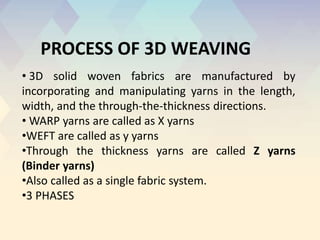

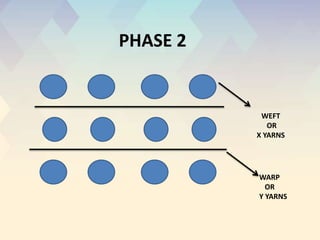

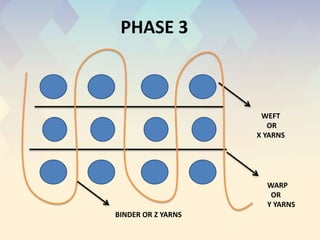

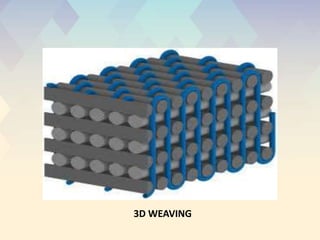

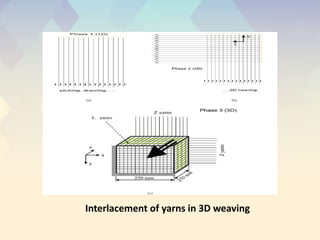

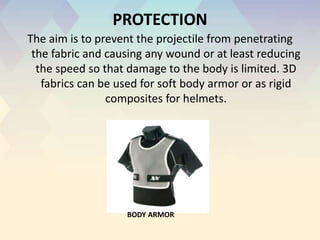

3D weaving involves interlacing yarns in three dimensions to create fabrics with thickness. It has several advantages over traditional 2D weaving. The presentation discusses the process of 3D weaving, which involves arranging warp, weft, and binder yarns in three phases. It also examines the structures, materials, and applications of 3D woven fabrics. Key applications discussed include filtration, aerospace, medical, sports, and protection fields. In conclusion, 3D weaving is an expanding technology however specialized machines for large-scale production remain limited.