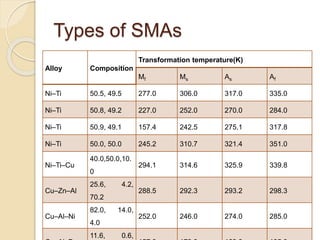

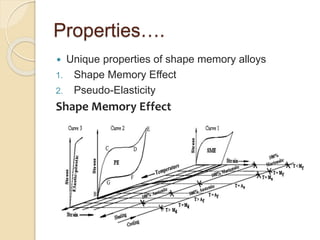

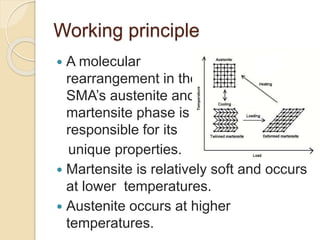

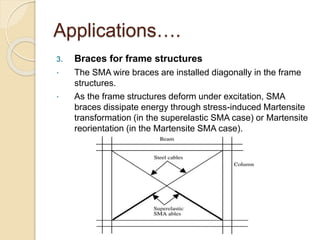

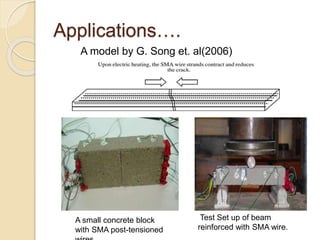

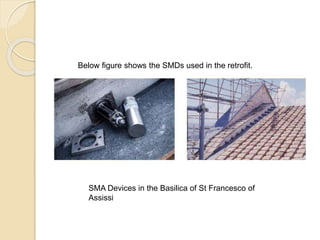

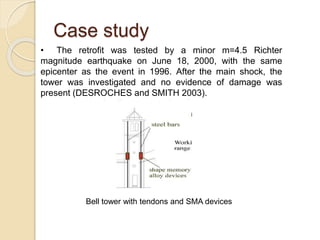

This document summarizes a seminar presentation on shape memory alloys and their applications in civil engineering. It begins with an introduction to shape memory alloys, including their ability to return to a predetermined shape with temperature changes. It then reviews the history, properties, working principles, literature on the topic, types of shape memory alloys, and applications in civil engineering structures. These include use as reinforcement, prestressing, braces, damping elements, and for structural self-rehabilitation. The document concludes with case studies on retrofitting historic structures in Italy with shape memory alloys.