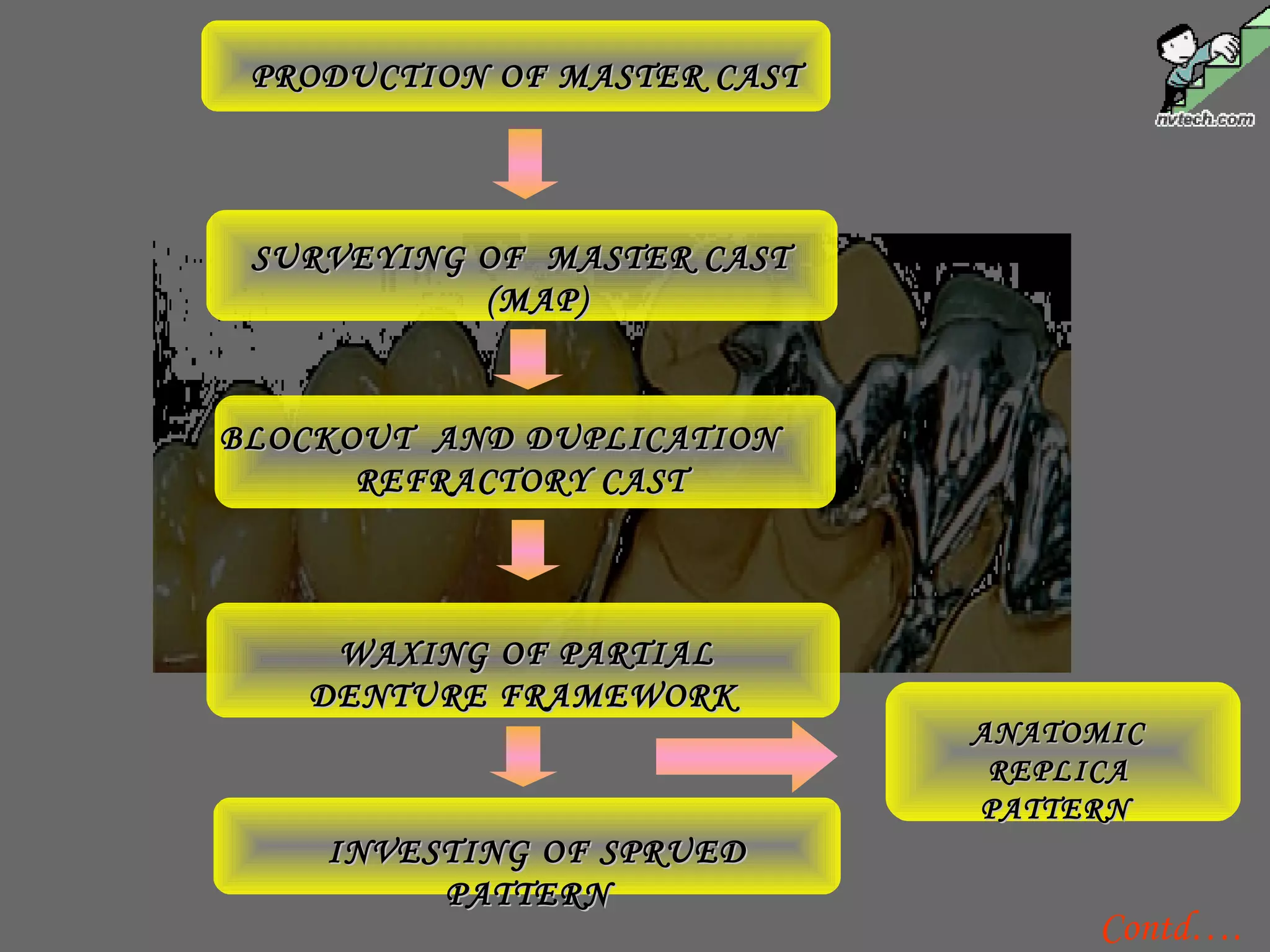

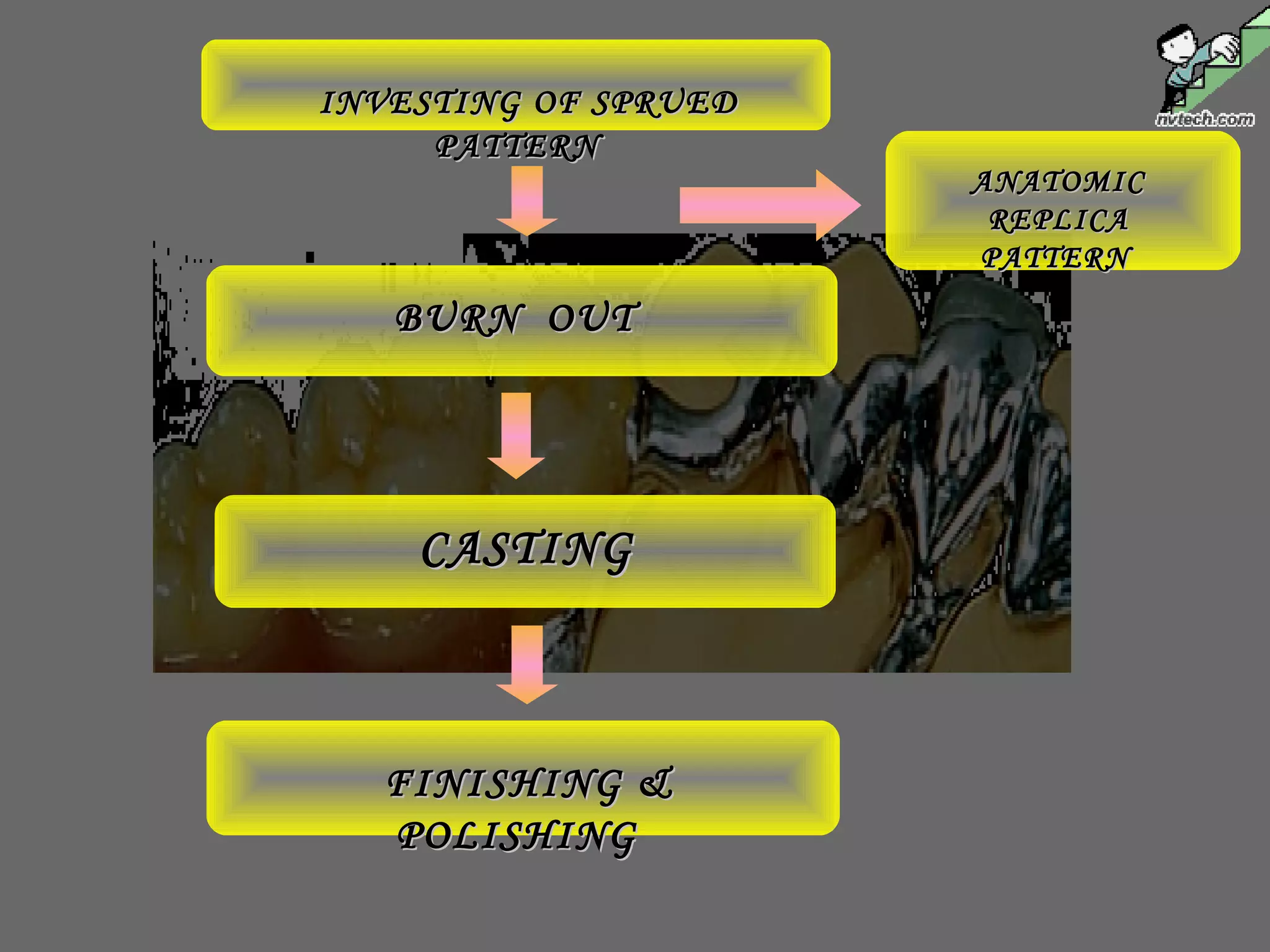

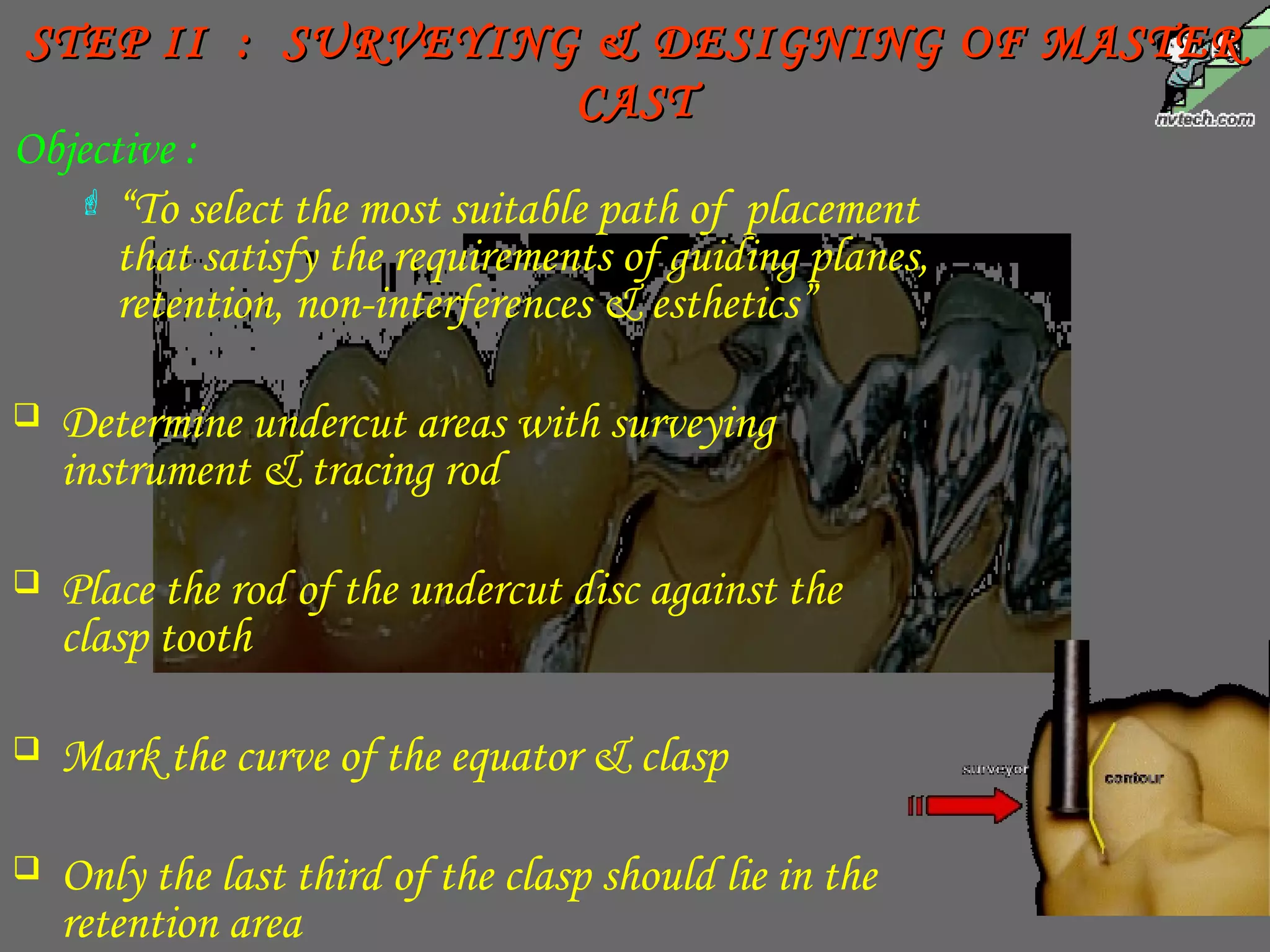

