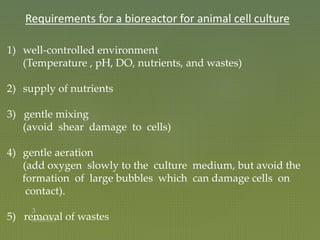

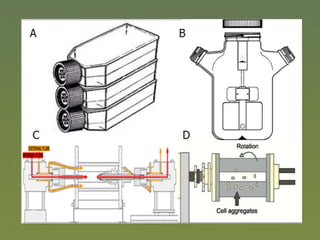

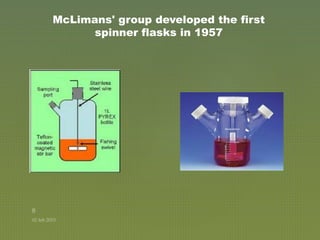

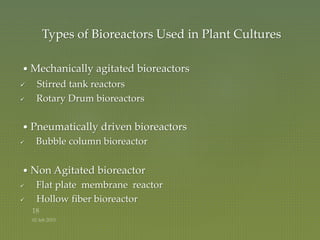

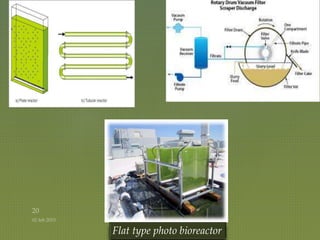

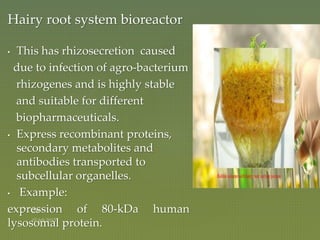

The document discusses various types of bioreactors used for animal and plant cell cultures, emphasizing essential requirements and specific designs tailored to cell type, growth conditions, and applications. It includes descriptions of different reactor types such as spinner flasks, rotary perfusion bioreactors, and various plant bioreactors, highlighting their advantages and disadvantages. The document also touches on the applications of these systems in producing monoclonal antibodies, recombinant proteins, and other therapeutic products.