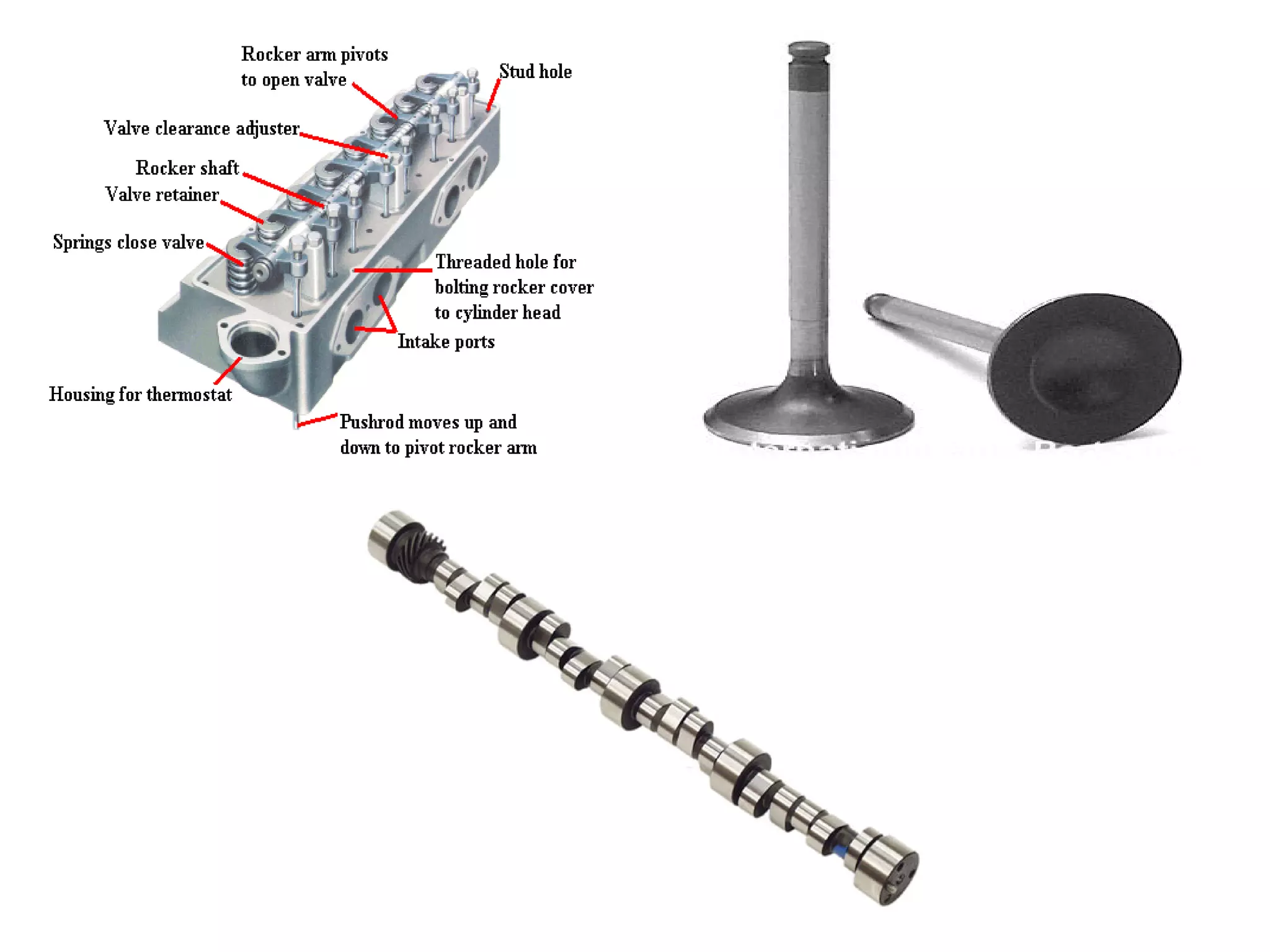

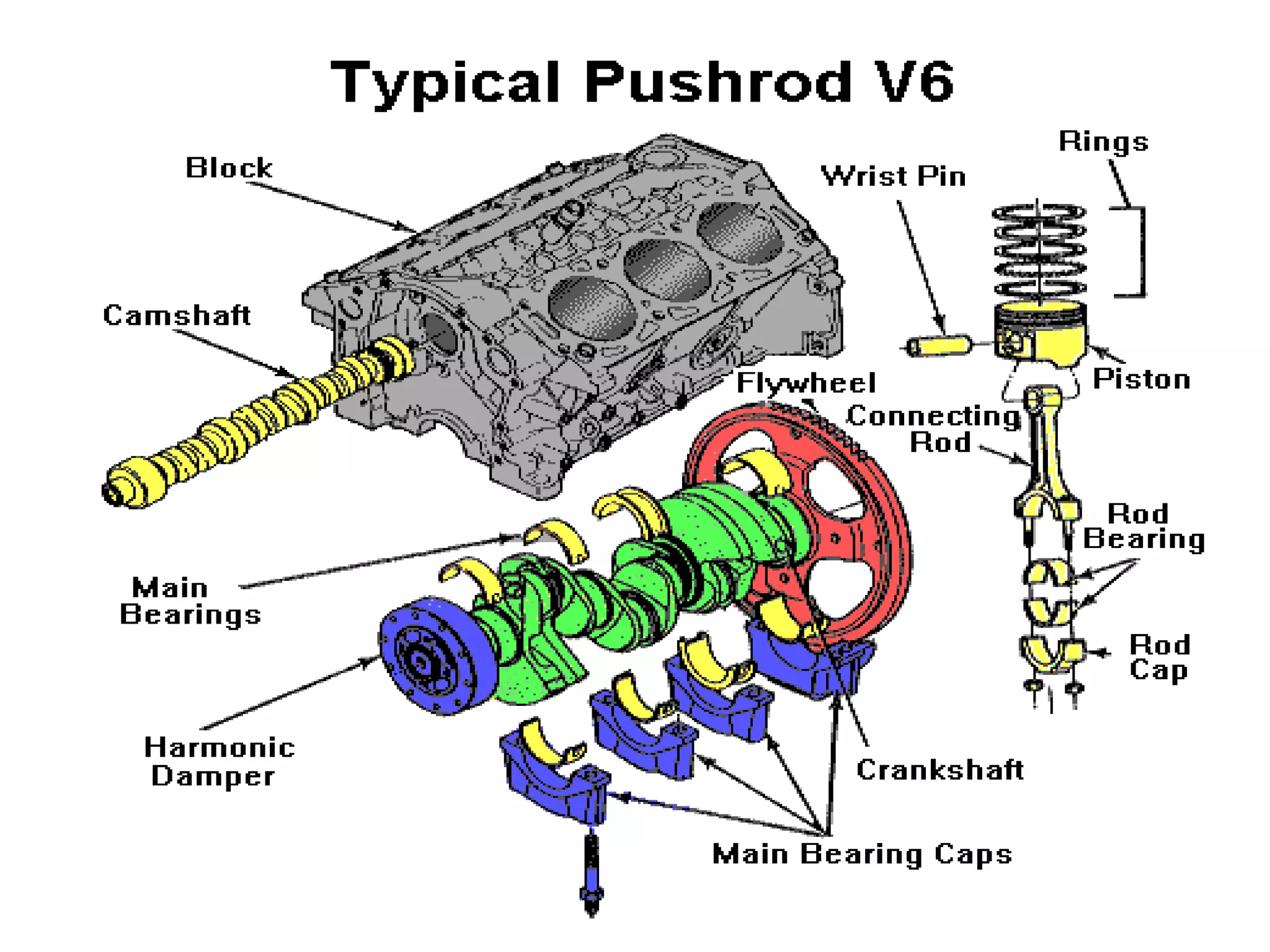

