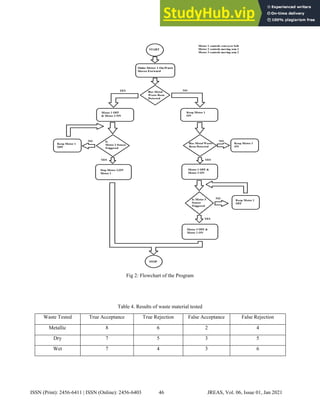

This document describes an automated waste segregator system that uses sensors and mechanical arms to sort household waste into three categories: metal waste, dry waste, and wet waste. An Arduino microcontroller is used to control the sensors and mechanical components. Infrared sensors detect the presence of waste, inductive proximity sensors identify metal waste, and moisture sensors distinguish wet waste. Small DC motors and servo motors move the waste into the appropriate collection bins. The system was tested and achieved high accuracy in sorting metal waste, with room for improvement in sorting dry and wet waste. The automated waste sorting system provides an efficient solution for household waste management.

![ISSN (Print): 2456-6411 | ISSN (Online): 2456-6403 47 JREAS, Vol. 06, Issue 01, Jan 2021

Figure 3. Types of waste

4. Conclusion

In this paper, the development of a low-

cost automated waste separator powered by Arduino

micro-controller is presented to effectively sort waste

according to its base at the household or small society

level. During the development process, the waste

separator prototype control system and sensing

mechanism are integrated using an Arduino Uno micro-

controller. The sensing part is built to distinguish

among three types of waste: 1) metallic waste, 2) dry

waste and 3) wet waste. The metallic waste utilized the

inductive proximity sensor in relation to the magnetic

field concept. However dry and wet waste used

moisture sensors to verify electrical conductivity. The

prototype of the waste separator possessed high

sensitivity on metallic waste in comparison to other

waste. This means that dry and wet waste sensitivity

needs to be improved for effective sorting. The

proposed concept and developed prototype have the

potential to be utilized in reducing the cost of solid

waste disposal in the future.

References

[1] M. K. Pushpa, Aayushi Gupta, Shariq Mohammed

Shaikh, Stuti Jha,Suchitra.V, “Microcontroller

Based Automatic Waste Segregator”,International

journal of innovative research in Electrical,

Electronics, Instrumentation and Control

Engineering Vol. 3, issue 5, May 2015.

[2] Amrutha Chandramohan, Joyal Mendonca, Nikhil

Ravi Shankar, Nikhil U Baheti, Nitin Kumar

Krishnan, Suma M S, Rashtreeya Vidyalaya

College of Engineering (R.V.C.E.) “Automated

Waste Segregator

[3] Abhay Bharadwaj, Rainer Rego, Anirban

Chowdhary, “IOT based solid waste management

system”, IEEE Annual India Conference

(INDICON), 2016.

[4] P. Ash, Bist, A., and Chandran.S, S., “Moving

towards Zero-Waste: A

Case-Study from Kerala, India”, IEEE Global

Humanitarian Technology,Conference,SouthAsia

Satellite Conference, Trivandrum, India, 2013.

[5] Subhasini Dwivedi, Michael Fernandes, Rohit

Dsouza, A Review on PLC based Automatic Waste

Segregator, International Journal of Advanced Re-

search in Computer Engineering and Technology

(IJARCET) Volume 5 Issue 2, February 2016

[6] Fachmin Folianto, Yong Low, Wai Yeow,

"Smartbin smart waste management system", IEEE

International Conference on Intelligent Sensors

Sensors Network and Information Processing

(ISSNIP), 2015J.

[7] Clerk Maxwell, A Treatise on Electricity and

Magnetism, 3rd ed., vol. 2. Oxford: Clarendon,

1892, pp.68–73.

[8] S. Sakai, S. Sawell, A. Chandler, "World Trend in

Municipal Solid Waste Management" in

Environmental Preservation Center, Japan, vol. 16,

pp. 341, 1996.

[9] "Smart Garbage Monitoring and Clearance System

using Internet of Things", 2017 IEEE International

Conference on Smart Technologies and

Management for Computing Communication

Controls Energy and Materials (ICSTM), 2 – 4

August 2017.

[10] Mahmudul Hasan Russel, Mehdi Hasan

Chowdhury, Md. Shekh Nairn Uddin, Ashif

Newaz, Md. Mehdi Masud Talukder,

"Development of Automatic Smart Waste Sorter

Machine", International Conference on Mechanical

Industrial and Materials Engineering 2013

(ICMIME2013), 1–3 November, 2013.

METALLIC WASTE

True Accepatnce

True Rejection

False Acceptance

False Rejection

DRY WASTE

True Acceptance

True Rejection

False Acceptance

False Rejection

WET WASTE

True Acceptance

True Rejection

False Acceptance

False Rejection](https://image.slidesharecdn.com/automatedwastesegregator-230806144012-8ea47e29/85/AUTOMATED-WASTE-SEGREGATOR-5-320.jpg)