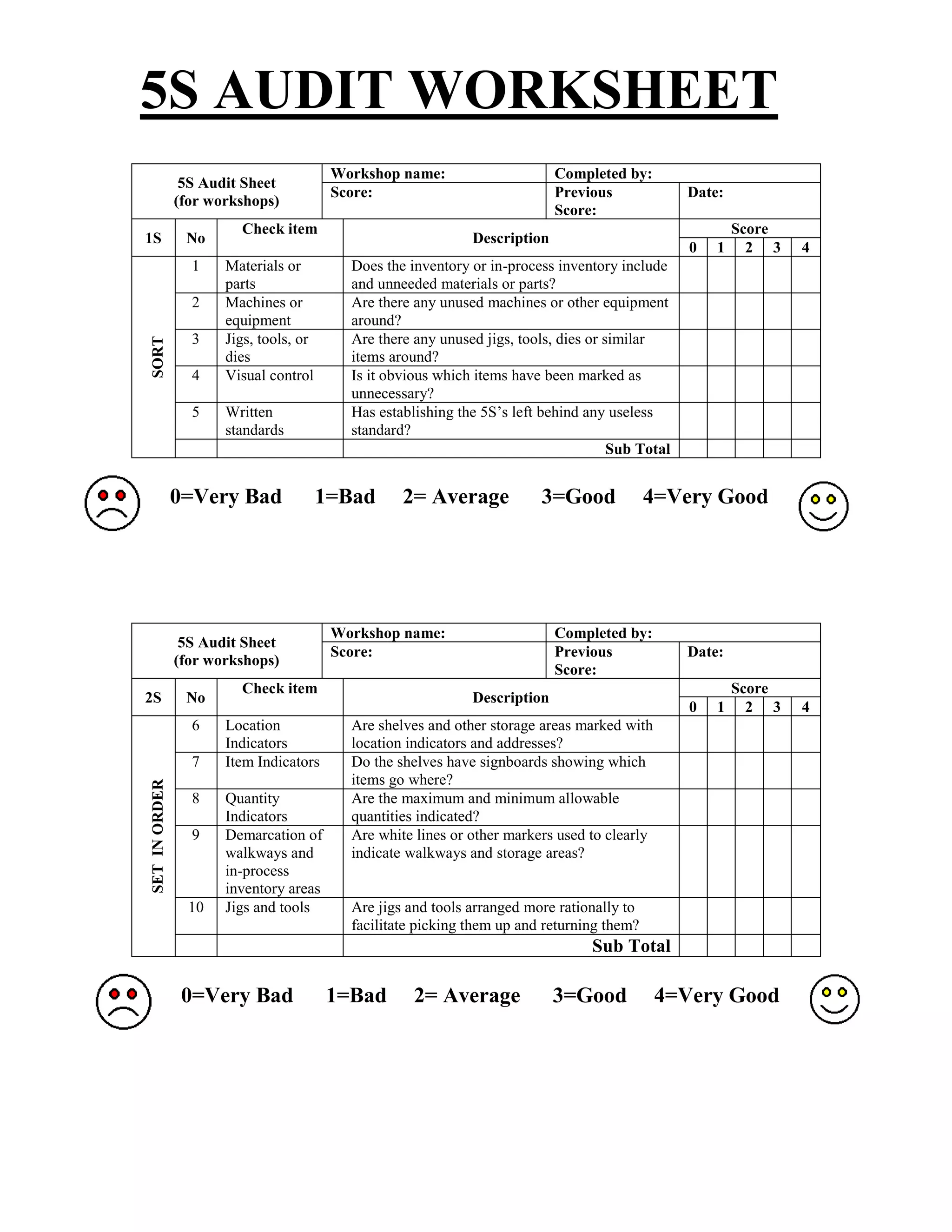

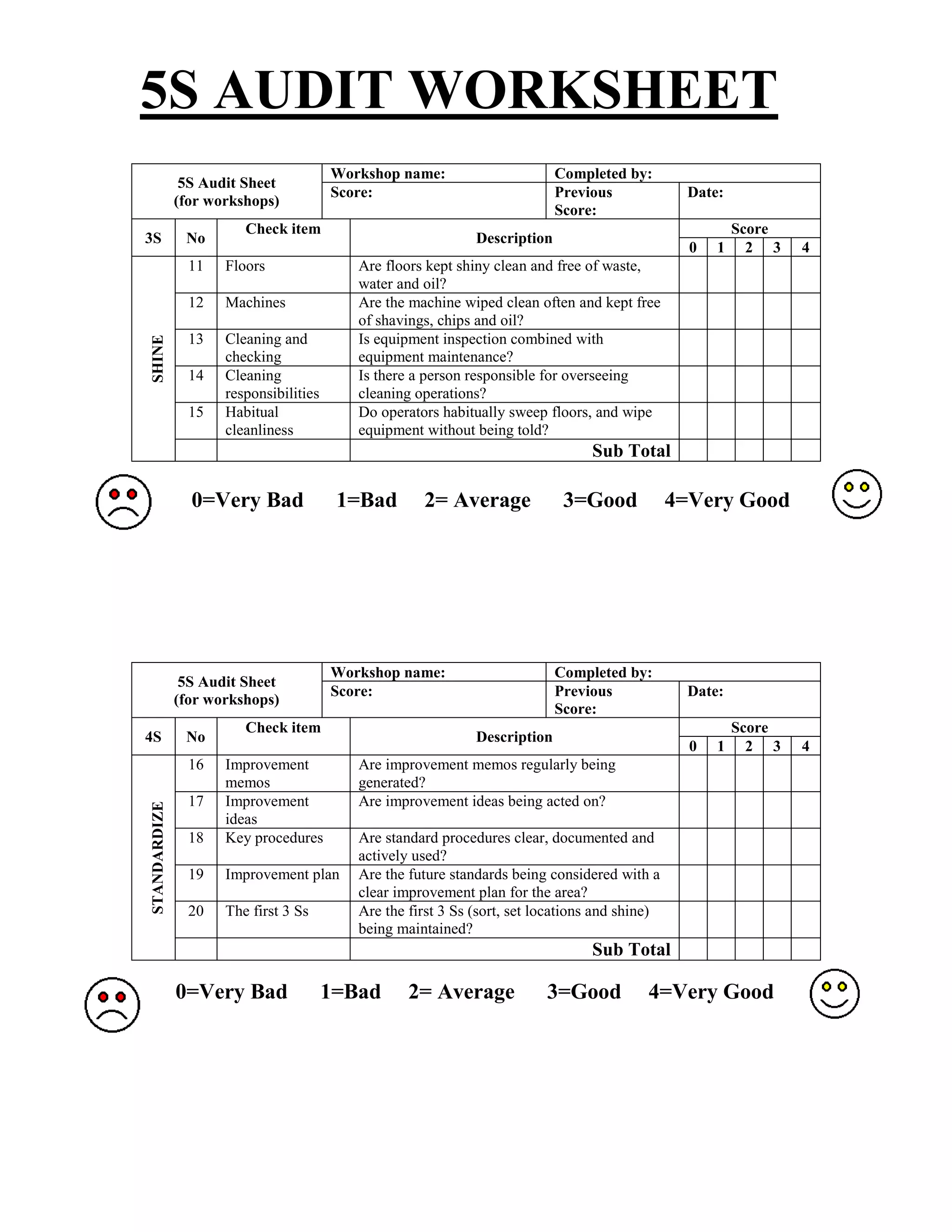

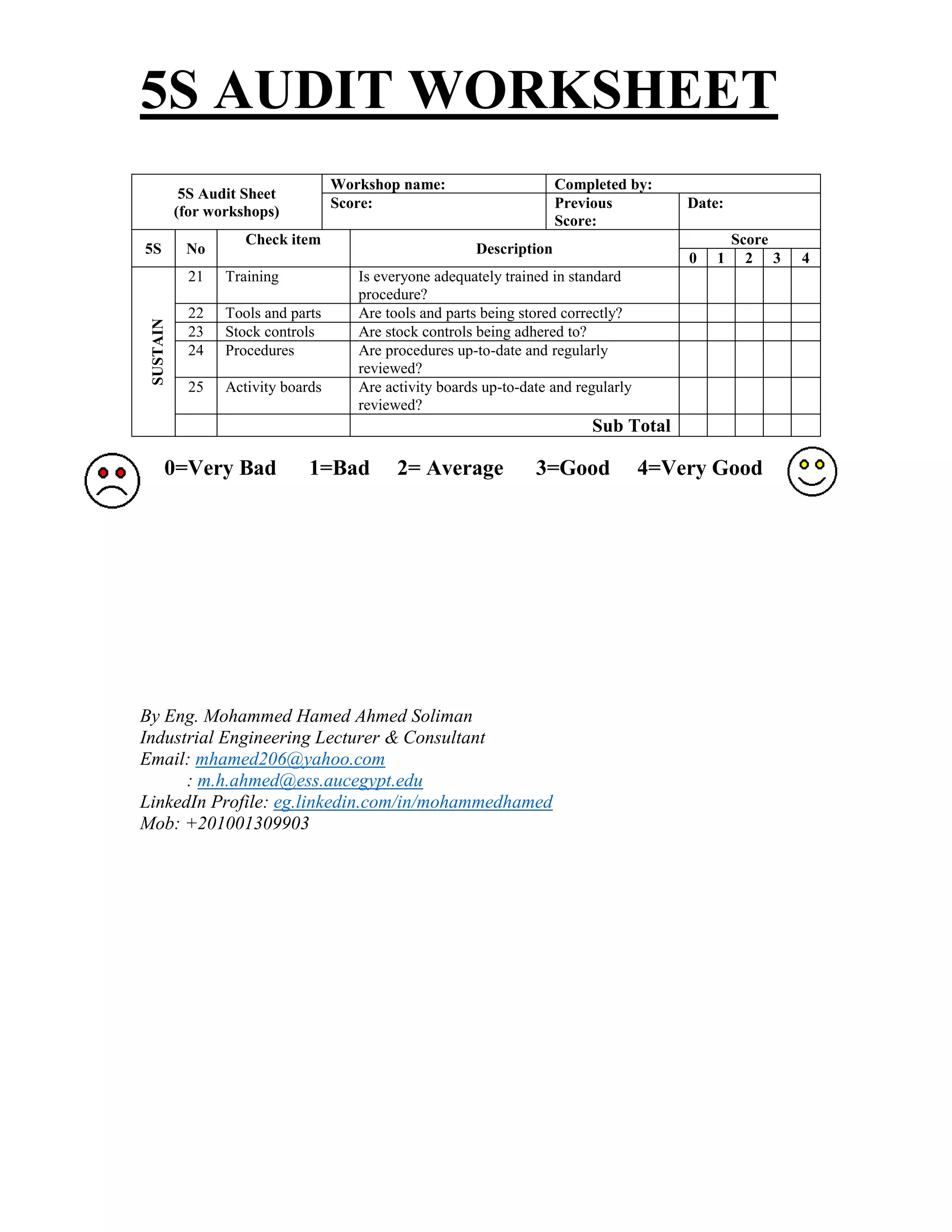

This document contains a 5S audit worksheet to evaluate implementation of 5S (Sort, Set In Order, Shine, Standardize, Sustain) in a workshop. It includes 25 check items across the 5 categories to assess aspects like unnecessary inventory, cleanliness of machines and floors, visual controls, documented standards, training, and adherence to procedures. Scores from 0 to 4 are given for each item, with 0 being very bad and 4 being very good. The previous and current total scores are recorded to measure improvement over time in implementing the 5S methodology to organize and clean the workshop.