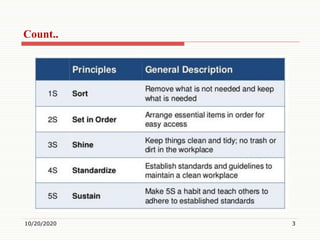

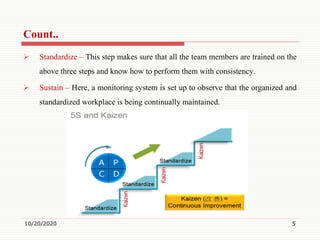

The document discusses the principles and benefits of 5S, a methodology used in total quality management. The 5 steps of 5S are Sort, Set in Order, Shine, Standardize, and Sustain. These steps involve organizing a workspace by removing unnecessary items, labeling necessary items, cleaning, training employees on the system, and sustaining the organized workspace. Benefits of 5S include improved quality, productivity, safety, employee morale, and company image by creating an organized, efficient workspace that minimizes errors and waste.