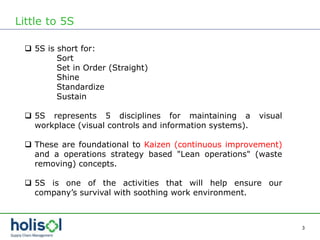

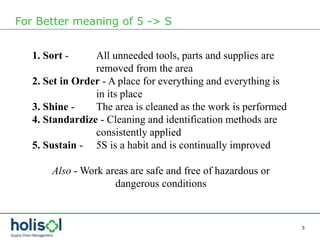

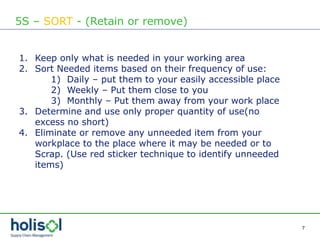

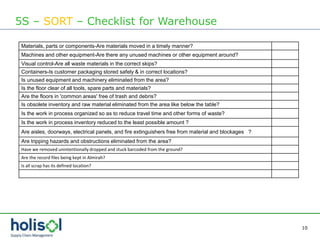

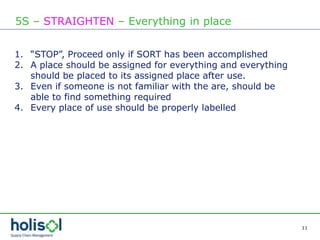

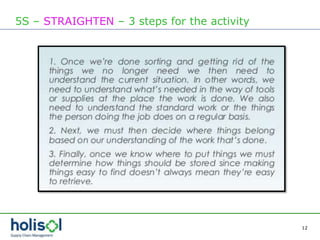

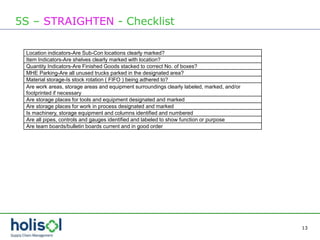

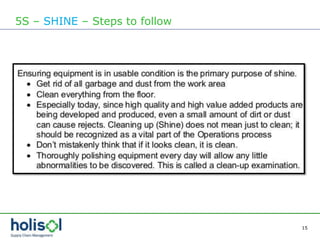

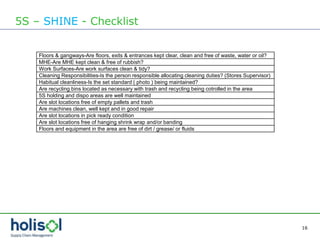

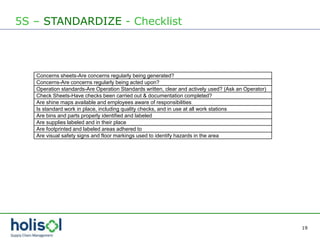

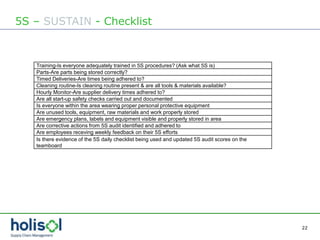

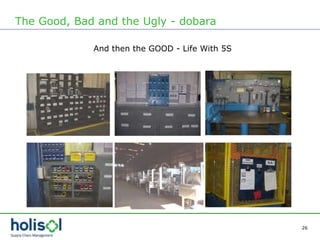

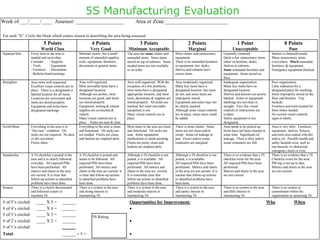

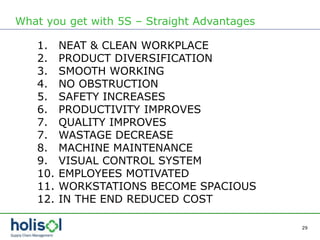

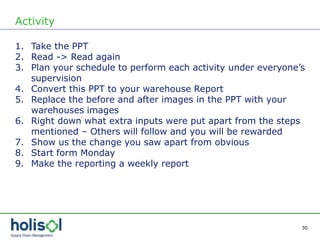

The document provides comprehensive training on the 5S methodology, which stands for Sort, Set in order, Shine, Standardize, and Sustain, aimed at creating an organized and efficient workplace. It outlines each 'S' in detail, including objectives, steps, checklists, and suggestions for maintaining a clean and productive environment while highlighting the importance of continuous improvement and training in 5S practices. Additionally, it discusses the benefits of implementing 5S, such as increased safety, improved productivity, and reduced costs.