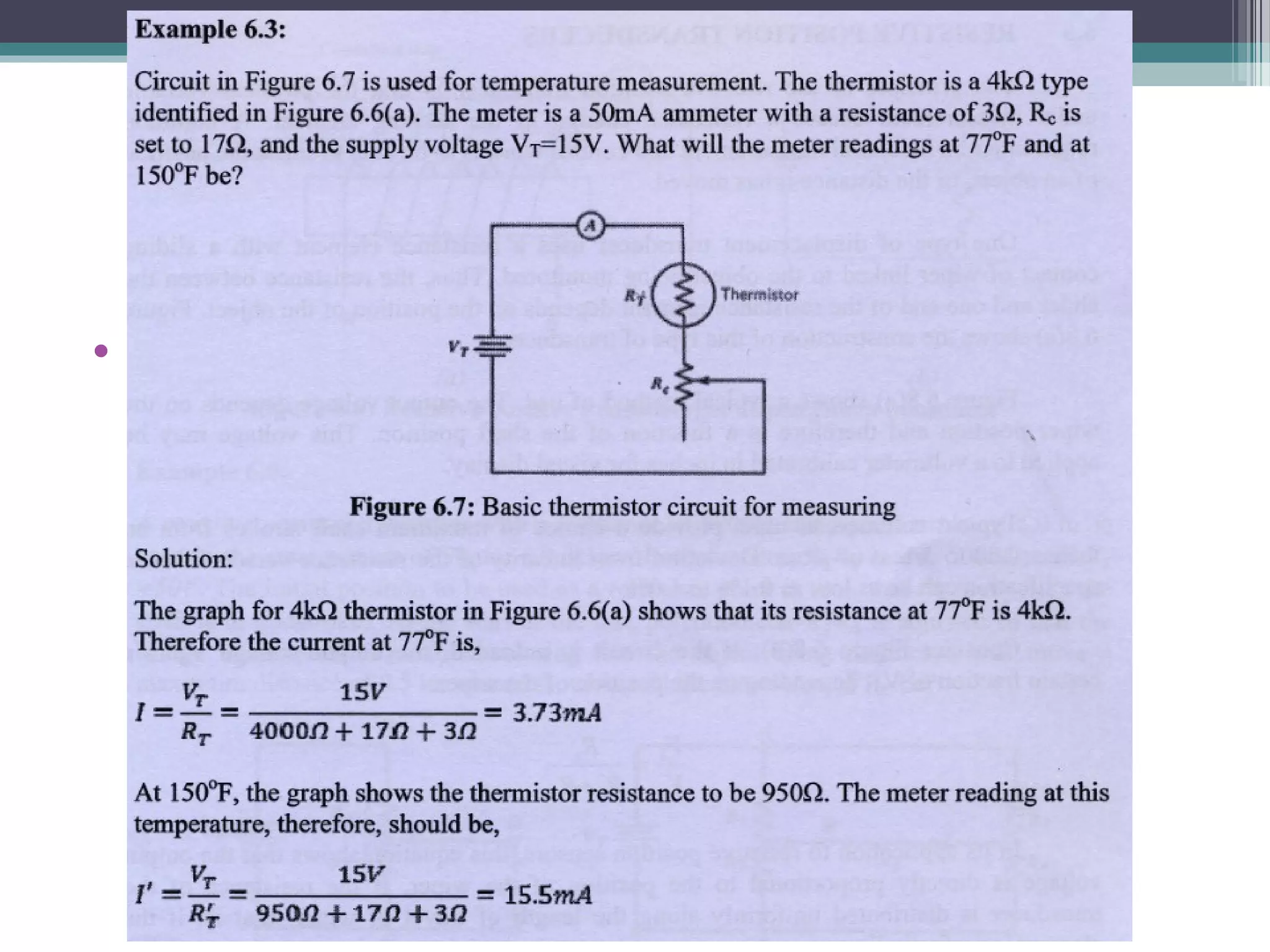

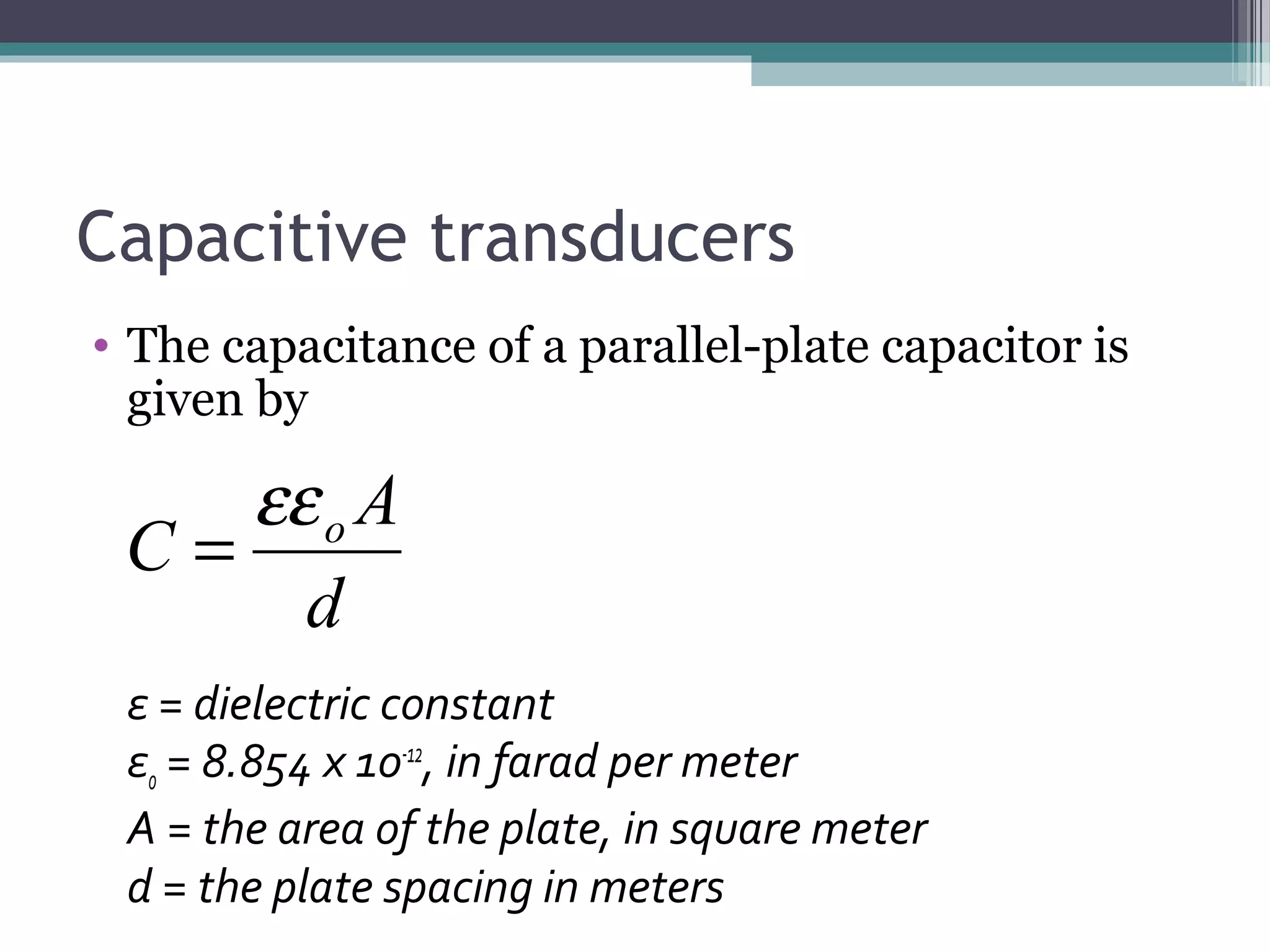

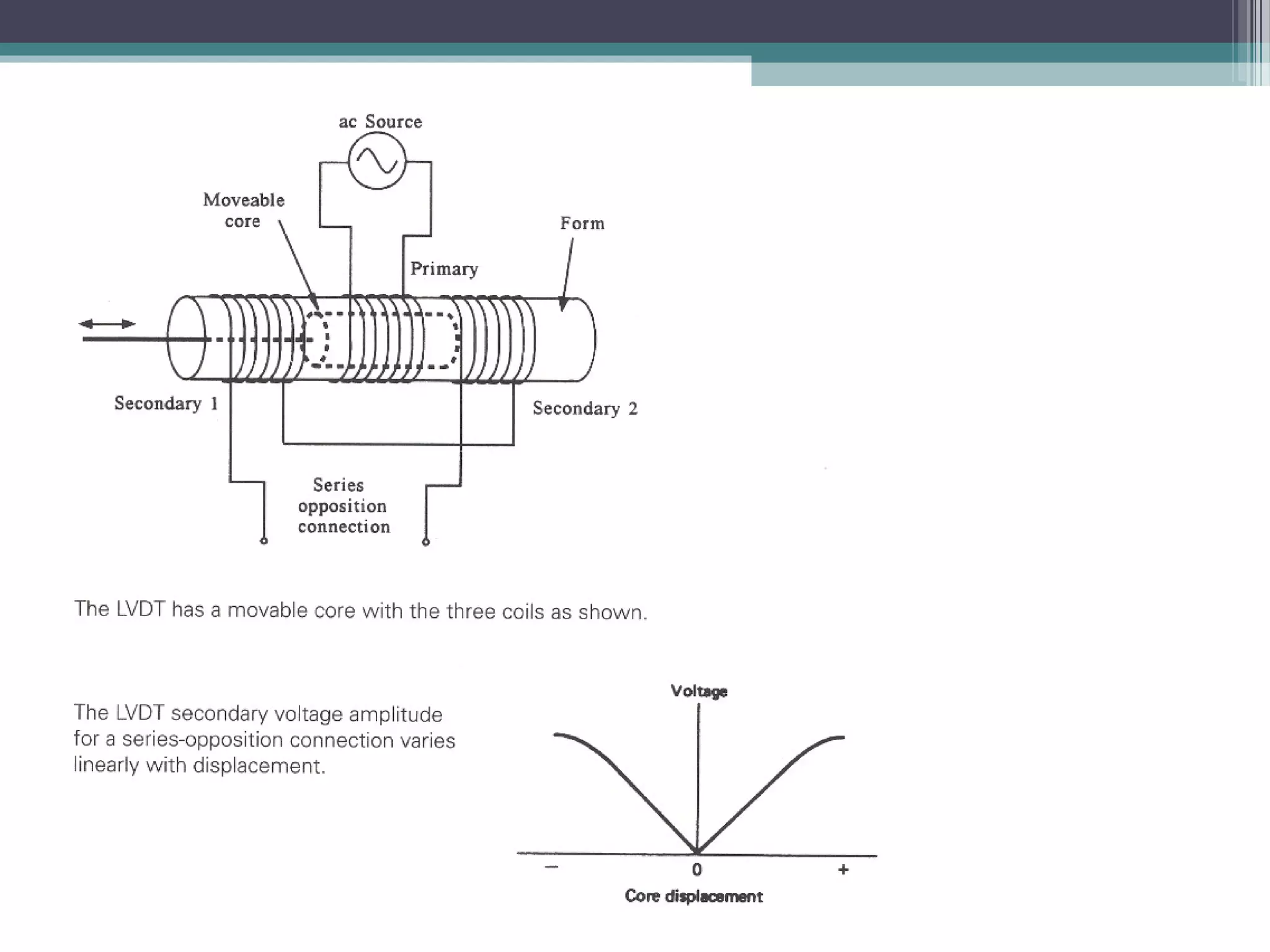

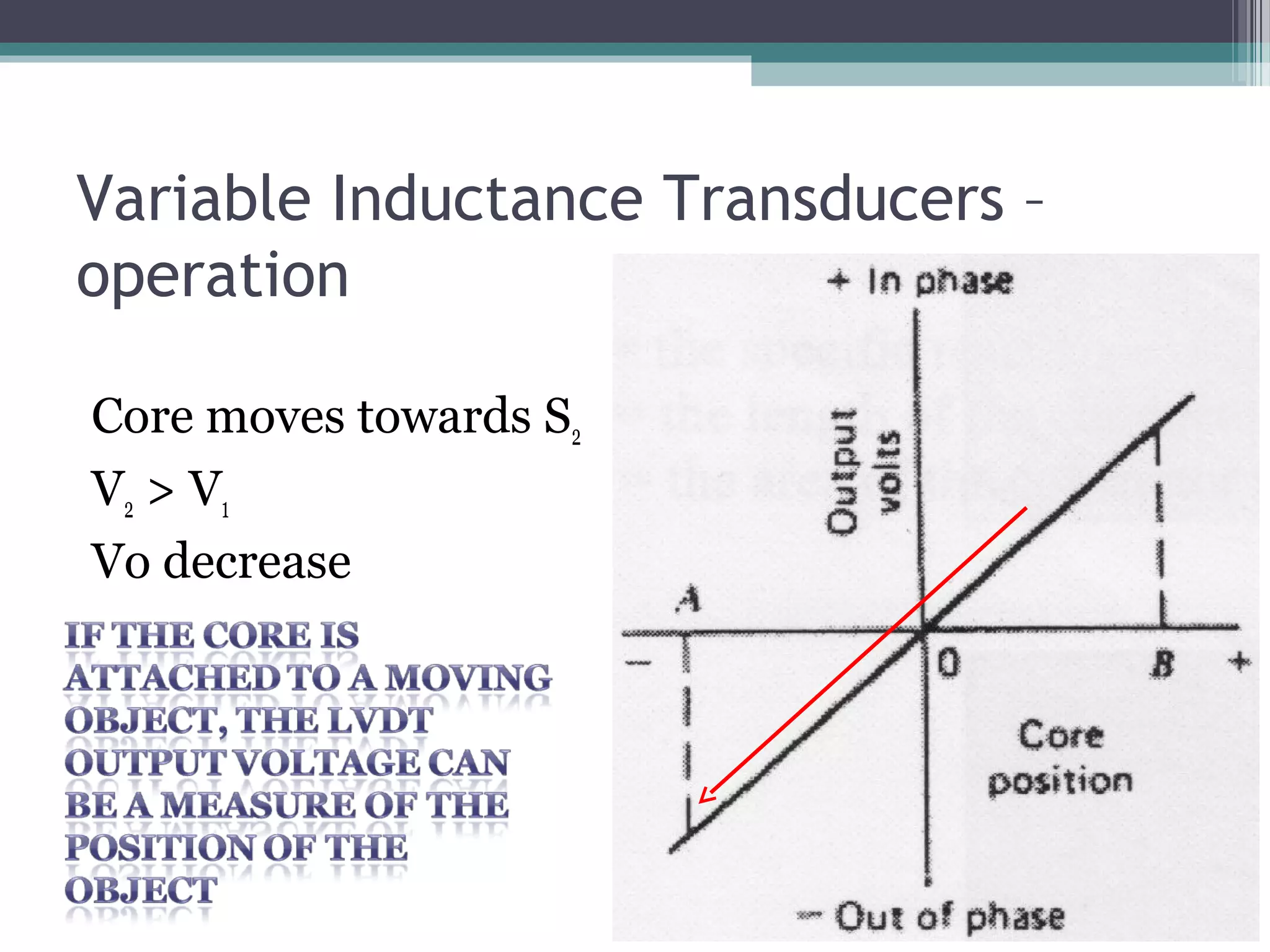

