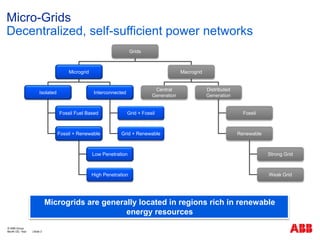

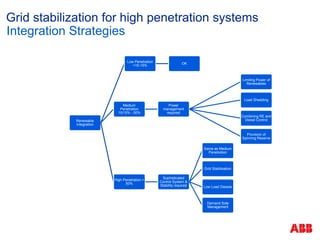

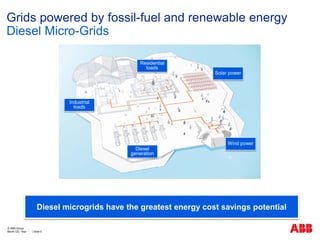

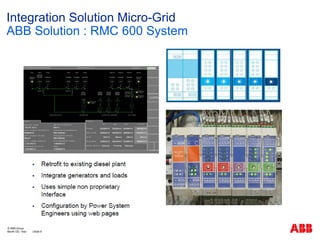

This document discusses microgrids and renewable energy integration. It notes that microgrids are decentralized, self-sufficient power networks that are generally located in regions rich in renewable energy resources. Integrating high levels of renewable energy into microgrids presents challenges in maintaining grid stability due to the intermittent nature of renewable sources. The document proposes that intelligent control systems and grid stabilization technologies can enable high renewable energy penetration of up to 100% while keeping the voltage and frequency stable and maximizing fuel savings and return on investment. ABB provides solutions like the Remote Microgrid Controller and PowerStore flywheel system to stabilize grids and maximize the benefits of integrating renewable energy at high levels.

![ABB RE+ and battery energy storage

An alternative solution when applicable

Load

Charge Discharge

t [hrs]

Supply power

Absorb power Absorb power

EnergystoredinESS

ABB’s comprehensive battery energy storage solutions

Based on proven power converter technology

Turnkey and modular solutions suitable for all power levels (~25kW to 70 MW)

Solutions designed and developed independently of battery technology

Month DD, Year | Slide 23

© ABB Group

Applications: peak demand

shaving or load shifting

Longer stored energy discharge

timescale; minutes to hours

Enable fossil fuel generators to

run at stable outputs

Maximize renewable energy load

factor](https://image.slidesharecdn.com/ttnhquj4szg4wdc2xlyk-signature-1314db6b8f9c714f509aa7ef811db97b93ec1e111303b5ecde6d32c8762df600-poli-161024023408/85/abb-micro-grids-and-renewable_energy_integration-23-320.jpg)

![ESS applications fall into 2 categories

Segmentation between long and short discharge time

ESS = Energy Storage System

100 kW 1 MW 10 MW 100 MW 1000 MW

10

1000

100

10 h

1 h

10 min

Power requirement [MW]

30

300

End-user

peak shaving

Frequency

regulation

Load leveling

(postponement of

grid upgrade)

Renewables integration

Energy

Power

Load leveling

(generation

utilization)

Dischargetime[min]](https://image.slidesharecdn.com/ttnhquj4szg4wdc2xlyk-signature-1314db6b8f9c714f509aa7ef811db97b93ec1e111303b5ecde6d32c8762df600-poli-161024023408/85/abb-micro-grids-and-renewable_energy_integration-38-320.jpg)

![Energy

Power

100 kW 1 MW 10 MW 100 MW 1000 MW

10

1000

100

10 h

1 h

10 min

Dischargetime[min]

Power requirement [MW]

30

300

Pumped-Hydro

Lithium ion battery

Flow battery / emerging technologies

Sodium Sulfur battery

Lead acid battery

Super-capacitor / flywheel

Right technology for right application

Segmentation on ‘power’ and ‘energy’ technologies](https://image.slidesharecdn.com/ttnhquj4szg4wdc2xlyk-signature-1314db6b8f9c714f509aa7ef811db97b93ec1e111303b5ecde6d32c8762df600-poli-161024023408/85/abb-micro-grids-and-renewable_energy_integration-39-320.jpg)