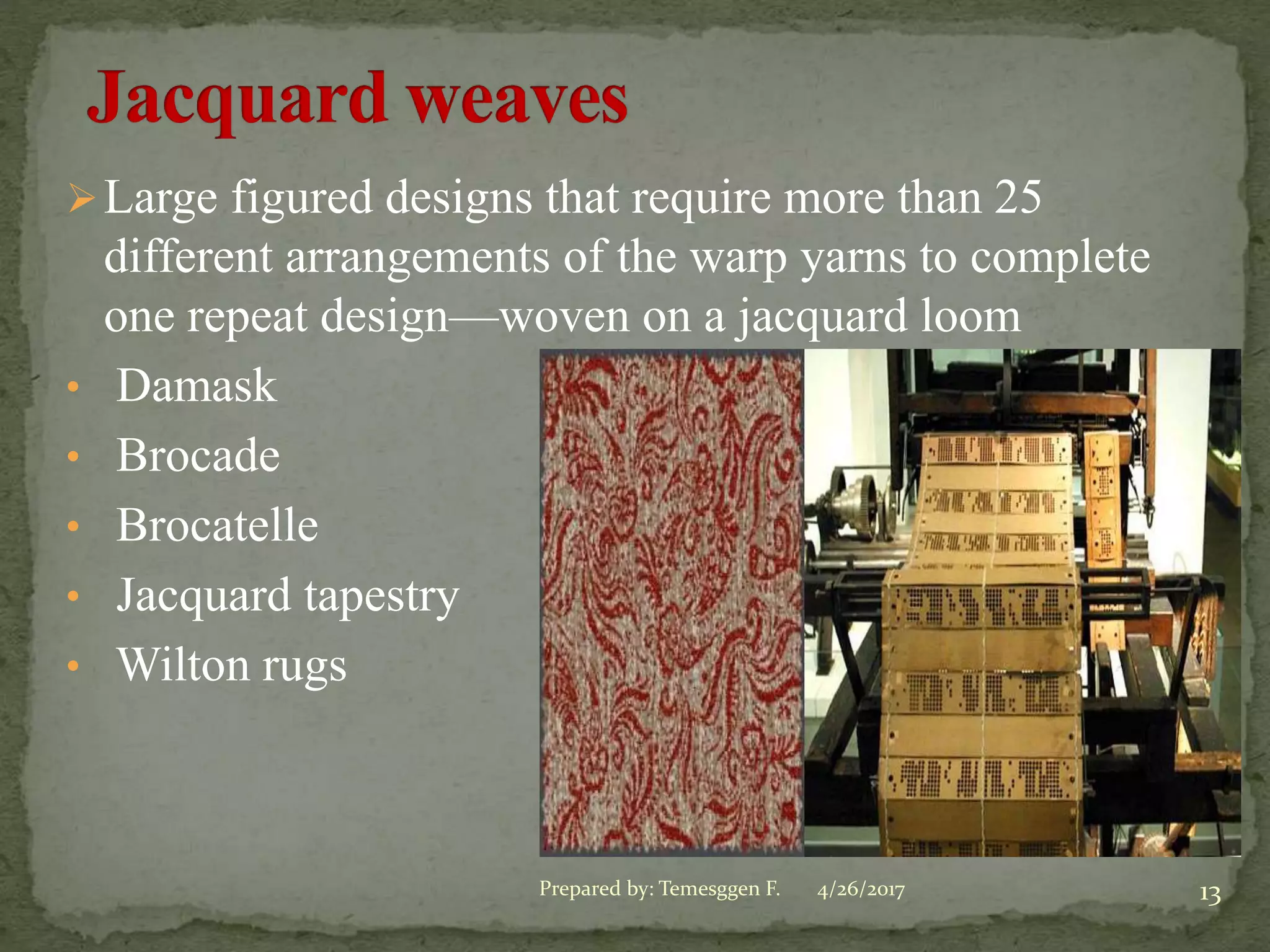

This document discusses the jacquard shedding mechanism used in weaving looms. It covers the scope and classification of jacquard looms, their operating principle, limitations of mechanical jacquards, and electronic jacquard machines. It also describes jacquard weaves produced using this mechanism and references used in preparing the document.