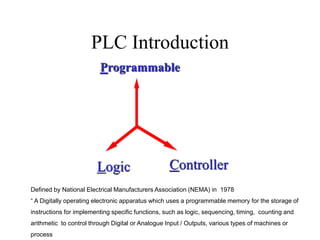

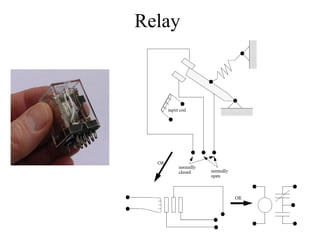

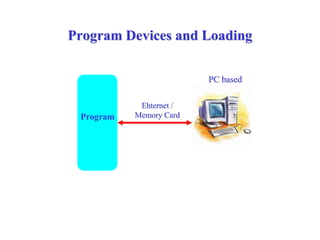

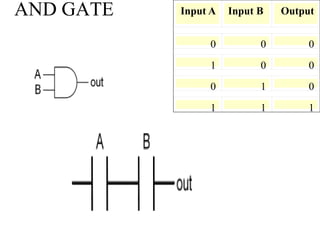

The document discusses programmable logic controllers (PLCs). It defines PLCs as digitally operating electronic devices that use programmable memory to implement logic functions to control machines and processes through digital and analog inputs and outputs. The document outlines the history and evolution of PLCs from relay-based to solid-state designs. It describes typical PLC architectures, components, programming languages like ladder logic, applications in machine control and other industrial processes, and advantages of PLCs over traditional electromechanical controls.