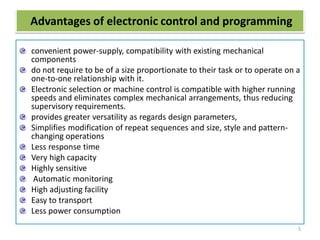

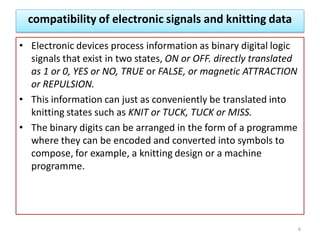

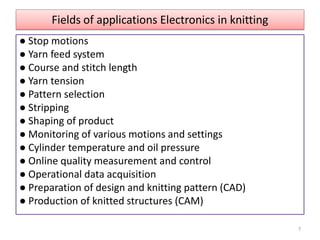

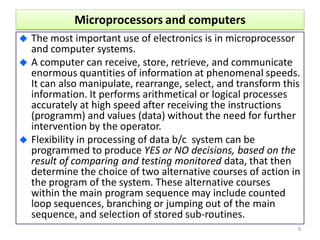

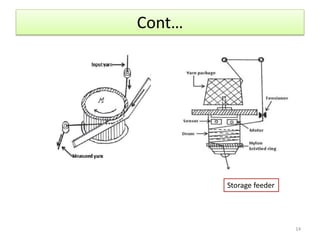

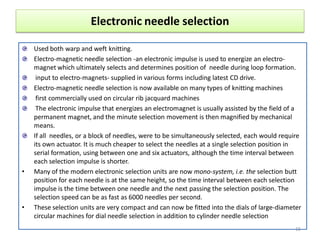

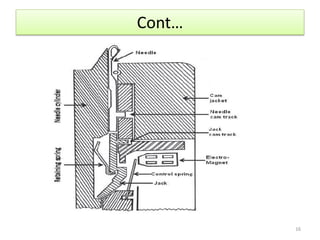

This document discusses the use of electronics in knitting machines. It provides advantages of electronic control over mechanical control, such as higher speeds, easier programming, and greater versatility. It describes various applications of electronics like stop motions, yarn feeding systems, needle selection, and pattern selection. Microprocessors and computers allow storing large amounts of knitting data and programs. Computerized knitting machines can be programmed to move the carriage and select needles electronically for complex patterns. Overall, electronics have significantly improved knitting machine capabilities and productivity.