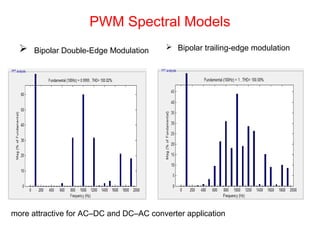

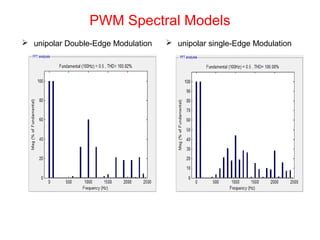

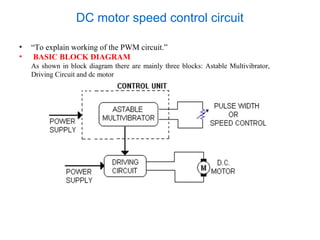

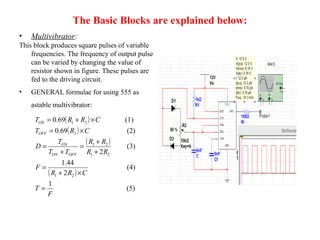

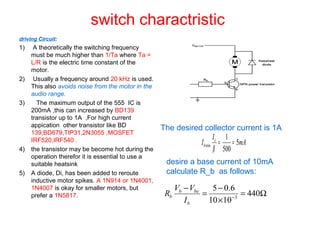

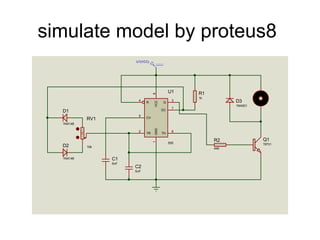

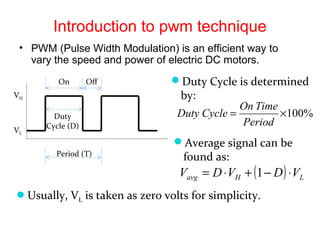

The document discusses the PWM (pulse width modulation) technique for controlling the speed of DC motors, detailing the generation of PWM signals using MATLAB Simulink and spectral modeling. It describes a DC motor speed control circuit comprising an astable multivibrator, driving circuits, and the motor, along with the specifications and operation of a PWM motor speed control kit. Conclusions highlight the motor's response to average pulse values rather than individual pulses, emphasizing the impact of duty cycle variations on speed regulation.

![Generate PWM signal in MATLAB Simulink

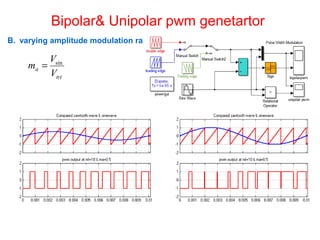

A.Varying Frequency modulation ratio

sinf

f

m tri

f =

The binary PWM output

can be mathematically written as

( ) ( ) ( )[ ]tctrtb pwm −= sgn](https://image.slidesharecdn.com/dcmotorspeedcontrollerbypwmtechnique-160606101744/85/Dc-motor-speed-controller-by-pwm-technique-4-320.jpg)