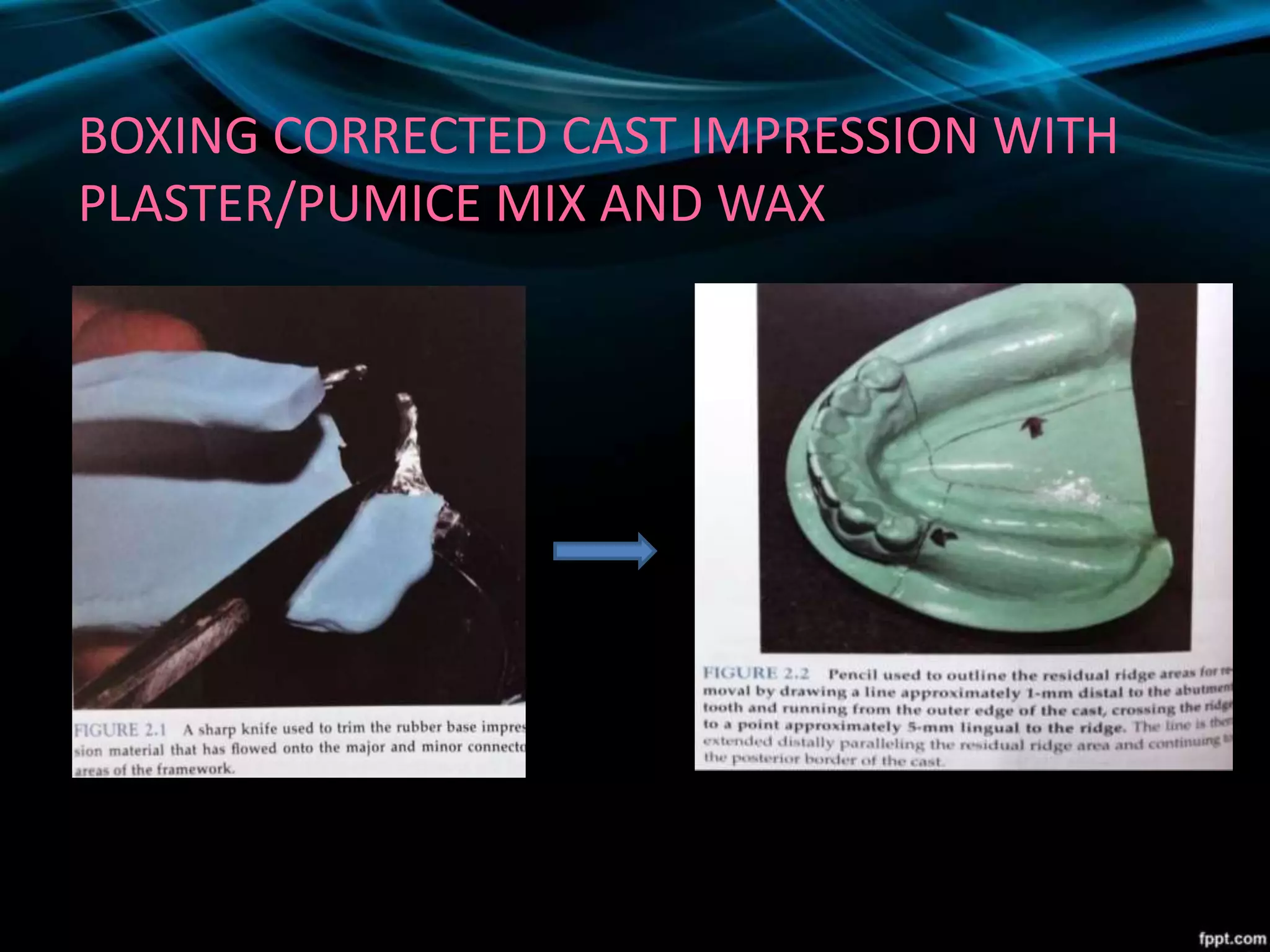

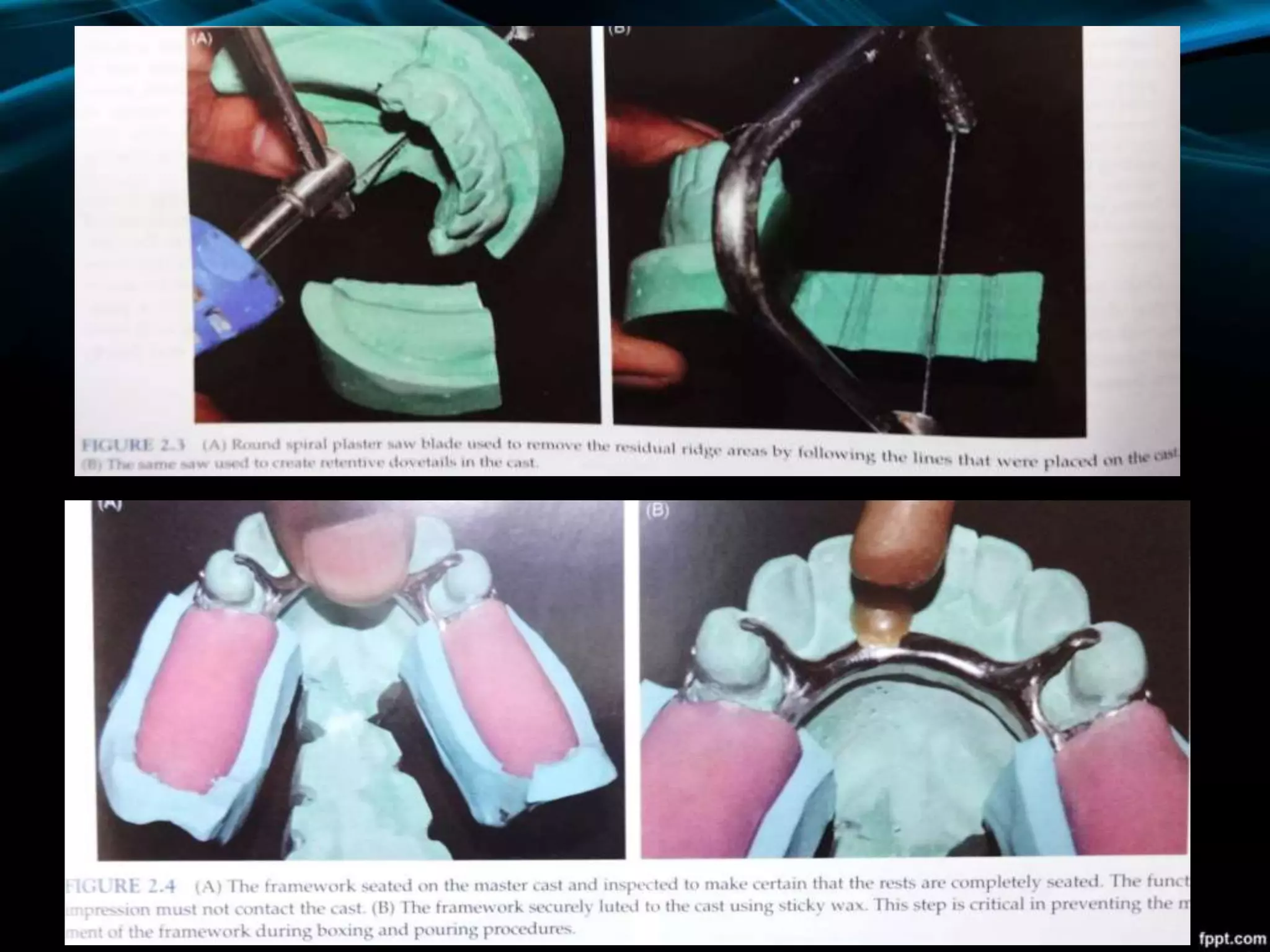

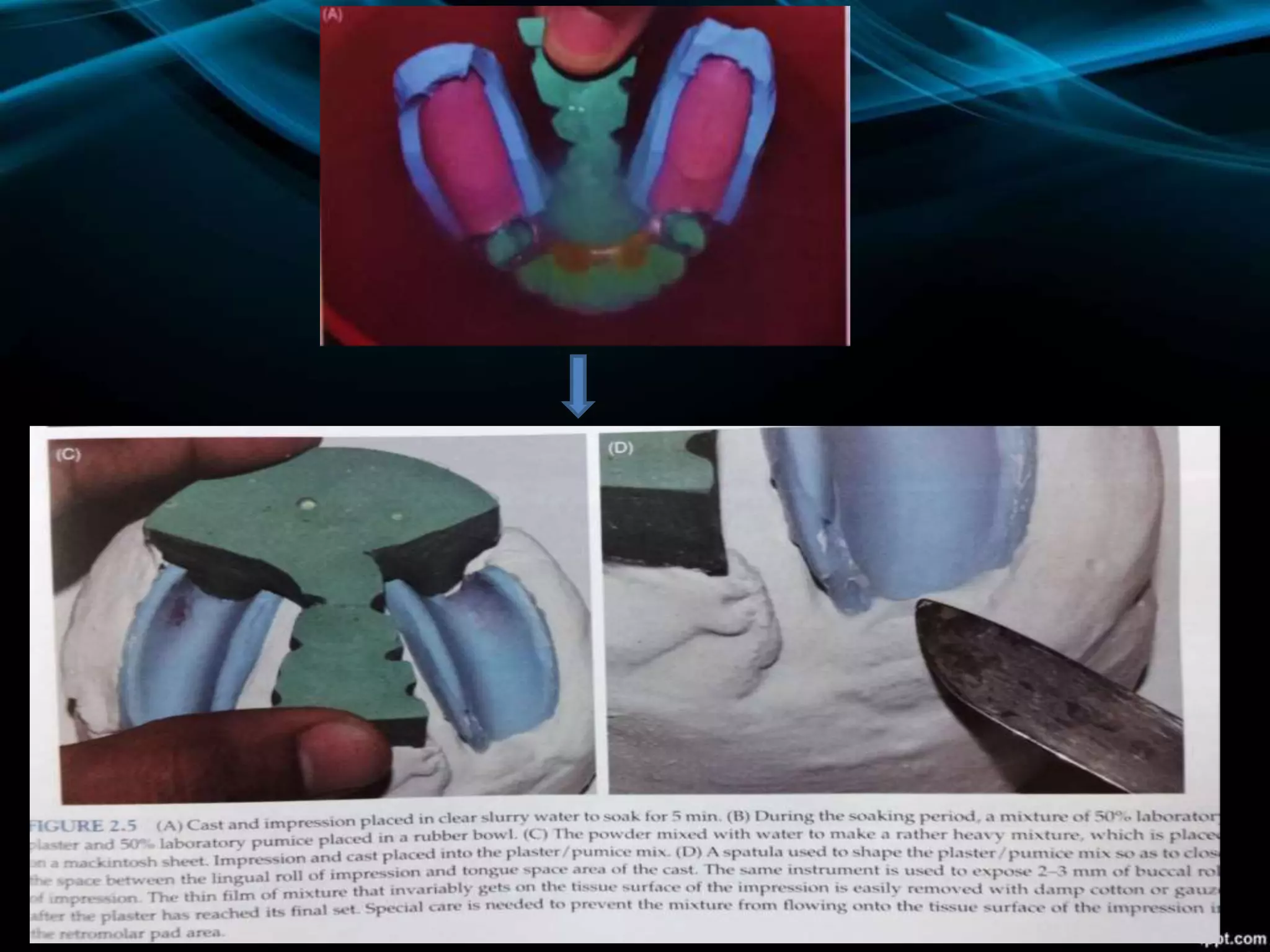

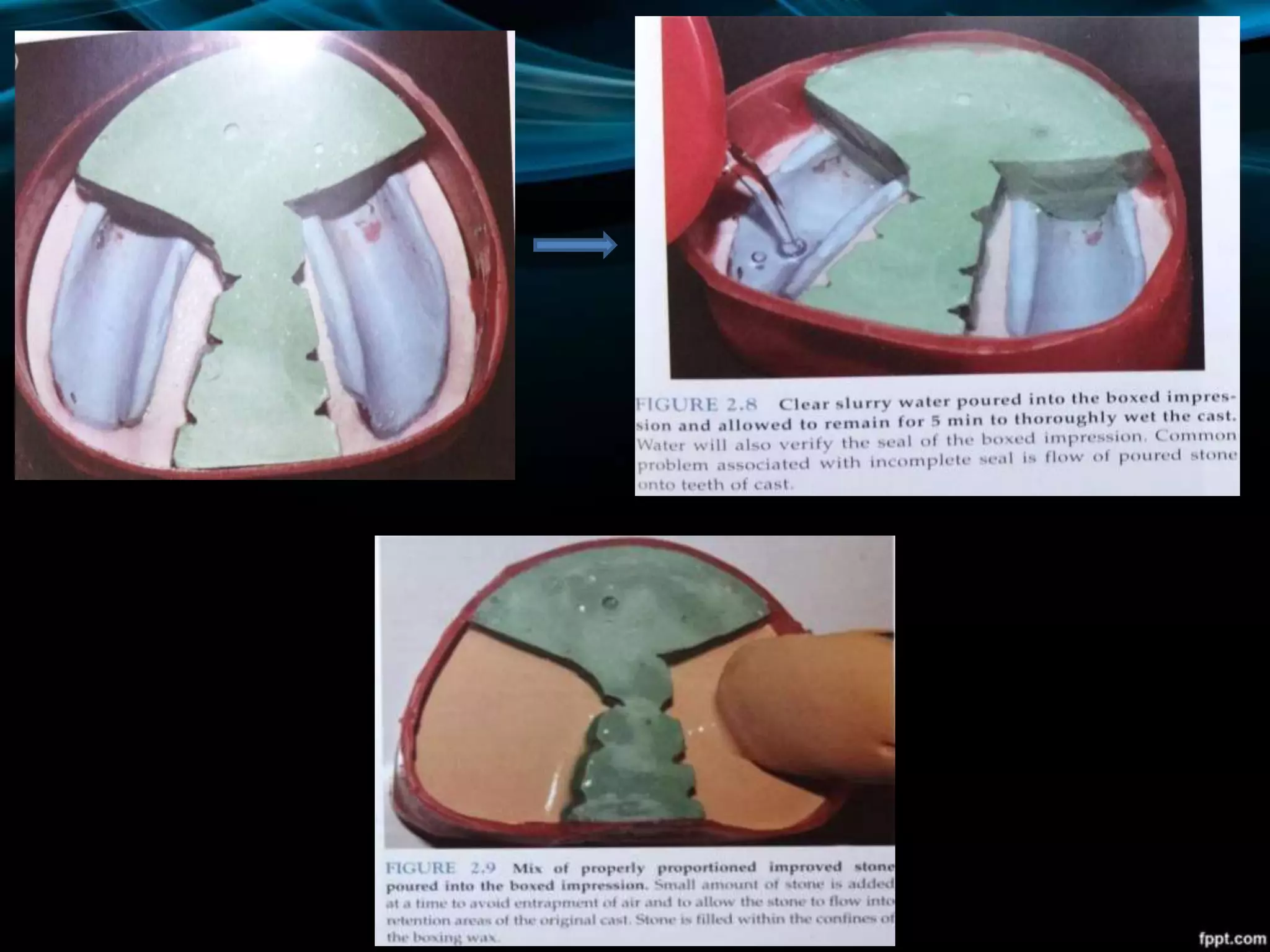

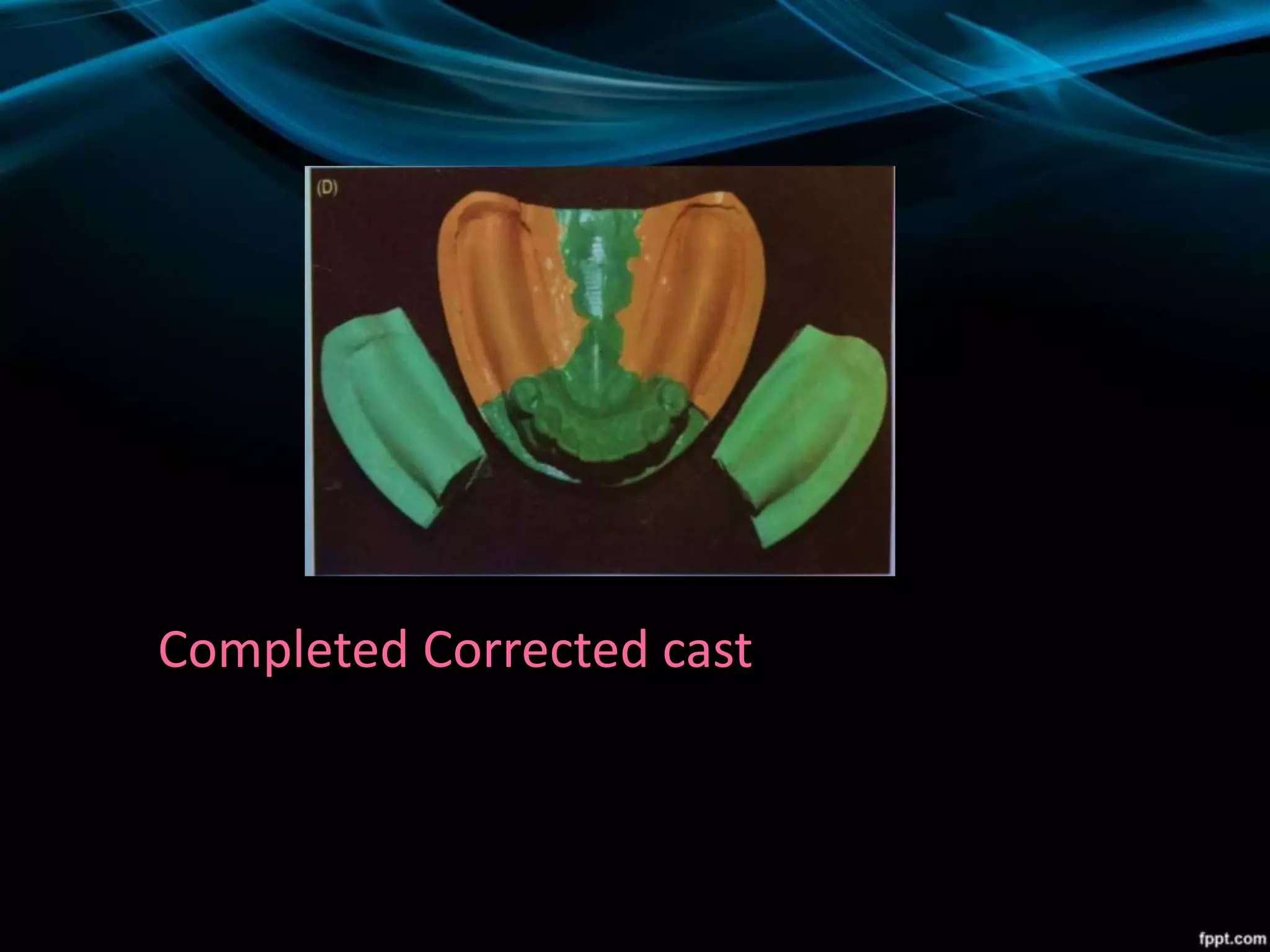

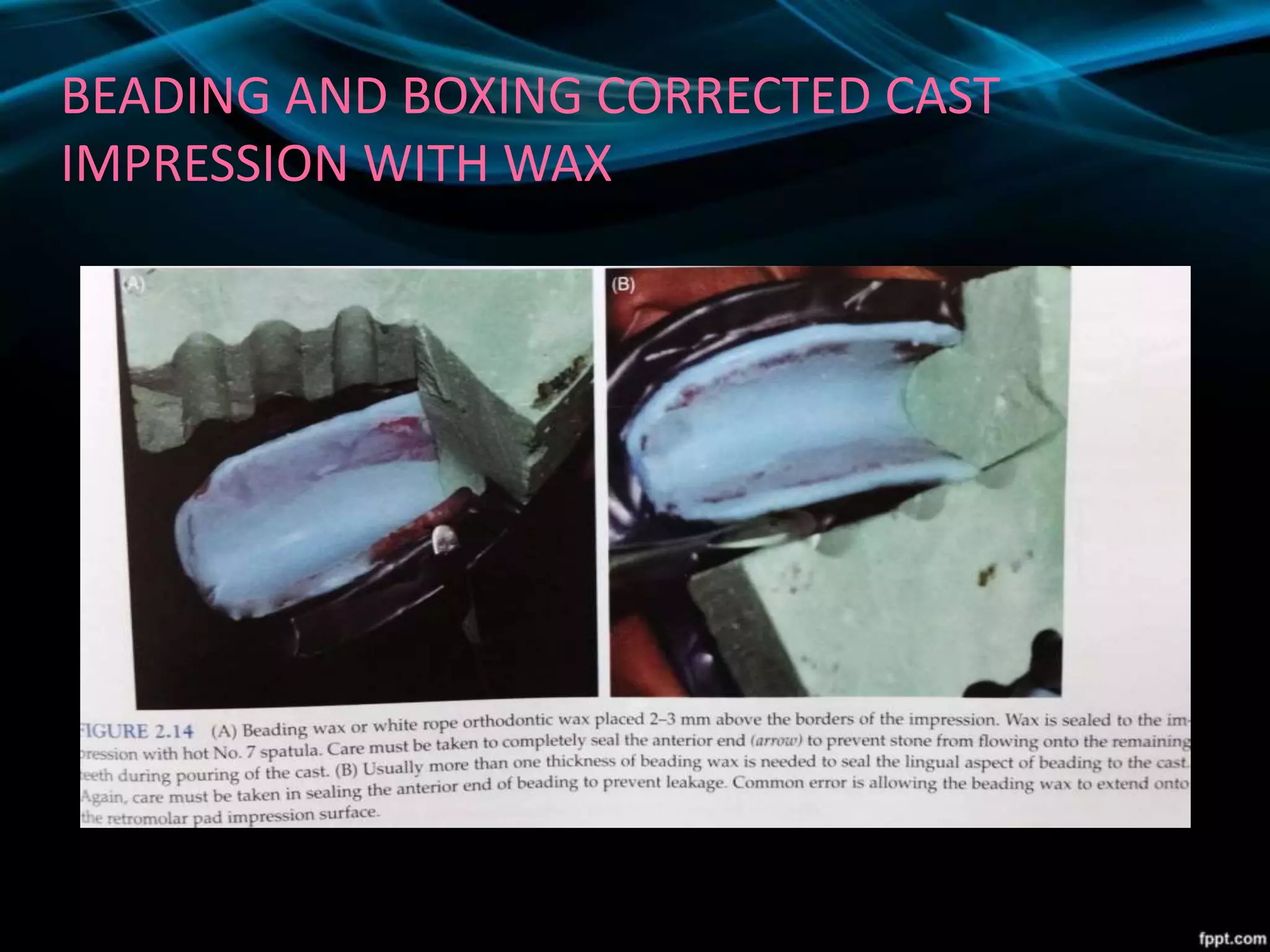

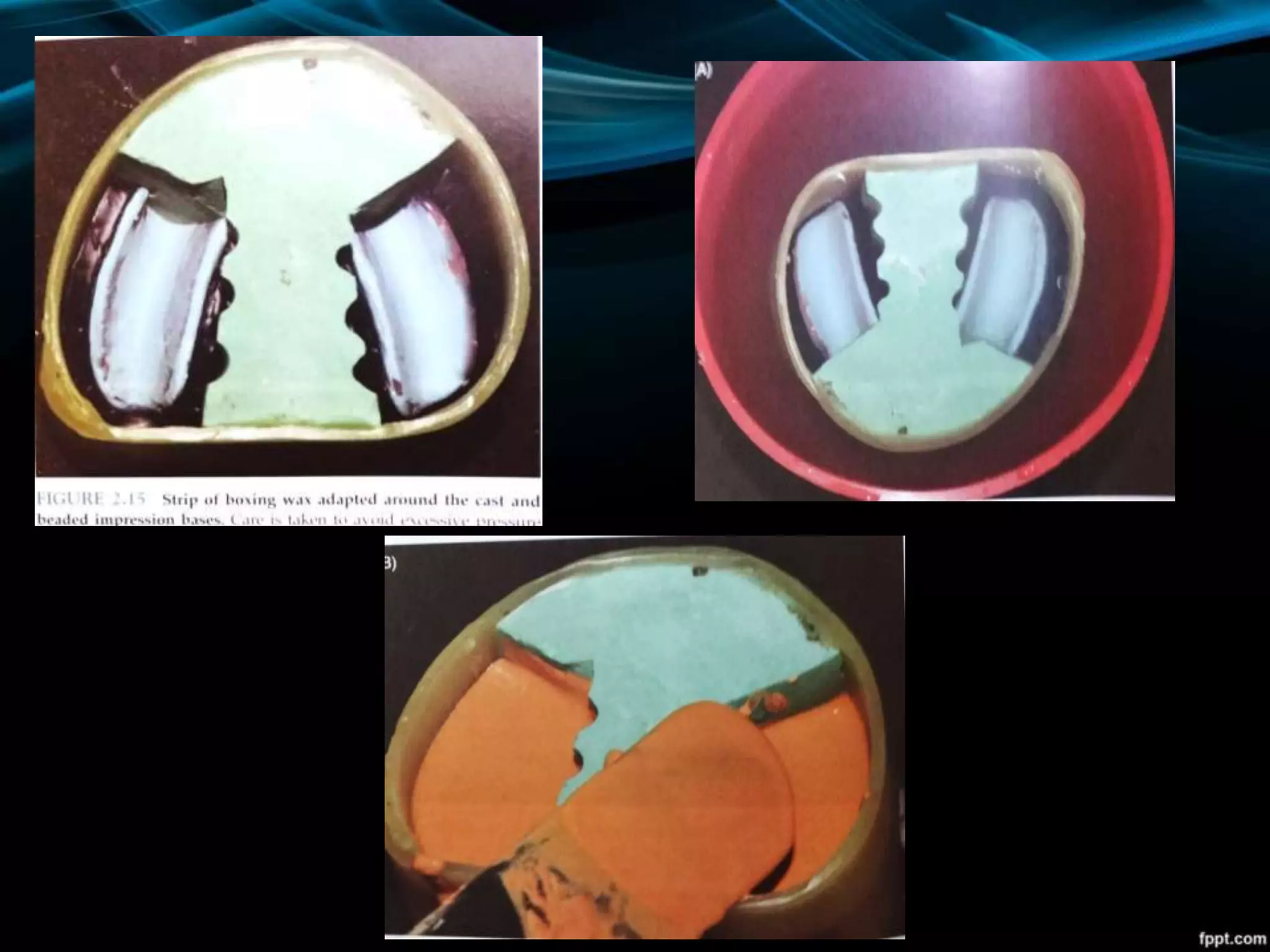

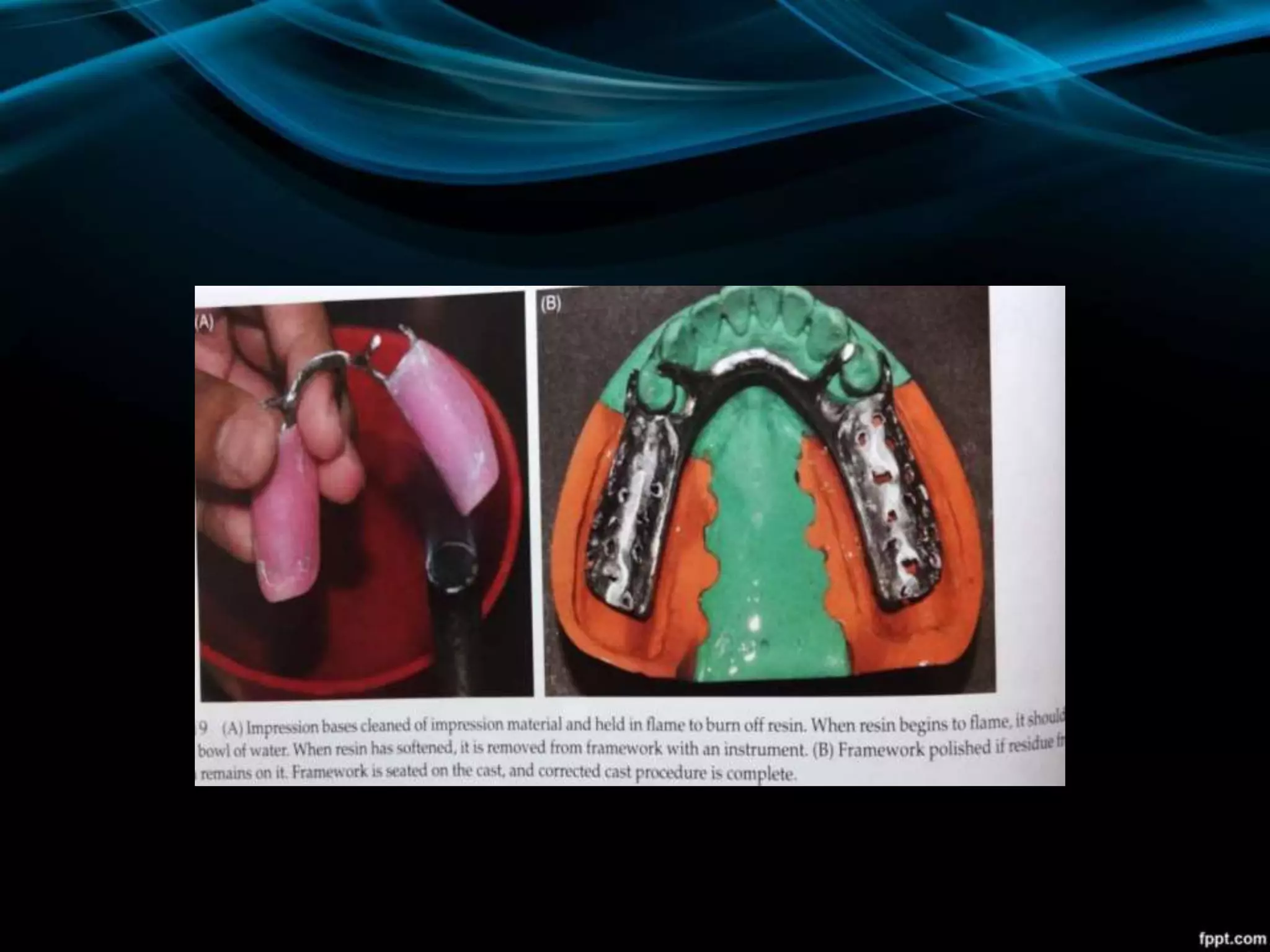

