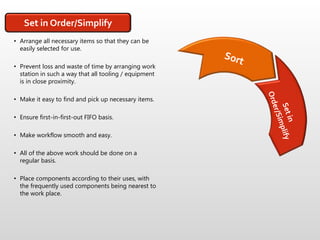

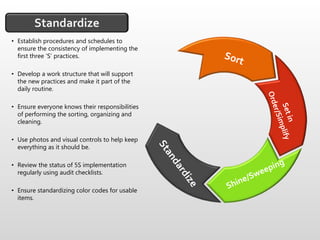

The 5S methodology, developed post-World War II by Toyota engineers, focuses on organized, efficient workspaces through five principles: Sort, Set in Order, Shine, Standardize, and Sustain. It emphasizes eliminating waste, ensuring that tools and materials are readily accessible, and maintaining clean work environments. While initially designed for production settings, 5S can be adapted to improve efficiency in various professional and personal contexts.