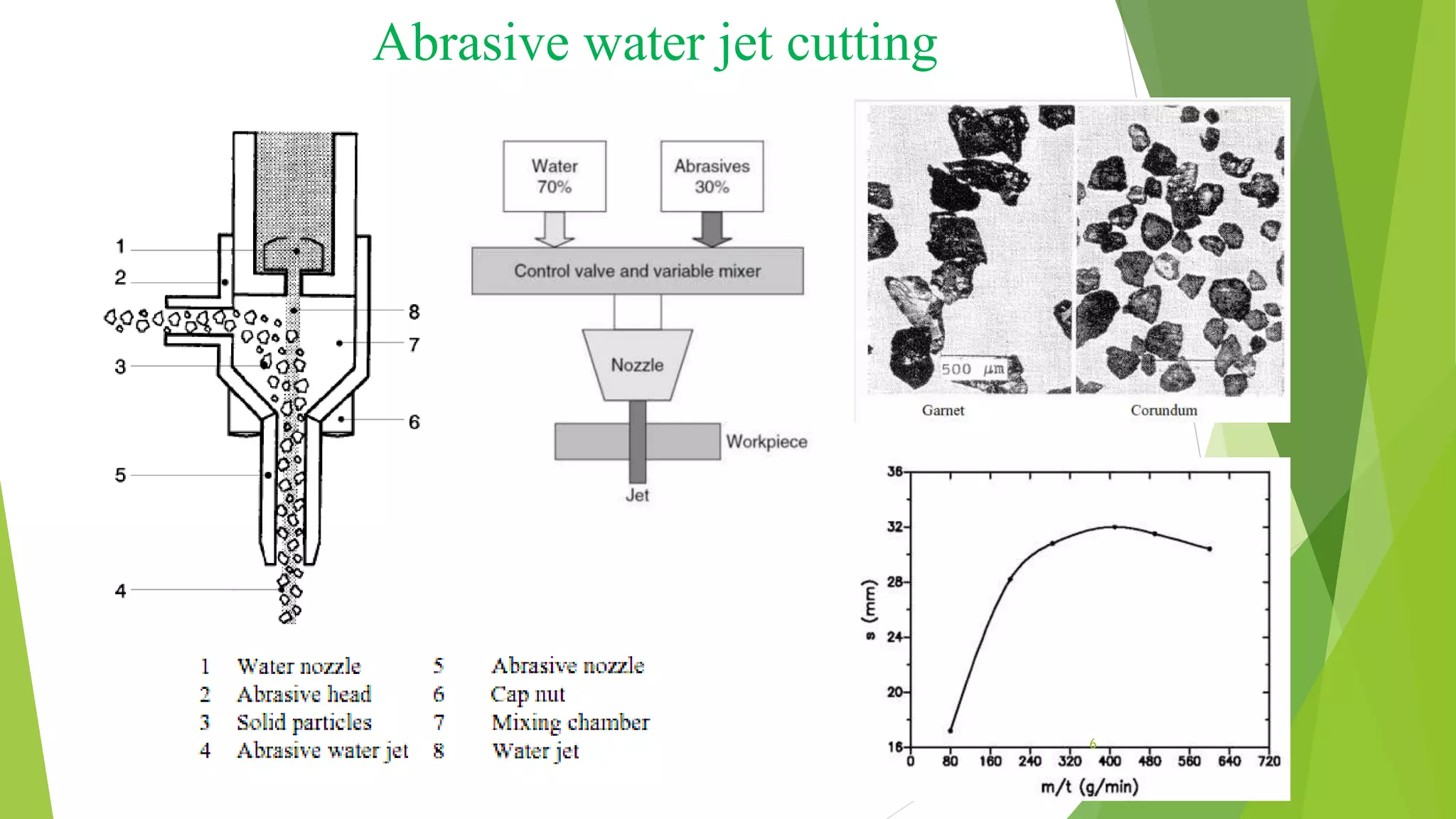

Water jet machining uses a high pressure stream of water, sometimes with an abrasive additive, to cut materials. Key aspects of the process include a water jet that travels at speeds of 540-1400 m/s to erode material from the workpiece surface. Parameters like pressure, abrasive grain size, and speed affect the performance and quality of cuts. Water jet machining provides advantages like flexibility, environmental friendliness, and stress-free cuts of many materials without heat or debris. However, initial costs can be high and material removal rates are low.