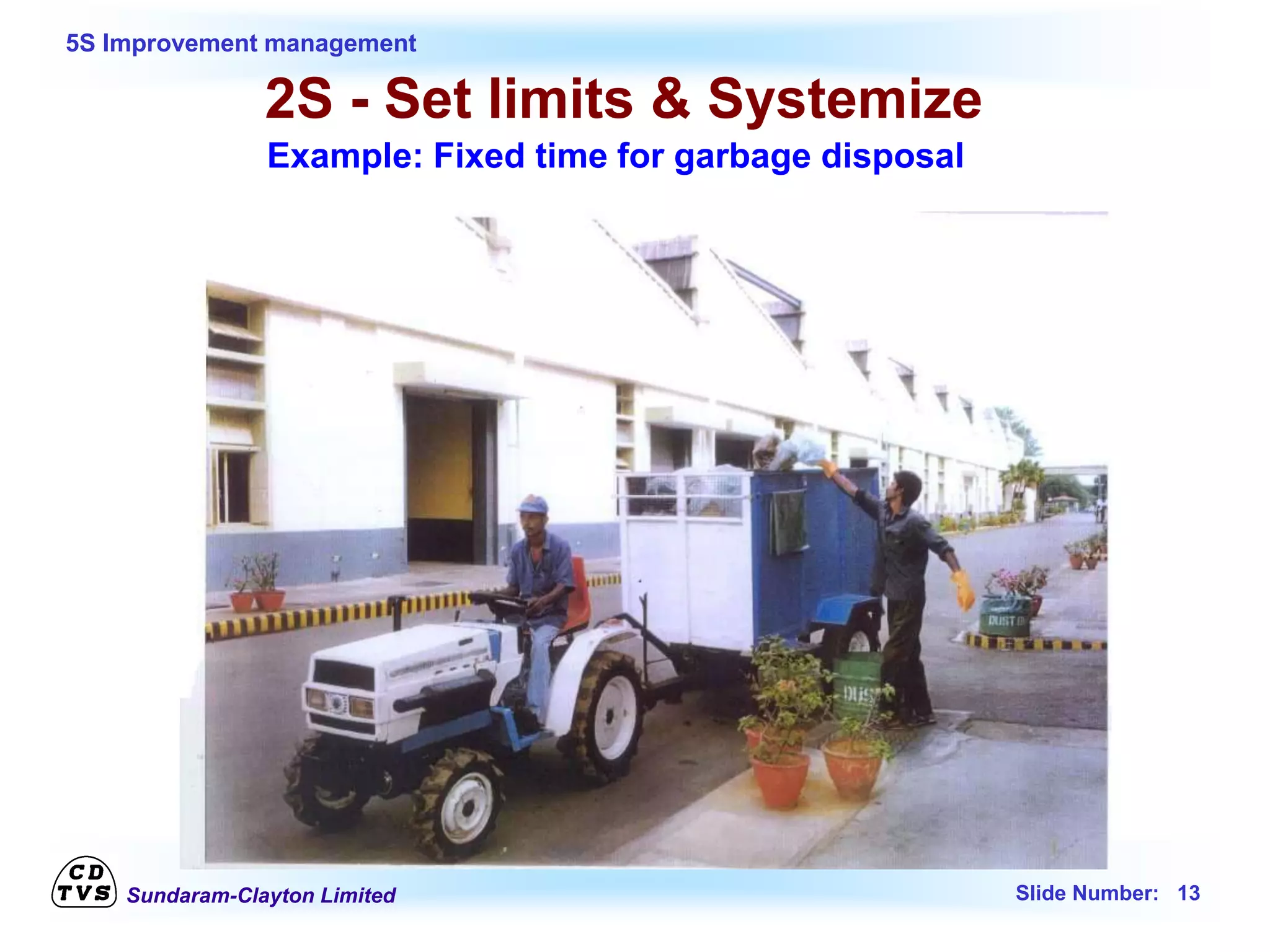

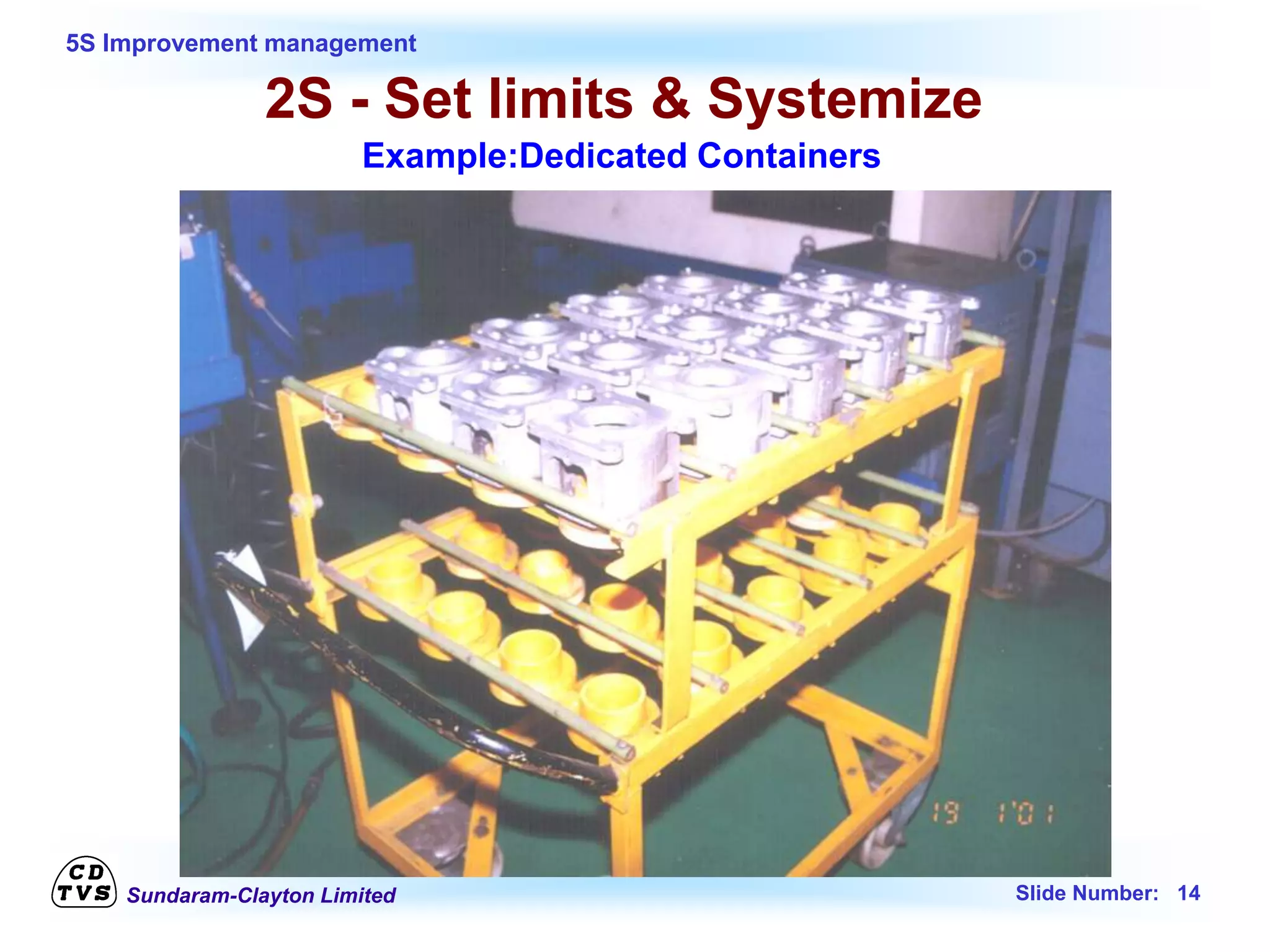

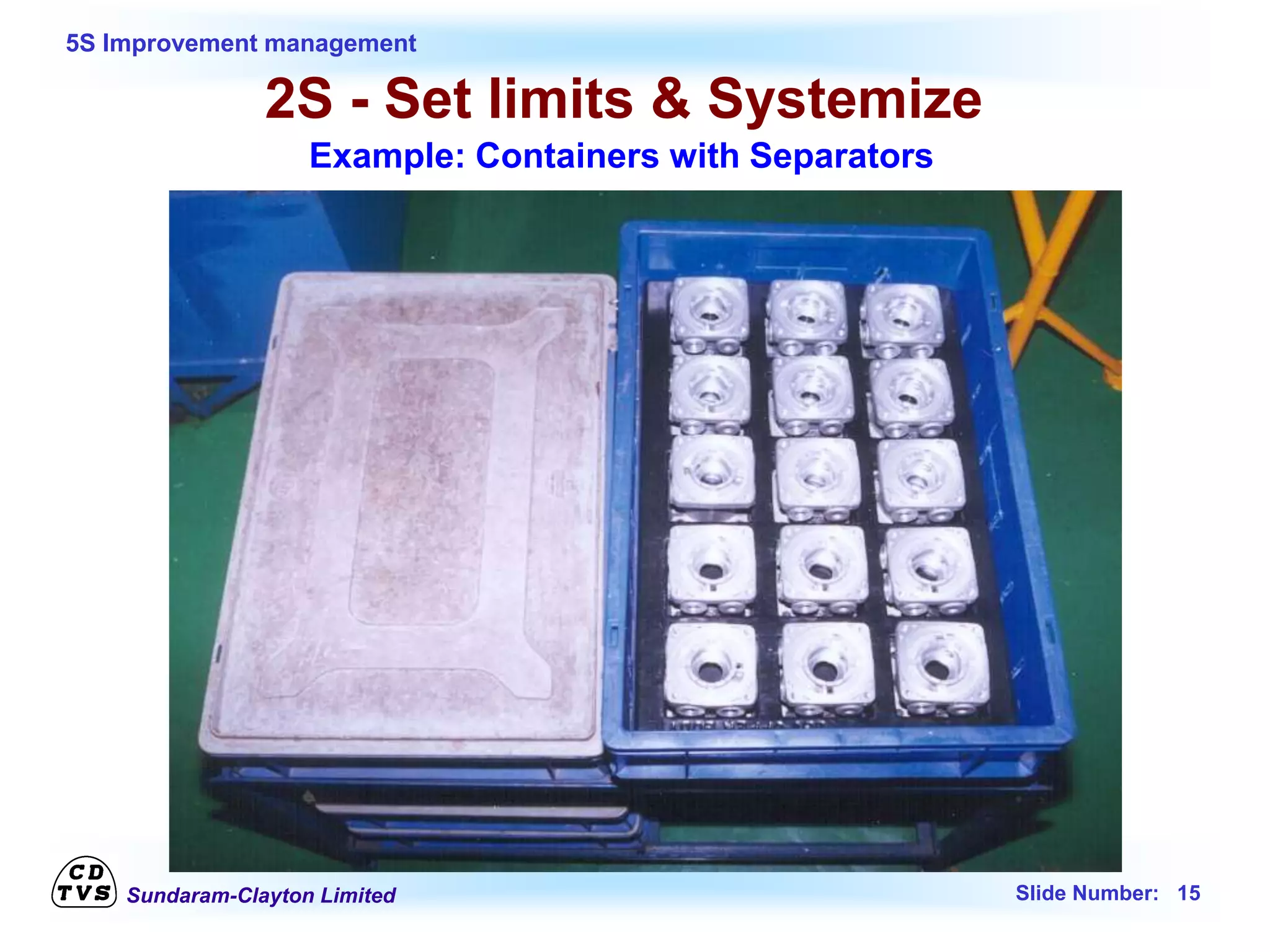