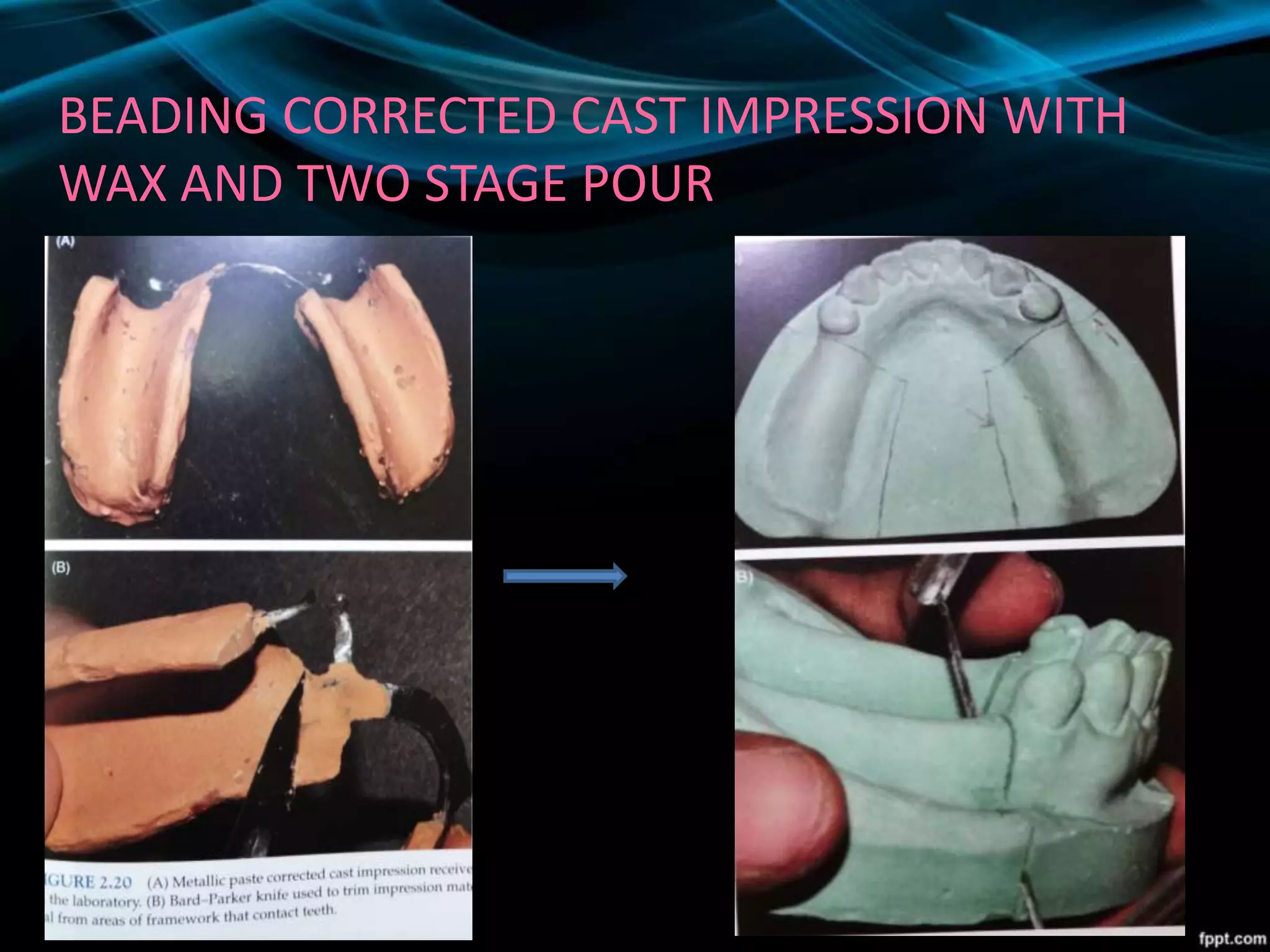

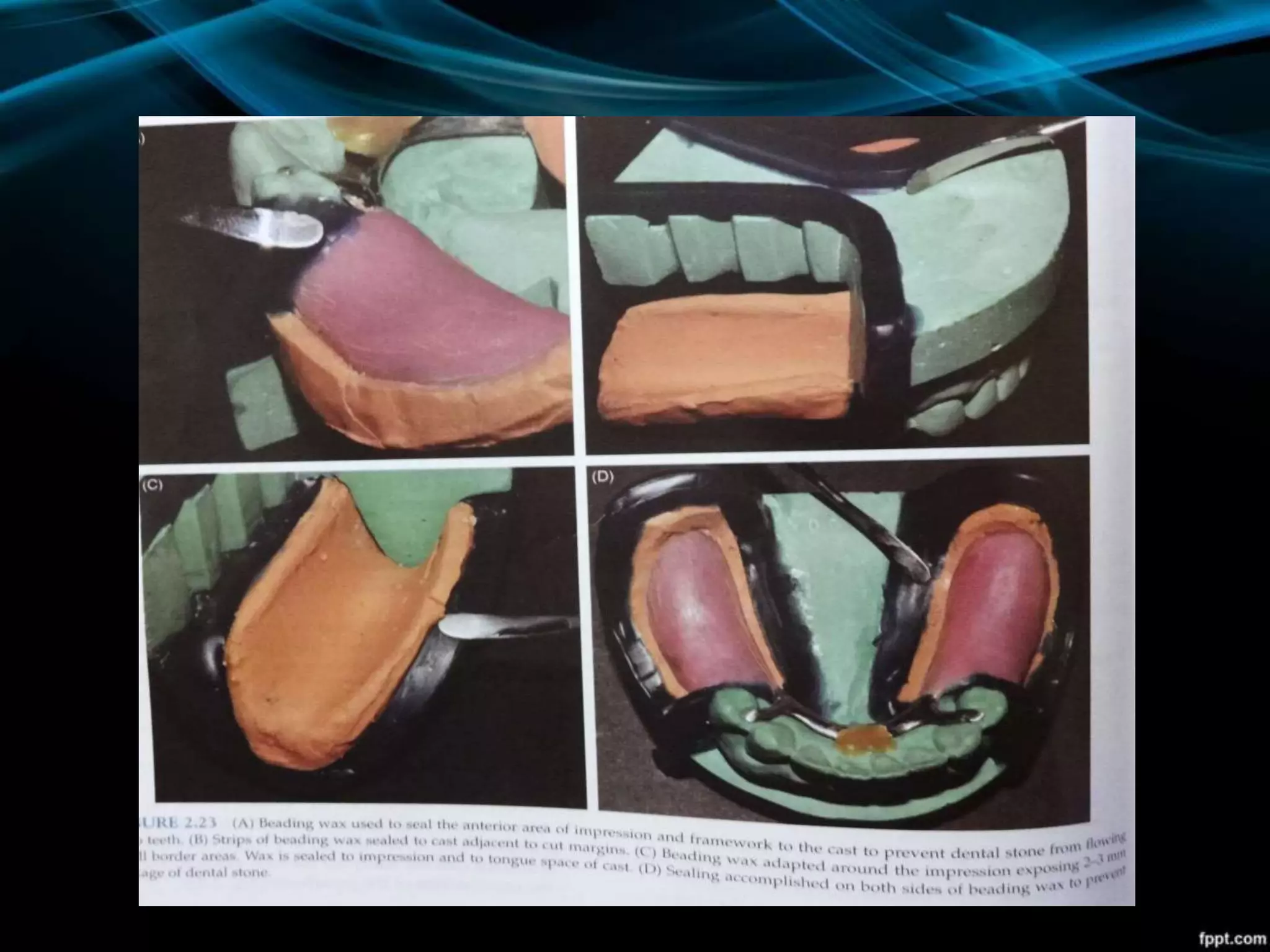

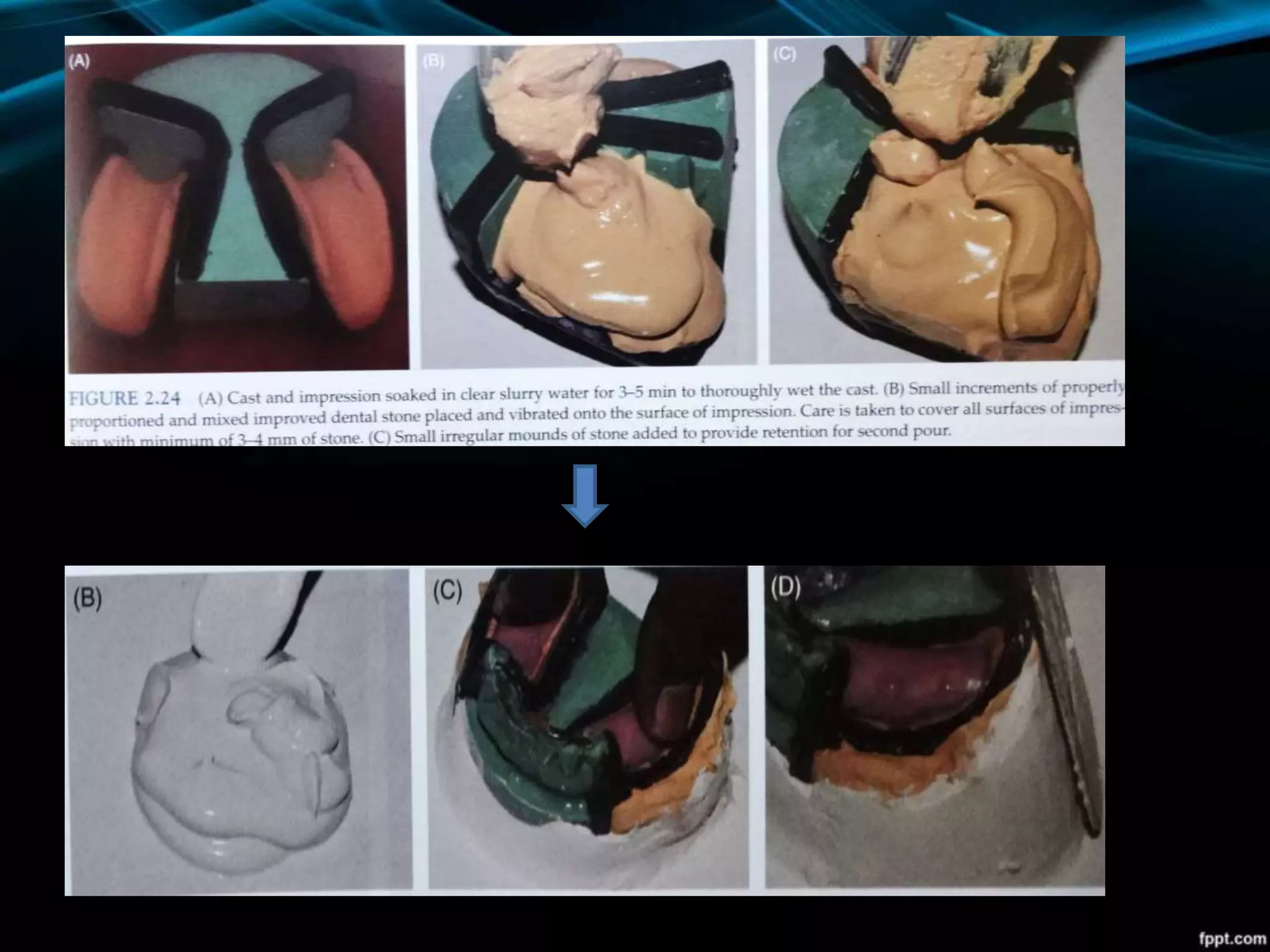

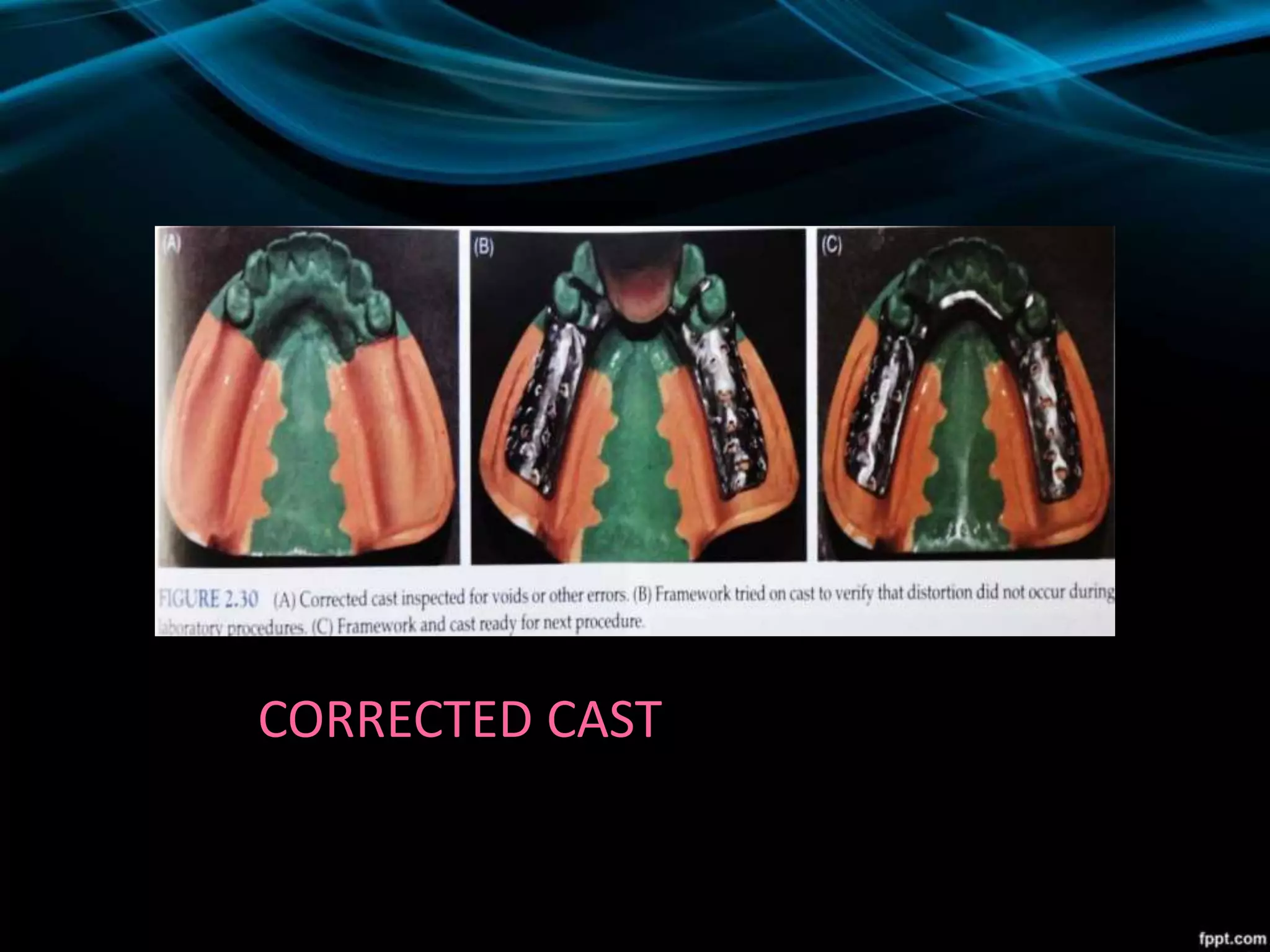

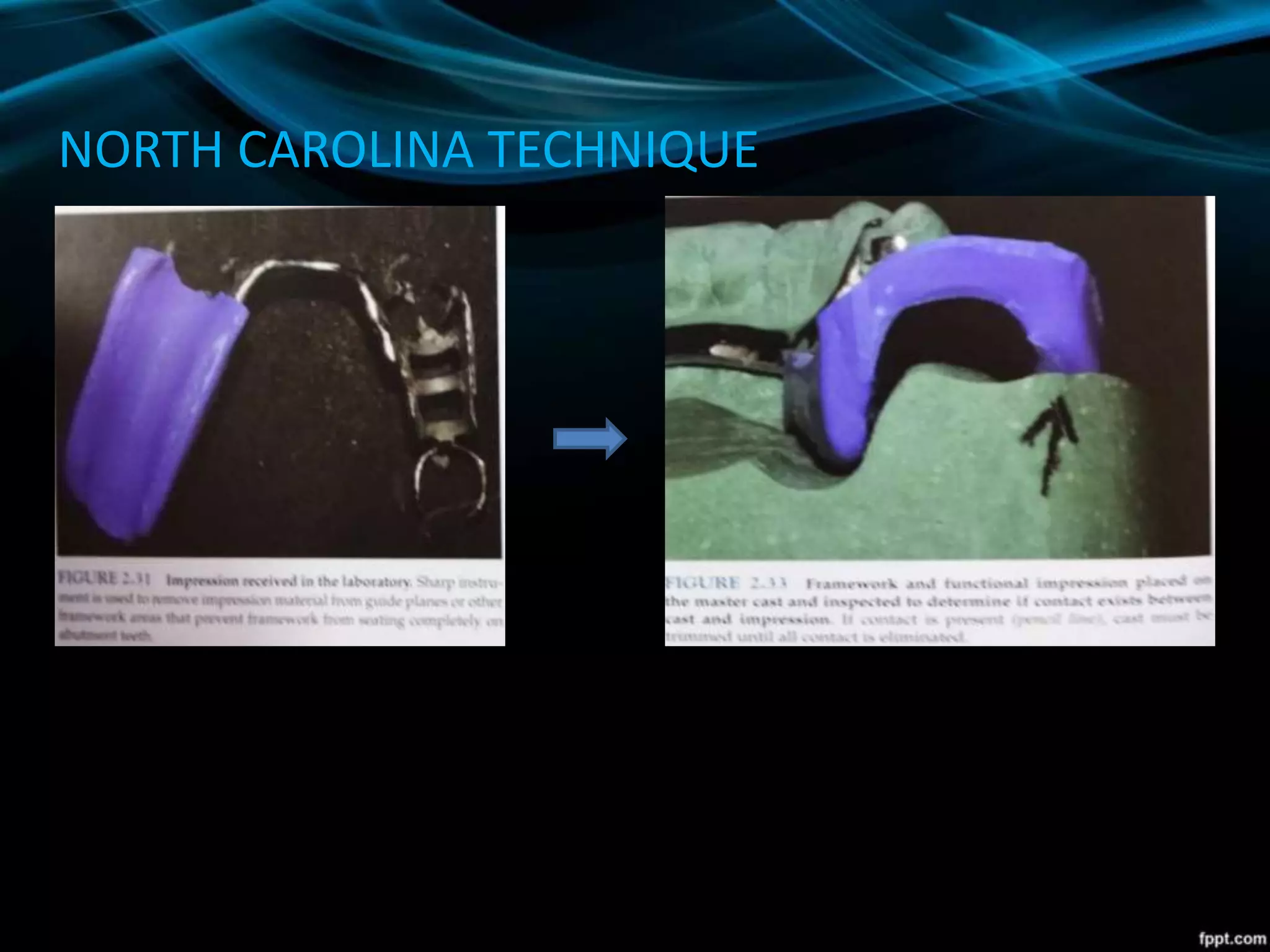

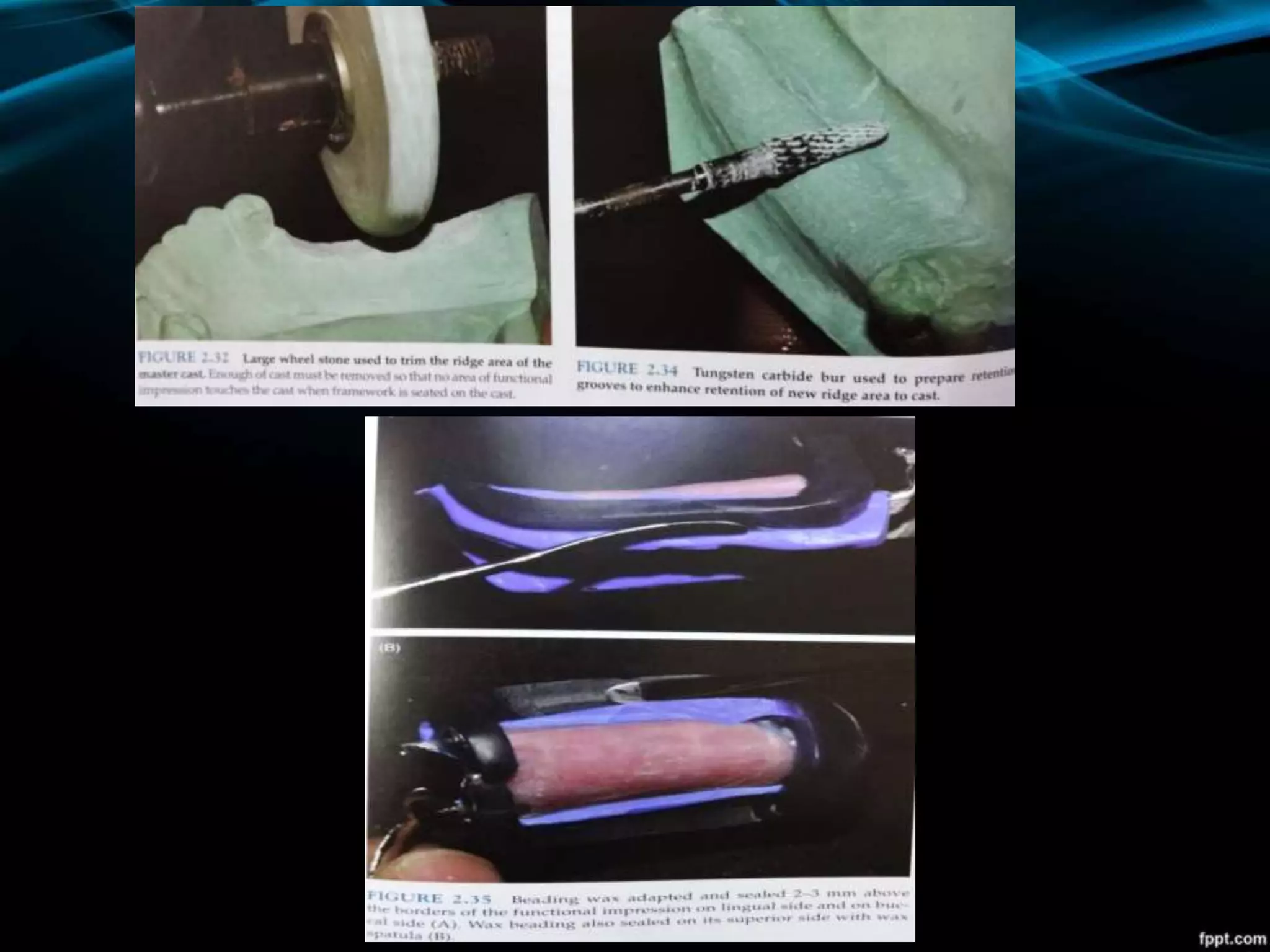

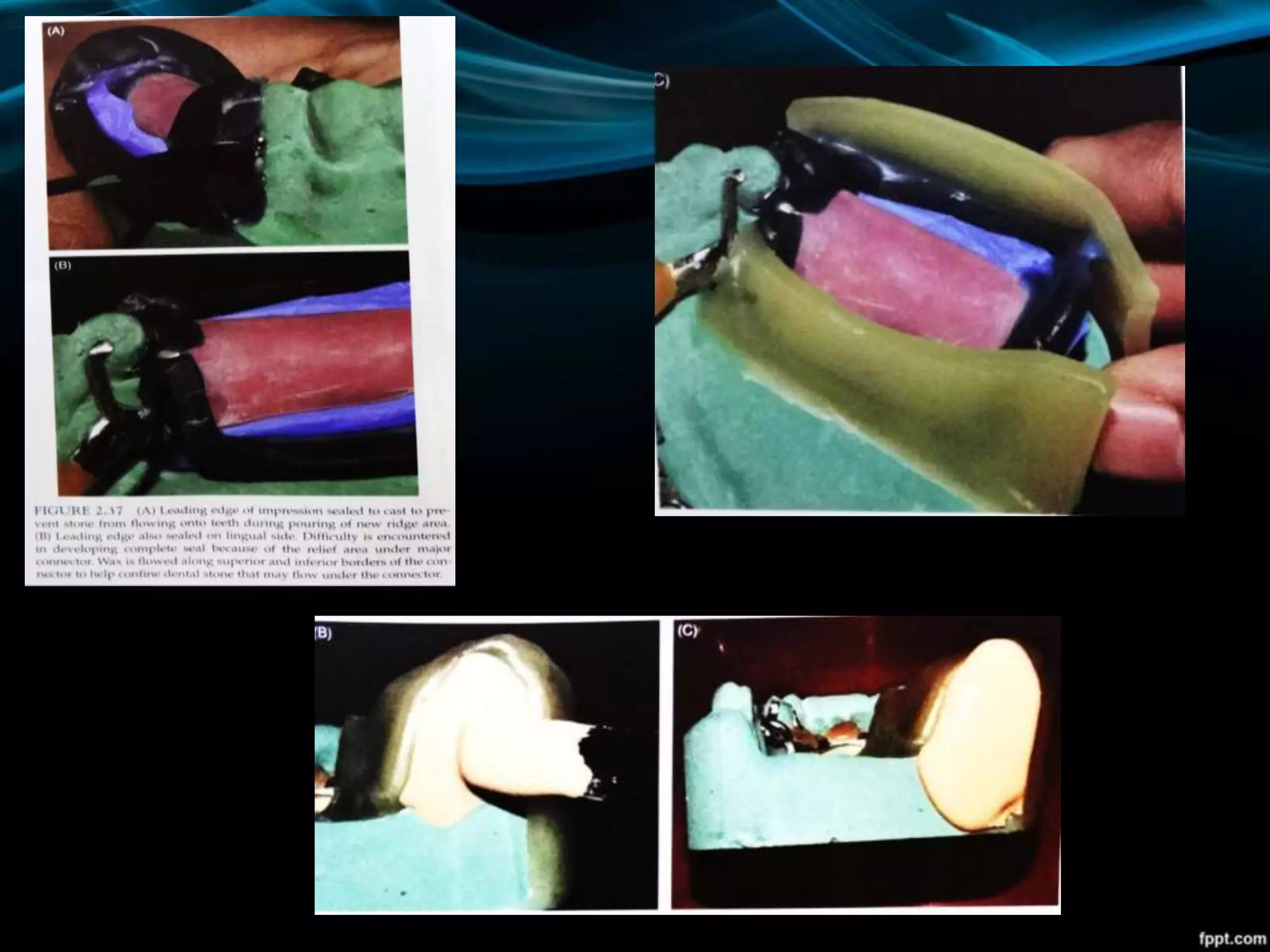

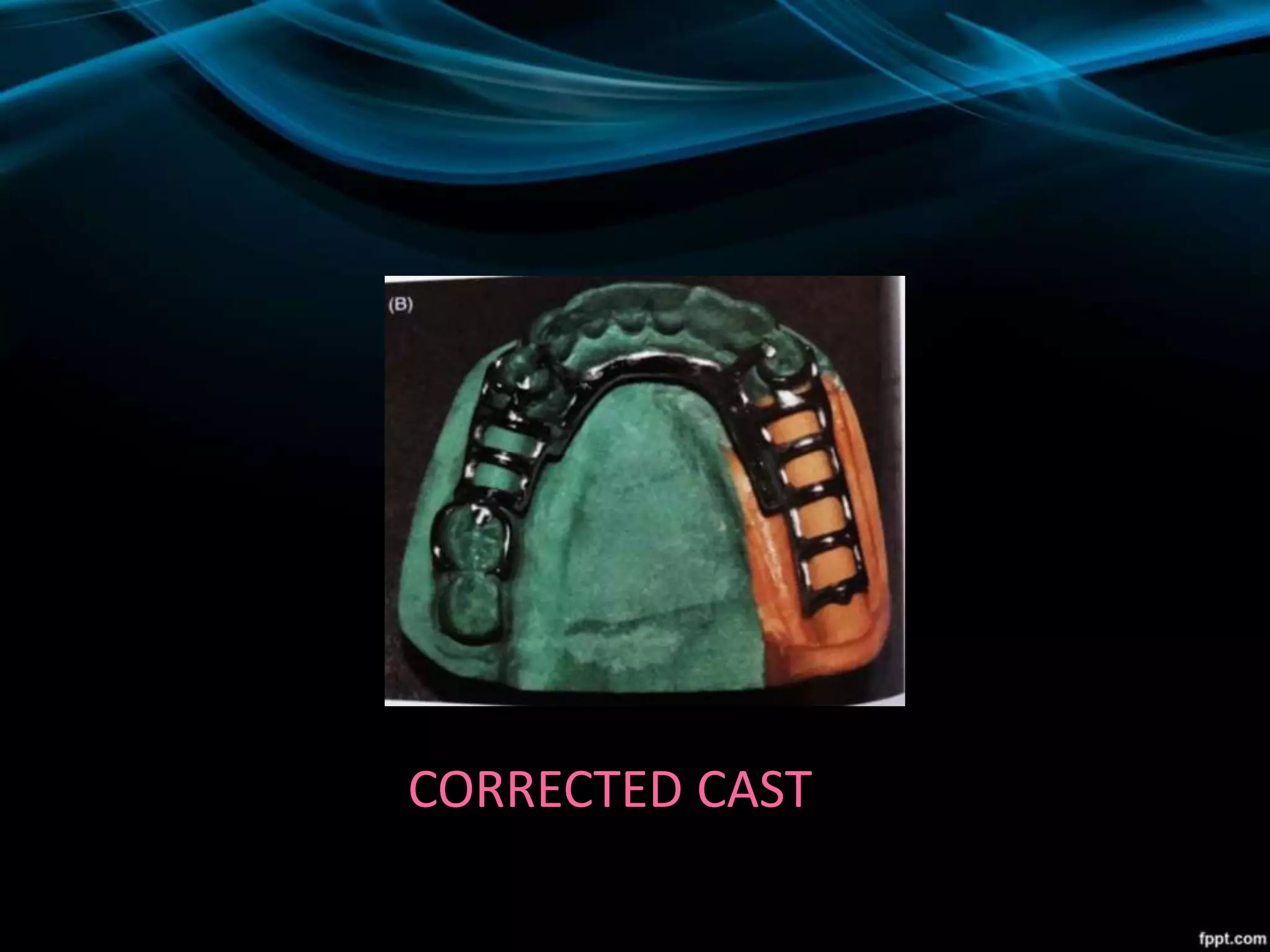

