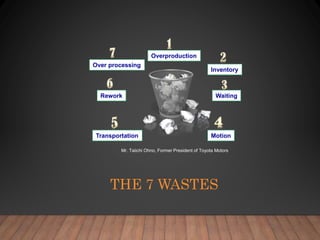

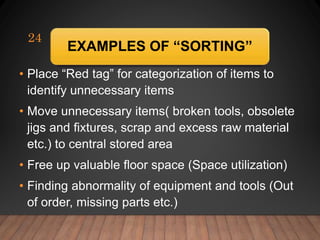

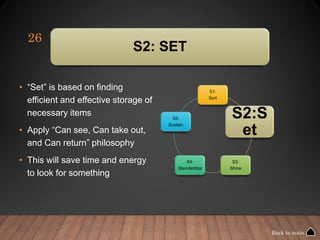

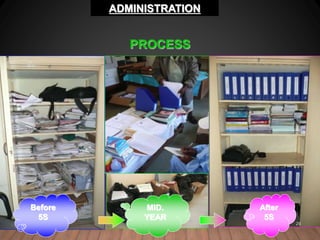

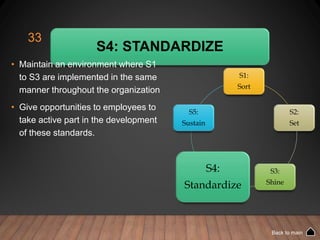

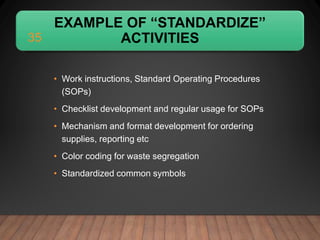

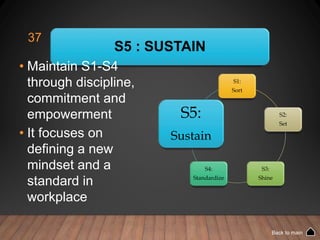

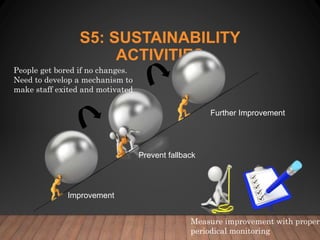

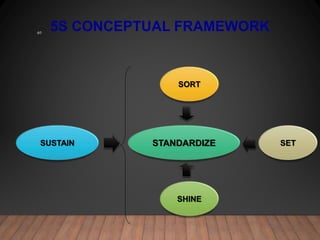

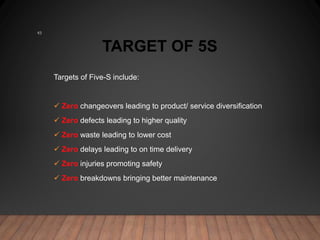

5S is a philosophy and methodology for organizing and managing workspaces through a process of sorting, setting in order, shining, standardizing, and sustaining. The goals of 5S are to reduce waste, improve efficiency, and create a safer work environment by eliminating unnecessary items, properly storing and labeling necessary items, cleaning the workspace daily, standardizing processes, and sustaining these practices over time. Implementing 5S involves categorizing all equipment and tools, improving storage methods, developing cleaning routines, creating standards and procedures, and establishing inspections and training to maintain the 5S system.