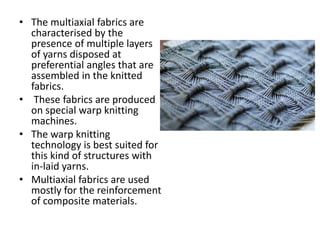

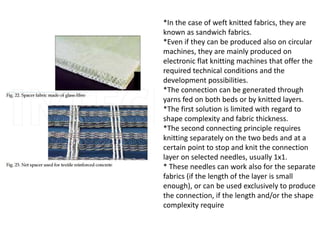

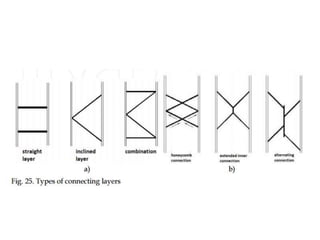

This document discusses 3D knitting technology. It describes how 3D knitting machines can digitally design and produce customized clothing. It then discusses different types of 3D knitted fabrics like multiaxial fabrics produced on special warp knitting machines with layers of yarns at different angles, and sandwich/spacer fabrics made of two separate fabrics connected by yarns or knitted layers. The document also covers companies involved in 3D knitting like Nike, UnderArmour, Karl Mayer, Shima Seiki, Stoll, and Santoni.