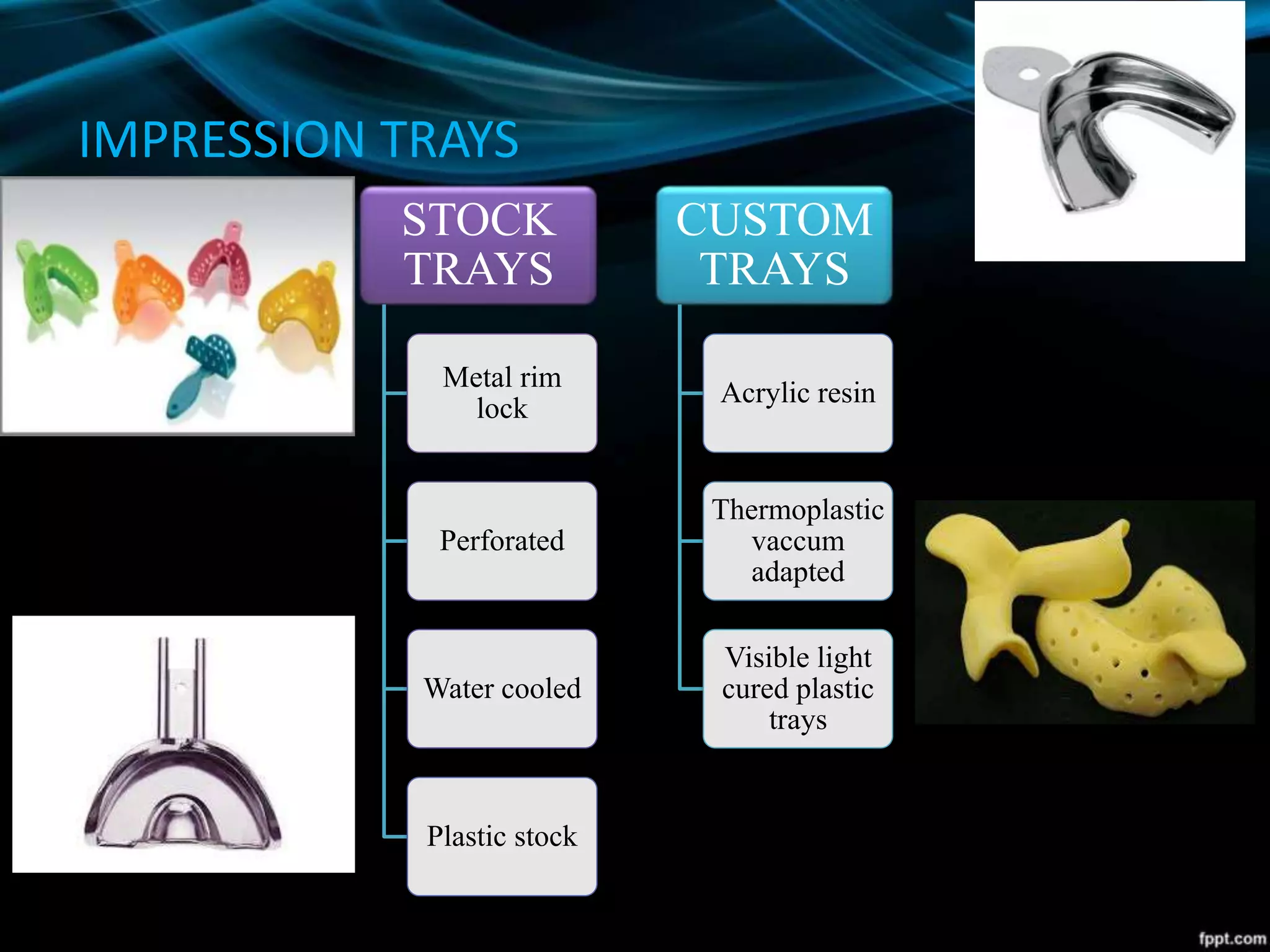

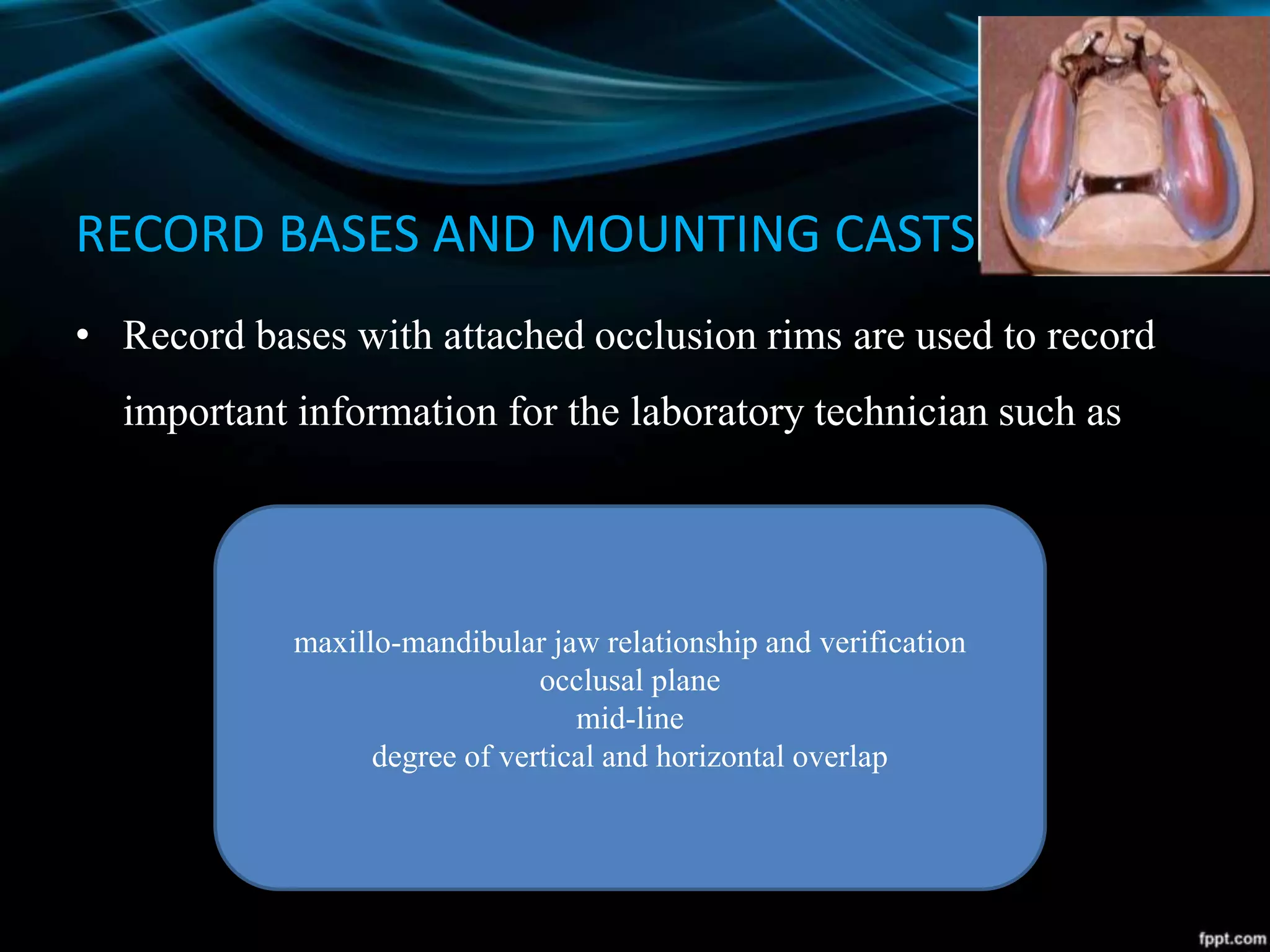

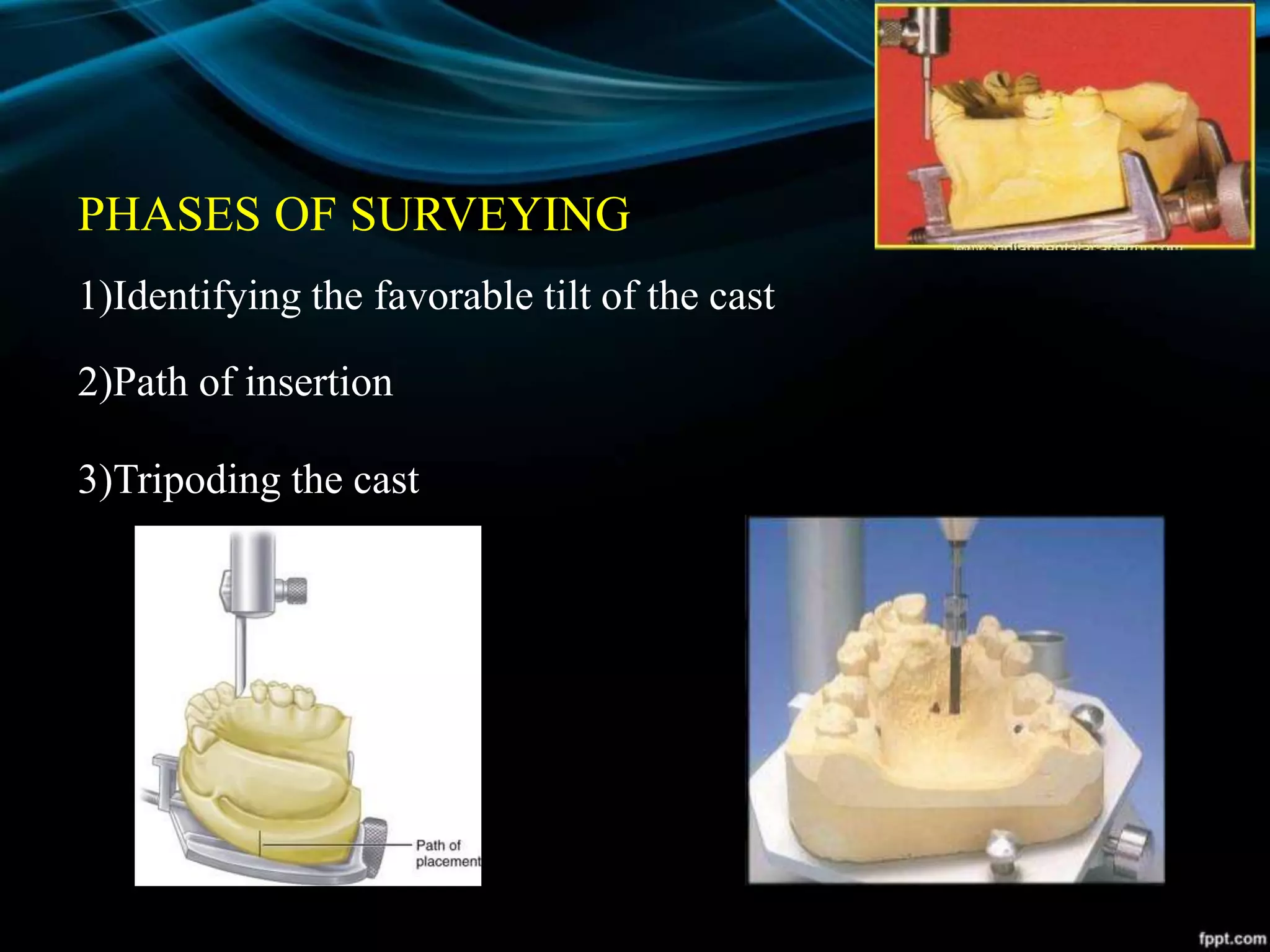

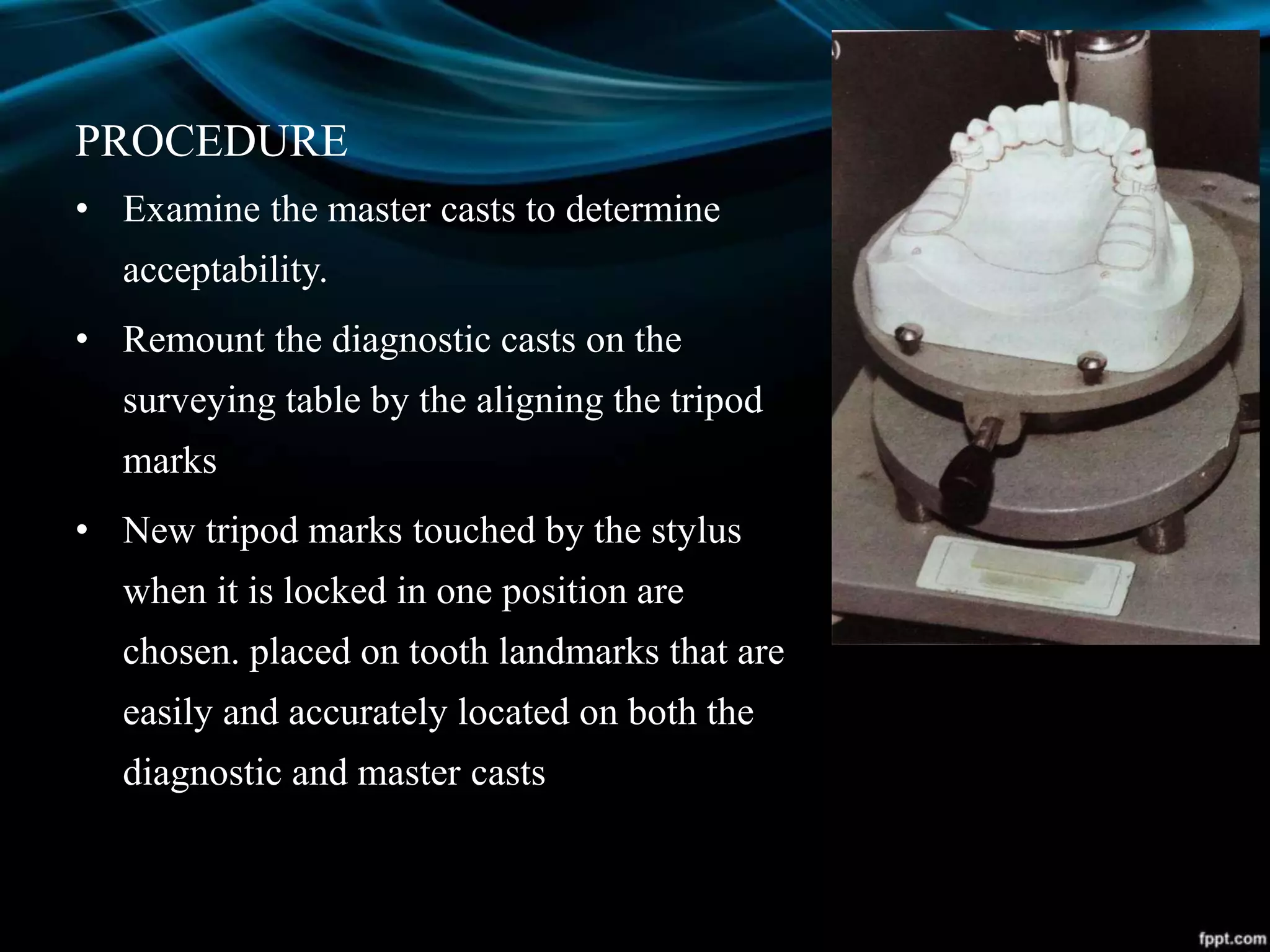

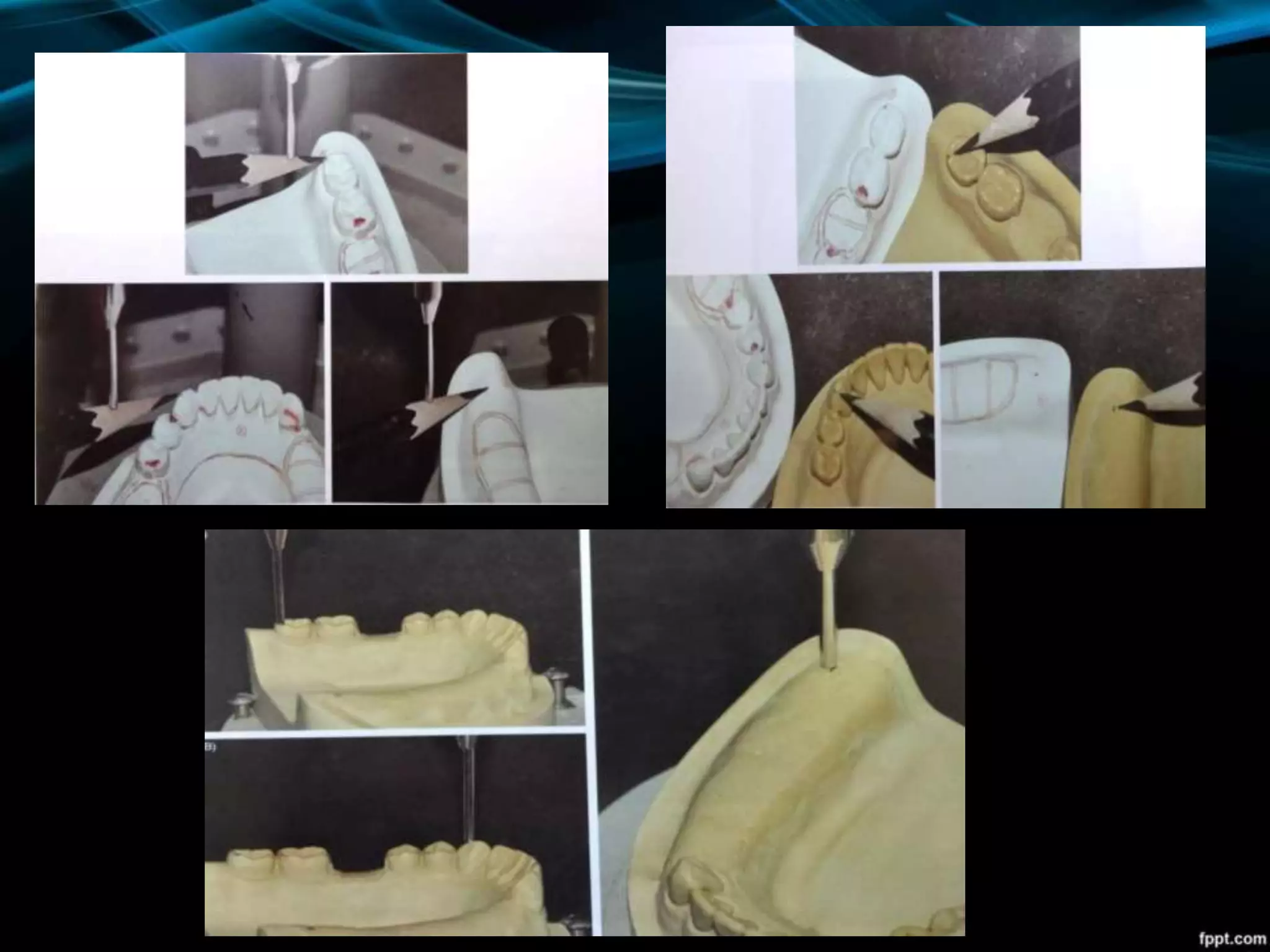

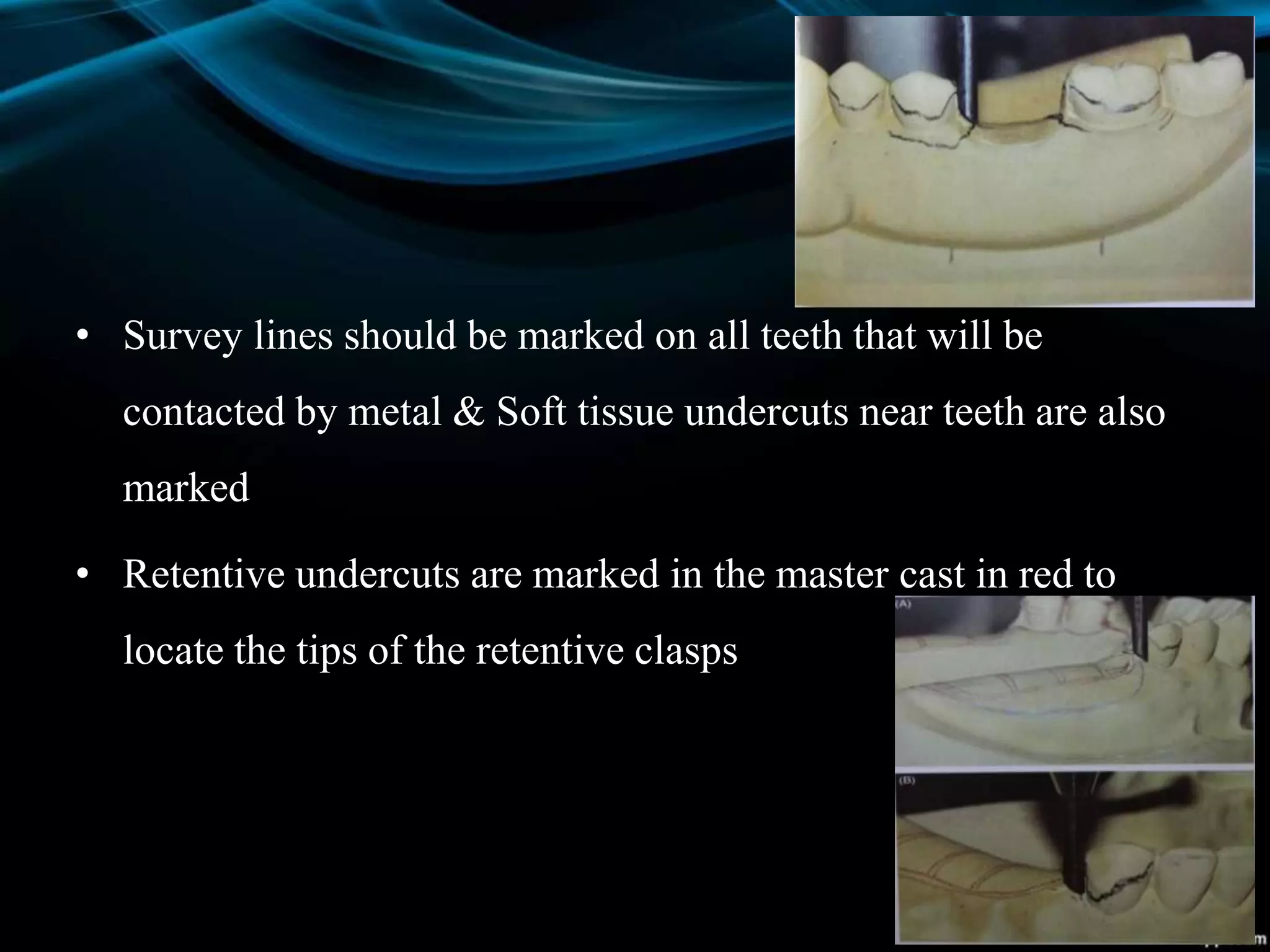

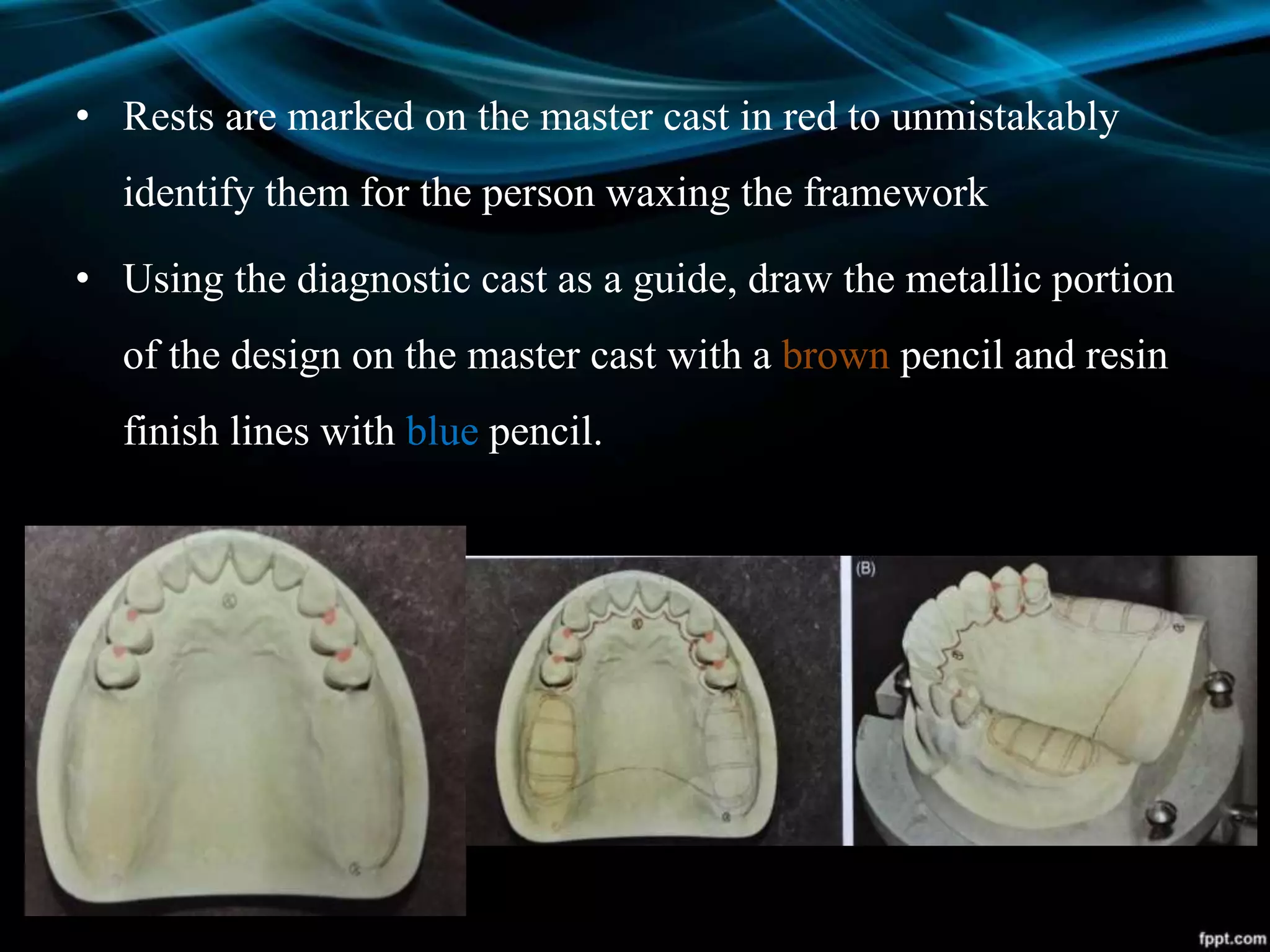

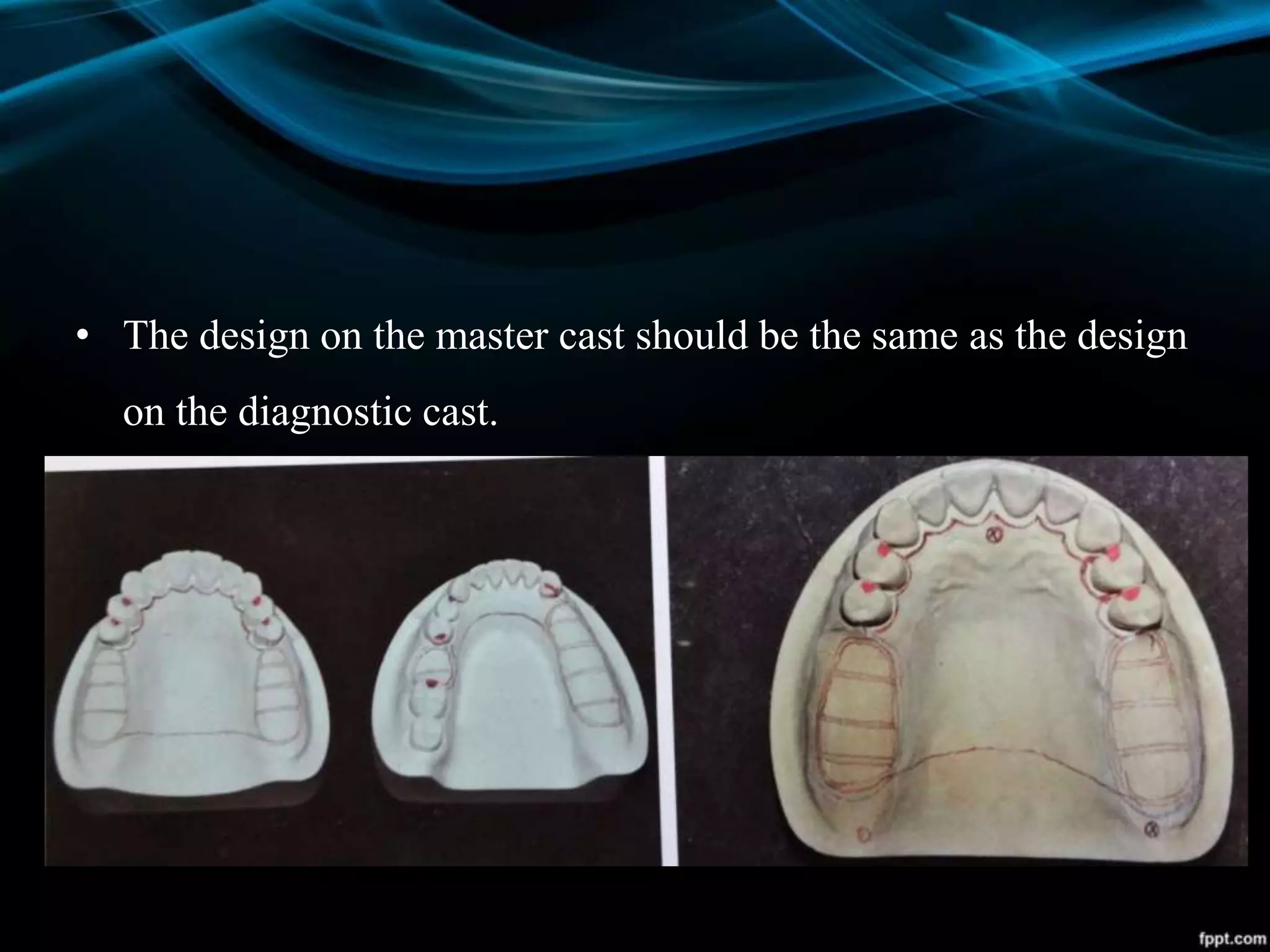