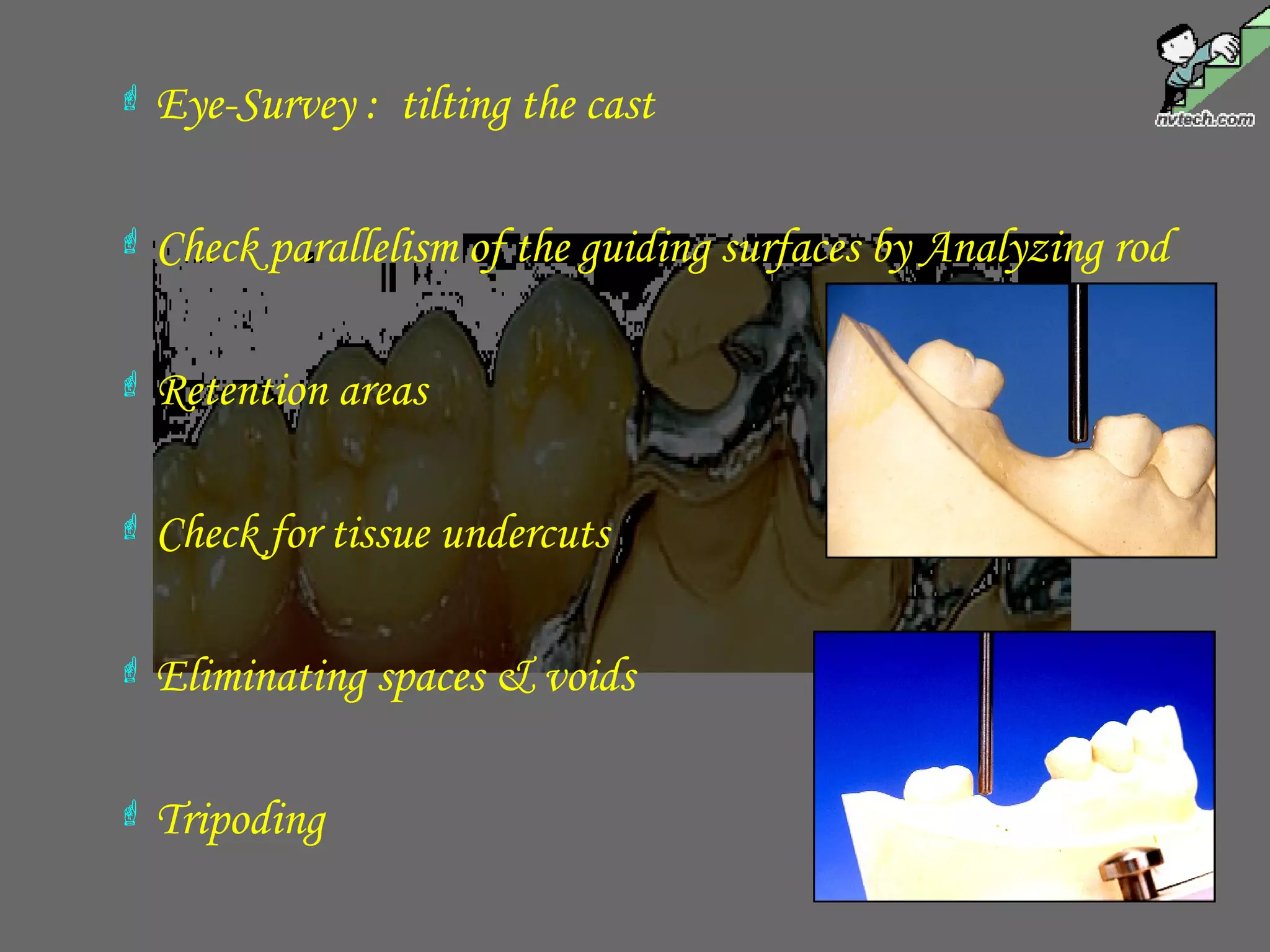

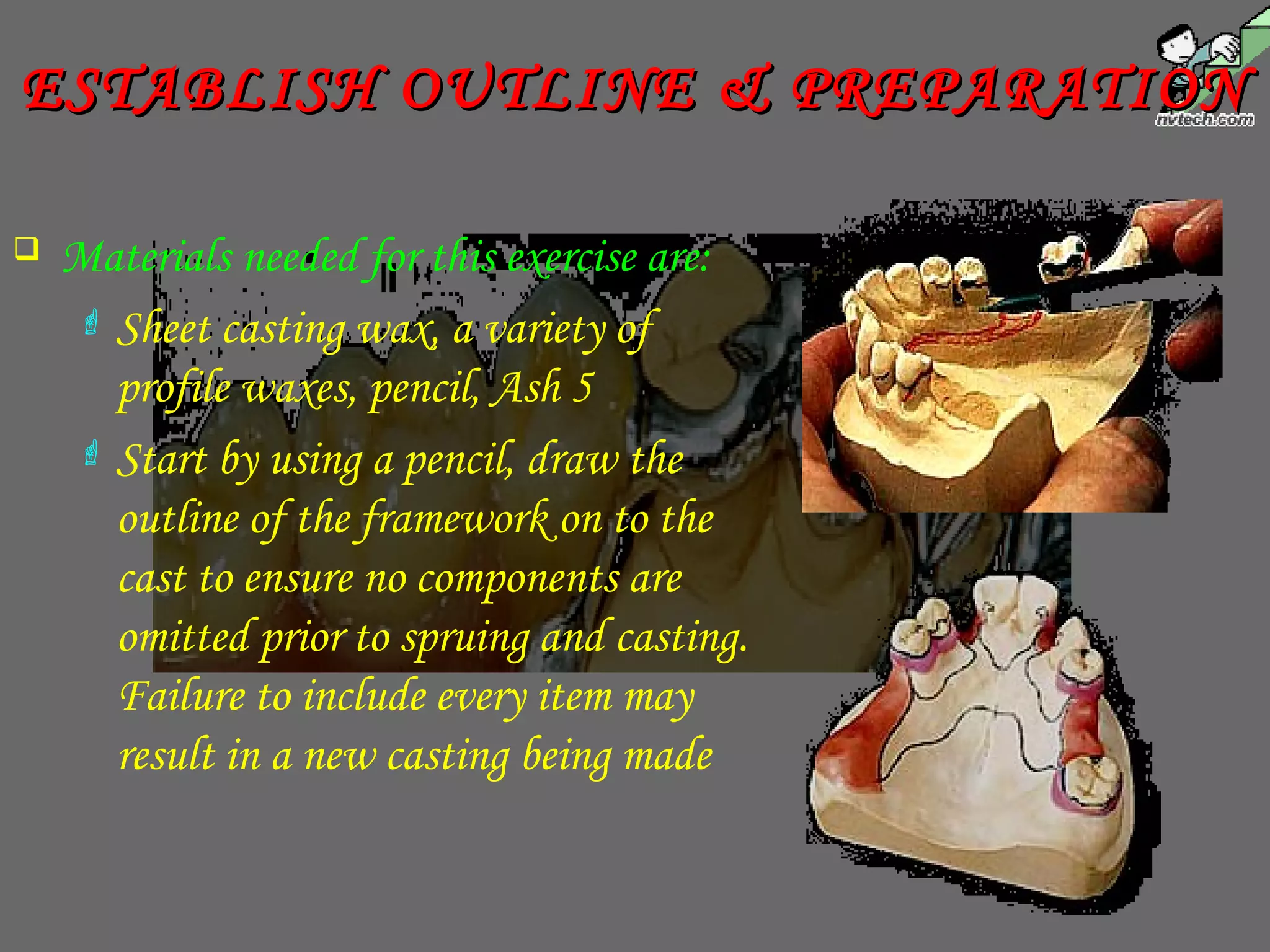

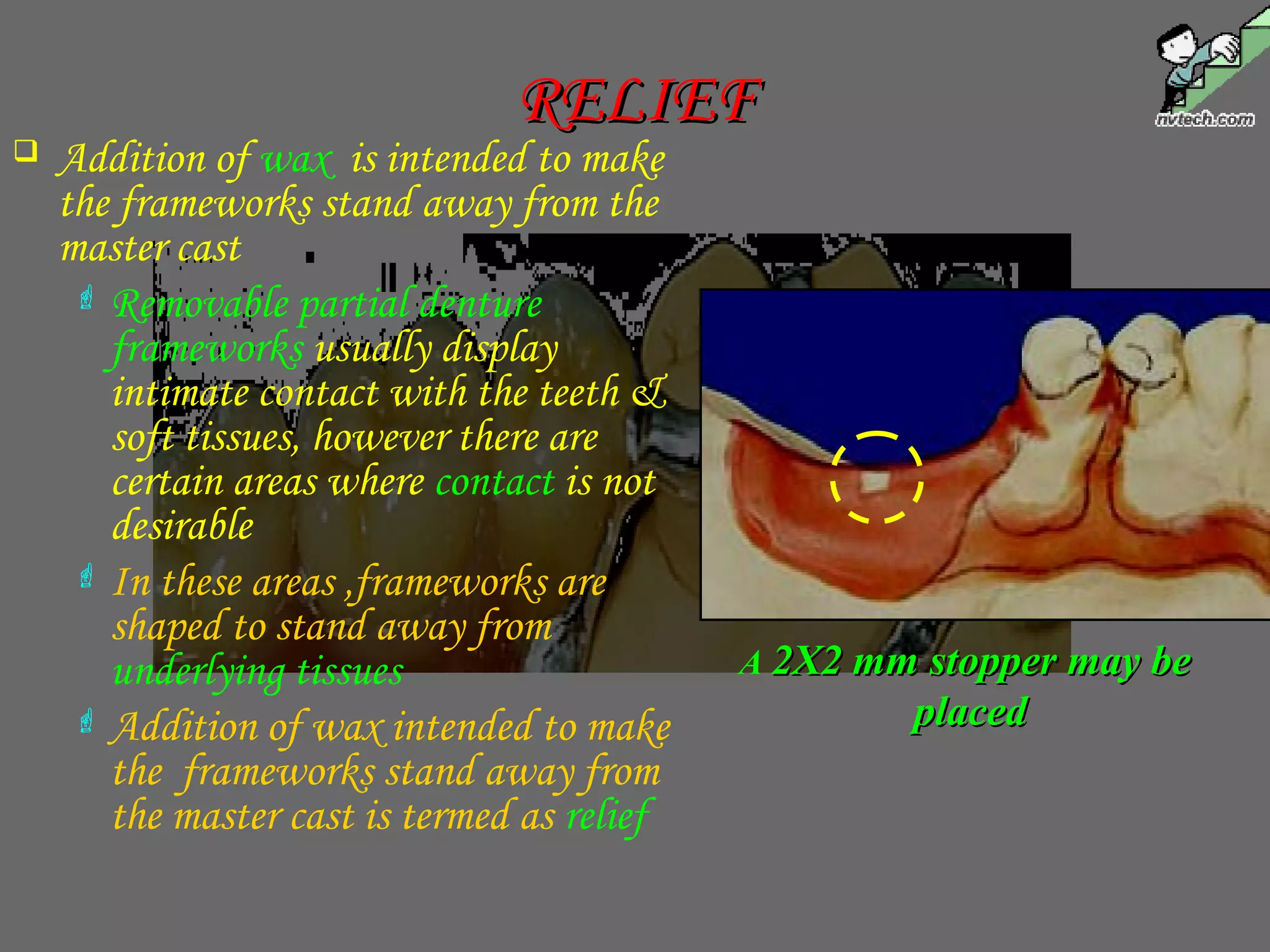

