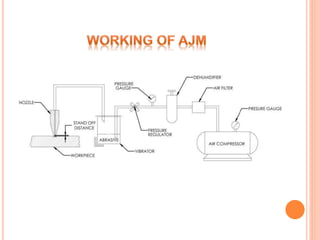

The document describes abrasive jet machining. It involves removing material from a workpiece using a high-velocity stream of air or gas mixed with abrasive particles. Key components include an air compressor, abrasive delivery system, nozzle, and motion system to direct the abrasive stream. The mixing tube is where abrasive mixes with pressurized air before exiting the nozzle to erode material. A CNC motion system provides automated precision control over the machining process.