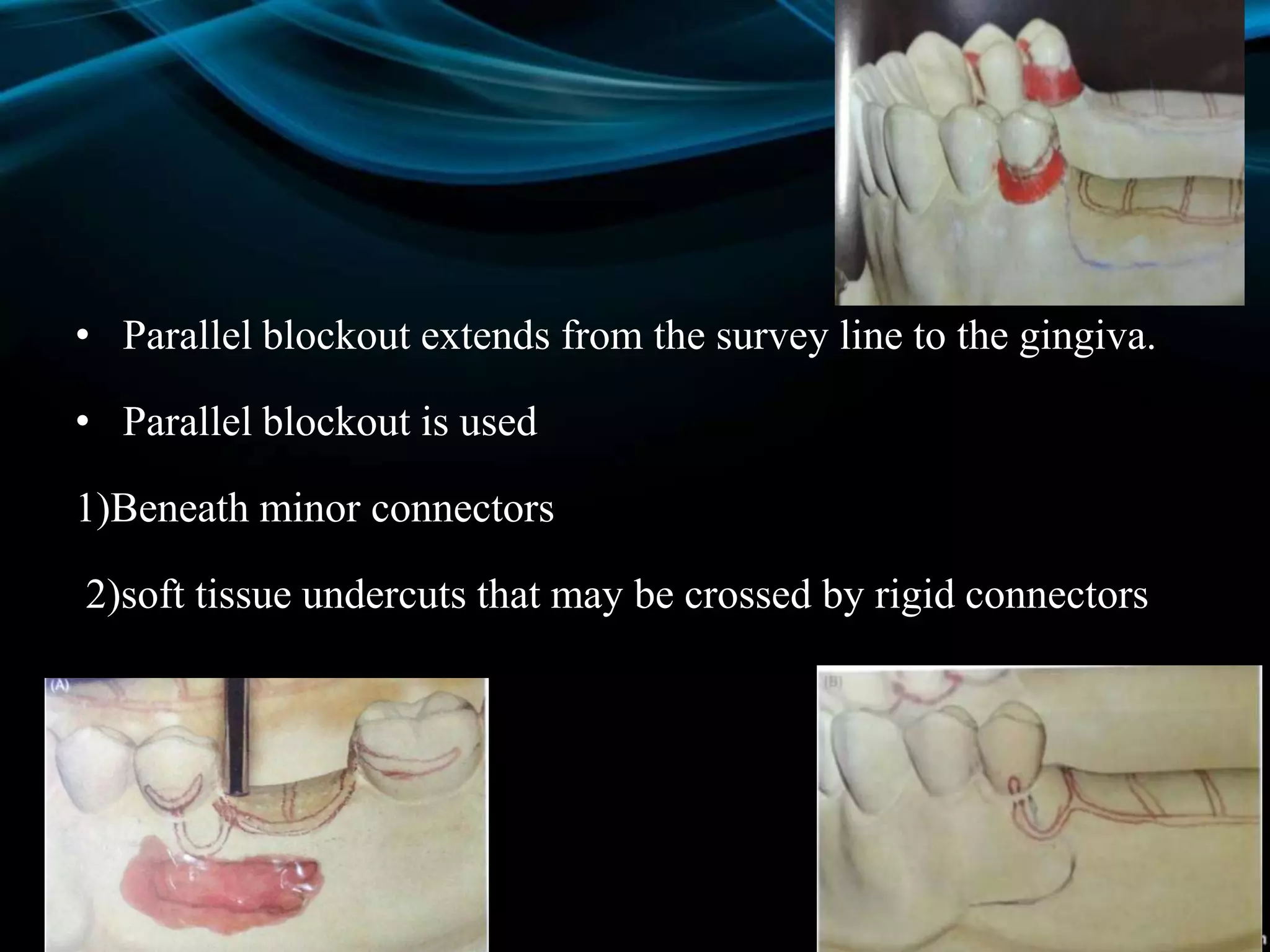

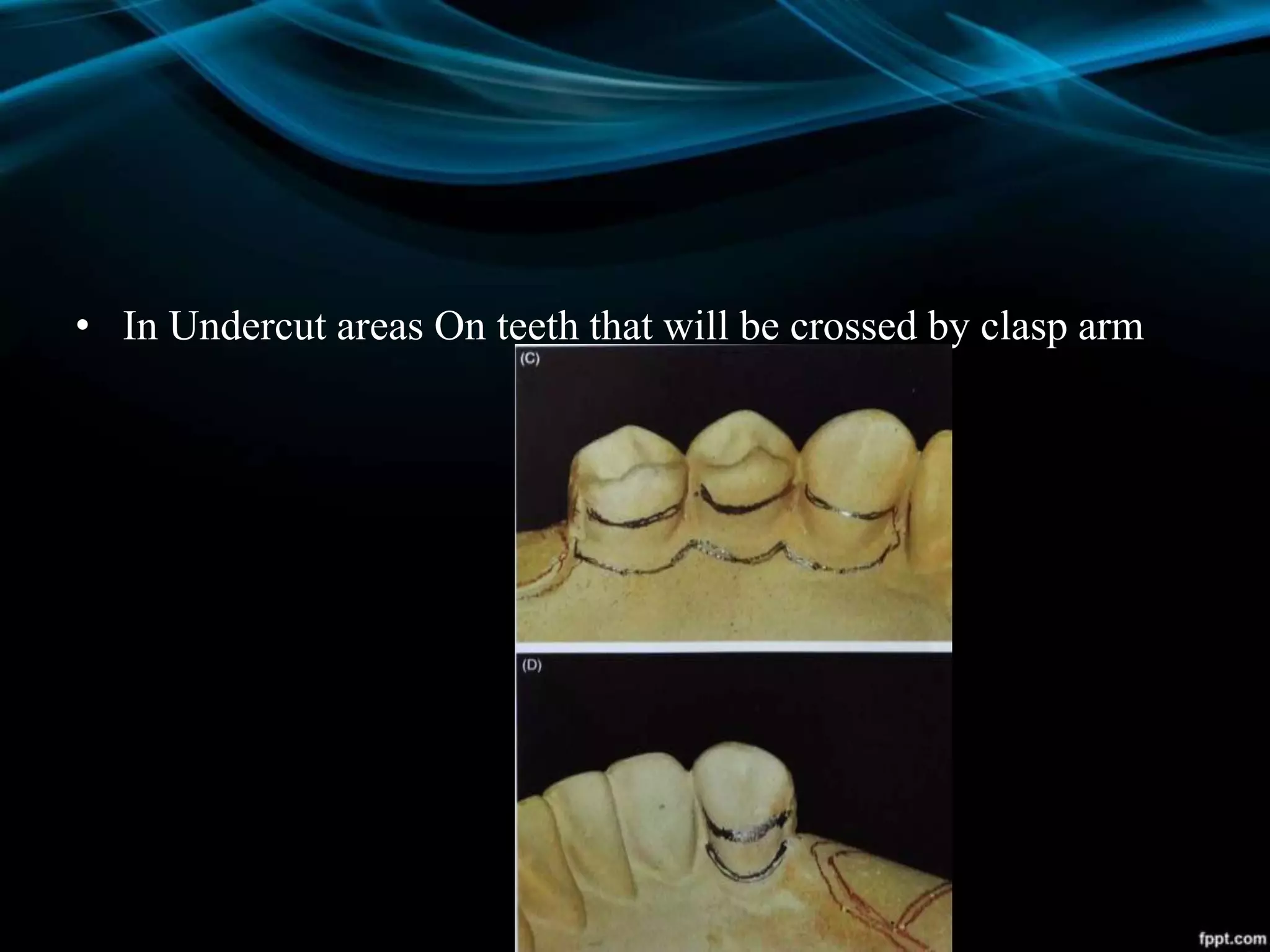

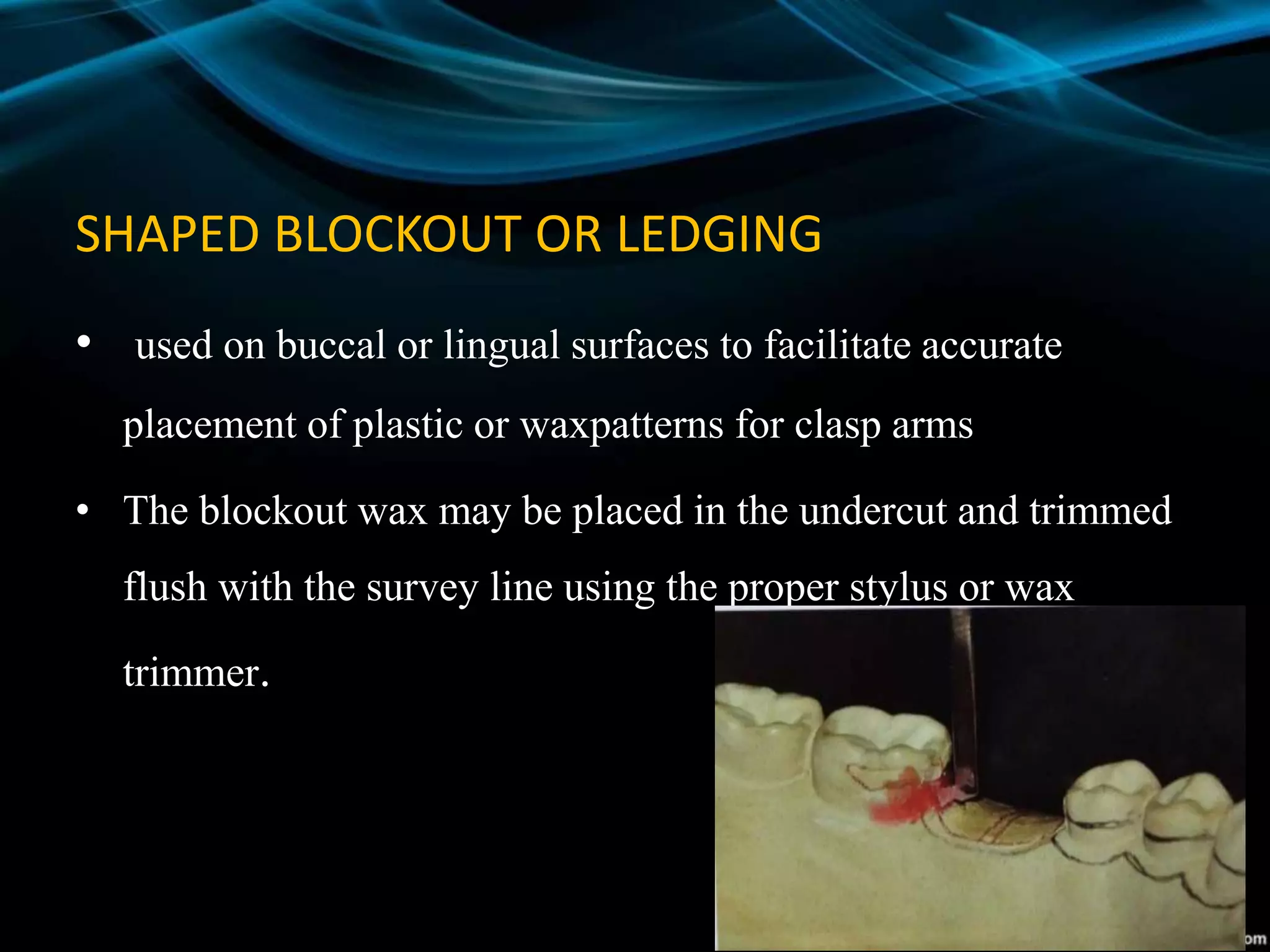

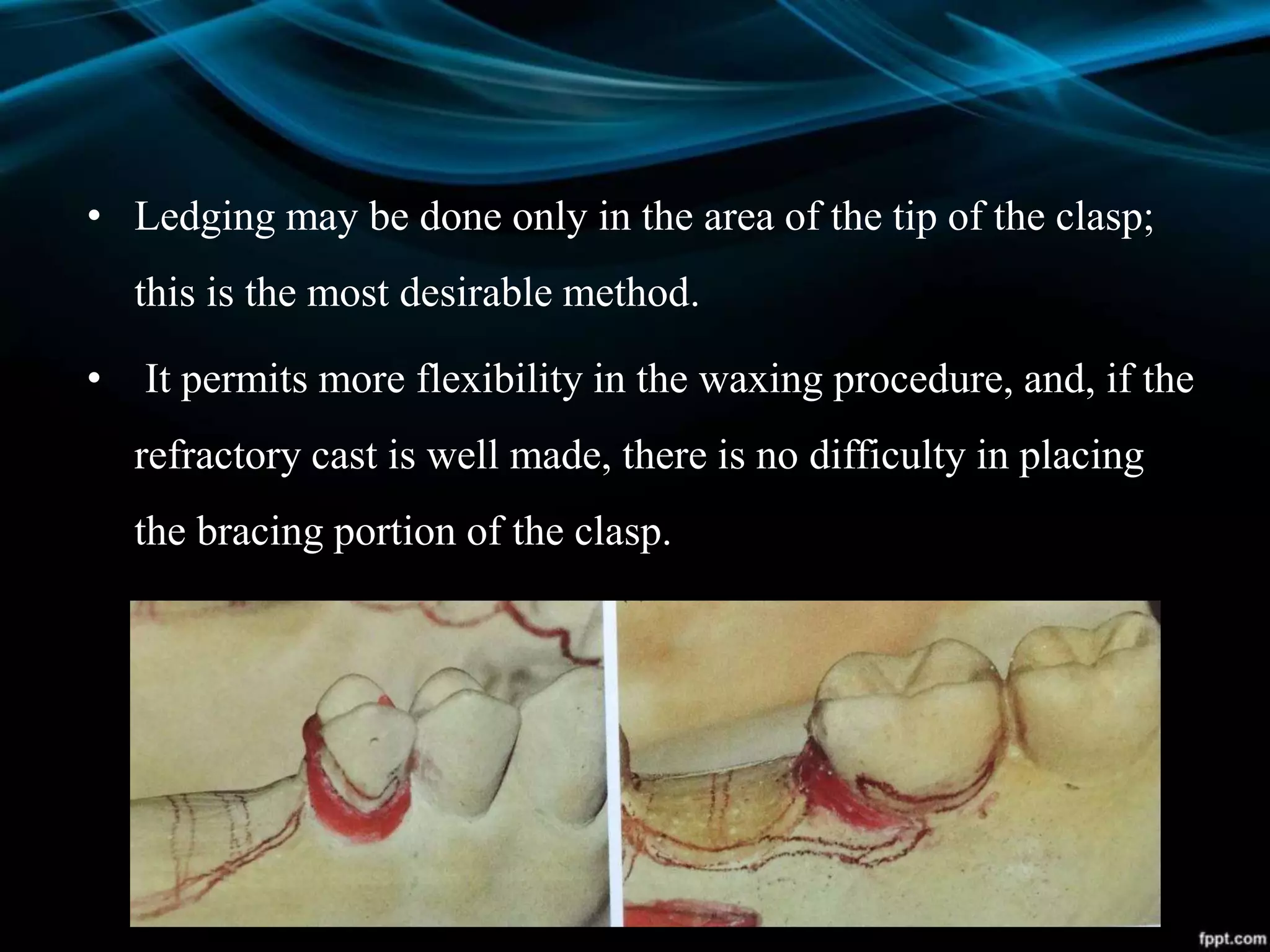

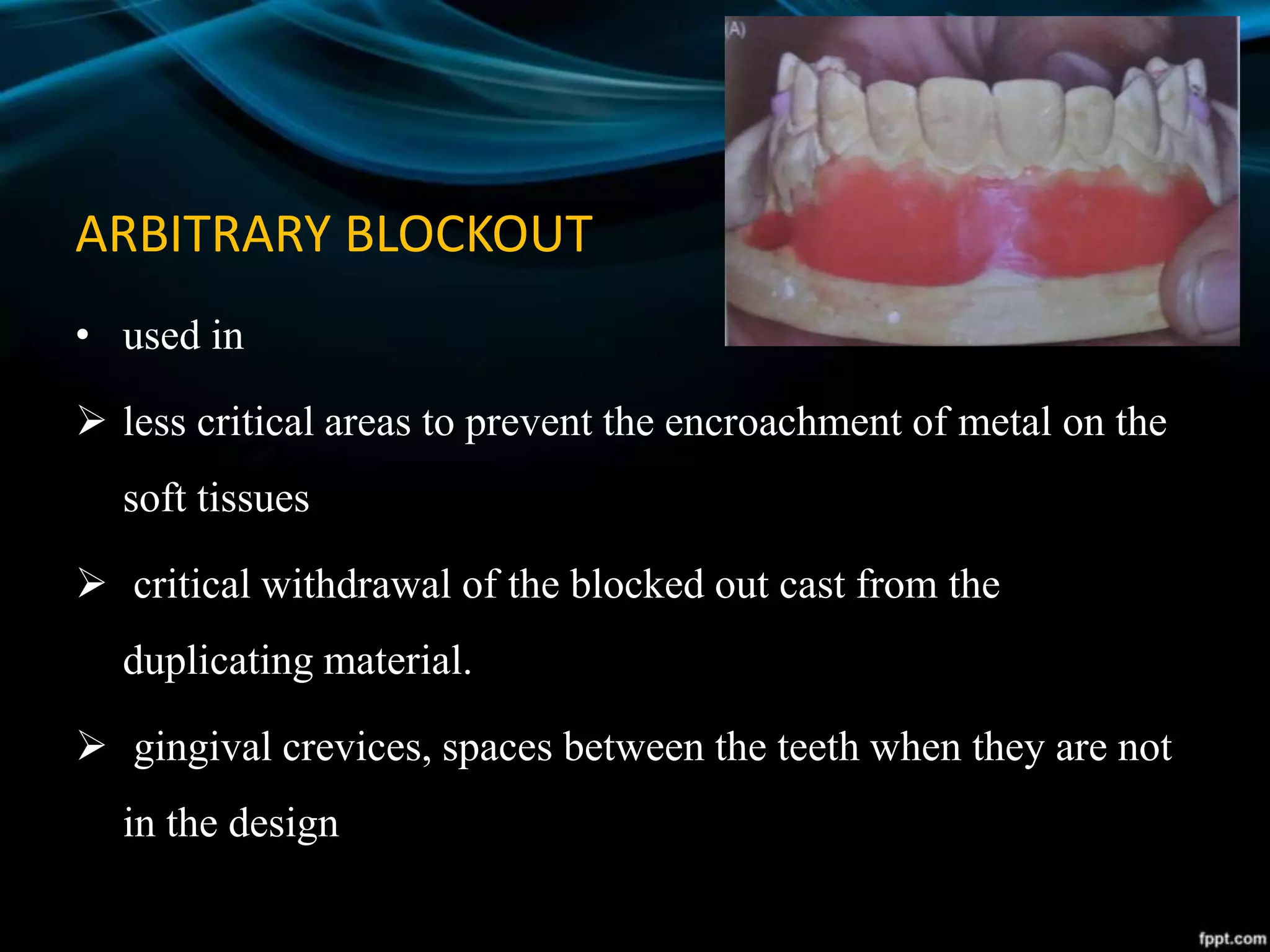

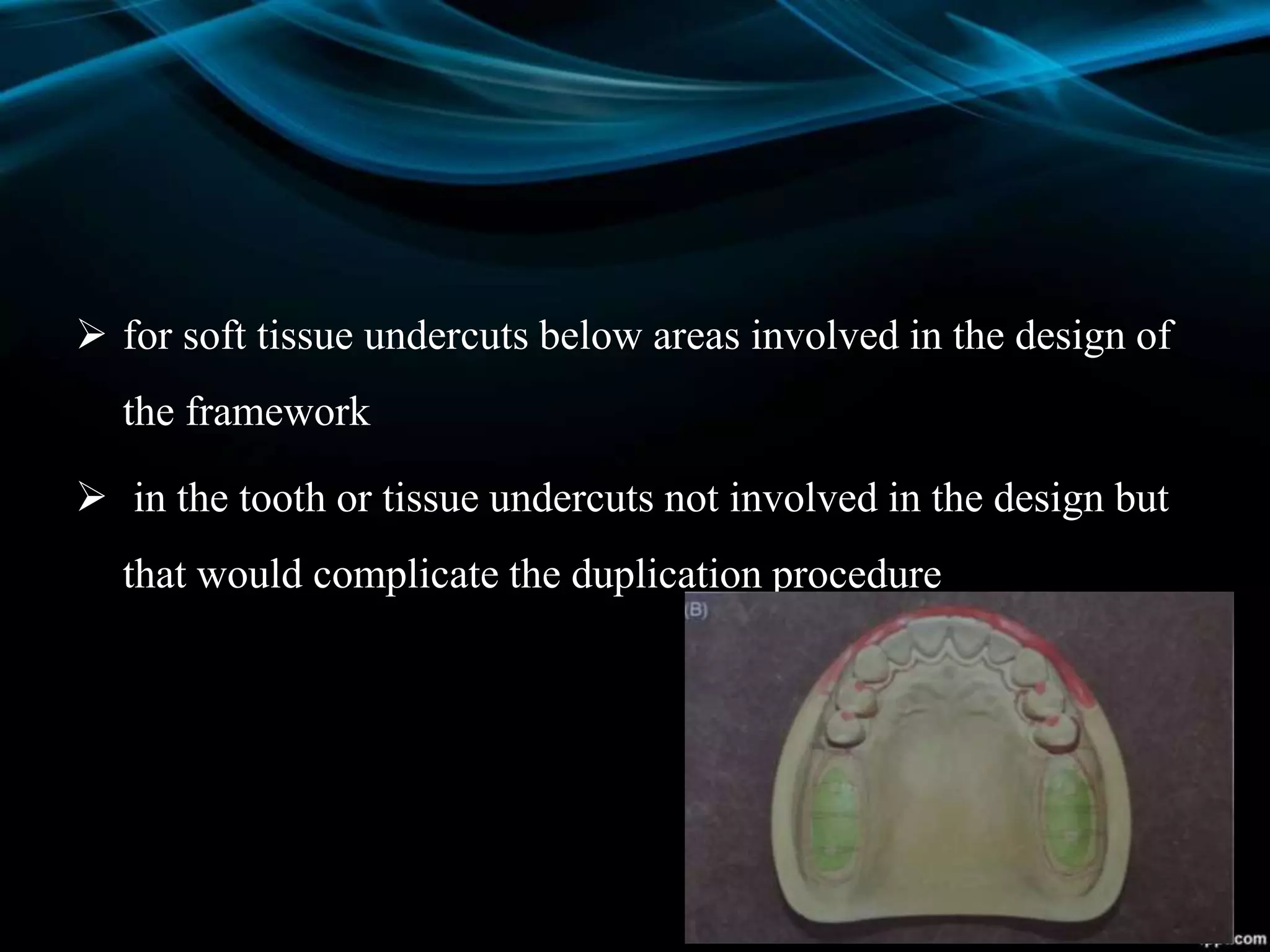

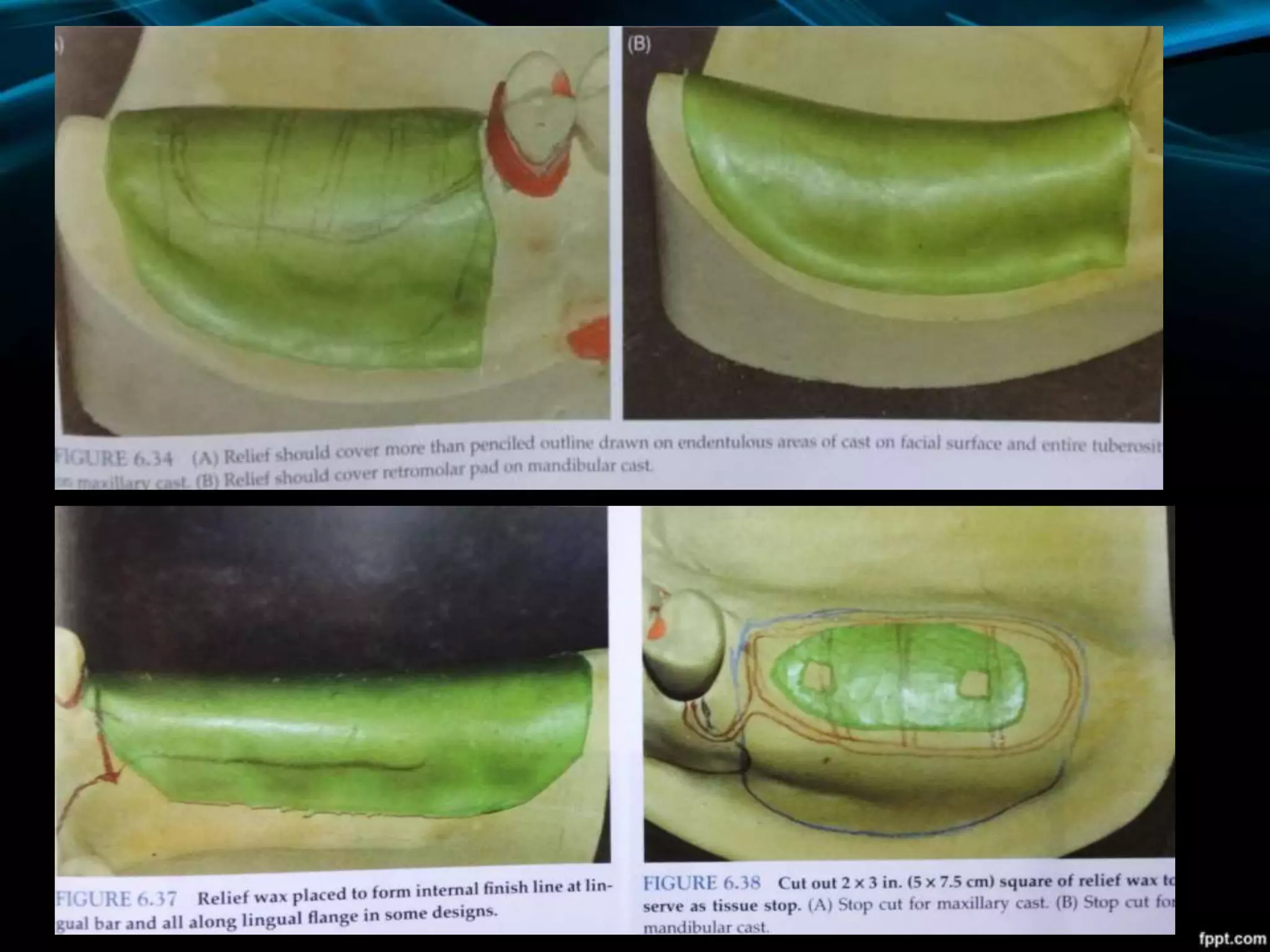