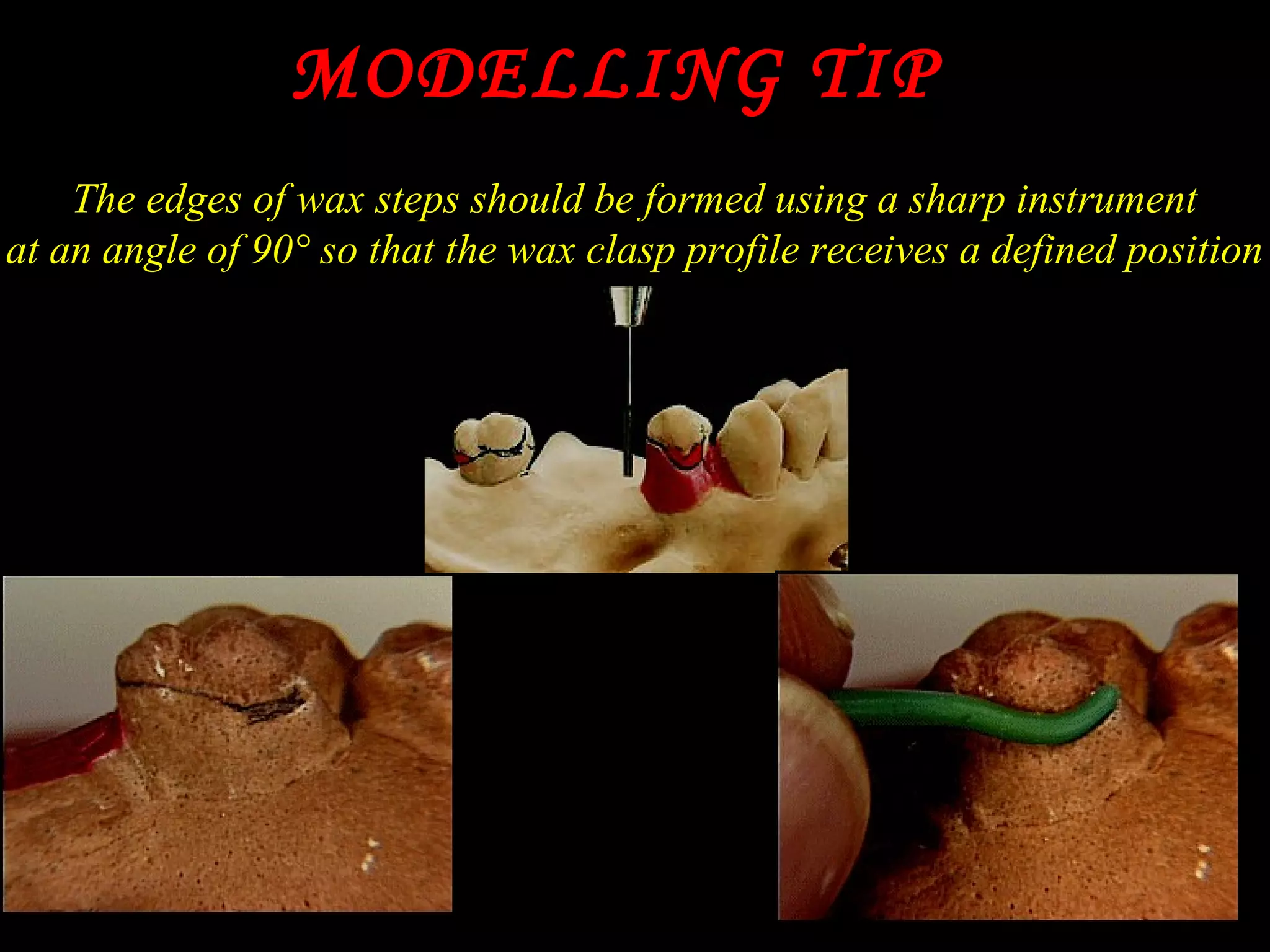

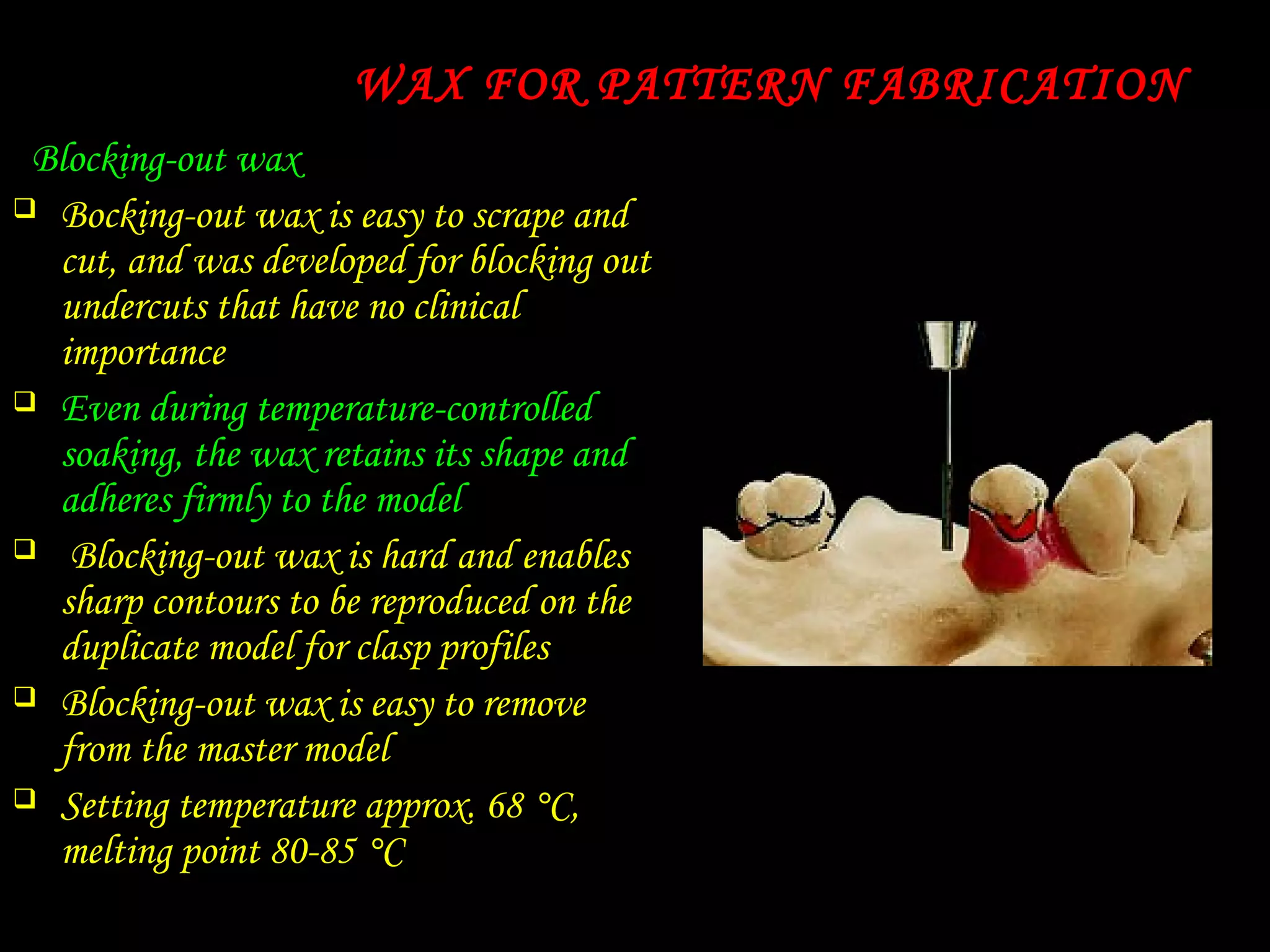

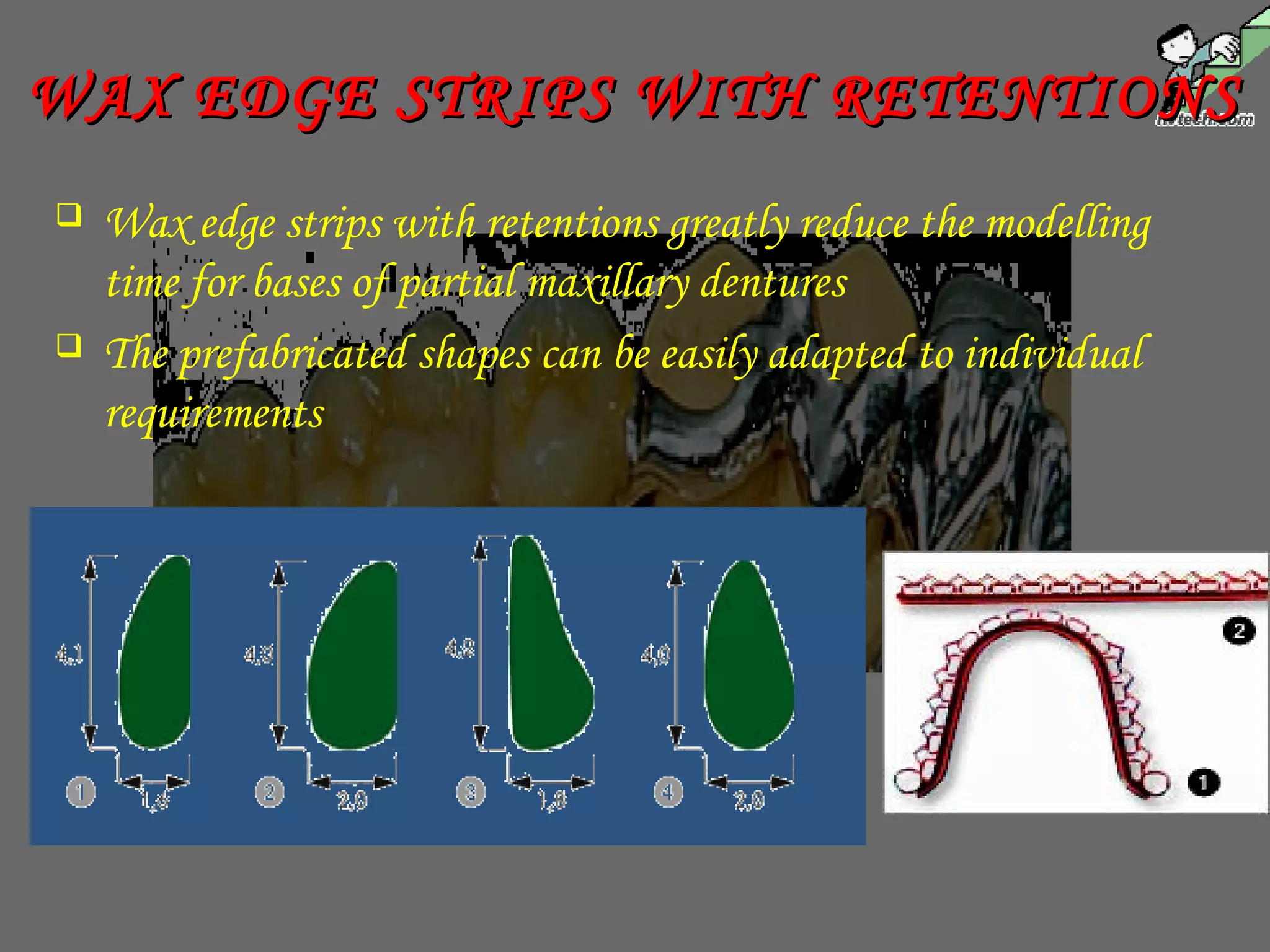

