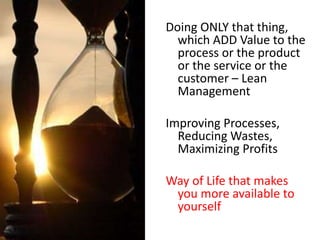

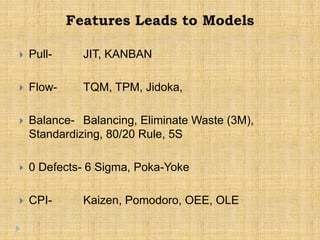

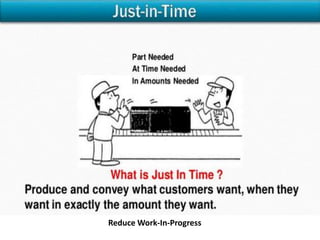

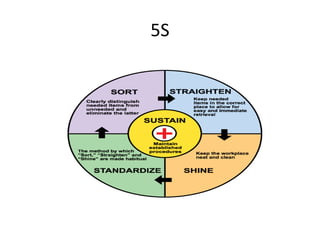

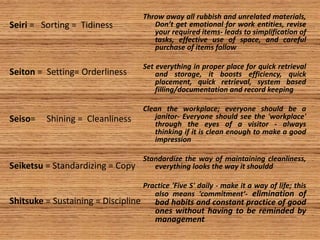

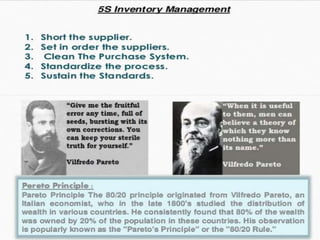

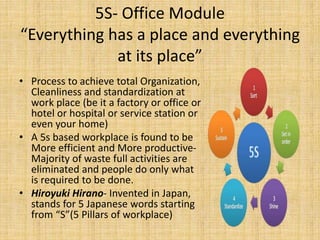

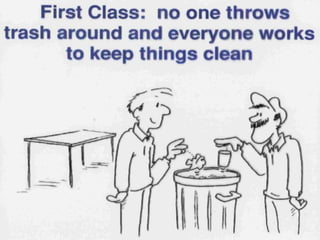

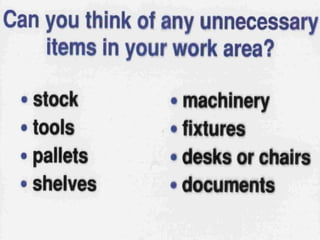

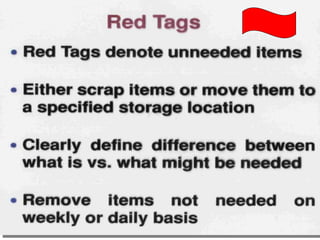

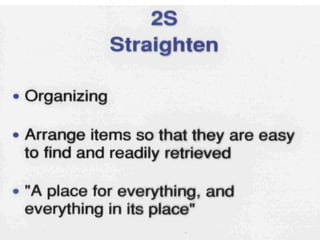

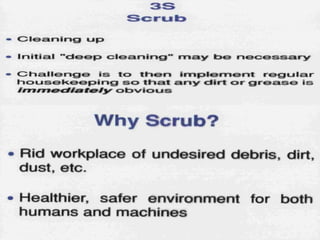

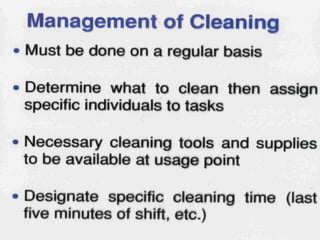

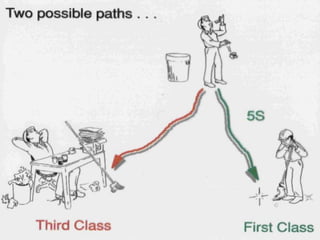

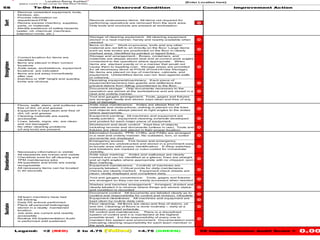

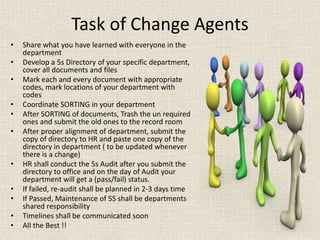

This document discusses Lean management principles and implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) in the workplace. It provides examples of applying 5S to organize workstations, documents/items, and computers. Implementing 5S brings benefits like reducing search time, faster response times, and a safer work environment. The document encourages readers to be change agents and help implement 5S in their departments through activities like developing a 5S directory and coordinating the sorting process.