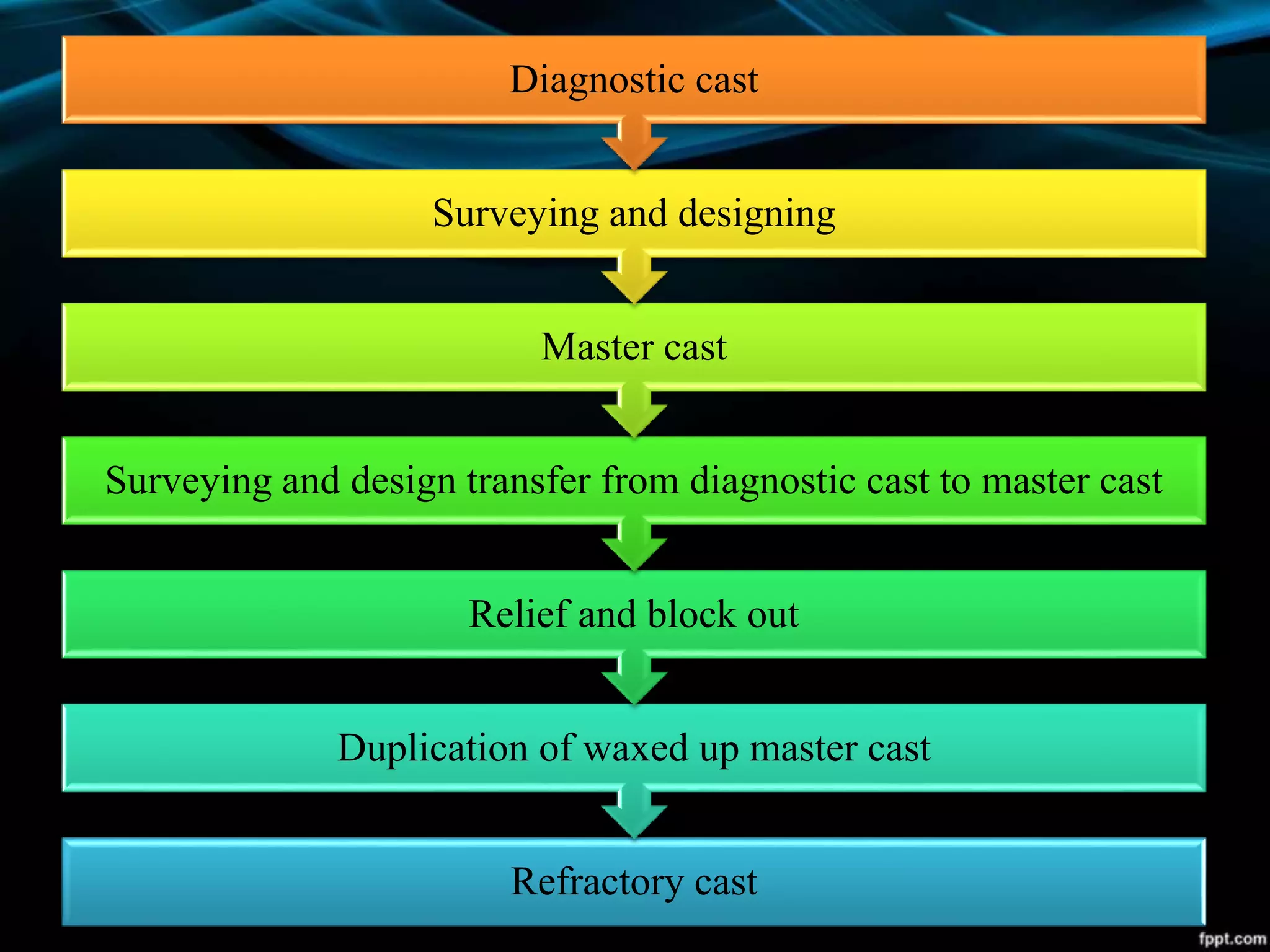

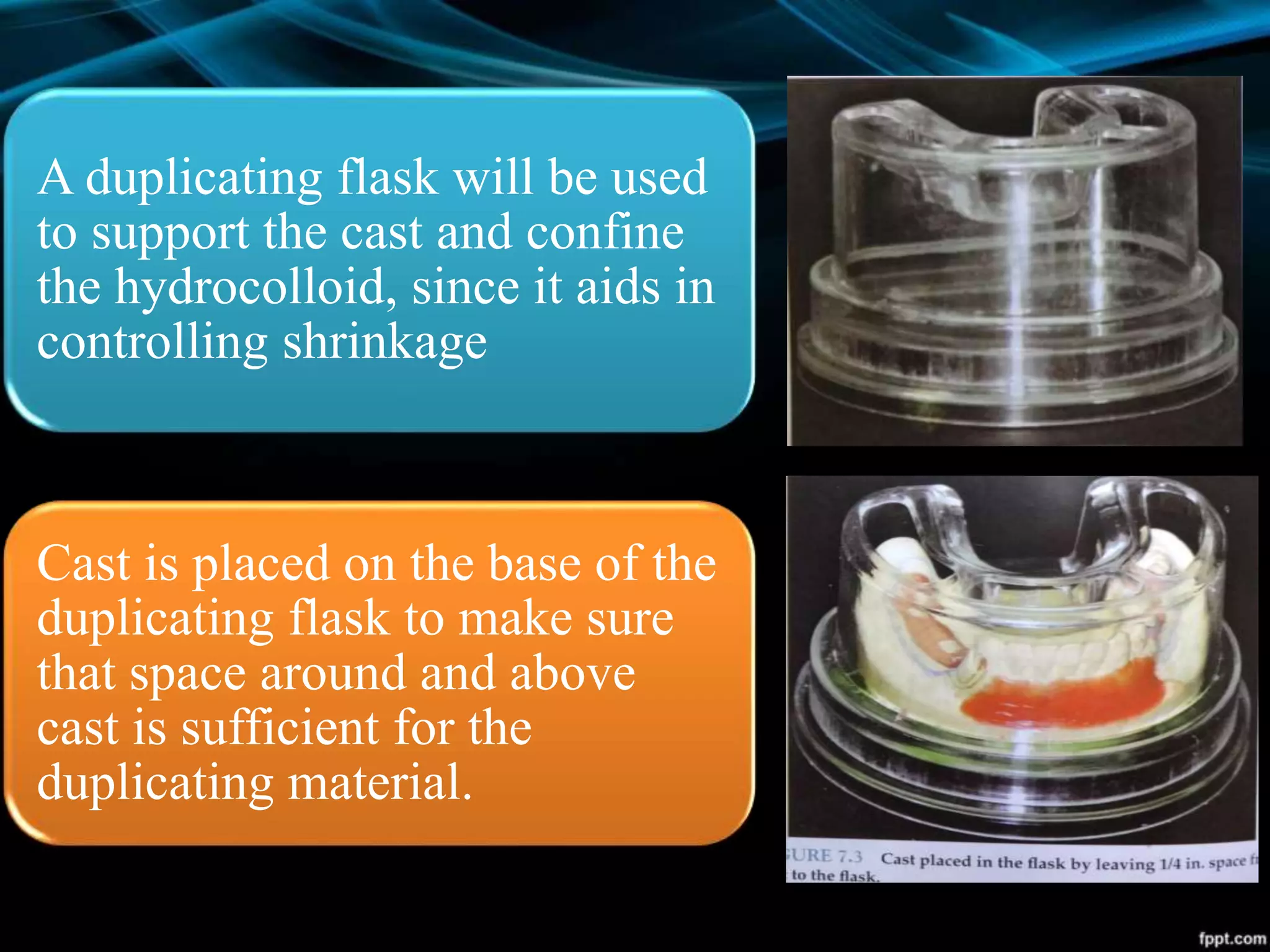

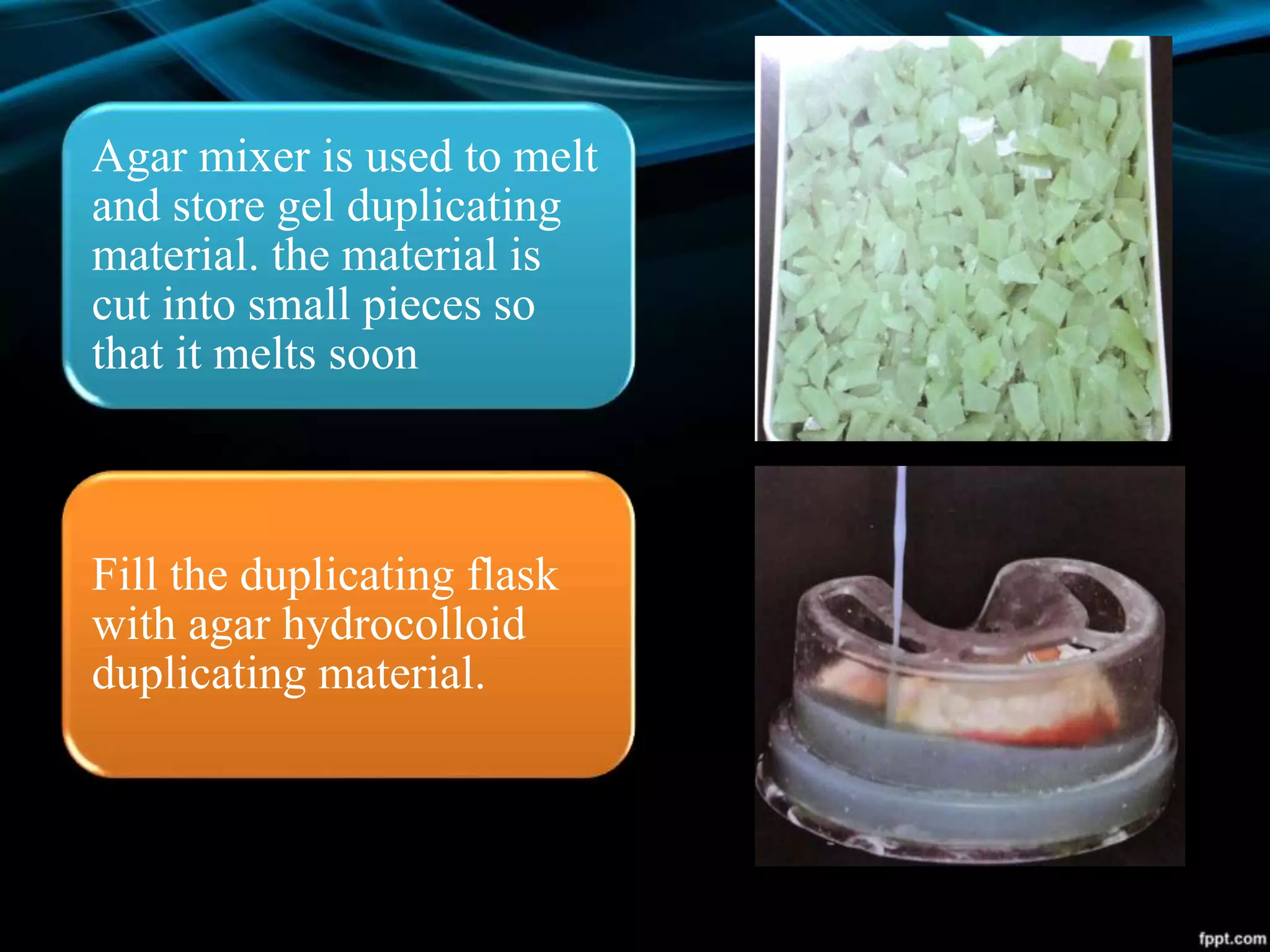

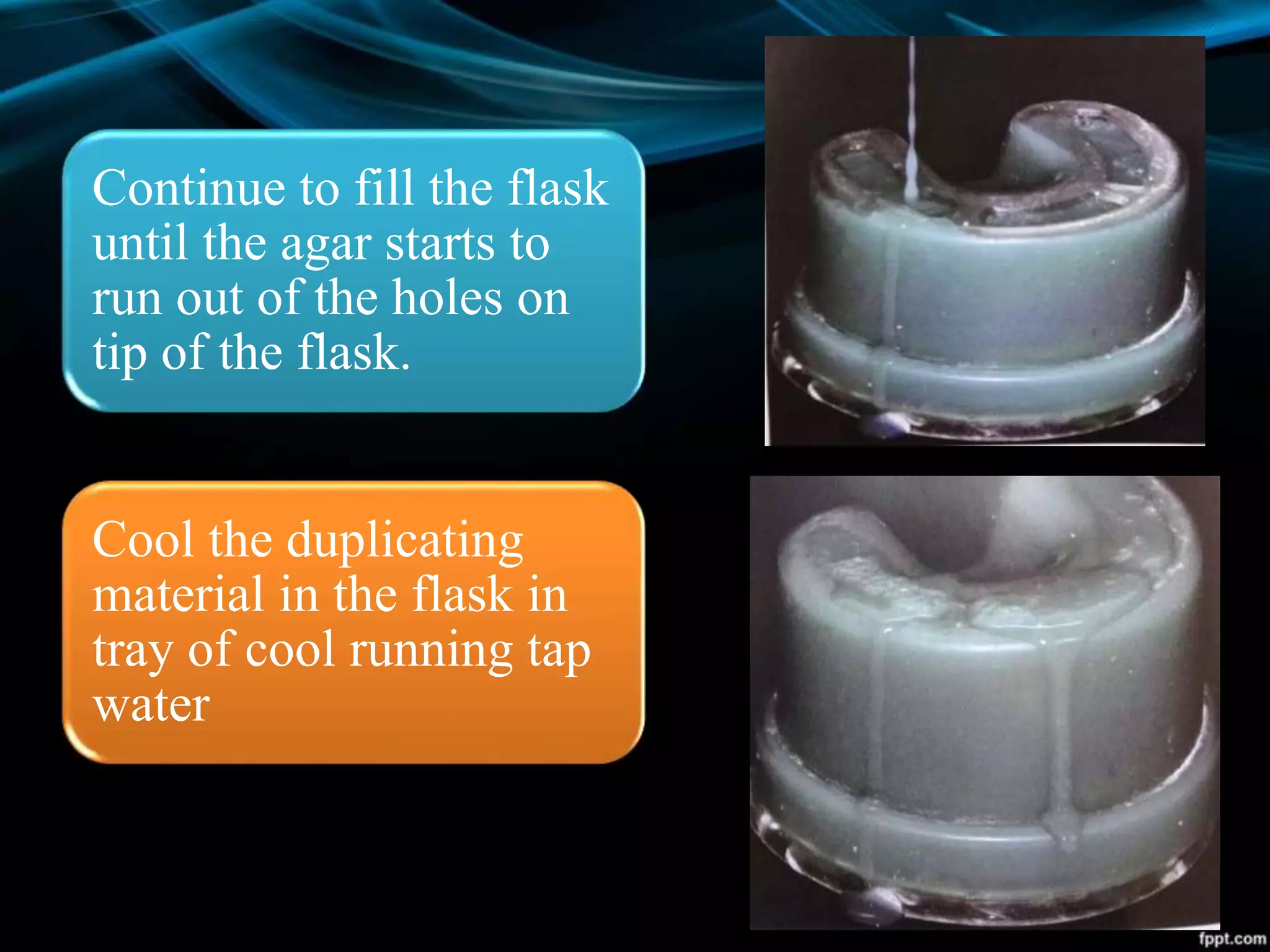

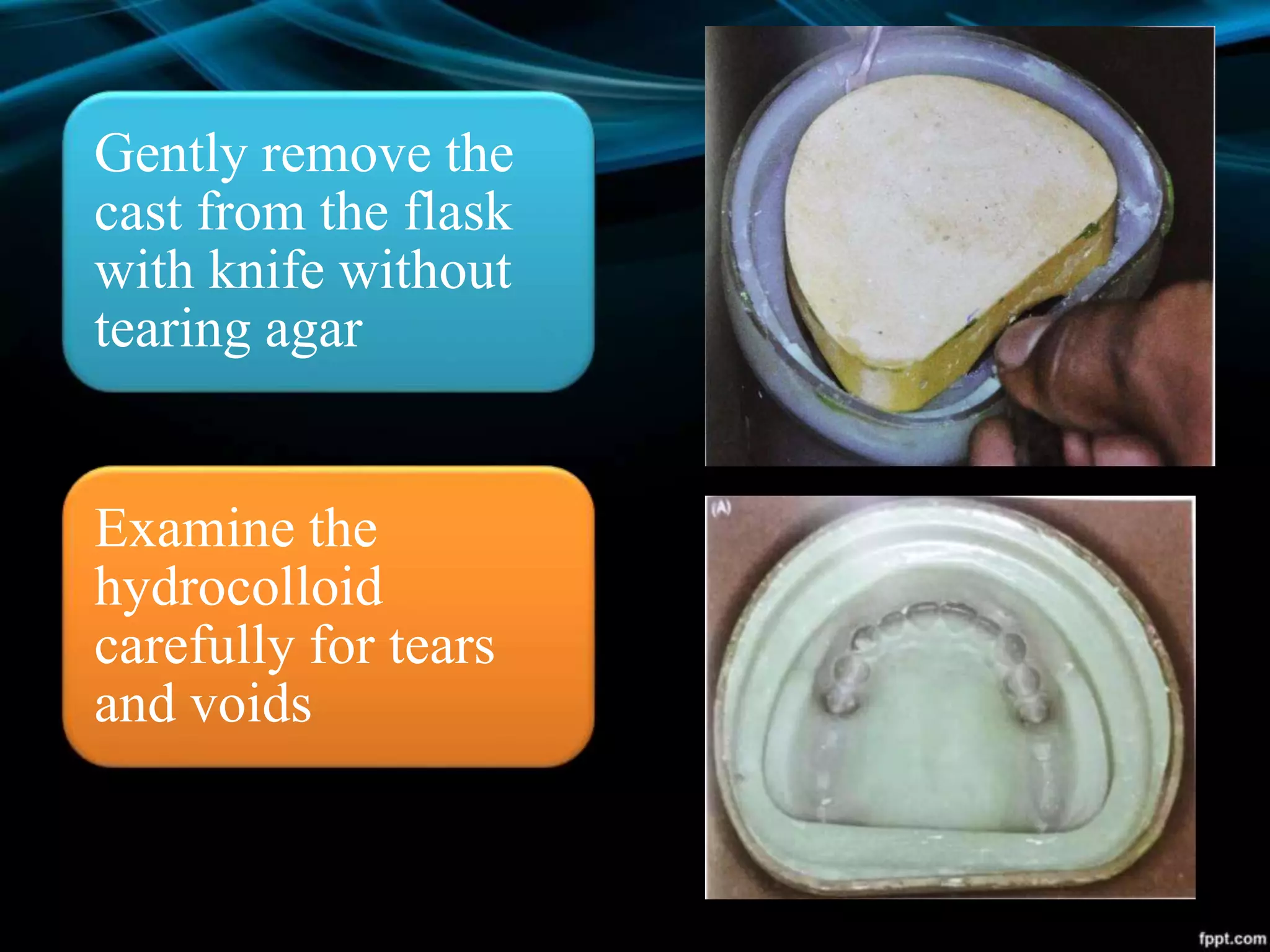

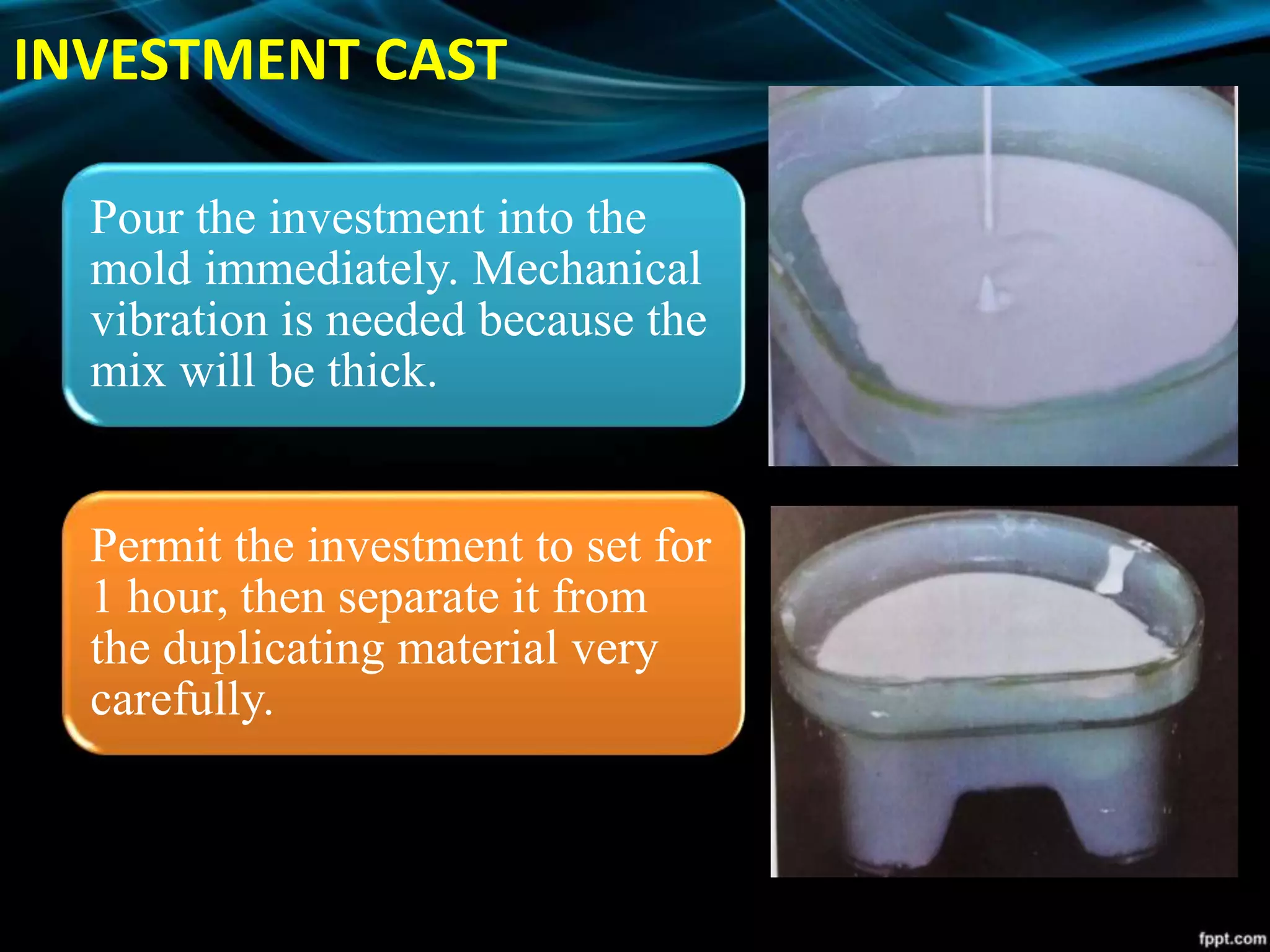

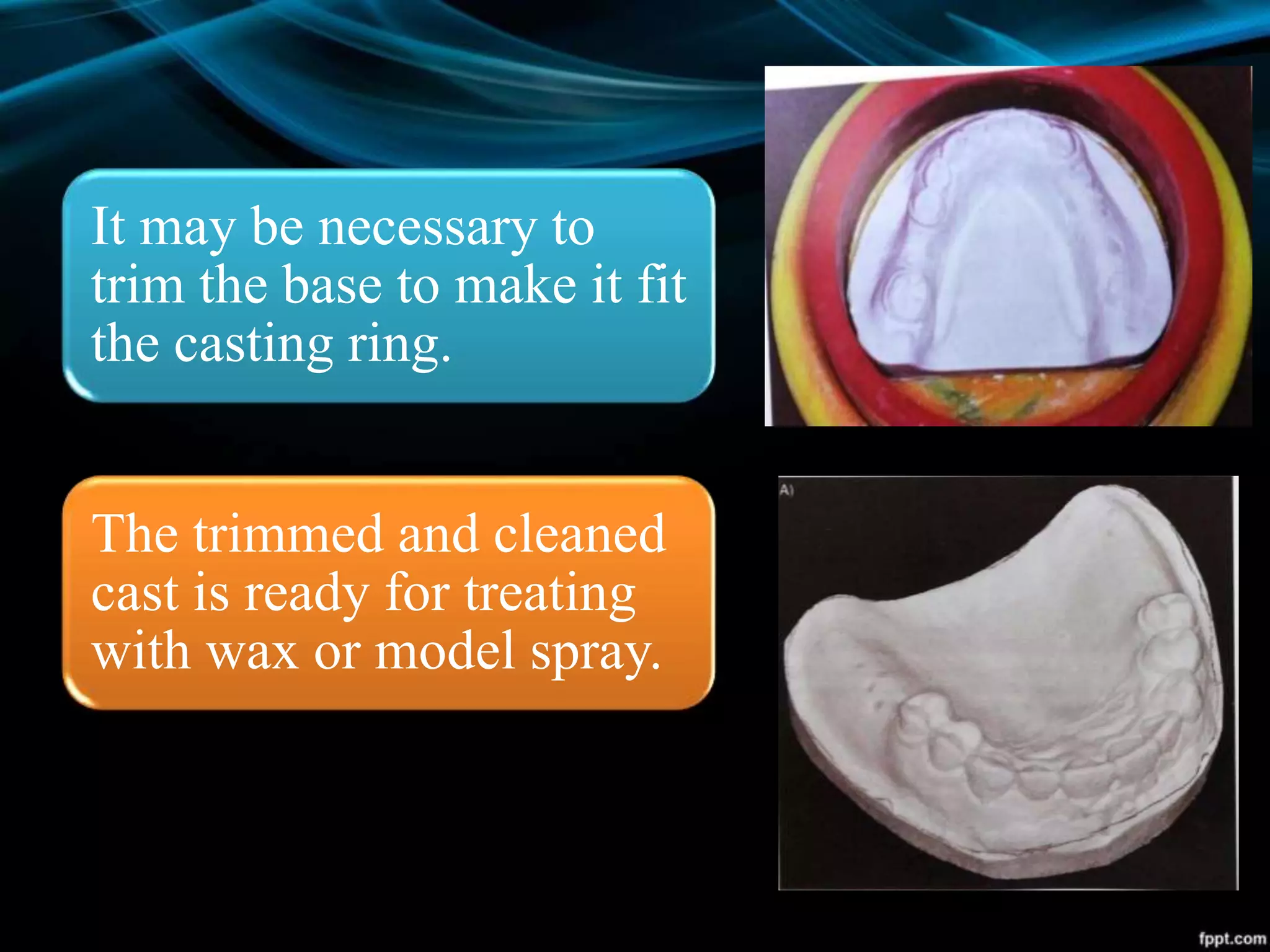

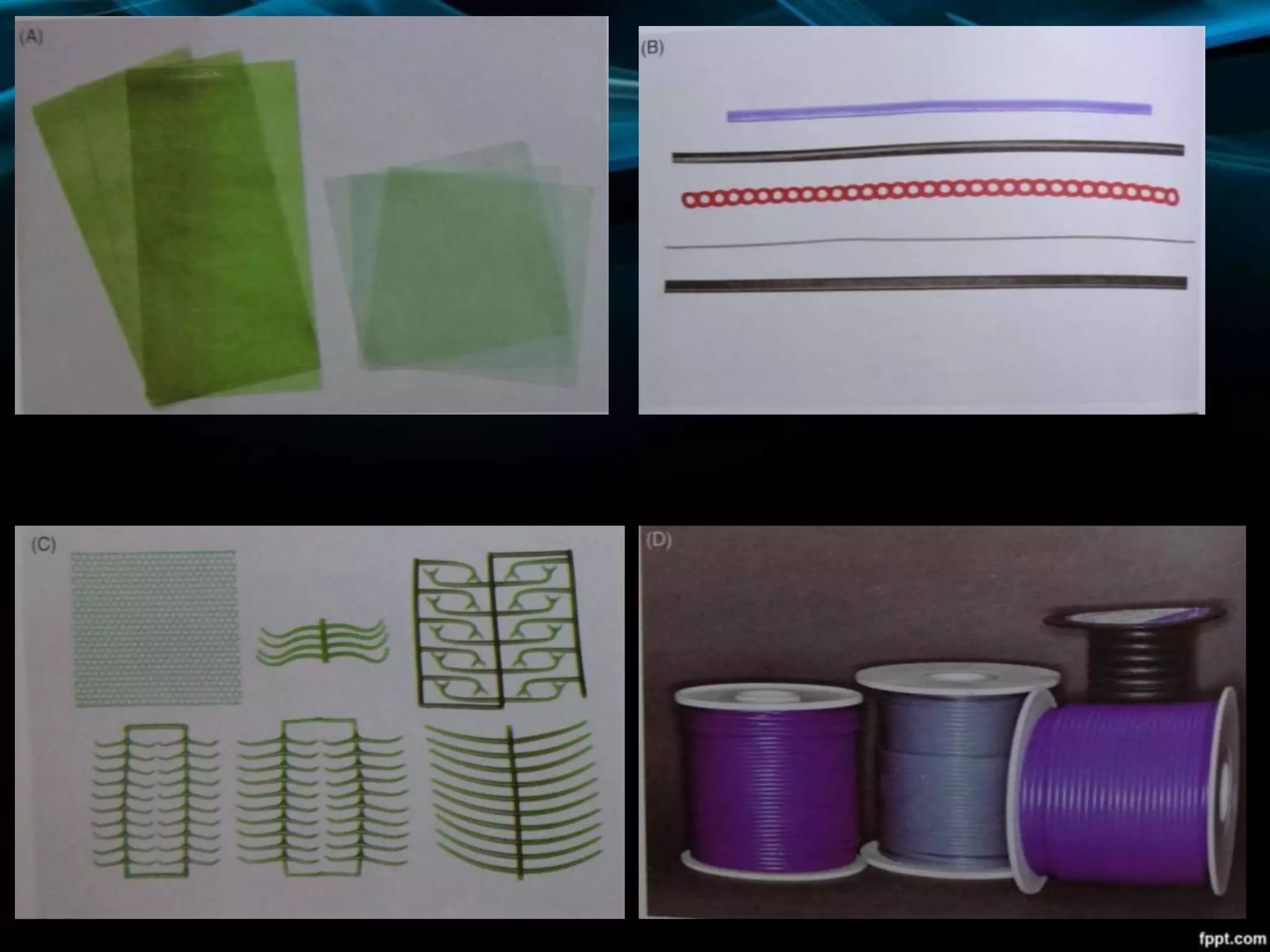