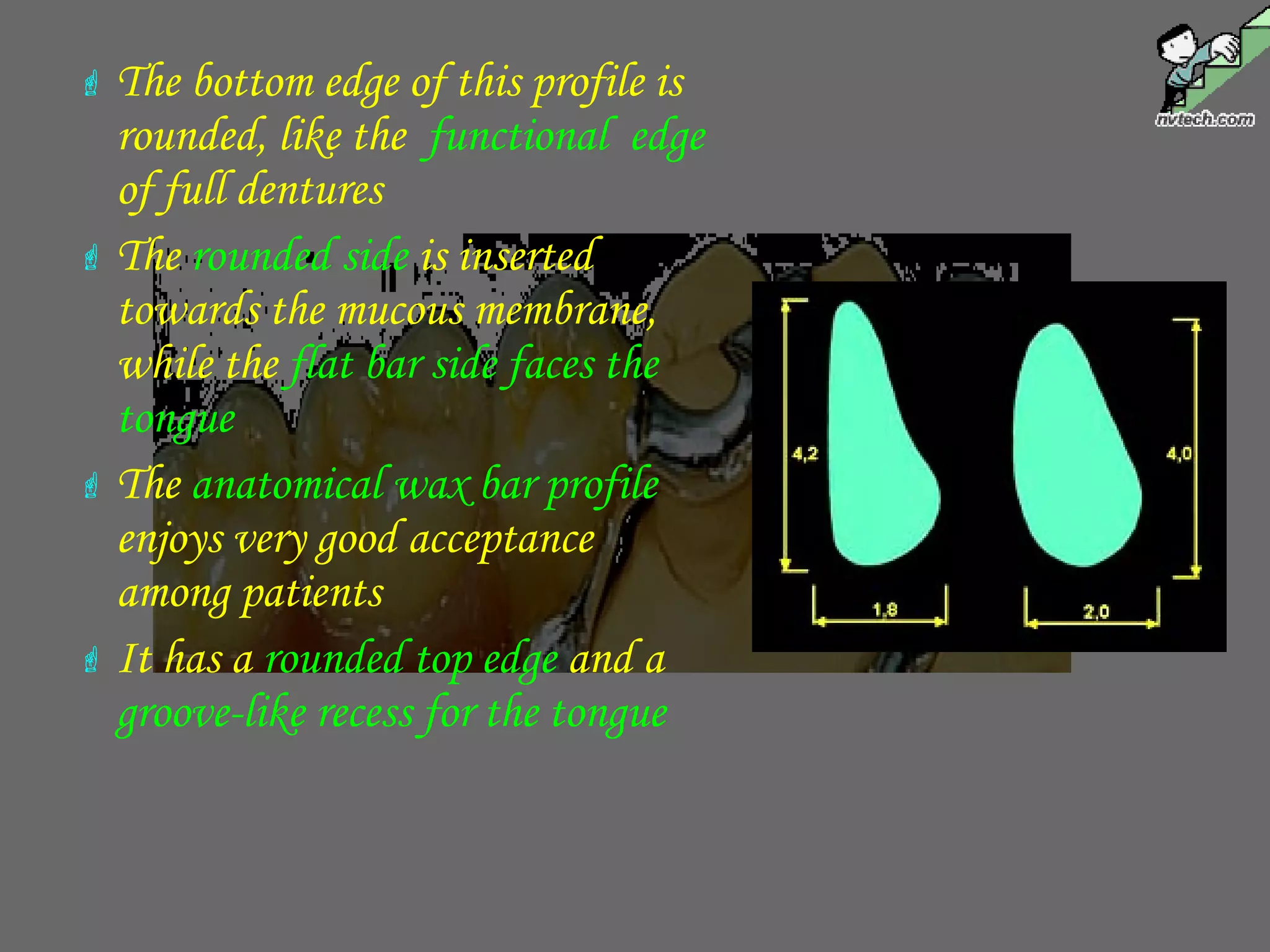

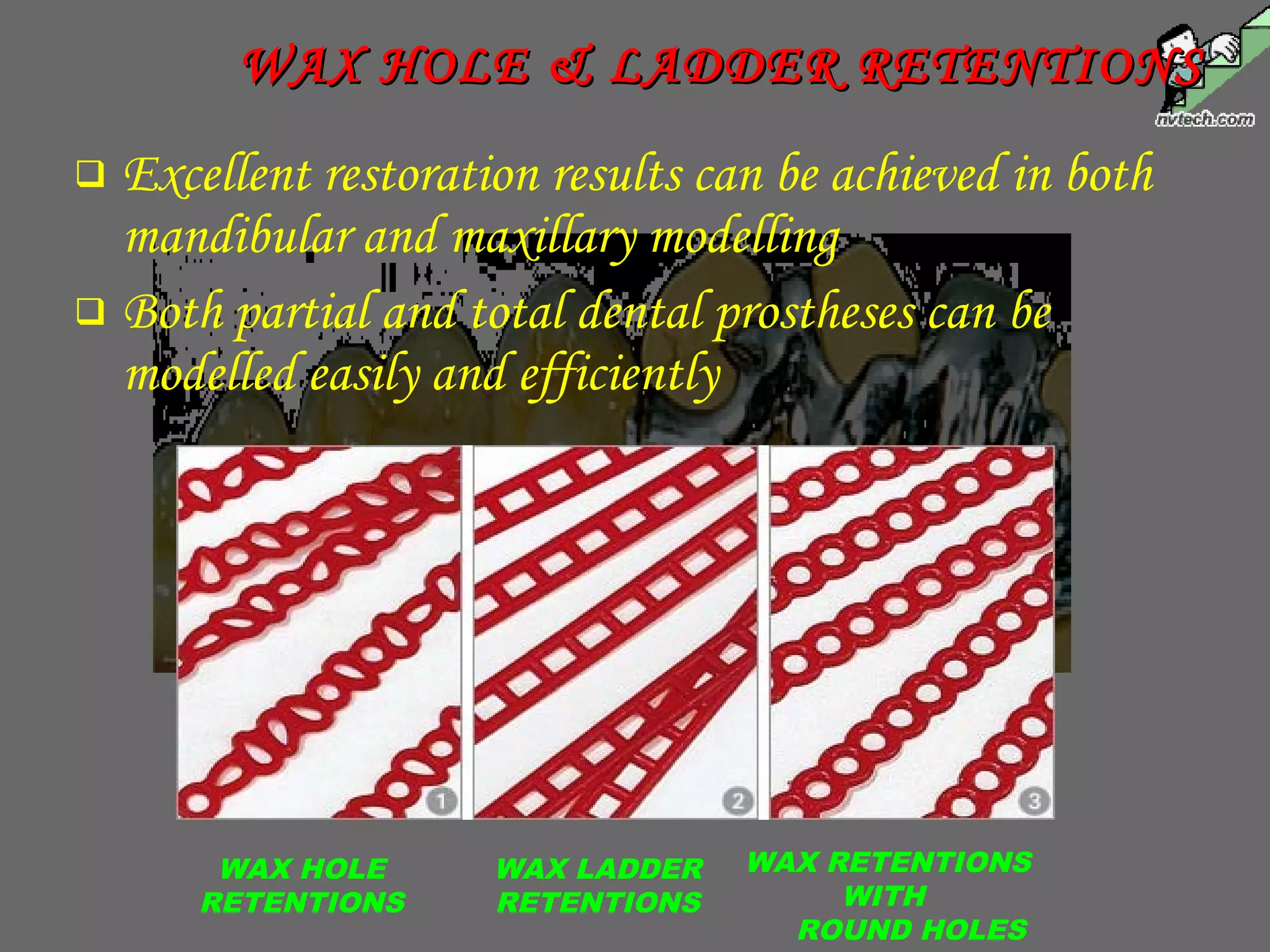

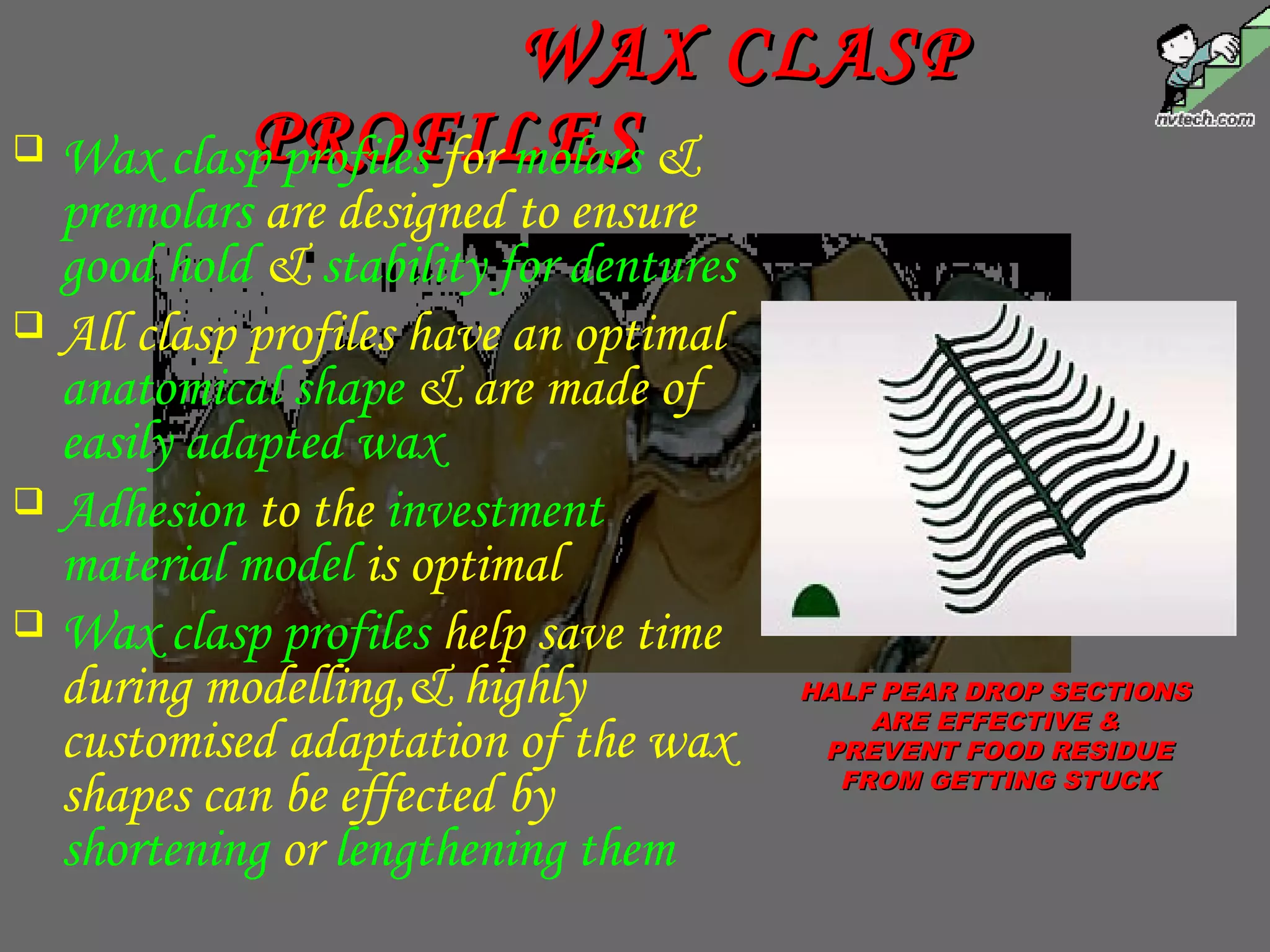

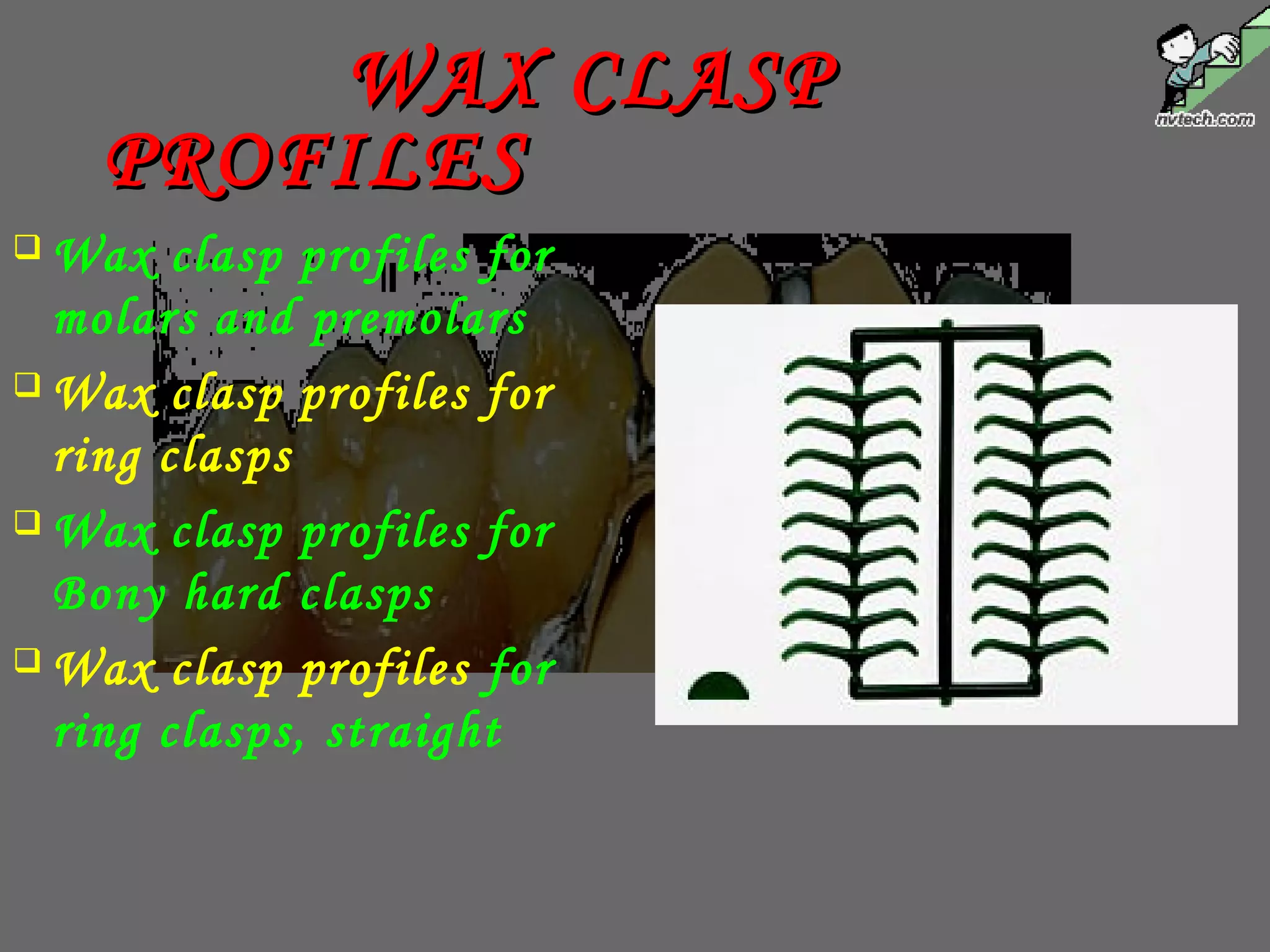

