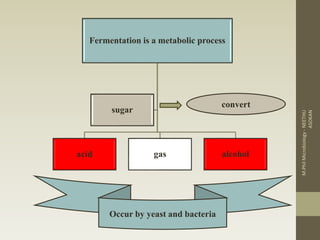

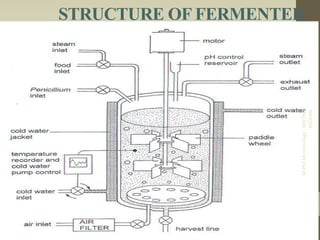

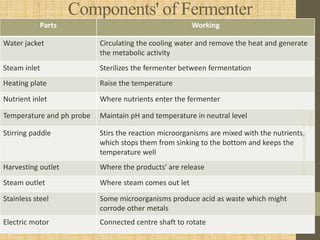

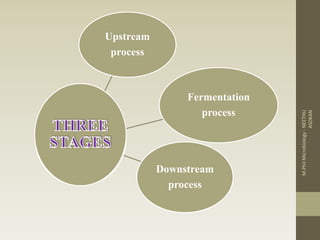

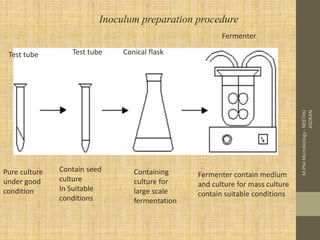

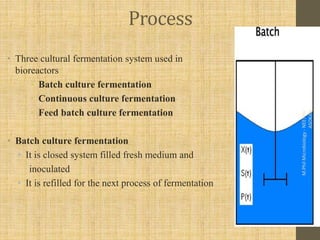

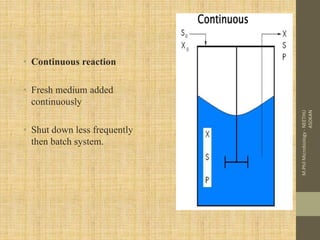

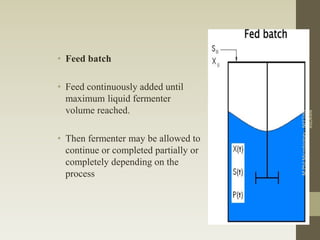

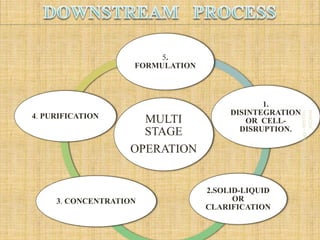

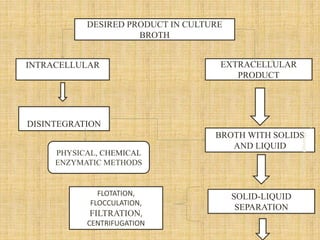

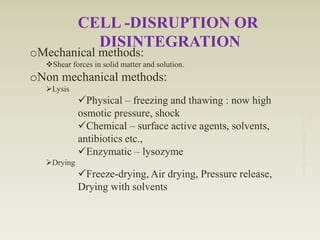

The document discusses fermentors and bioreactors. It describes how fermentors are closed vessels used for large-scale fermentation processes to produce products like antibiotics, amino acids, and organic acids. The document outlines the key components of fermentors, including a water jacket, stirring paddles, and inputs and outputs for nutrients, products, and steam. It also discusses upstream processing like medium preparation and sterilization, inoculation, and the different types of fermentation systems like batch, continuous, and fed-batch culture. Downstream processing steps like product extraction, purification, and formulation are also summarized.

![CONCENTRATION METHODS

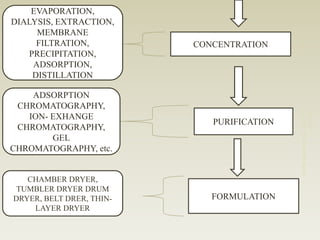

• The purity or concentration of metabolite

Evaporation –steam as heat source

Extraction – the cell mass and more or less clear solution

obtained

Adsorption – special polymer resins (chemical) used for

the isolation of hydrophilic metabolites that cannot be extract

with organic solvents.

Filtration – separation of biomolecules and particles [pore

size]

Precipitation – removal of product from the solvent

Dialysis – semi permeable membrane

M.PhilMicrobiology-NEETHU

ASOKAN](https://image.slidesharecdn.com/upstreamanddownstreamprocess-191204192526/85/Upstream-and-down-stream-process-27-320.jpg)