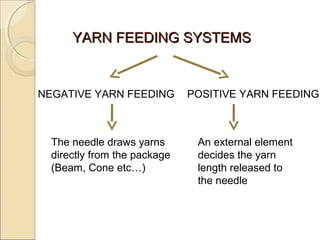

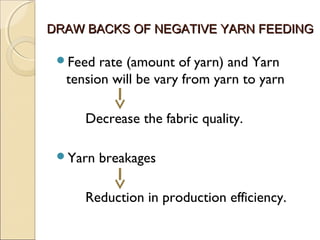

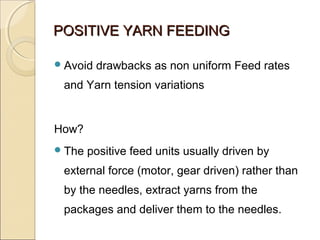

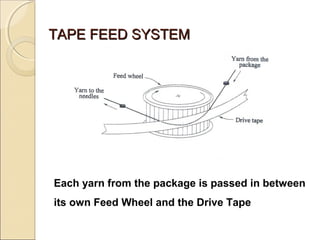

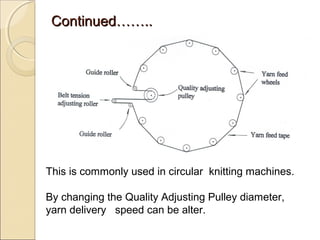

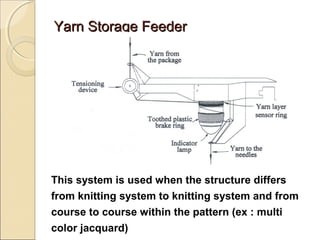

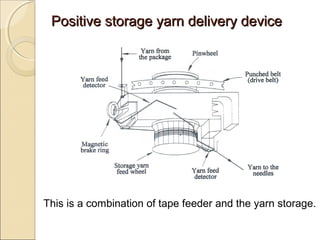

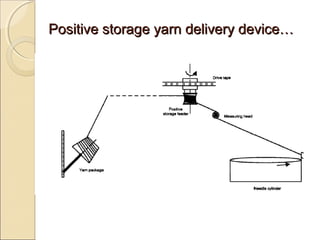

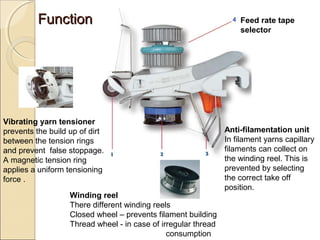

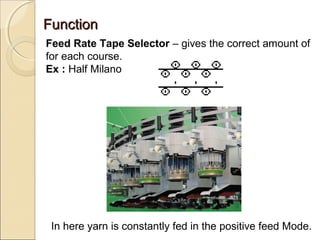

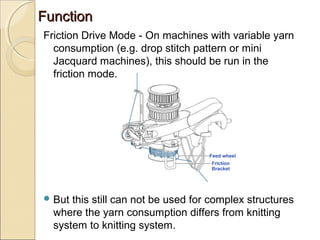

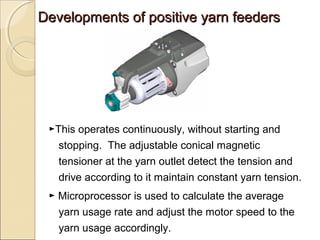

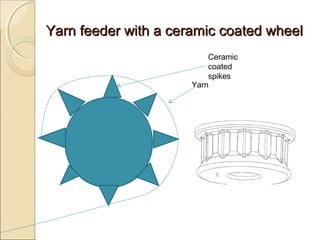

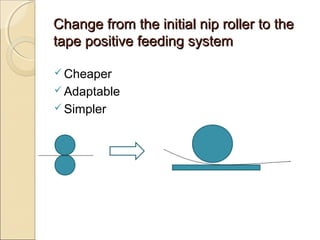

This document discusses positive yarn feeding systems and how they affect fabric quality. It provides information on different types of positive yarn feeding systems including tape feed mechanisms and storage feeders. Positive yarn feeding helps control fabric properties and quality by providing uniform yarn tension and detecting faults before knitting. Modern systems use microprocessors and pre-calculated yarn requirements to precisely control yarn delivery. While positive feeding improves quality, it can also cause yarn breakage issues which manufacturers work to overcome through innovations like ceramic coated feed wheels.