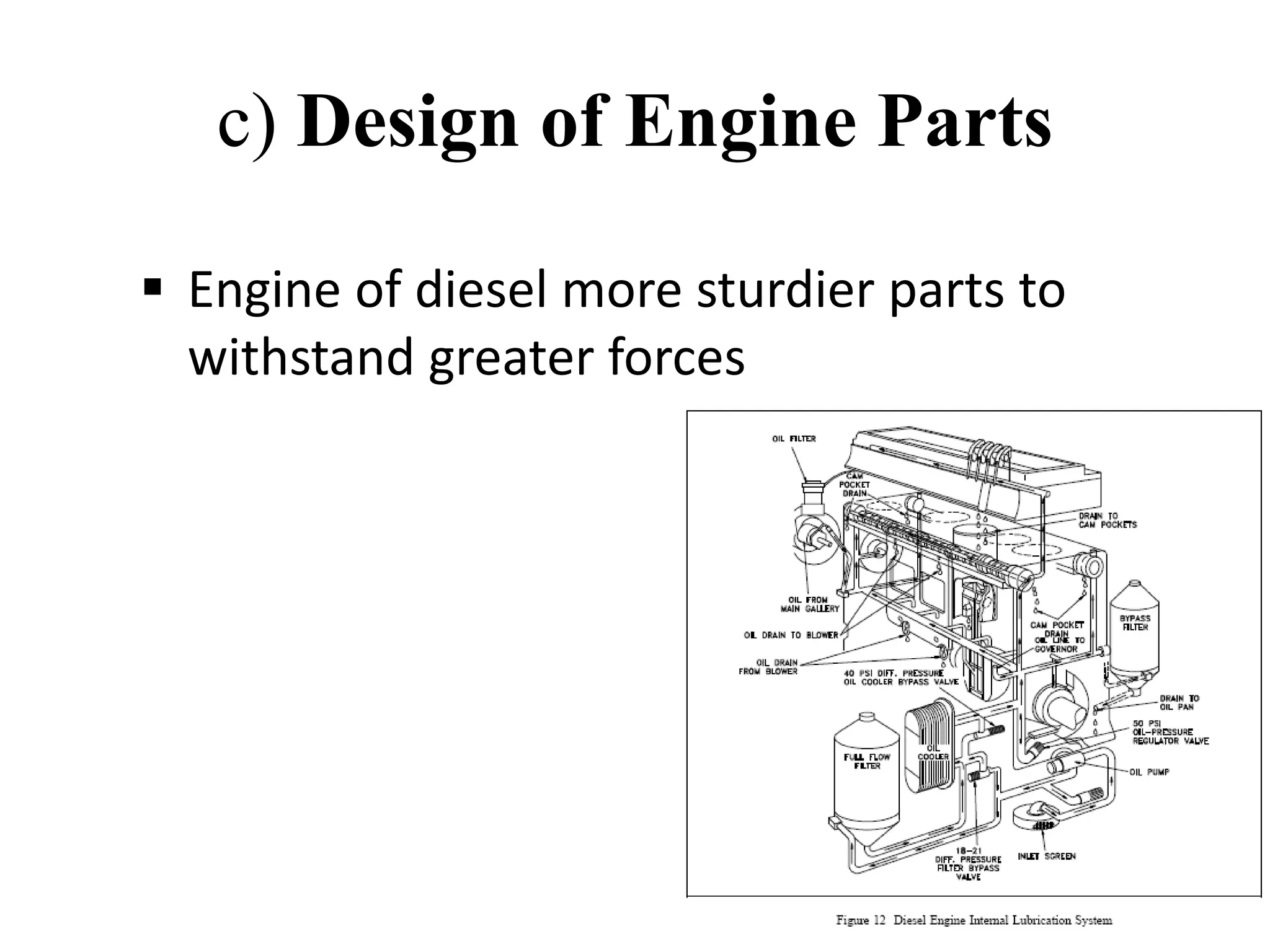

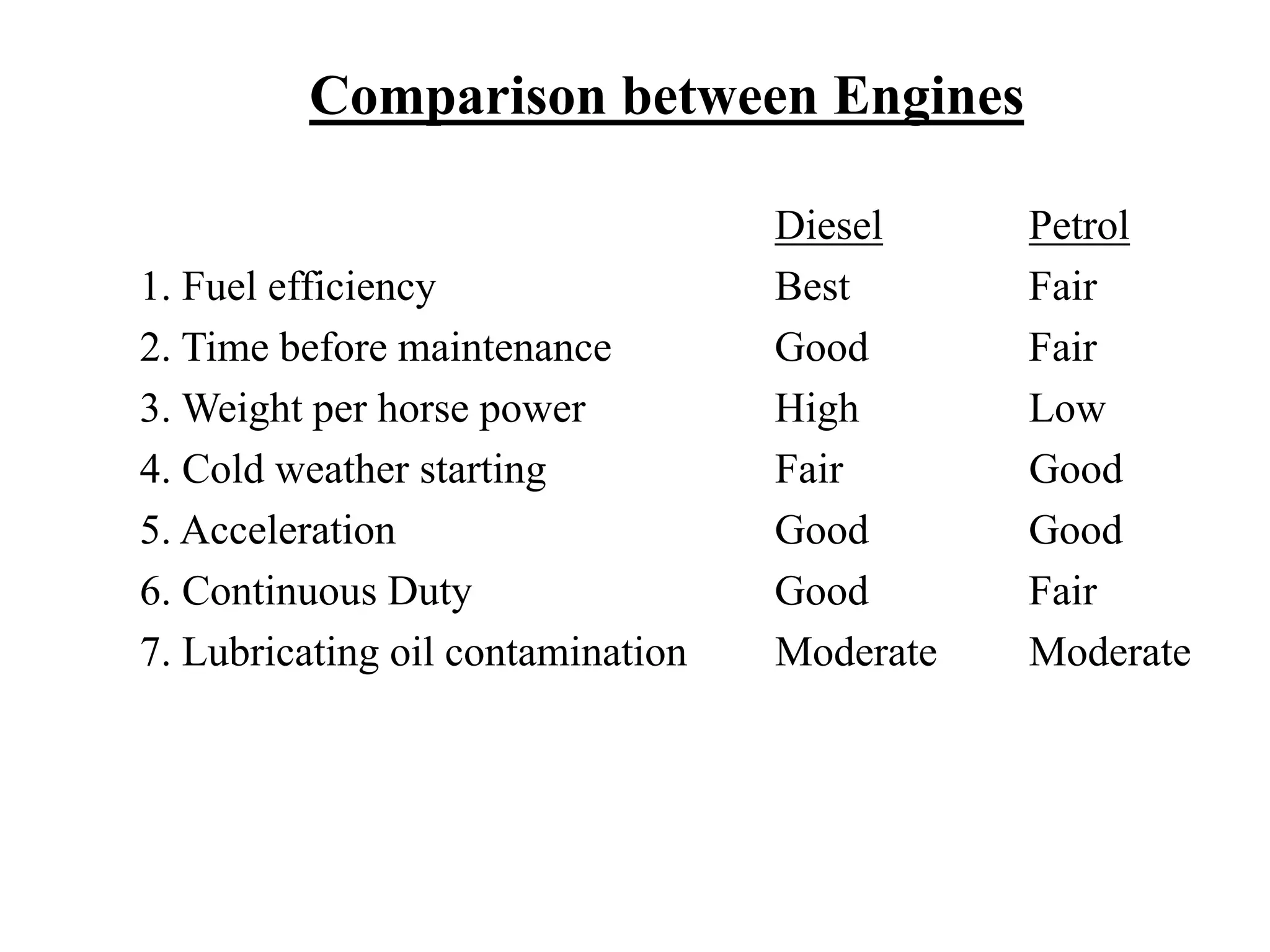

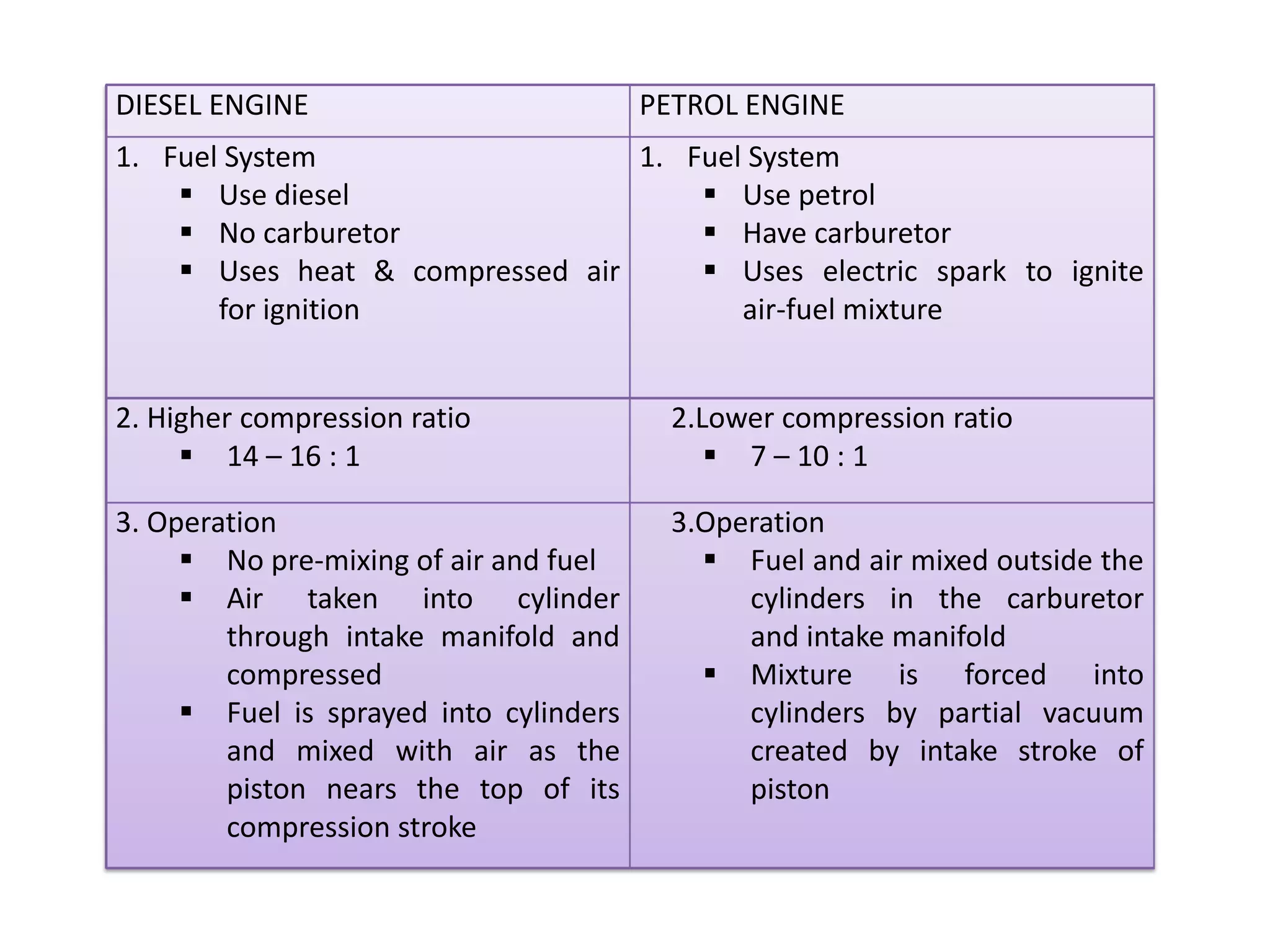