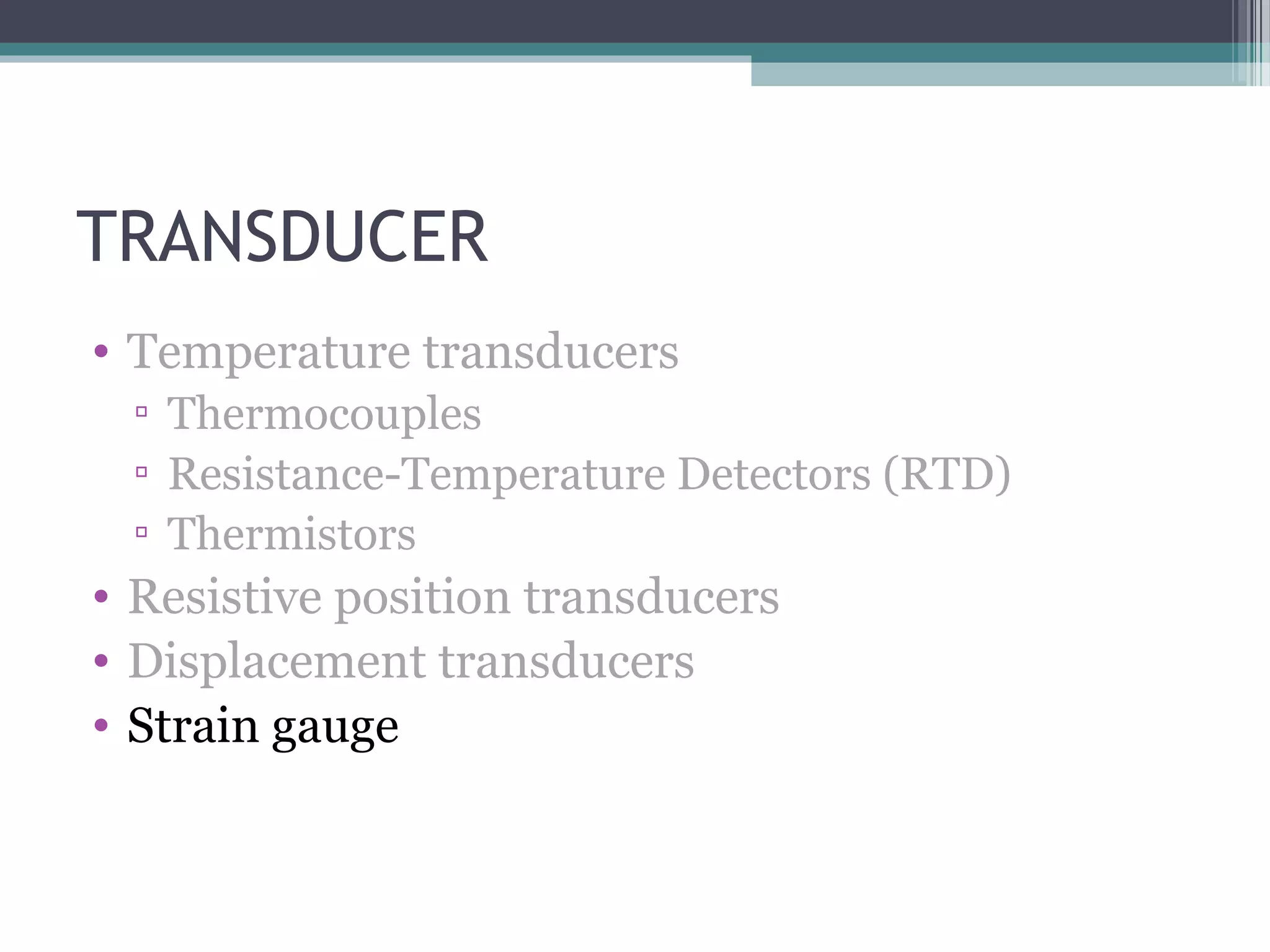

This document provides an overview of sensors and instrumentation. It discusses key concepts like measurement, instruments, transducers, sensors, and different types of sensors like pressure sensors, displacement sensors, and strain gauges. Measurement involves quantitatively comparing an unknown quantity to a standard unit. Instruments are devices that measure physical quantities and can be mechanical, electrical or electronic. Transducers convert one form of energy to another while sensors measure energy levels and output electrical signals.

