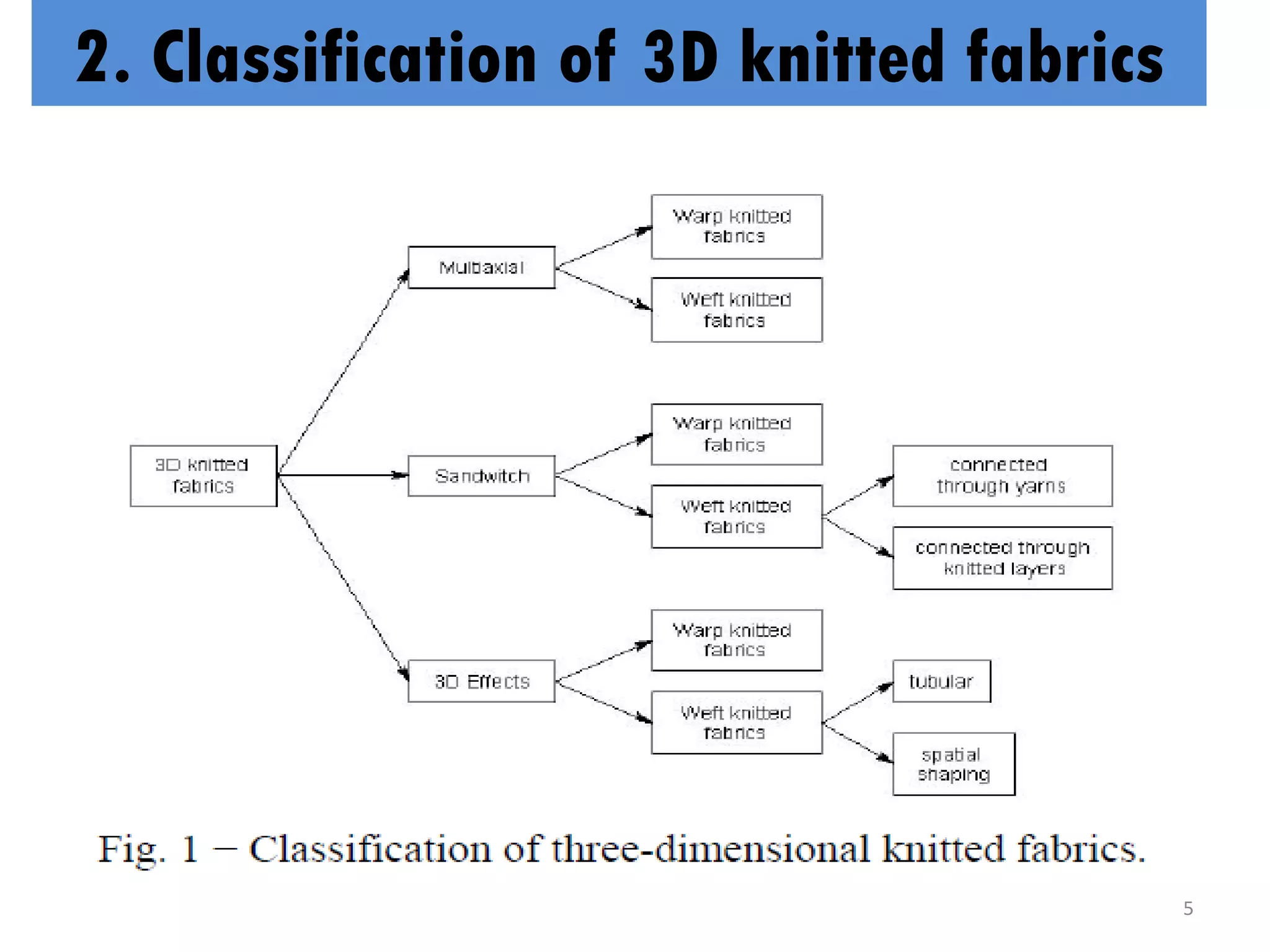

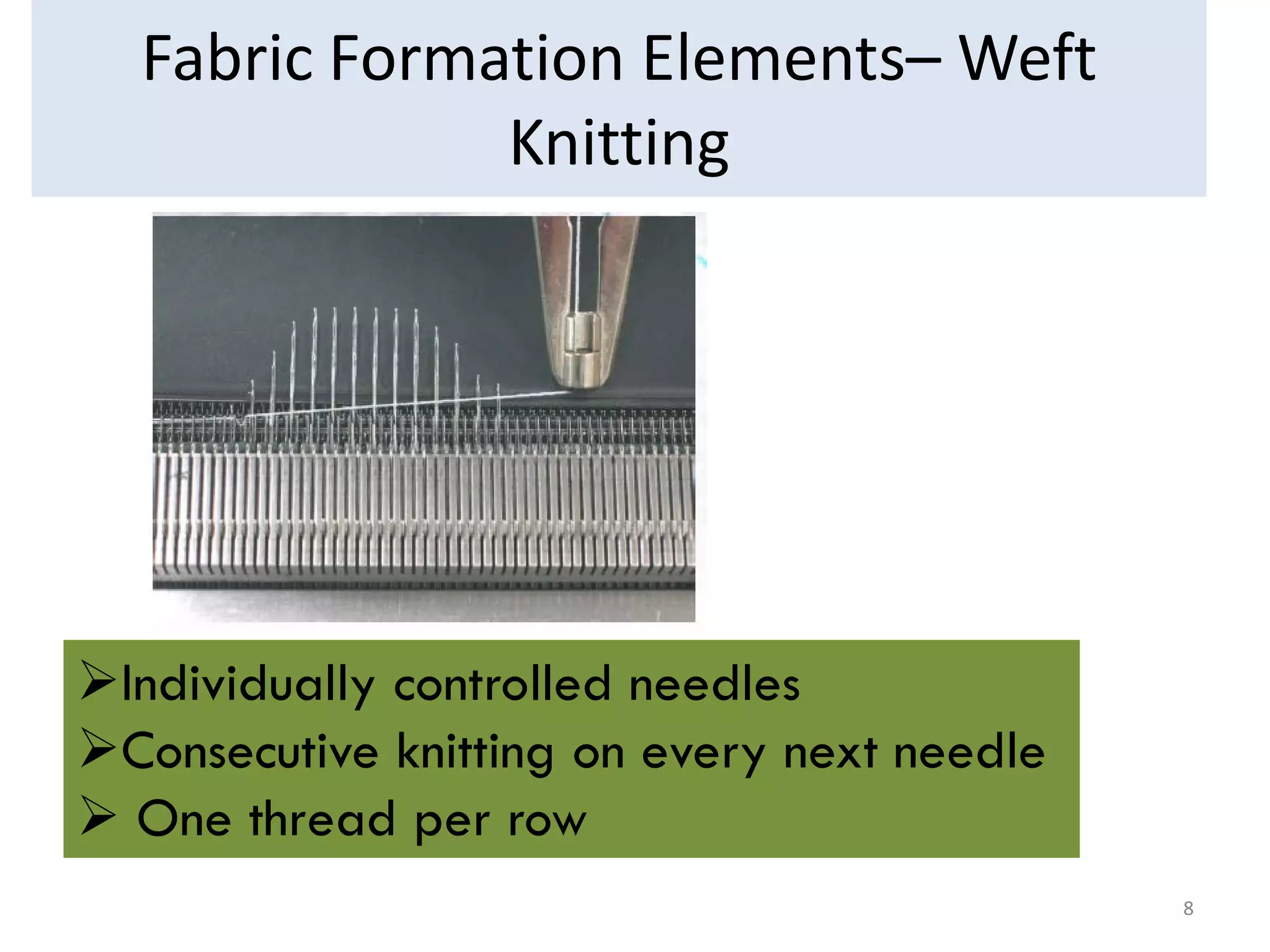

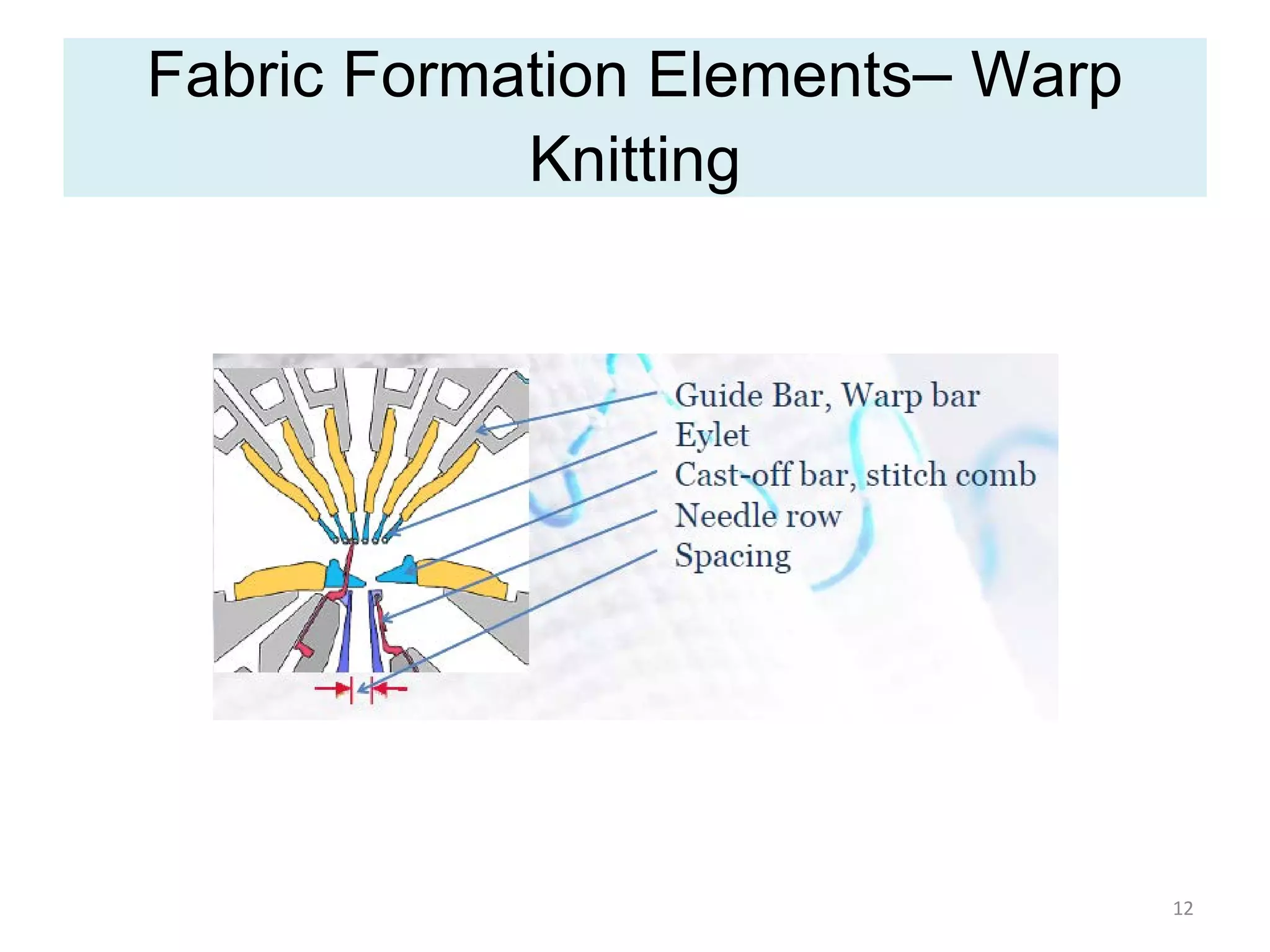

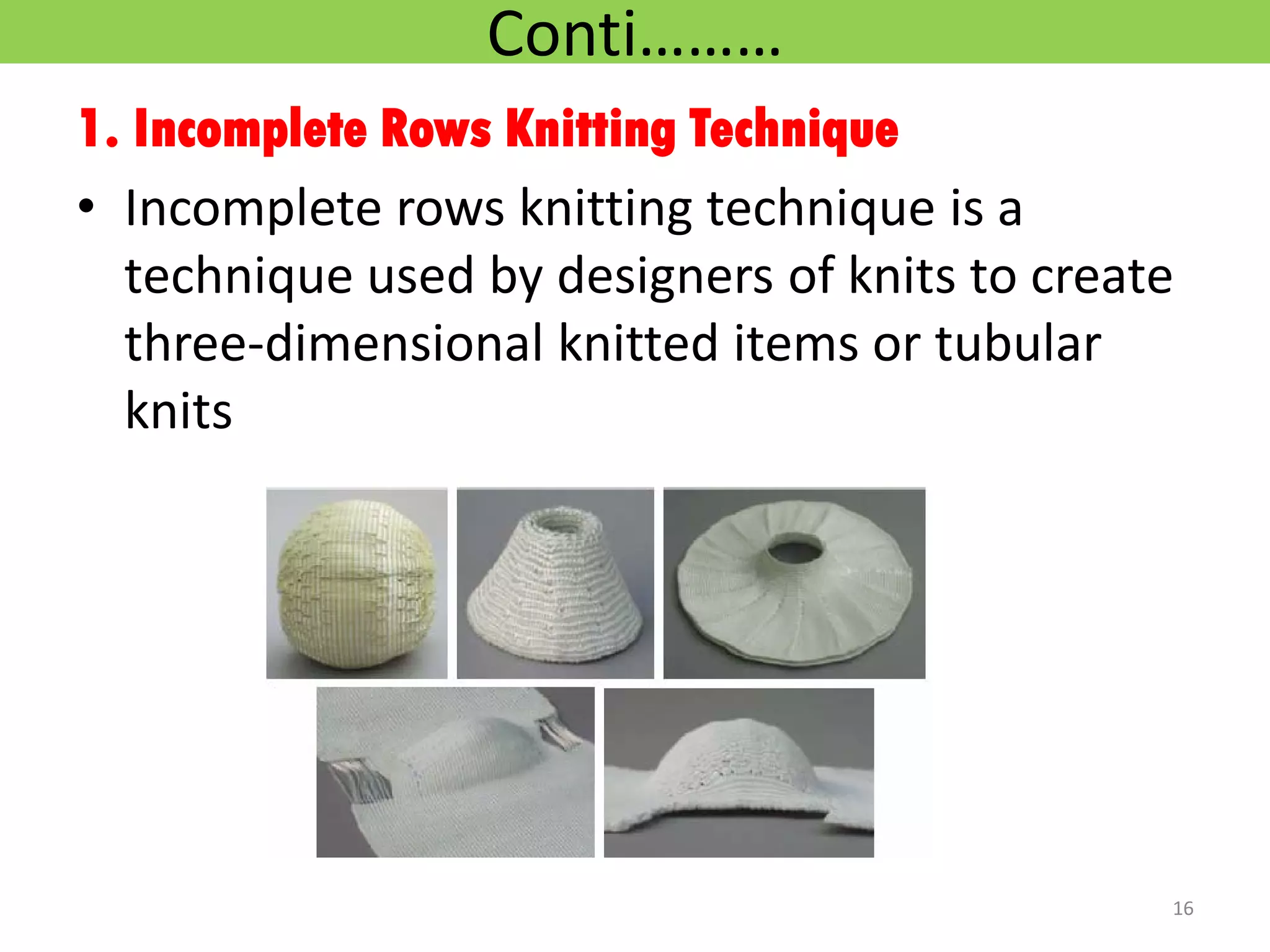