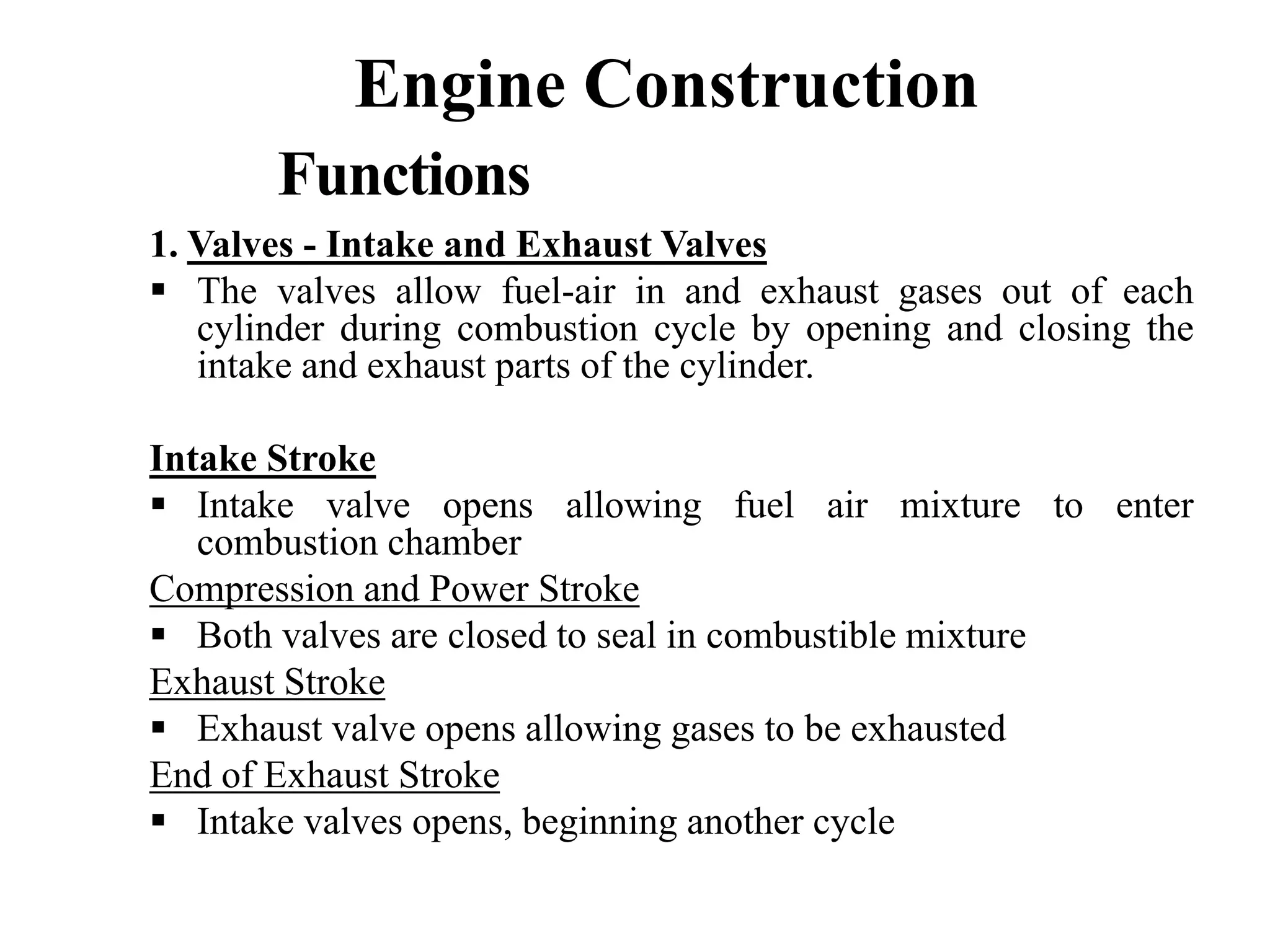

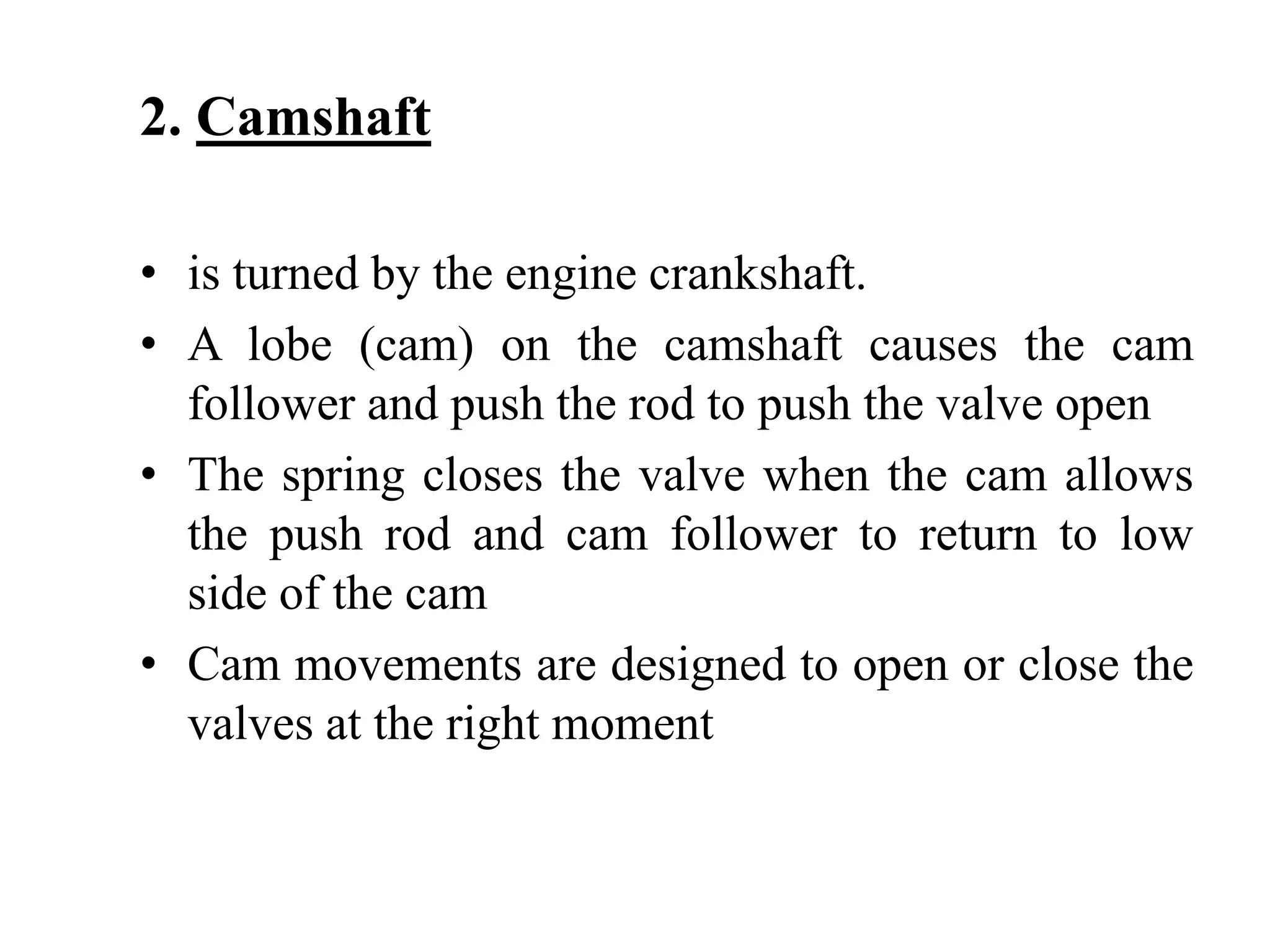

