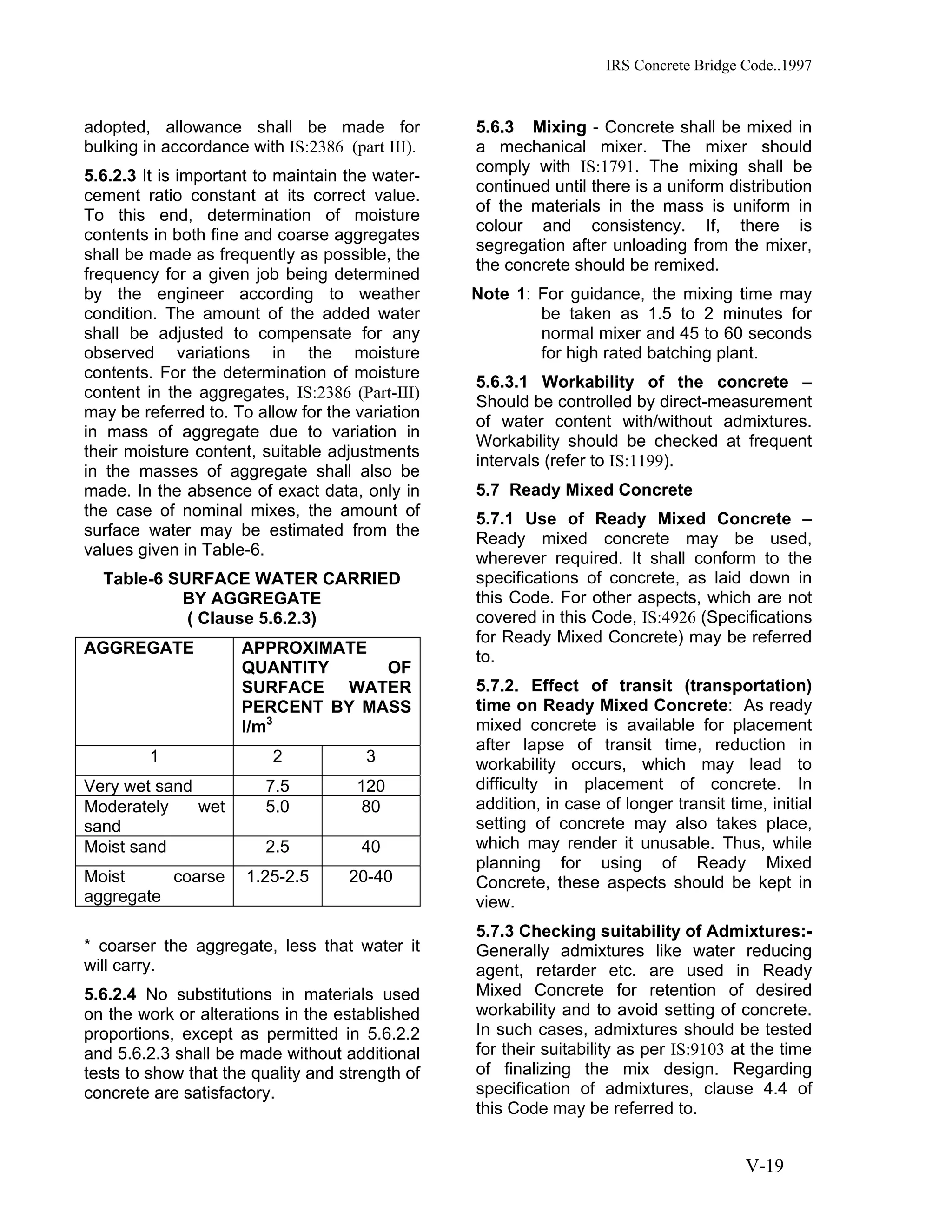

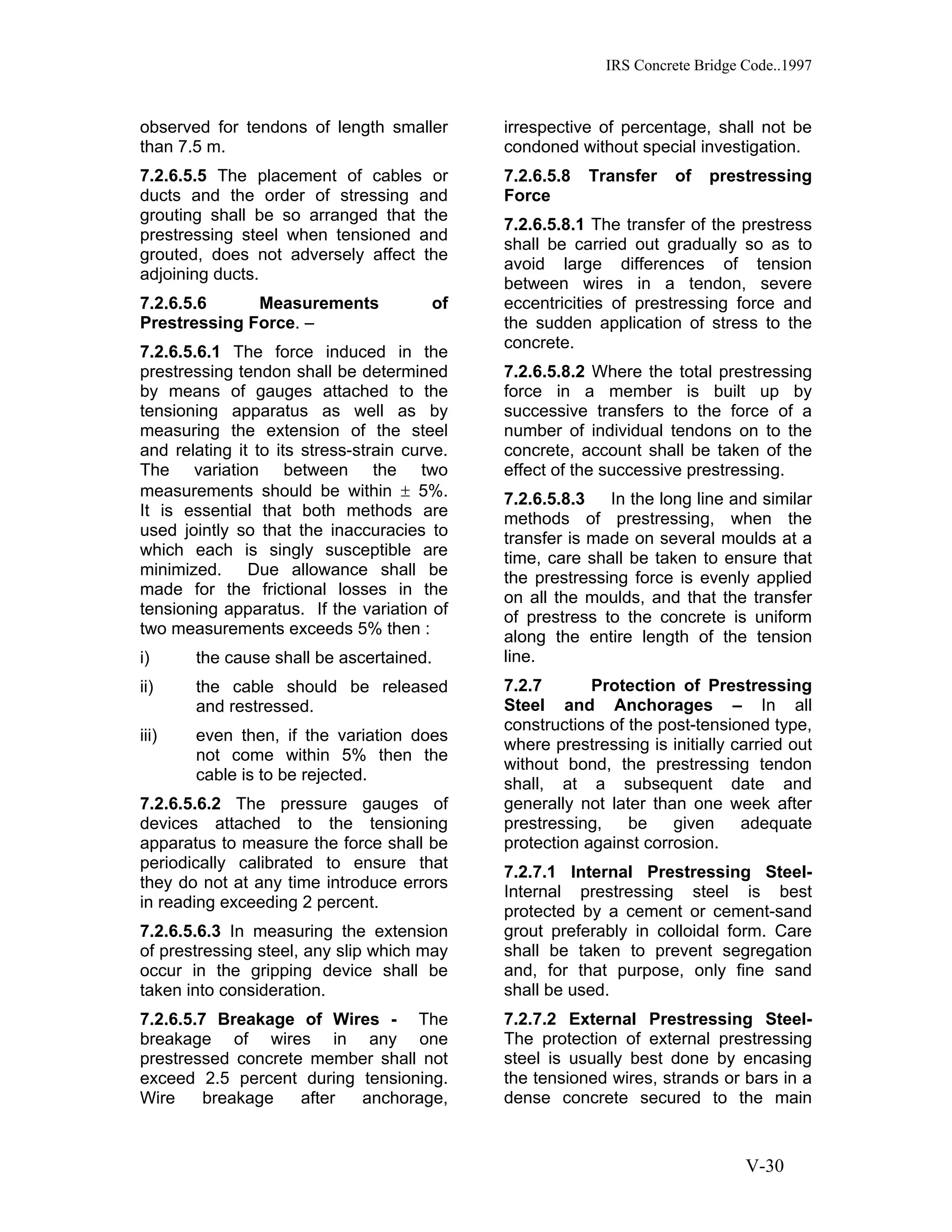

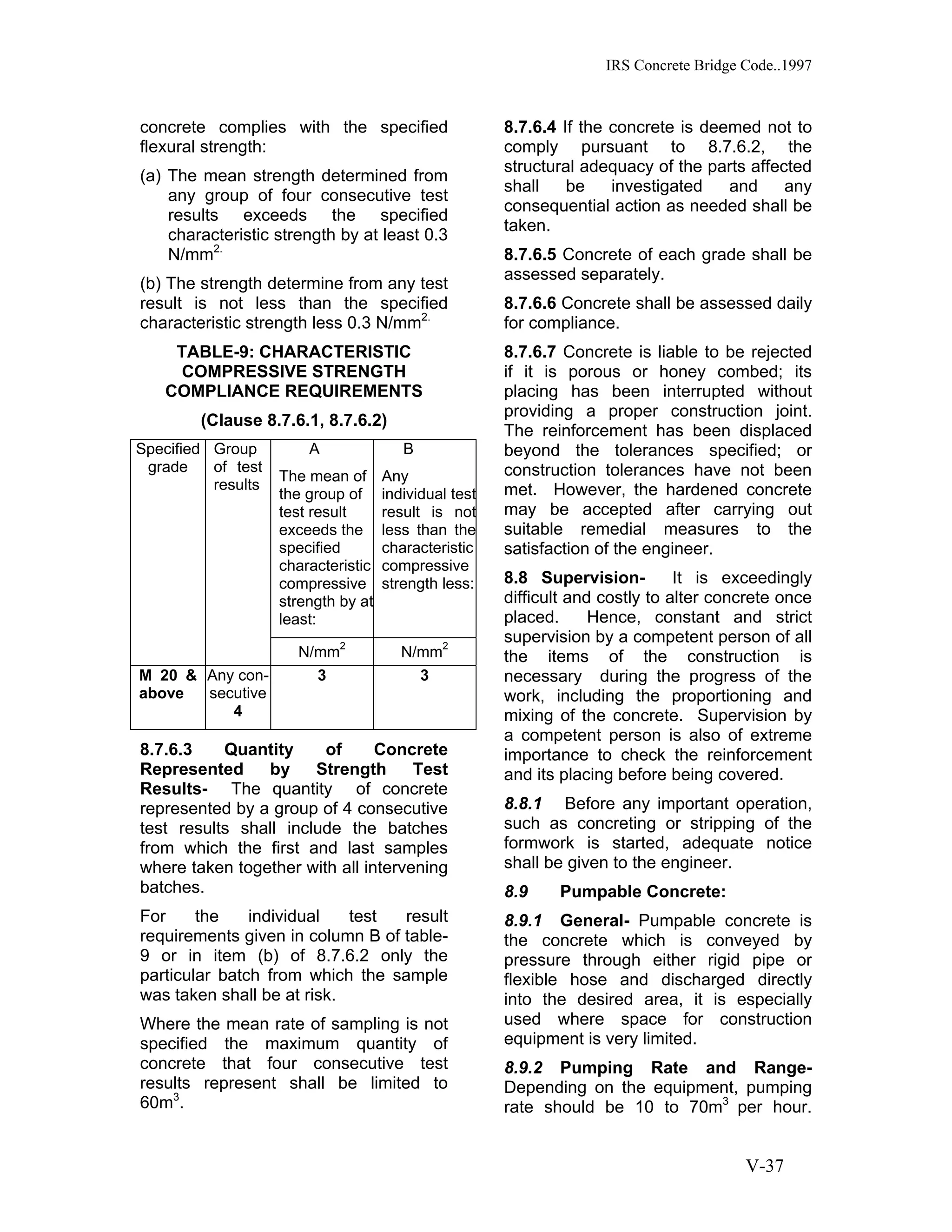

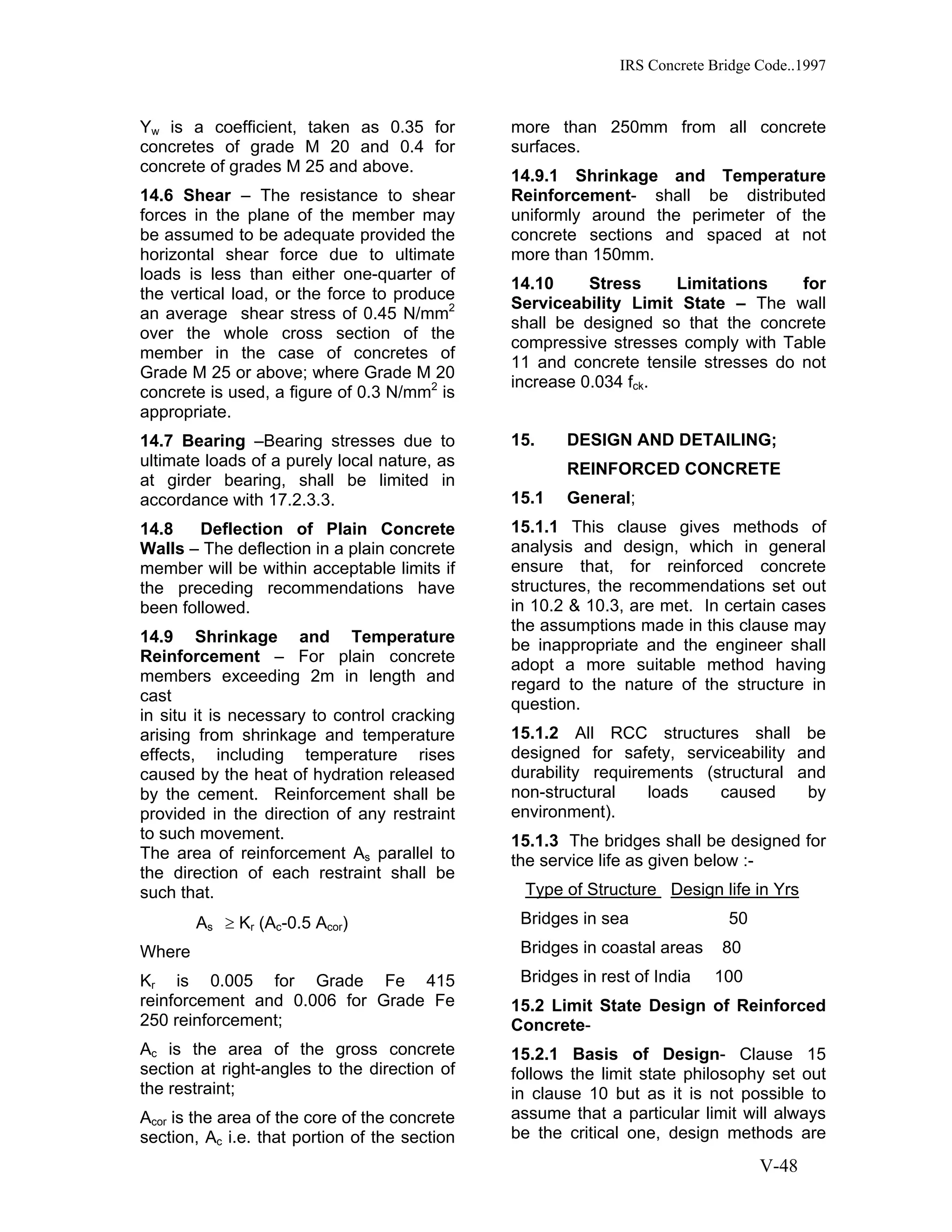

16.8.5.2 The following

recommendations are appropriate to a

circular, square or rectangular anchor

plate, symmetrically positioned on the

end face of a square or rectangular post

tensioned member, the

recommendations are followed by some

guidance on other aspects.

