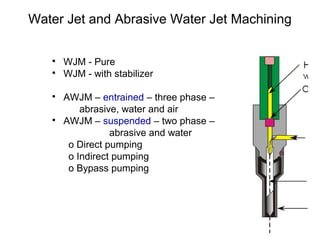

Abrasive jet machining (AJM) is a material removal process using a high-velocity stream of air, gas, or water mixed with abrasives to cut materials. Key components include an abrasive delivery system, control system, pump, nozzle, mixing tube, and motion system, which together enable precise machining. AJM offers advantages such as fast setup, low capital costs, and minimal heat generation, although it has limitations like low metal removal rates and non-reusable abrasive powders.