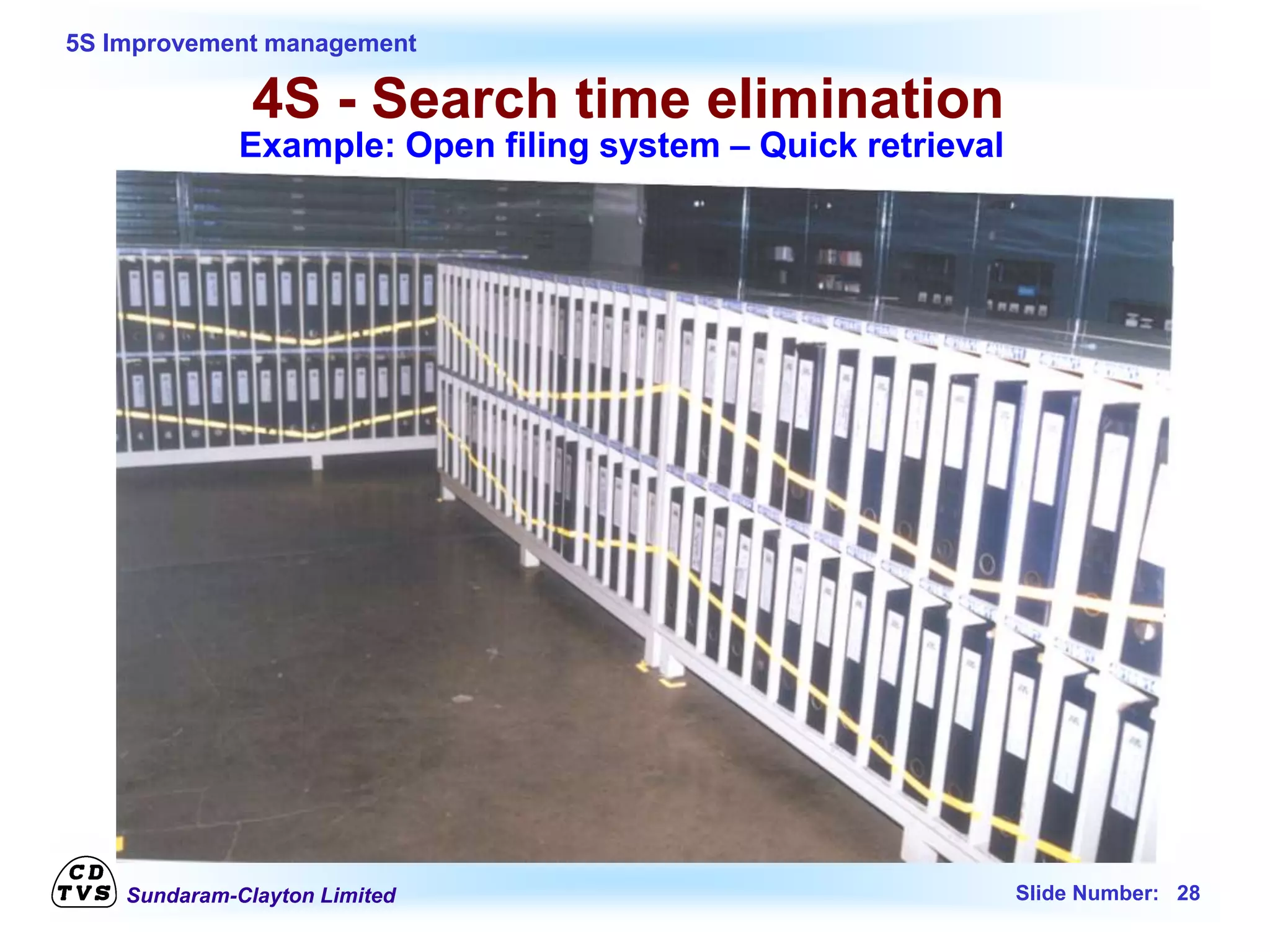

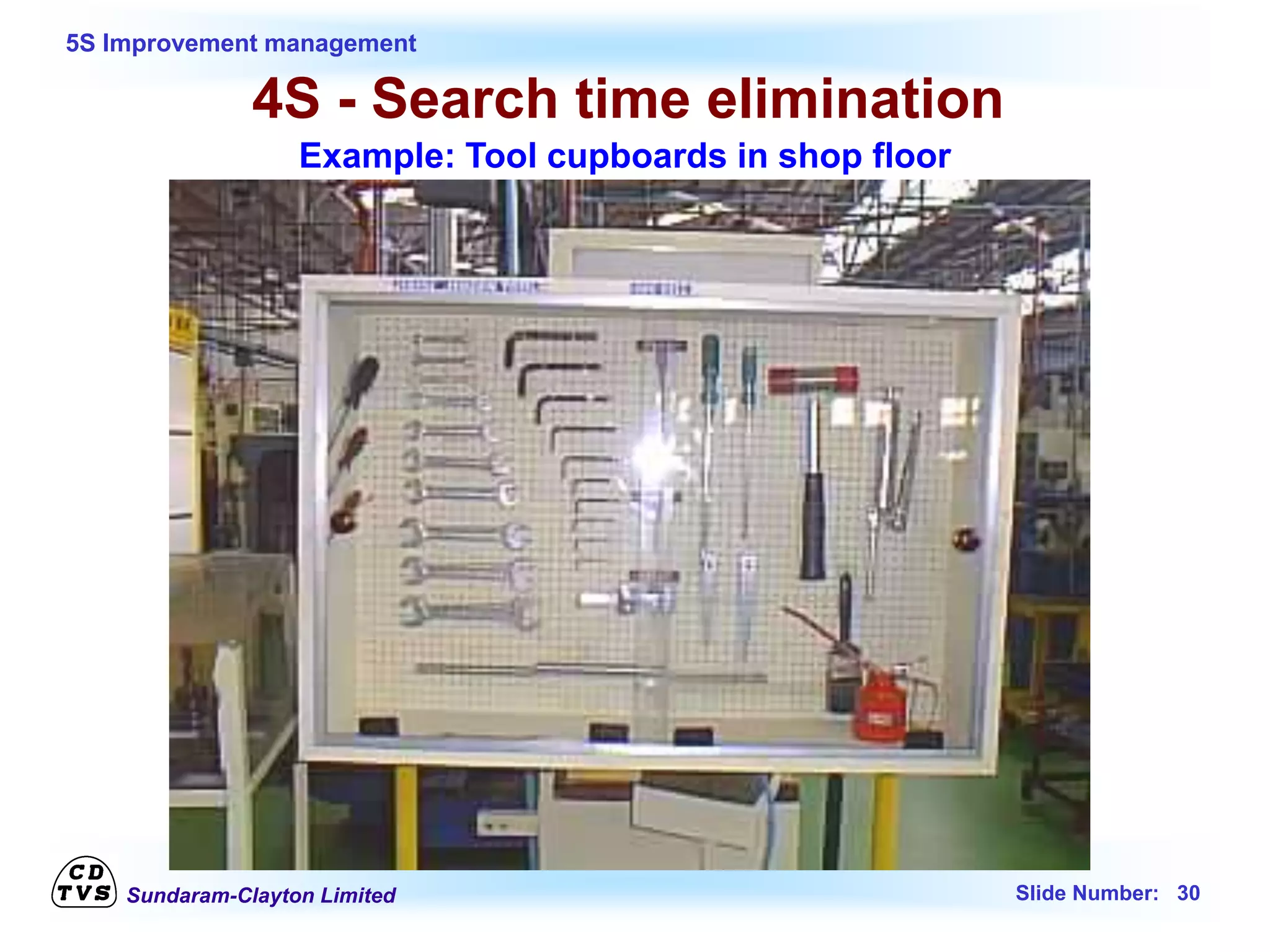

The document discusses the 5S methodology for improvement management used by Sundaram-Clayton Limited. It describes the 5S principles of sorting, setting in order, shining, standardizing, and sustaining. Examples are provided for how each S has been implemented, such as designating areas for different items and visual controls. Benefits include improved safety, quality, productivity and cost reduction. Continuous monitoring, communication and training are emphasized to maintain the 5S system.