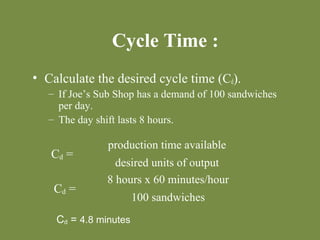

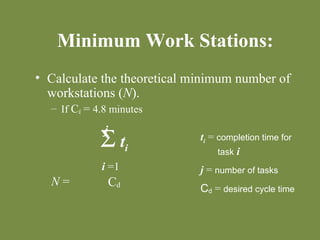

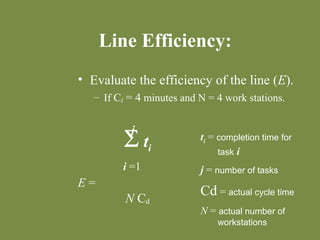

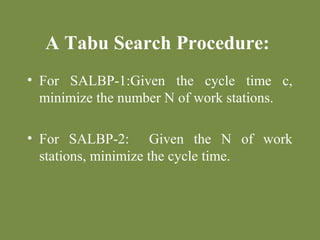

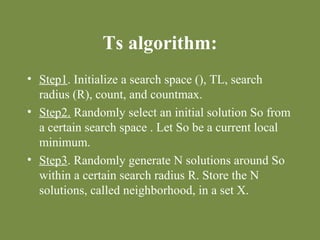

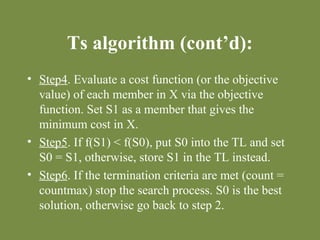

This document discusses optimal assembly line balancing. It defines assembly line balancing as assigning tasks to workstations while complying with precedence relationships and minimizing idle time. There are two types of assembly line balancing problems: SALBP-1 focuses on minimizing workstations given a cycle time, while SALBP-2 focuses on minimizing cycle time given a number of workstations. The document presents the tabu search algorithm as an AI technique for solving these assembly line balancing problems, which generates random solutions within a search radius to find an optimal balance.

![References:

• [1] ISSN 1750-9653, England, UK

International Journal of Management

Science and Engineering Management Vol.

3 (2008) No. 1, pp. 3-18.

• [2] www.springerlink.com,

SPRINGLERLINK. Istanbul technical

University, Istanbul turkey(16/02/09).](https://image.slidesharecdn.com/22d2optimalassemblylinebalancing222-110829065724-phpapp02-140901013146-phpapp02/85/22d2optimalassemblylinebalancing222-110829065724-phpapp02-18-320.jpg)