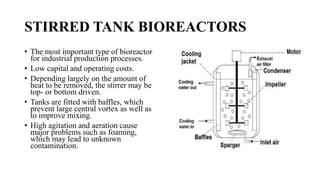

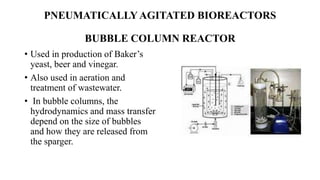

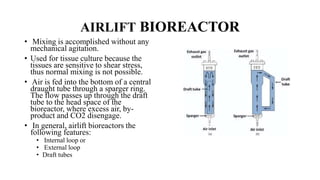

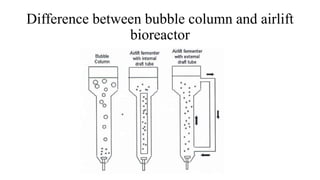

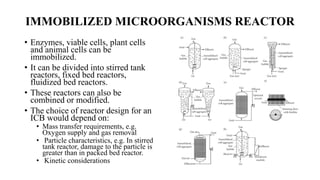

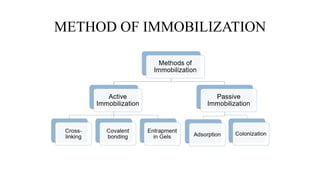

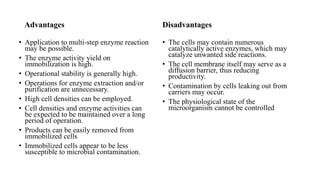

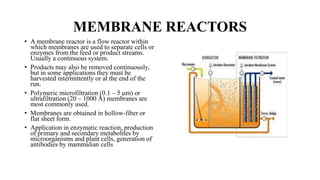

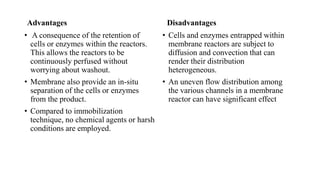

This document discusses different types of bioreactors used in bioprocesses. It describes stirred tank bioreactors, pneumatically agitated bioreactors including bubble columns and airlift bioreactors, immobilized microorganism reactors, membrane reactors, and photobioreactors. For each type, it provides details on their operation, examples of applications, and advantages and disadvantages. Strategies for choosing the appropriate bioreactor depend on factors like the microorganism, oxygen requirements, shear effects, and cleaning needs.