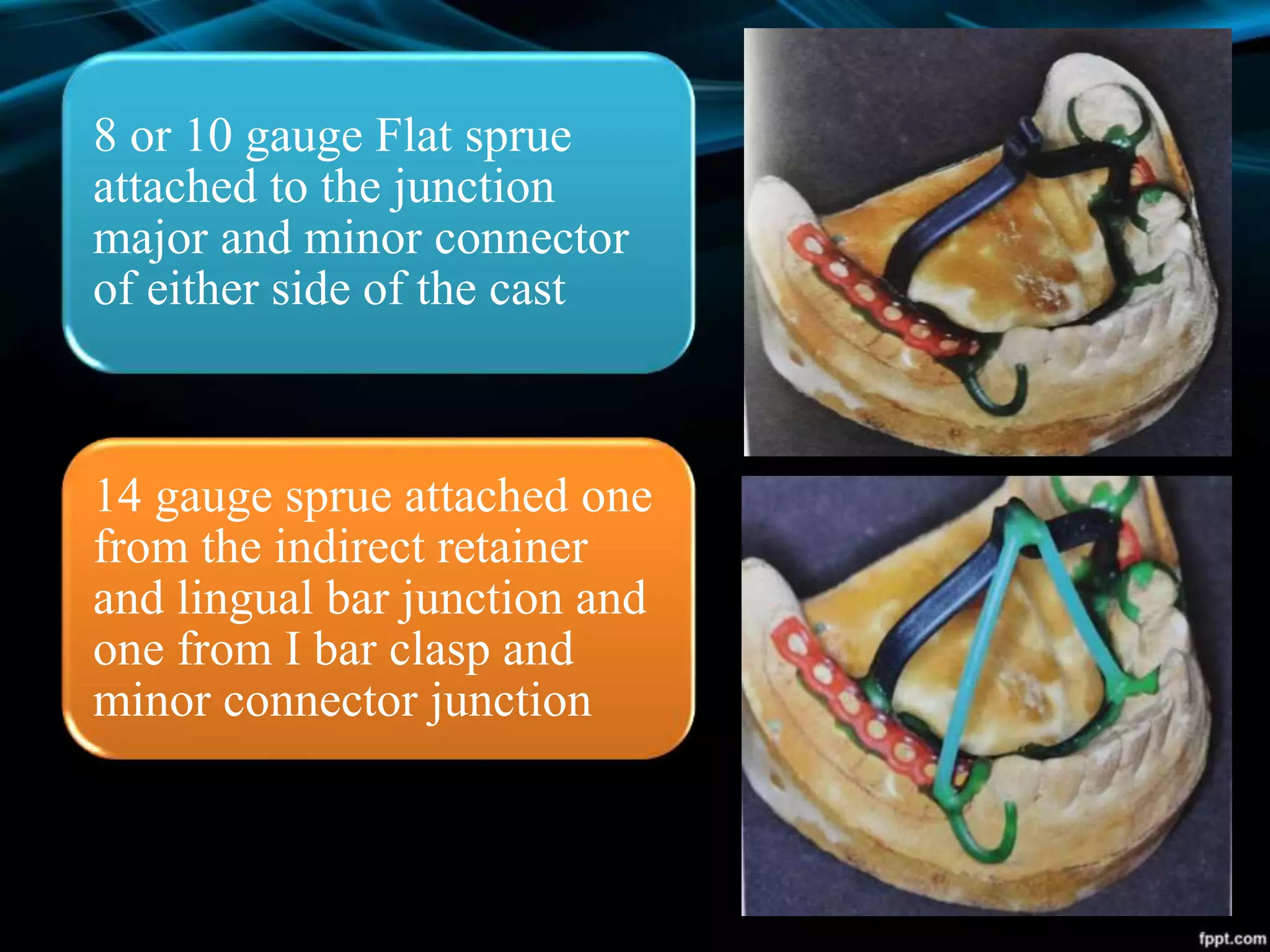

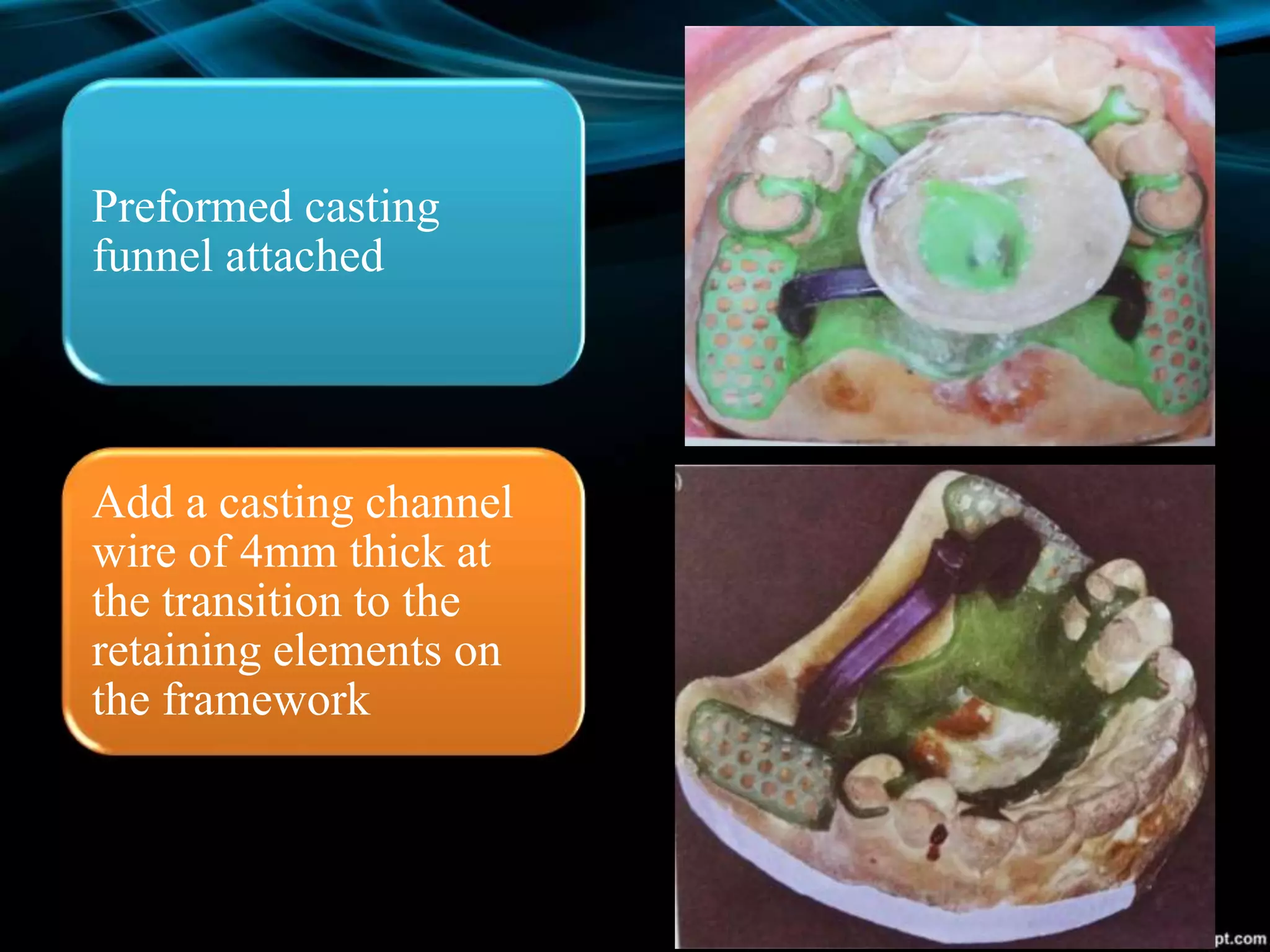

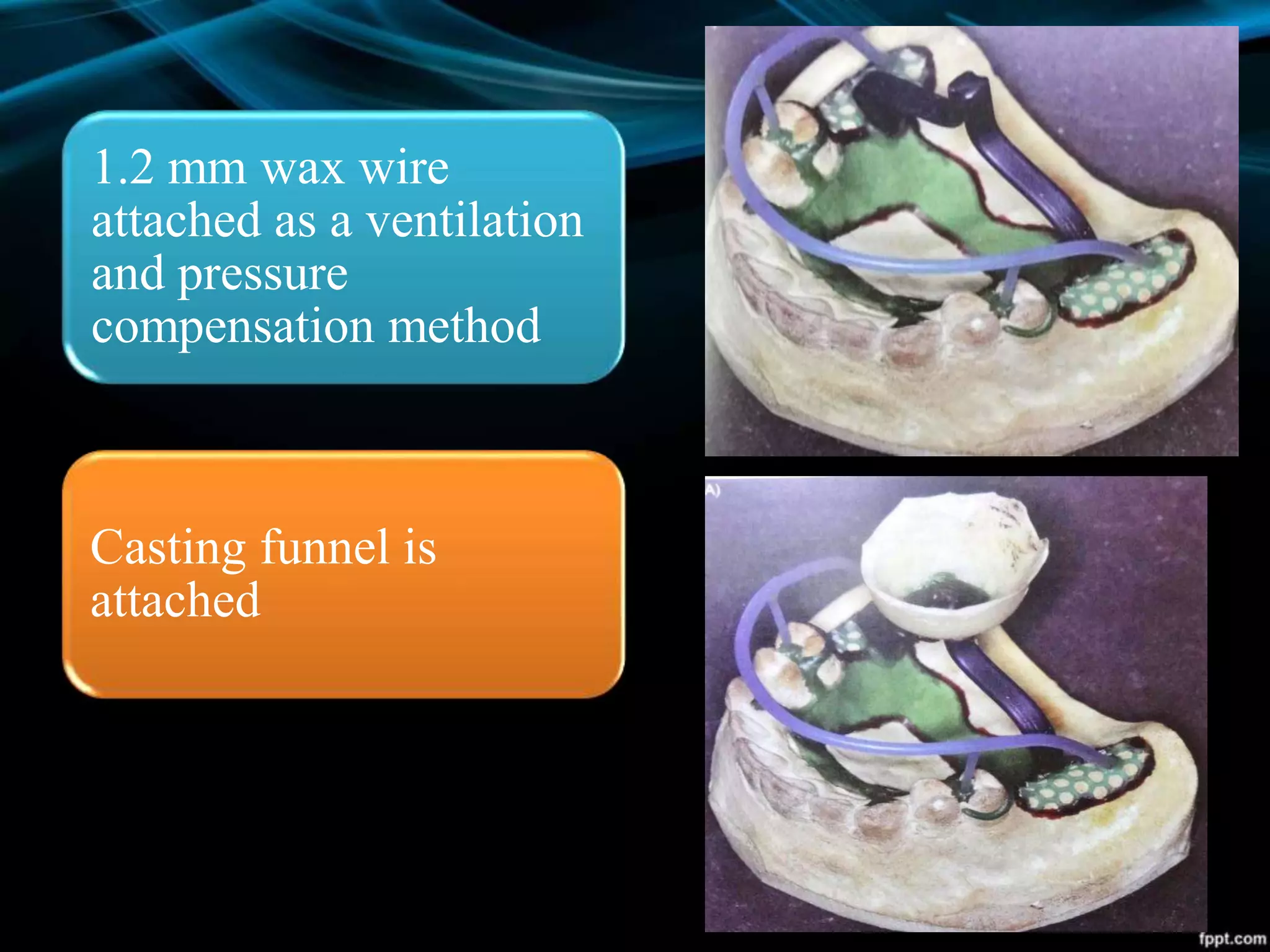

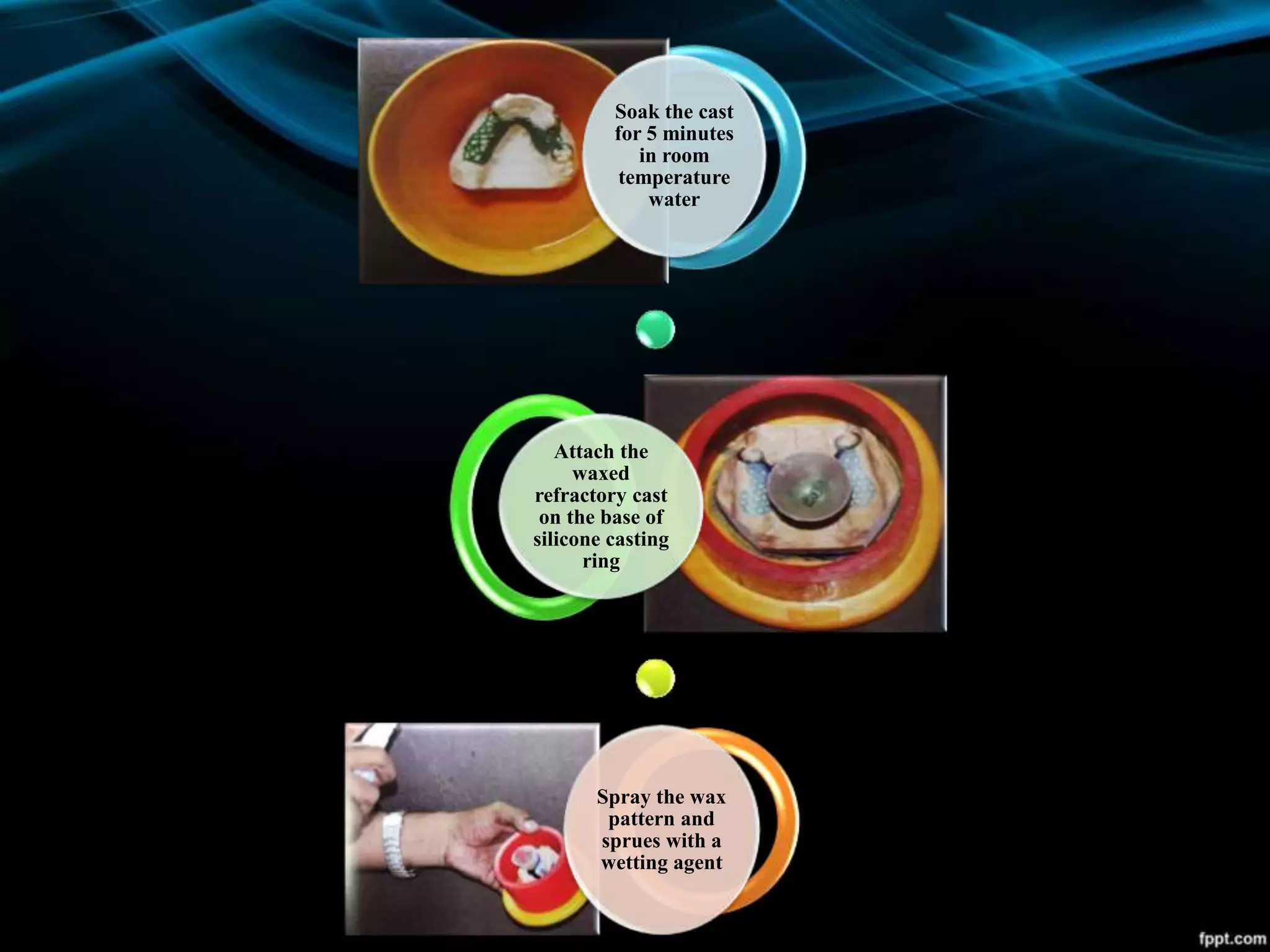

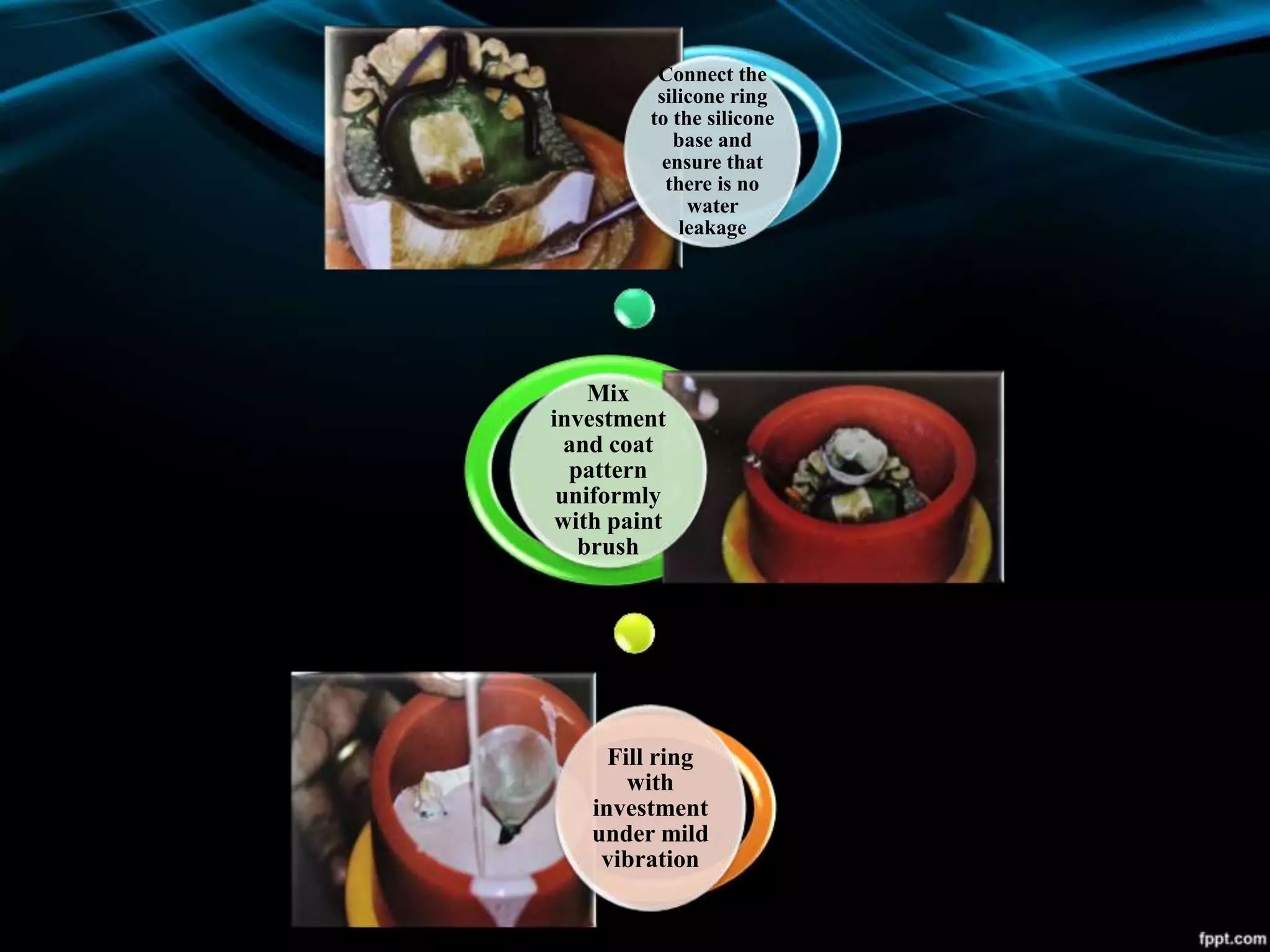

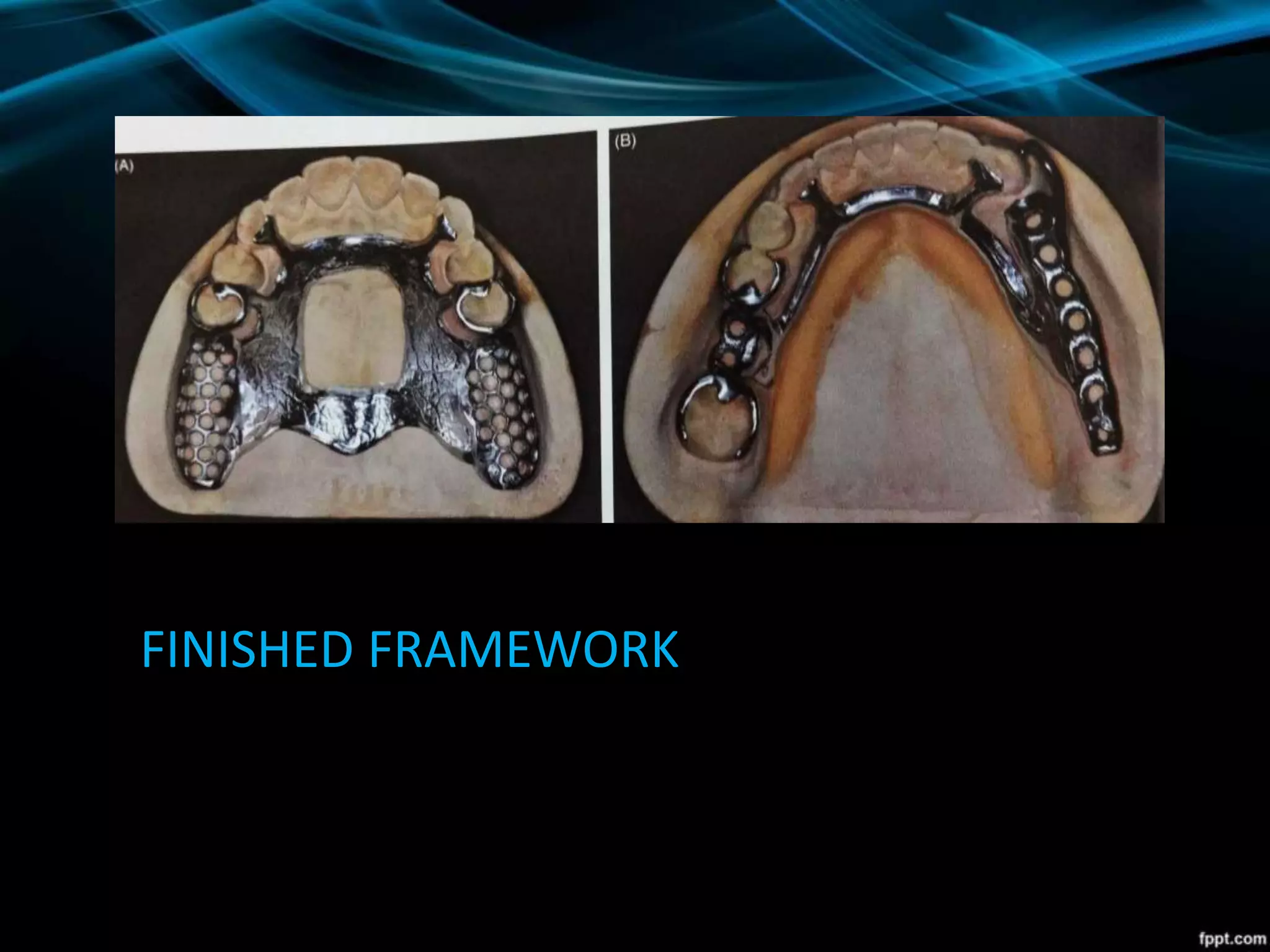

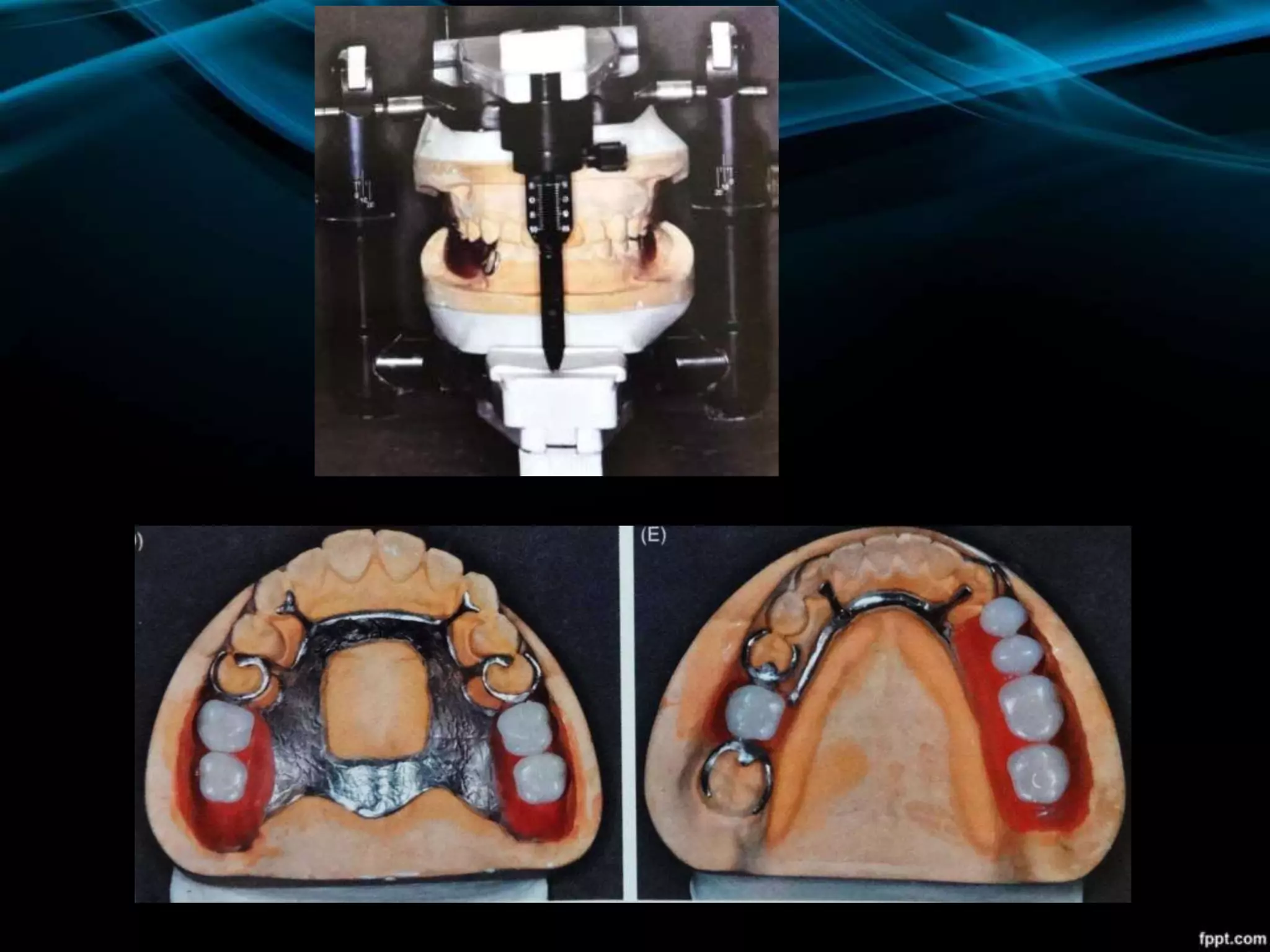

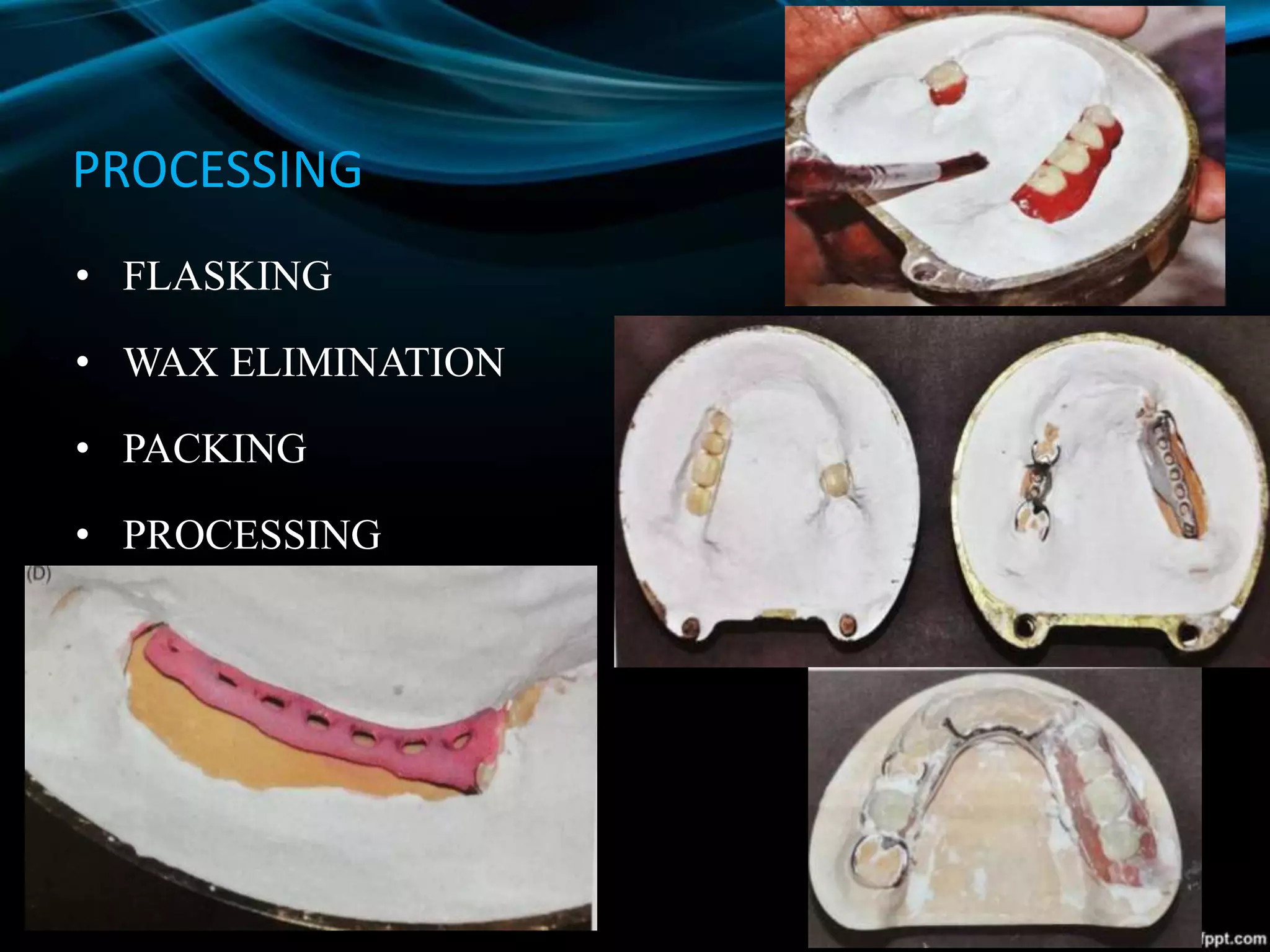

