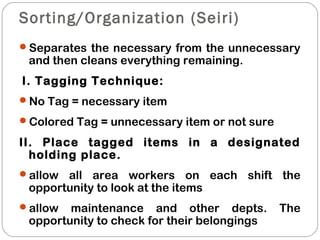

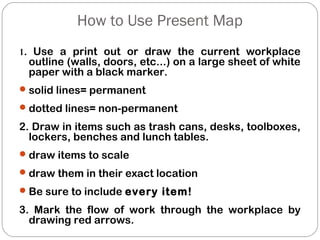

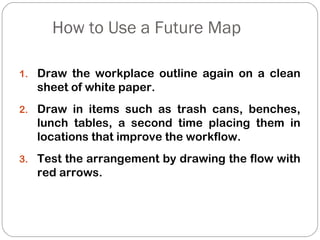

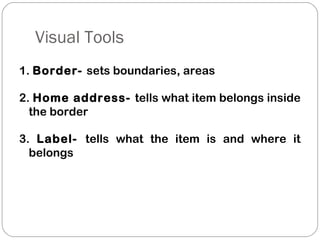

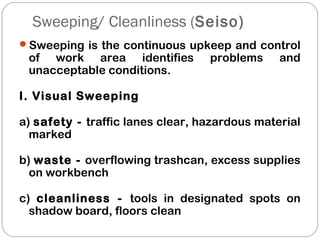

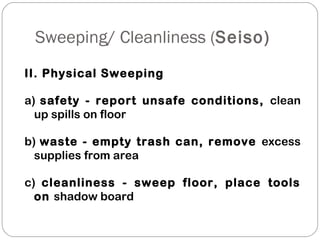

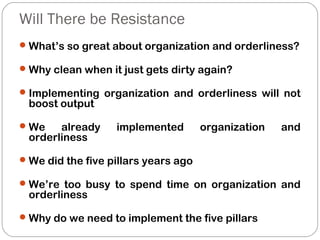

This document outlines the 5S methodology, which consists of five pillars - Sort, Set In Order, Shine, Standardize, and Sustain. The 5S process is designed to organize, clean, and standardize the workplace. It describes each of the five pillars in detail, providing examples of how to implement techniques such as visual controls, future workplace mapping, cleaning schedules, and documentation of work processes and standards. The benefits of 5S include improved safety, efficiency, and employee morale through a clean and orderly work environment.