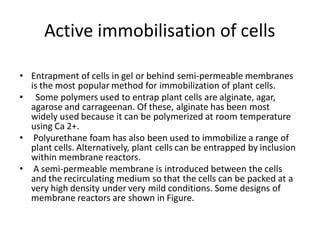

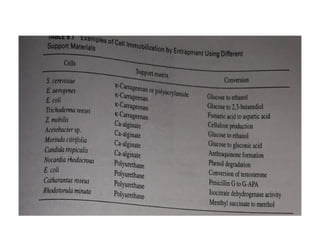

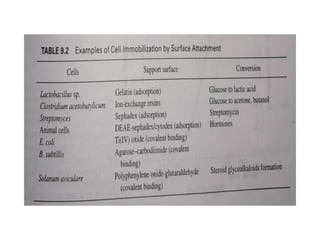

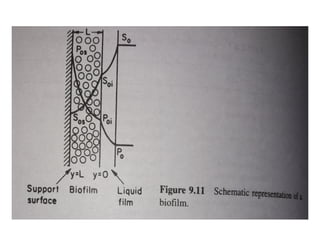

This document discusses different methods for immobilizing whole cells, including perfusion bioreactors and biofilm formation. Perfusion bioreactors culture cells continuously over long periods by feeding fresh media and removing waste, while various separation methods like hollow fiber membranes or centrifuges keep cells in the bioreactor. Perfusion offers advantages like improved product quality, smaller reactor size, and lower costs compared to traditional fed-batch systems. The document also covers immobilizing cells through entrapment in polymers, attachment to surfaces, or passive biofilm formation on supports.