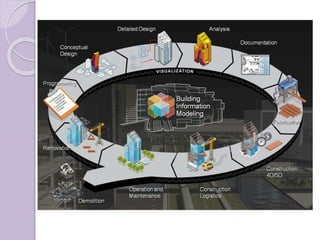

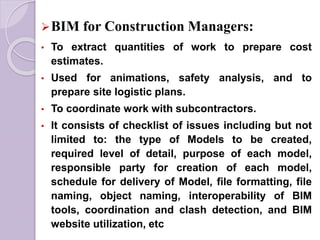

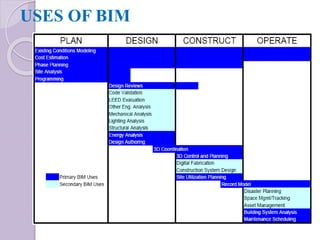

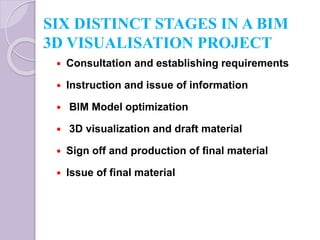

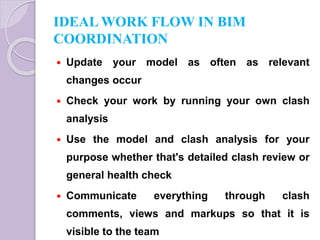

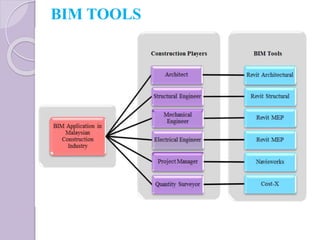

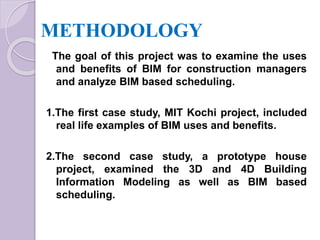

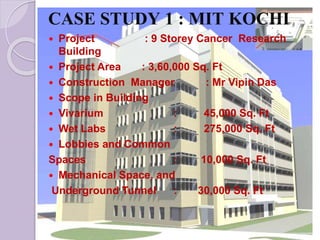

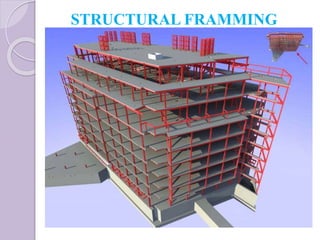

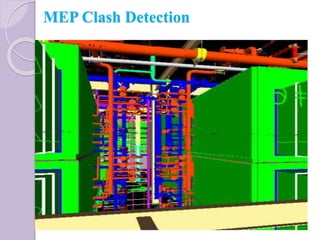

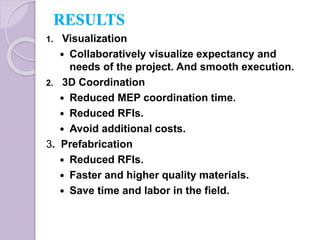

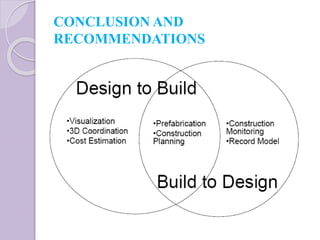

The document discusses the use of Building Information Modeling (BIM) in construction management. It describes how BIM allows for 3D modeling of building components and their properties. It then outlines several key uses of BIM for construction managers, including visualization, coordination, prefabrication, construction planning and monitoring, cost estimation, and generating a record model. The document also presents two case studies, one of the MIT Kochi project, to illustrate real-world examples of how BIM benefits construction projects through improved visualization, coordination, planning and cost control.