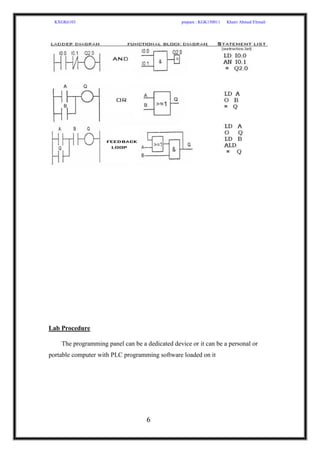

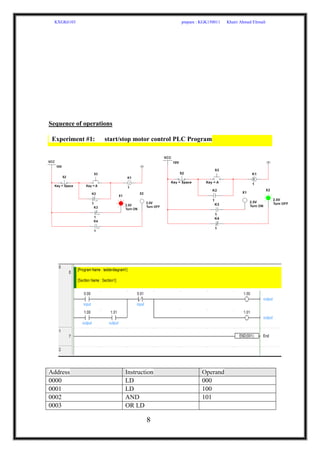

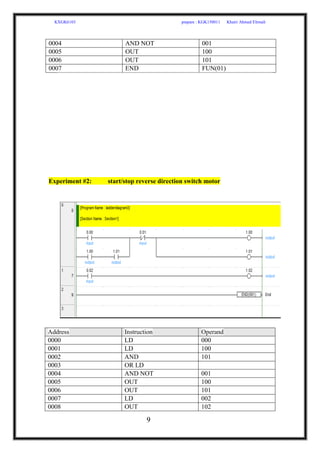

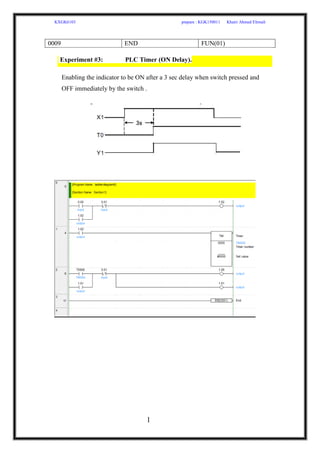

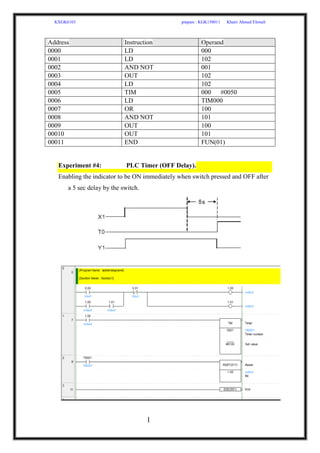

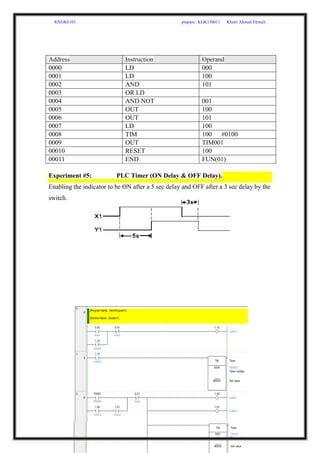

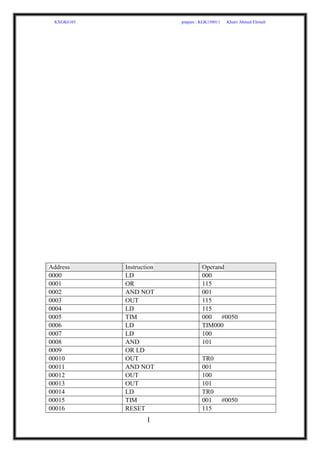

This document describes experiments conducted using a programmable logic controller (PLC) to control various functions. The experiments include: 1) using a PLC to start and stop a motor via push buttons, 2) adding reverse direction control, 3) using timers to add on/off delays, and 4) combining on/off delays. The purpose is to understand and implement ladder logic programming of a PLC. Key components of a PLC like the power supply, processor, input and output modules are discussed. Ladder logic programming allows flexible control of industrial machinery.