16.8.5.2.1 The bursting tensile forces

in the end blocks, or end regions of

bonded post-tensioned members, shall

be assessed on the basis of the tendon

jacking load. For temporarily unbonded

members, the bursting tensile forces

shall be assessed on the basis of the

tendon jacking load or the load in the

tendon at the ultimate limit state,

calculated using 16.2.4.3 whichever is

the greater.

16.8.5.2.2 The bursting tensile force ,

Fbst existing in an individual square end

block loaded by a symmetrically placed

square anchorage or bearing plate, may

be derived from Table 27,

Where

Yo is half the side of end block;

Ypo is half the side of loaded area;

Pk is the load in the tendon

assessed in accordance with the

preceding paragraph.

Fbst is the bursting tensile force.

This force, Fbst, will be distributed in

a region extending from 0.2Yo to 2Yo

from the loaded face of the end block.

Reinforcement provided to sustain the

bursting tensile force may be assumed

to be acting at its design strength

(0.87fy) except that the stress shall be

limited to a value corresponding to a

strain of 0.001 when the concrete cover

to the reinforcement is less than 50mm.

16.8.5.2.3 In the rectangular end block,

the bursting tensile forces in the two](https://image.slidesharecdn.com/irsconcretebridgecode-151106083454-lva1-app6891/75/Irs-concrete-bridge-code-100-2048.jpg)