The document discusses Kaoru Ishikawa's development of the Seven Basic Tools of Quality Control. Ishikawa was inspired by W. Edwards Deming's lectures on quality control tools in Japan in the 1950s. Ishikawa formalized seven graphical tools - including fishbone diagrams, histograms, Pareto charts, flowcharts, scatter plots, run charts, and control charts - that could be easily understood and applied by all workers to solve 95% of quality-related problems. The tools provide visual means to analyze processes, identify issues, and monitor quality improvements.

![Spirit Proprietary 6

The Basic Seven (B7)

Tools of Quality

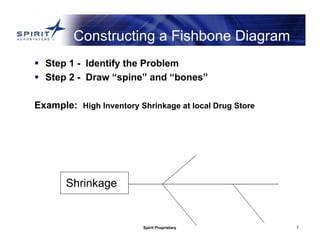

1] Fishbone Diagrams

No statistics involved

Maps out a process/problem

Makes improvement easier

Looks like a “Fish Skeleton”](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-6-320.jpg)

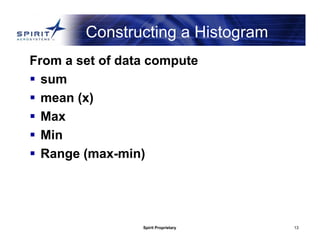

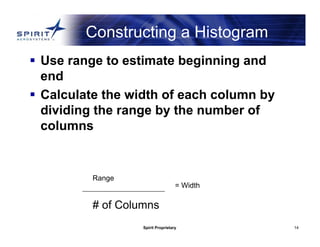

![Spirit Proprietary 12

The Basic Seven (B7)

Tools of Quality

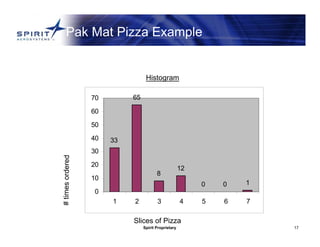

2] Histograms

Bar chart

Used to graphically represent groups of data](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-12-320.jpg)

![Spirit Proprietary 19

The Basic Seven (B7)

Tools of Quality

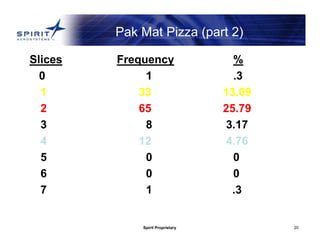

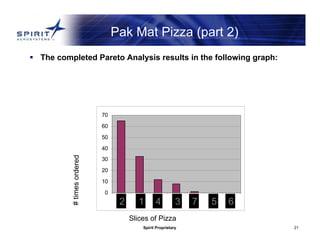

3] Pareto Analysis

Very similar to Histograms

Use of the 80/20 rule

Use of percentages to show importance](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-19-320.jpg)

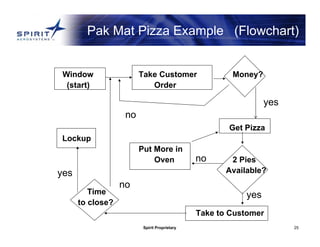

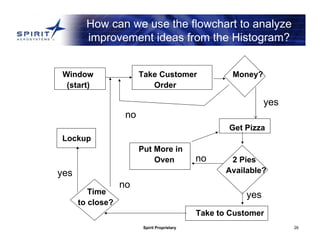

![Spirit Proprietary 23

The Basic Seven (B7)

Tools of Quality

4] Flowcharts

A graphical picture of a PROCESS

Process Decision

The process flow](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-23-320.jpg)

![Spirit Proprietary 28

The Basic Seven (B7)

Tools of Quality

5] Scatter Plots

2 Dimensional X/Y plots

Used to show relationship between

independent(x) and dependent(y)

variables](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-28-320.jpg)

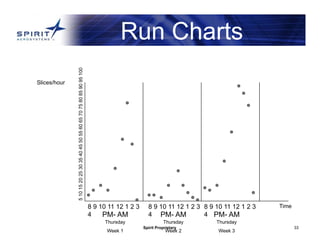

![Spirit Proprietary 32

The Basic Seven (B7)

Tools of Quality

6] Run charts

Time-based (x-axis)

Cyclical

Look for patterns](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-32-320.jpg)

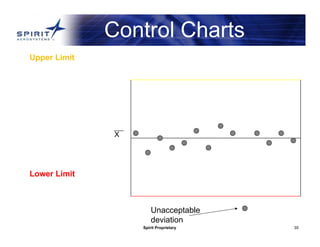

![Spirit Proprietary 34

The Basic Seven (B7)

Tools of Quality

7] Control Charts

Deviation from Mean

Upper and Lower Spec’s

Range](https://image.slidesharecdn.com/7qctoolpresentationmaterial-140808031712-phpapp02/85/7-qc-tool-presentation-material-34-320.jpg)