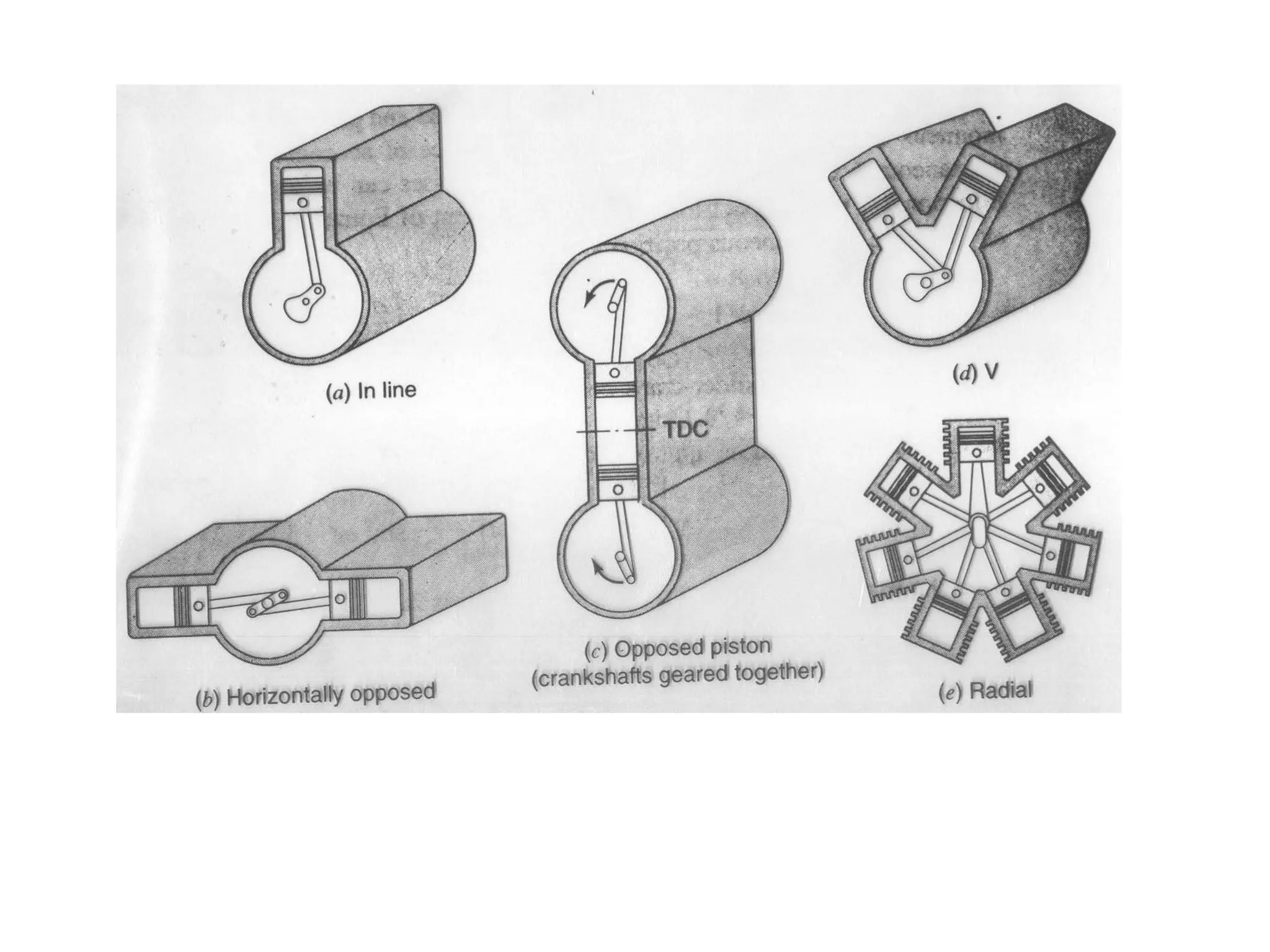

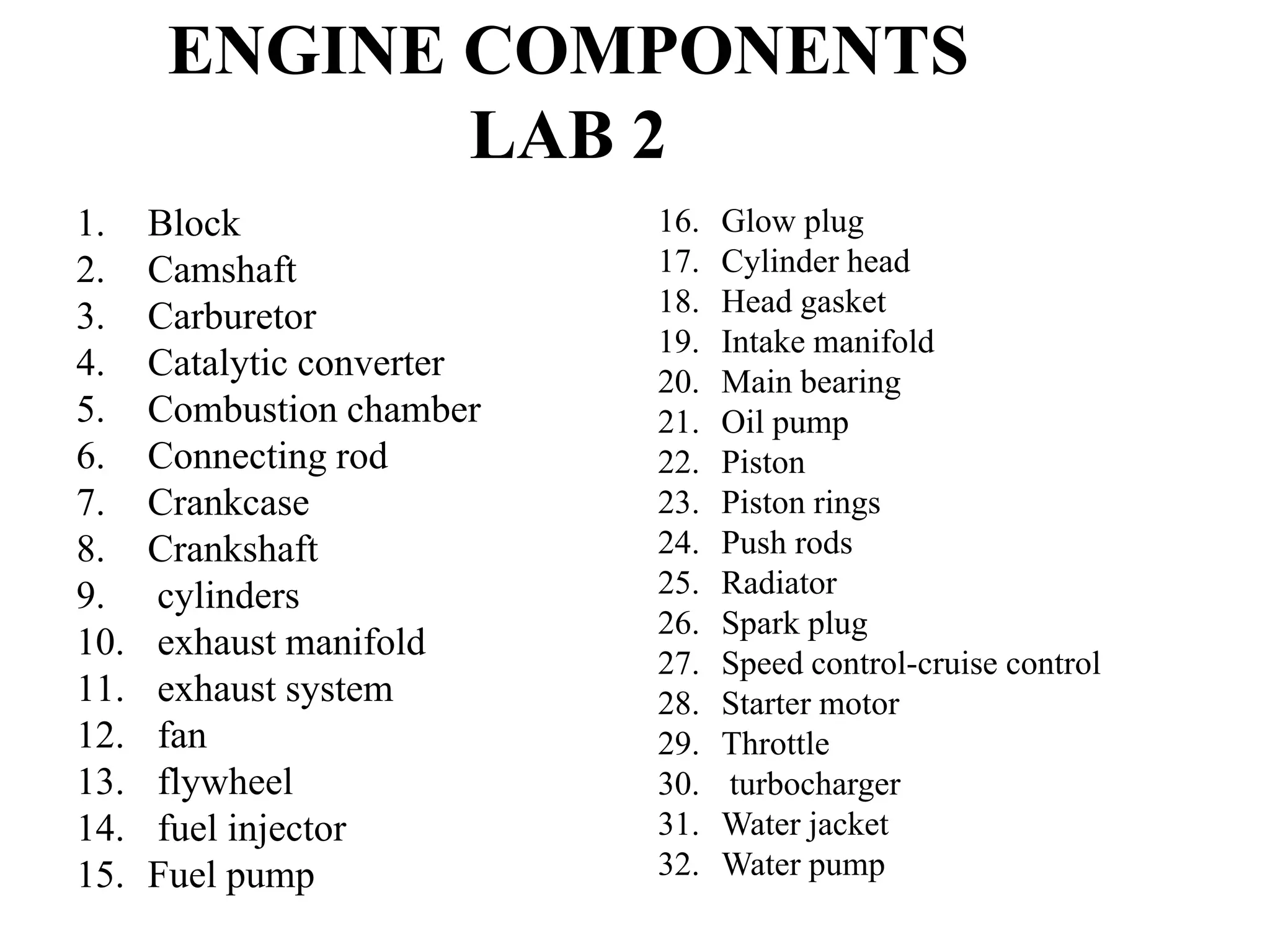

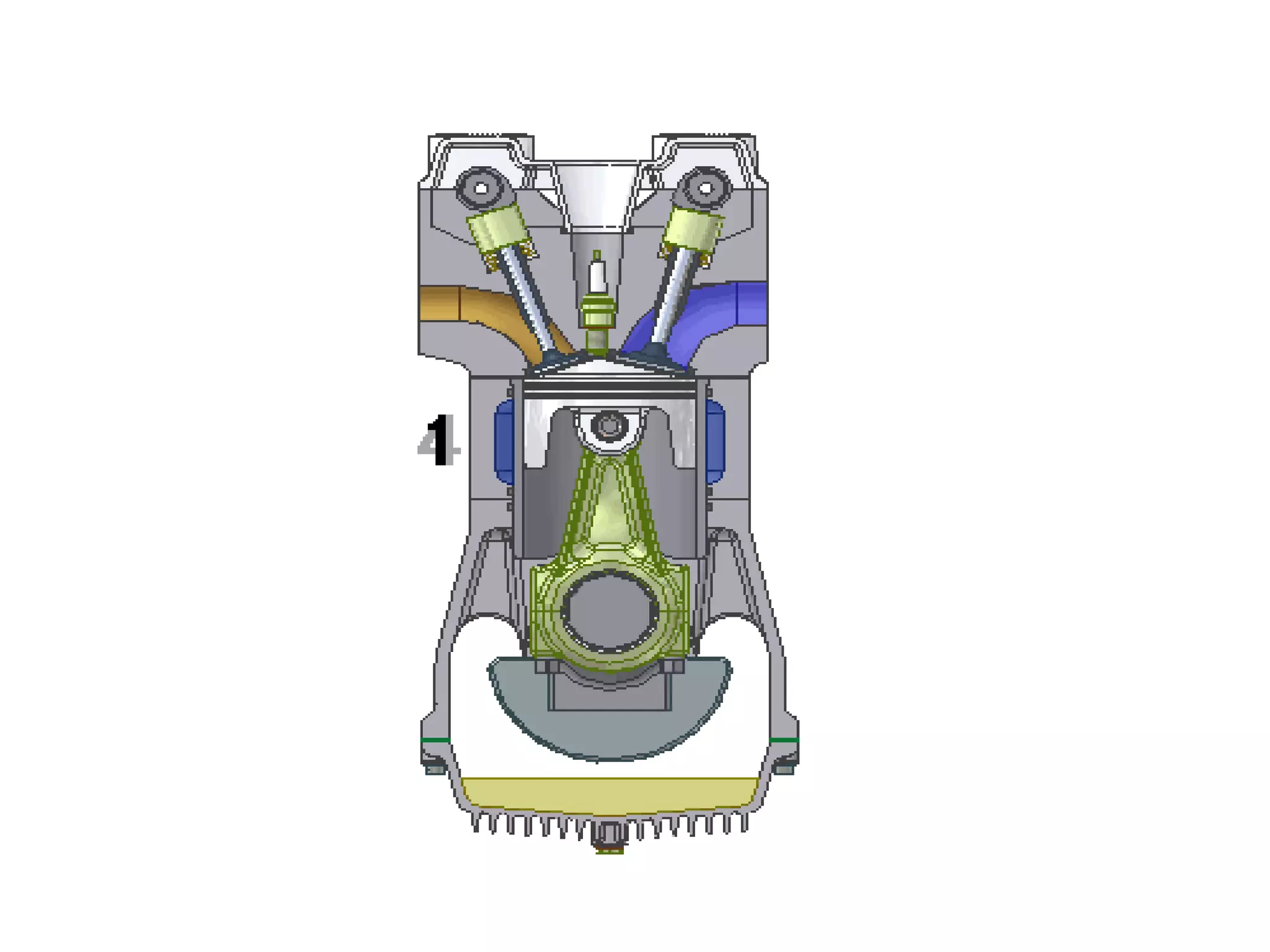