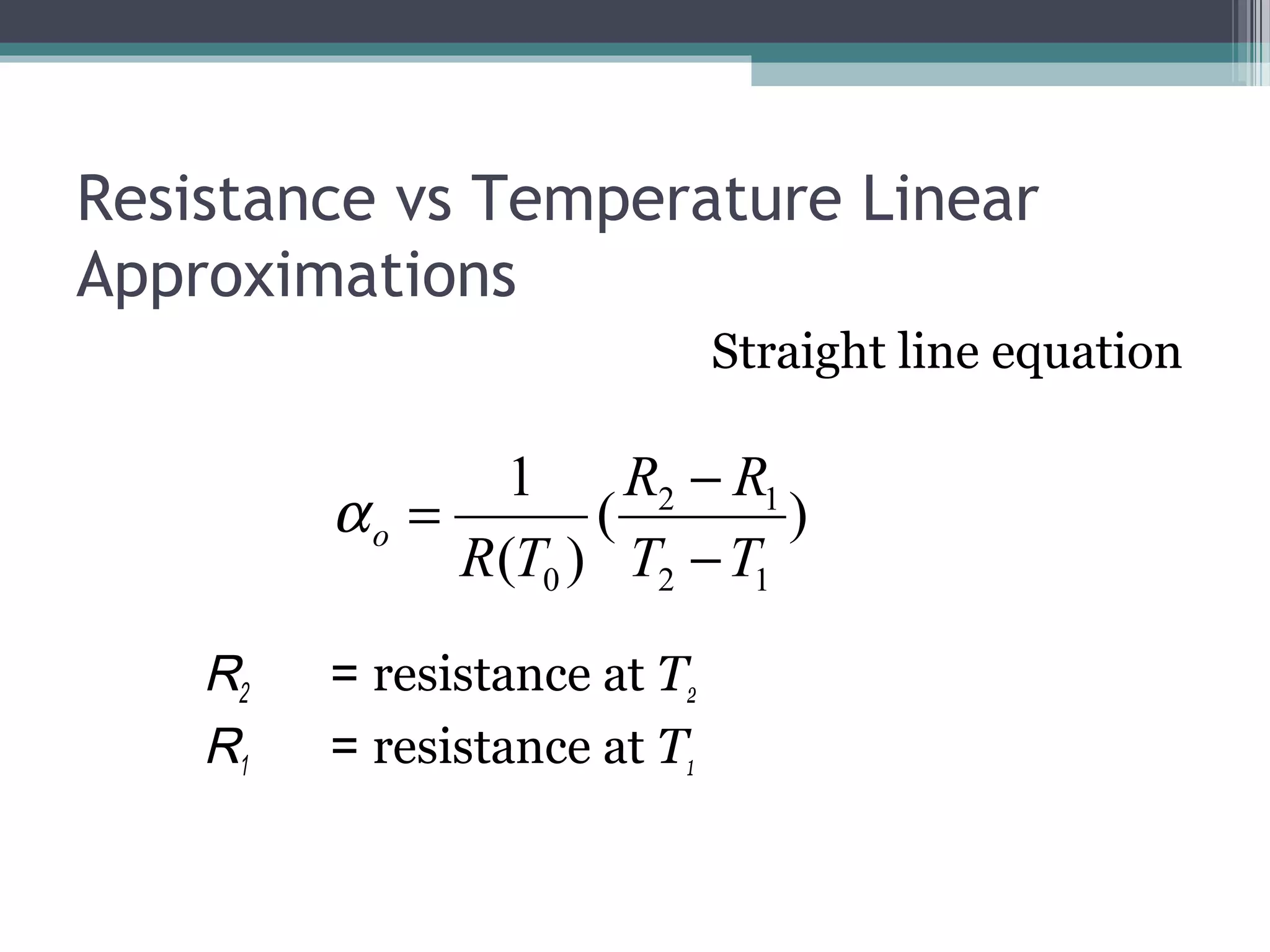

![Resistance vs Temperature

Approximations

Straight line equation

R(T) = approximation of resistance at

temperature T

R(T0) = resistance at temperature T0

αo = fractional change in resistance per

degree of temperature at T0

ΔT = T - T0

21]1)[()( TTTTTRTR oo <<∆+= α](https://image.slidesharecdn.com/transducermain222-150220113105-conversion-gate02/75/Transducer-main-58-2048.jpg)

![RTD – quadratic approximation

R(T) = quadratic approximation of

resistance at temperature T

R(T0) = resistance at temperature T0

α1 = linear fractional change in resistance

with temperature

α2 = quadratic fractional change in

resistance with temperature

ΔT = T - T0

21

2

21 ])(1)[()( TTTTTTRTR o <<∆+∆+= αα](https://image.slidesharecdn.com/transducermain222-150220113105-conversion-gate02/75/Transducer-main-62-2048.jpg)