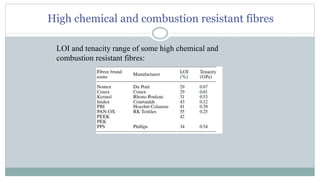

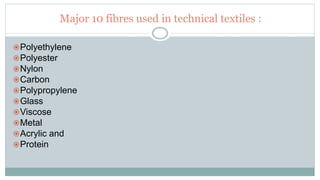

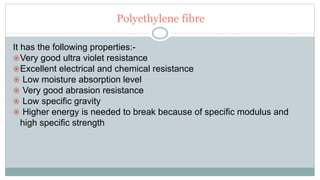

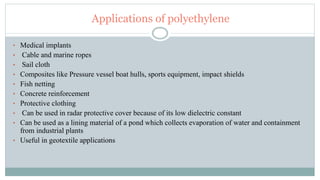

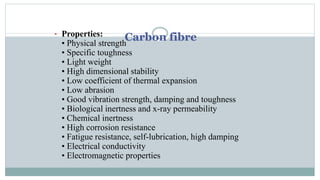

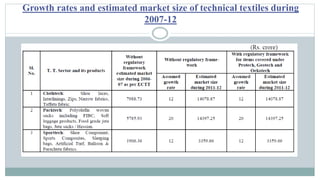

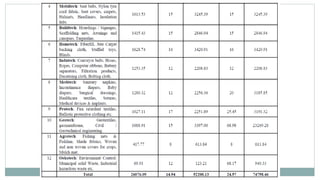

This document discusses various fibres used in technical textiles. It begins by defining technical textiles as materials selected for their performance properties rather than aesthetic qualities. The document then categorizes fibres used in technical textiles into conventional, high strength/modulus organic, high chemical/combustion resistant, high performance inorganic, and ultra fine/novelty fibres. Specific fibres discussed in more detail include polyethylene, polyester, nylon, carbon, polypropylene, glass, and metal fibres. Their properties and applications in areas like transportation, medical, construction, and protection are outlined. In closing, the document notes the high estimated growth rates of the technical textiles market between 2007-2012.