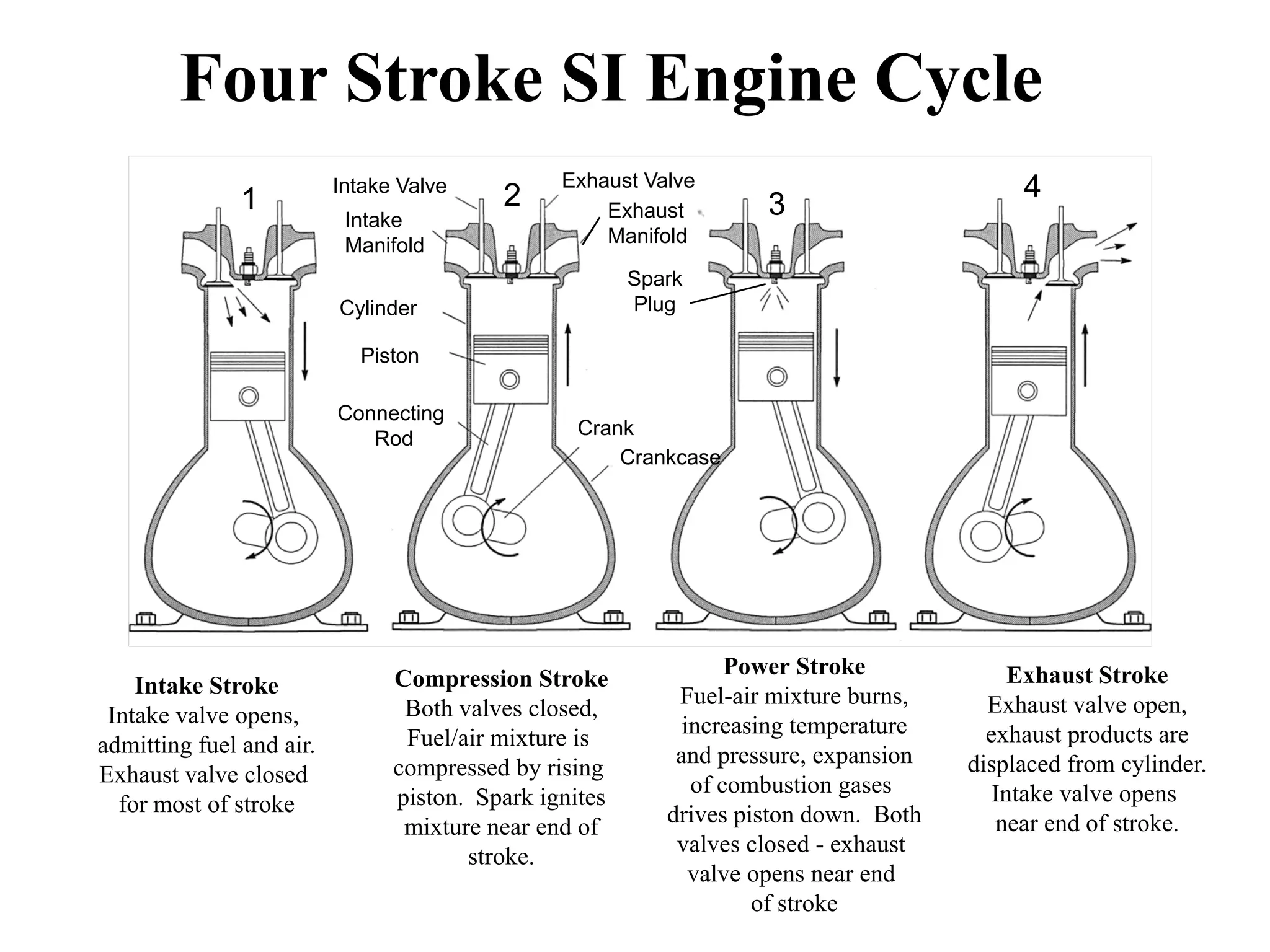

The document provides information about the basic parts of an internal combustion engine. It lists and describes the main components including the cylinder head, valves, camshaft, cylinder block, cylinders, piston, connecting rods, crankshaft, main bearings, flywheel, and timing drives. It explains their functions and how they work together in the engine combustion cycle.