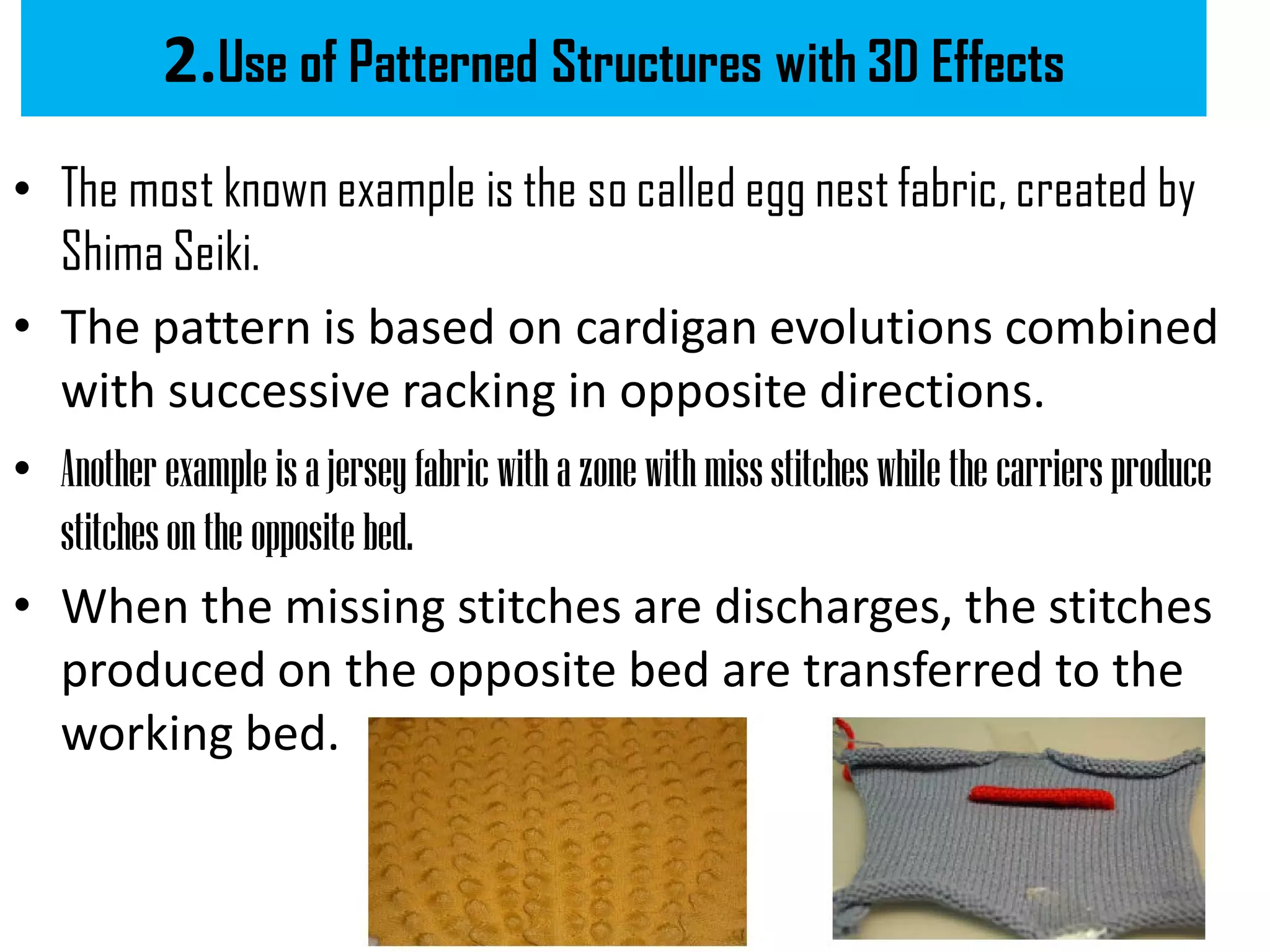

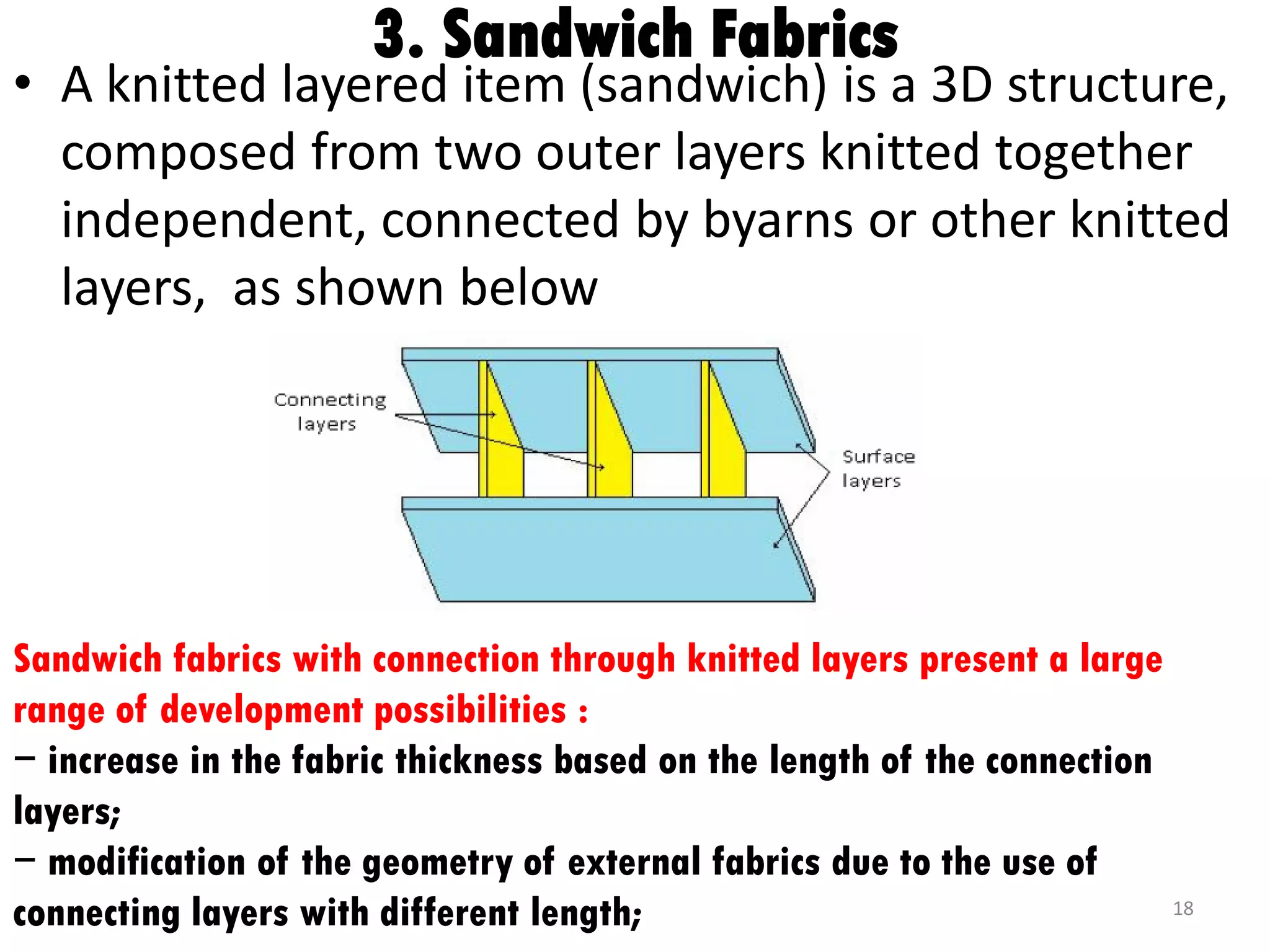

This document provides information about 3D knitted fabrics, including their classification, manufacturing methods, properties, machines used, and applications. It discusses two main manufacturing methods - weft and warp knitting. Weft knitting uses one yarn per row to form loops, resulting in elastic but low-thickness fabrics suitable for biomedical uses and composites. Warp knitting interconnects loops using multiple yarns per needle, producing thicker, less elastic fabrics used in composites, military armor, and medical stents. Principles for 3D knits include incomplete rows, patterns with racking, sandwich/spacer fabrics, and integral/seamless knitting techniques.