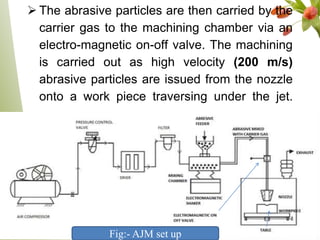

Abrasive Jet Machining (AJM) involves the use of high-velocity abrasive particles, propelled by a carrier gas, to remove material from a workpiece through micro-cutting and brittle fracture. The process utilizes a nozzle to direct the abrasive jet and allows for controlled parameters like distance and angle, making it suitable for intricate drilling in hard, brittle, and heat-sensitive materials. However, AJM has limitations such as low material removal rates and potential embedding of particles in ductile materials.