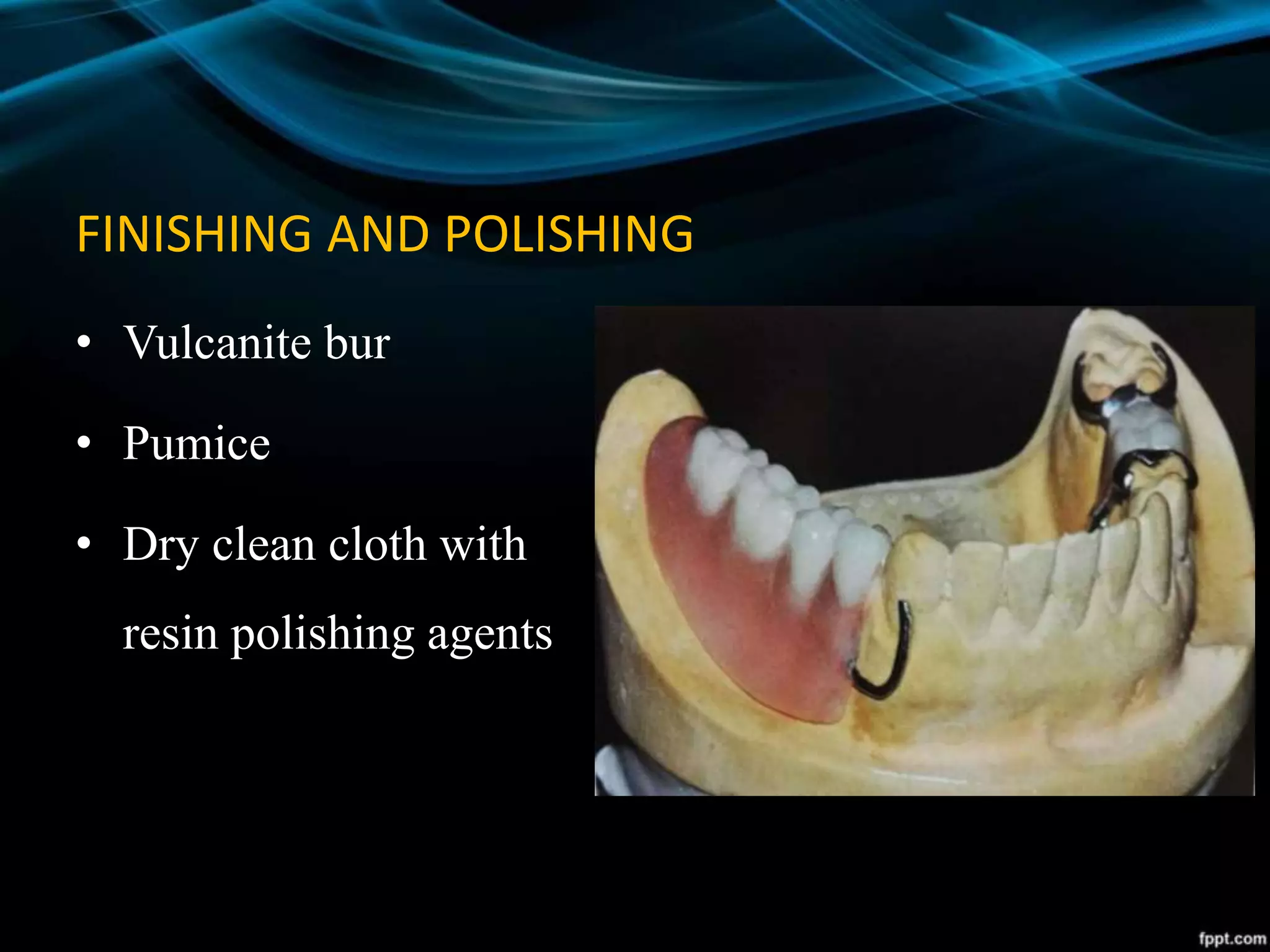

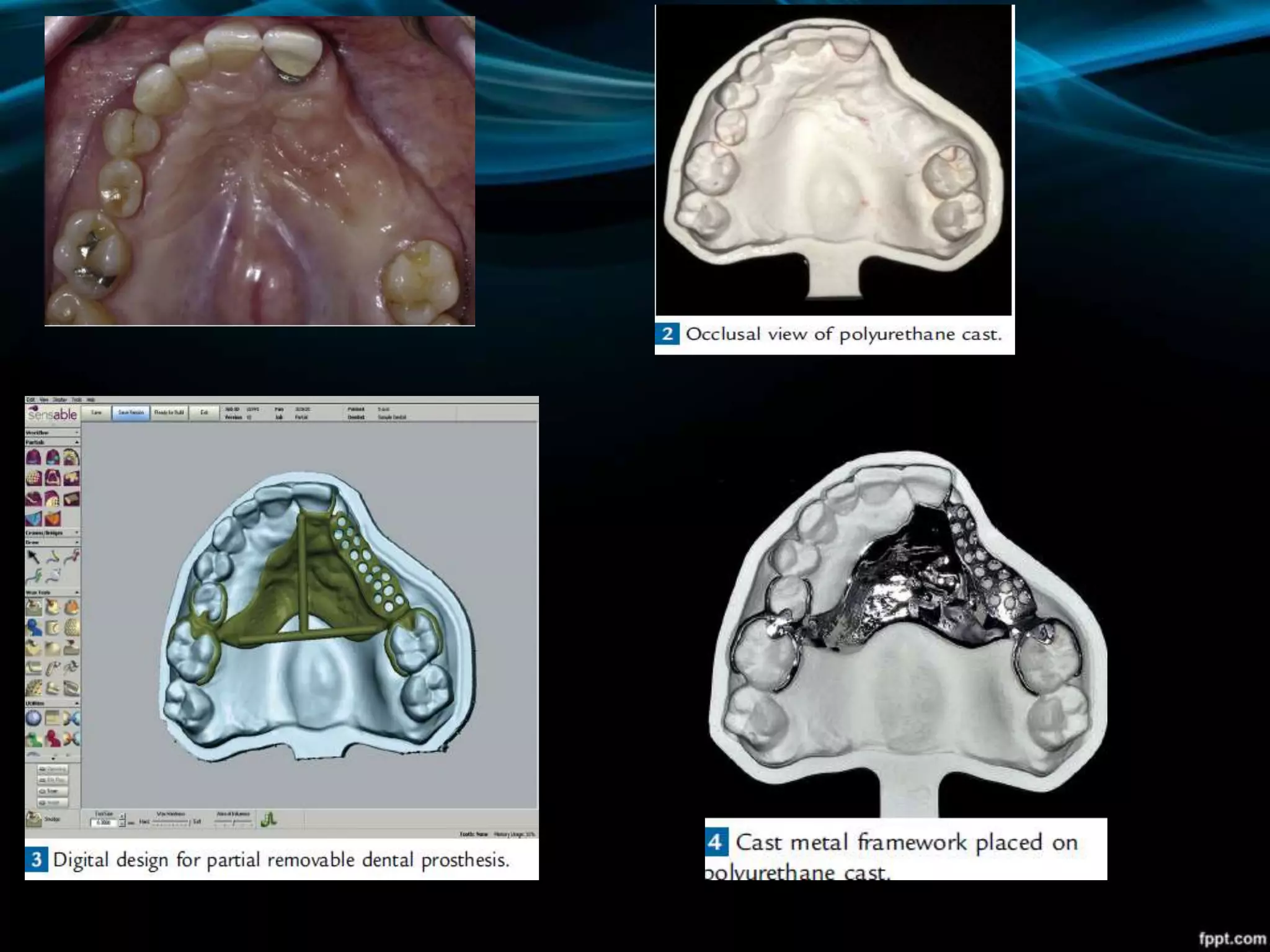

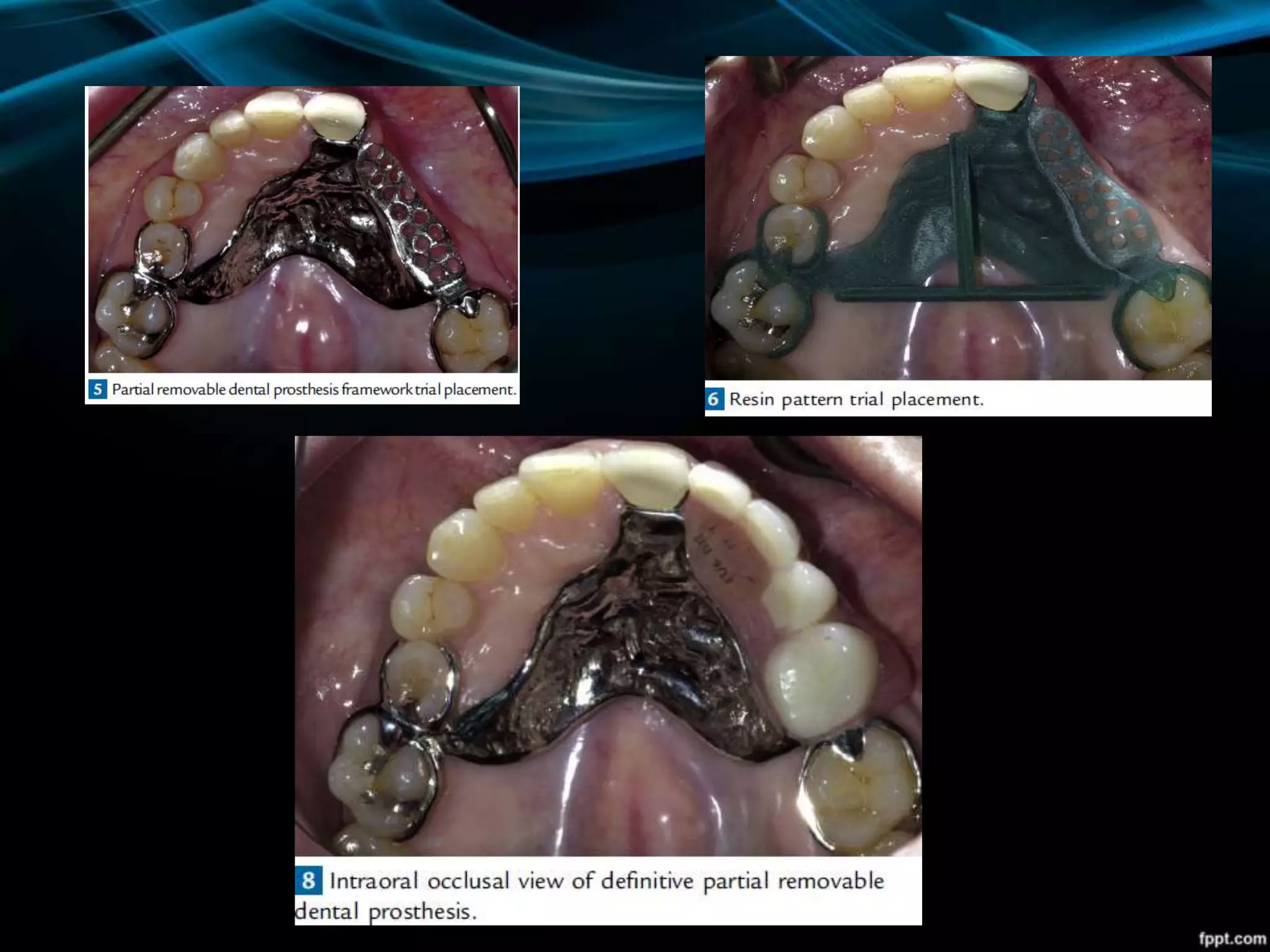

This document describes the laboratory procedures for fabricating a cast partial denture (CPD). It discusses making an accurate cast from the dental impression, including pouring, trimming, and correcting the cast. It also covers surveying the cast to determine the denture design, blocking out undercuts, duplicating the cast in refractory material, and waxing up the denture framework on the duplicated cast. The goal is to produce an accurate cast from which a well-fitting CPD can be fabricated following standardized laboratory techniques.