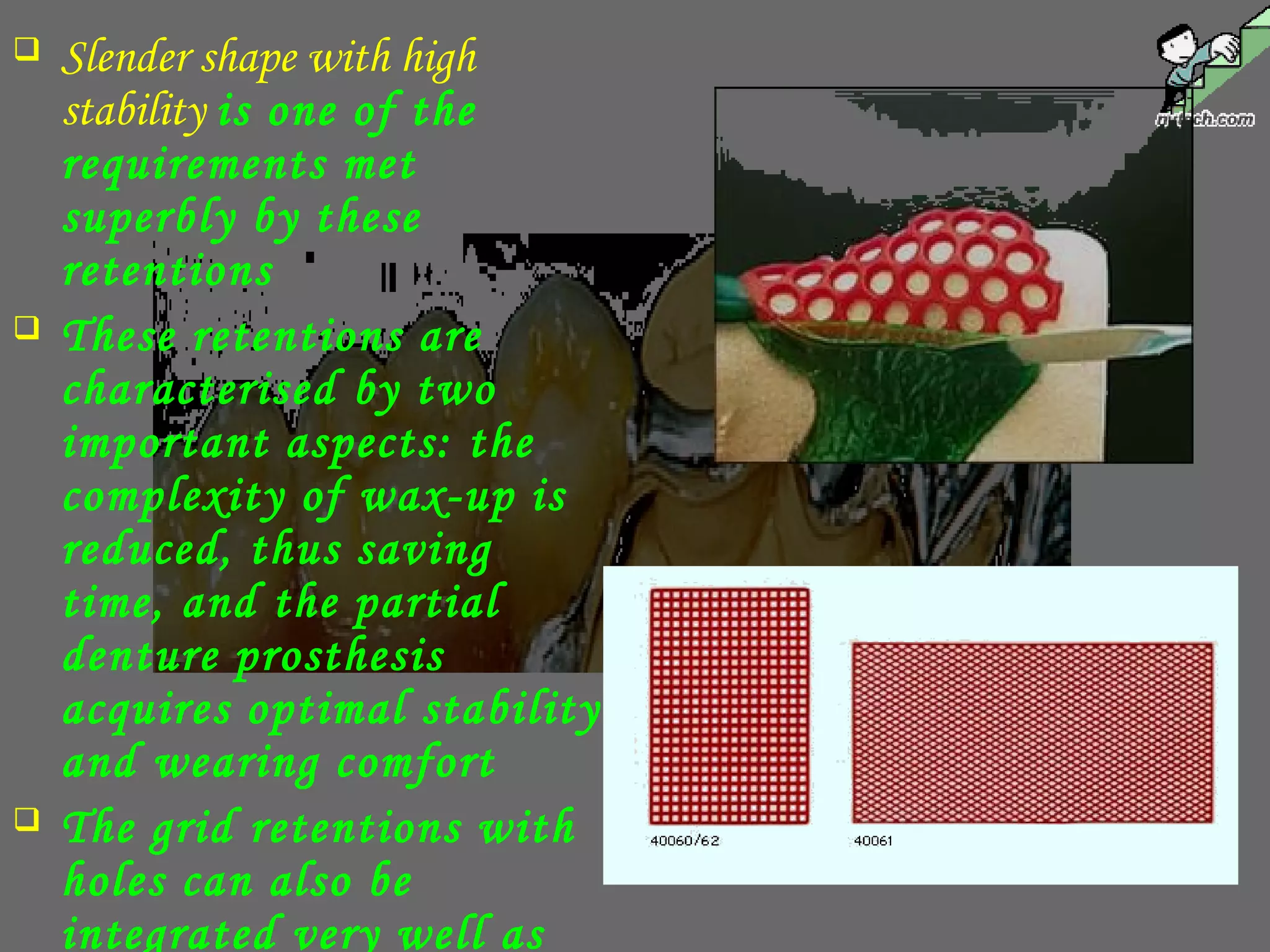

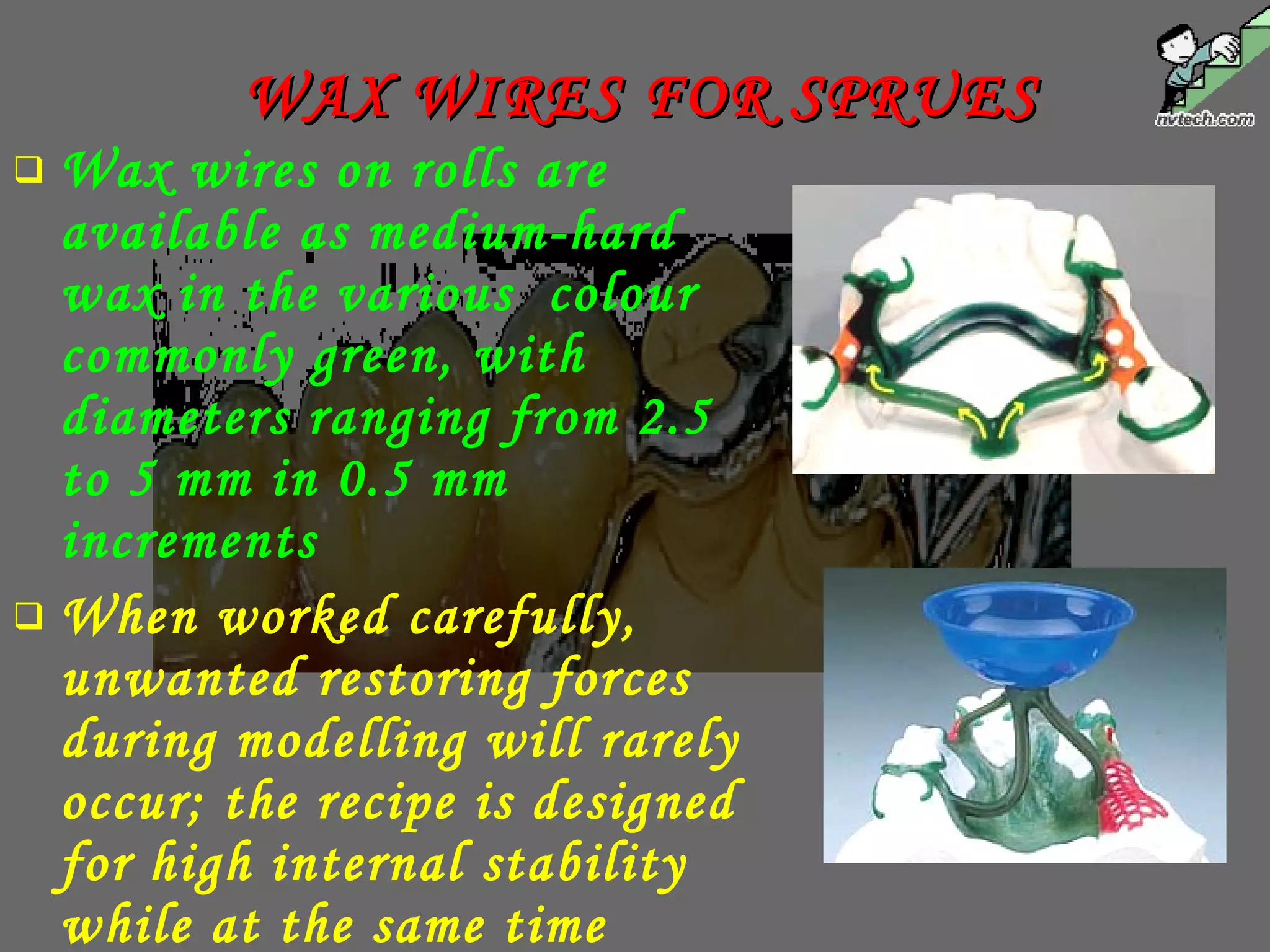

The document outlines the comprehensive process for the production and surveying of master casts used in creating partial dentures. It details the steps from preliminary impressions to the design and transfer of wax patterns, highlighting the equipment and materials required at each stage. Emphasis is placed on ensuring the proper design and retention features to achieve optimal fit and functionality of the dentures.