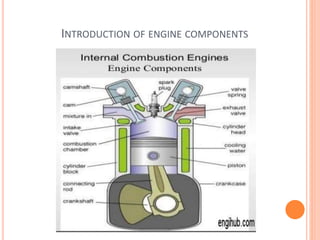

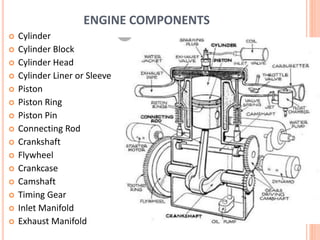

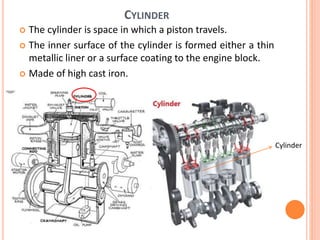

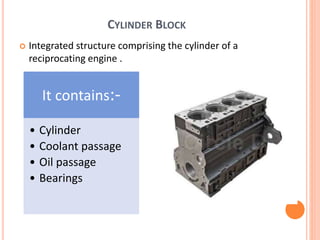

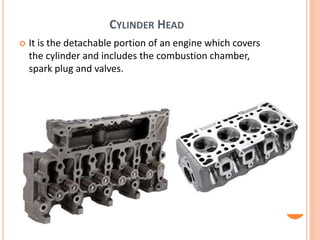

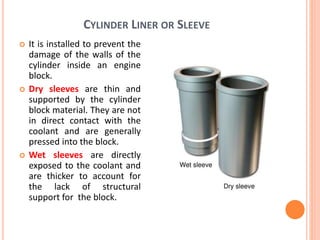

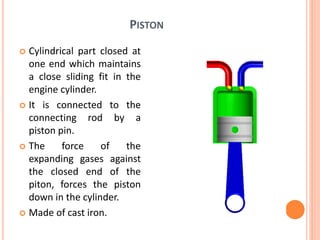

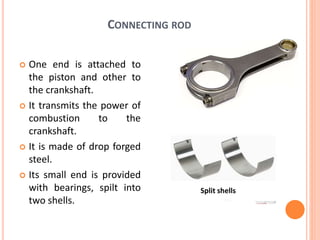

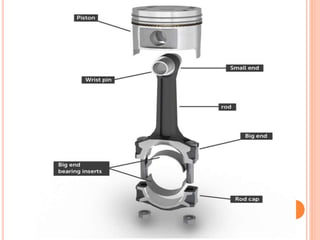

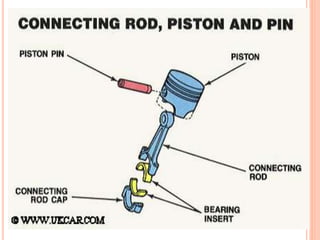

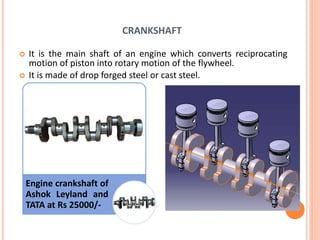

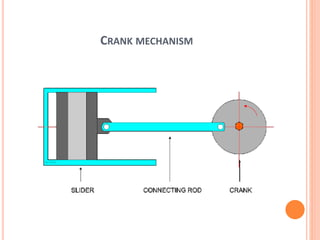

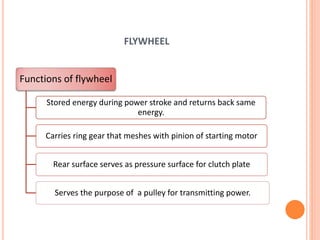

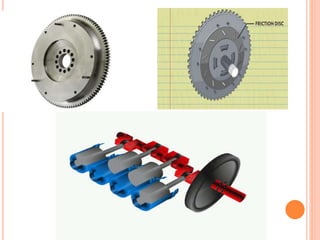

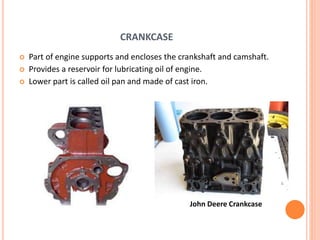

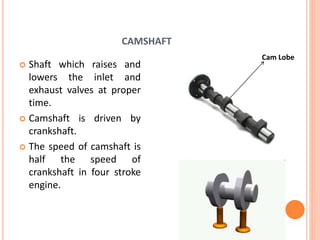

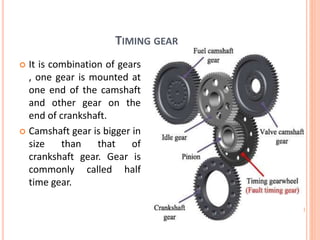

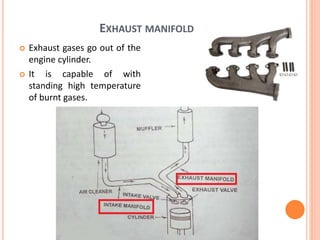

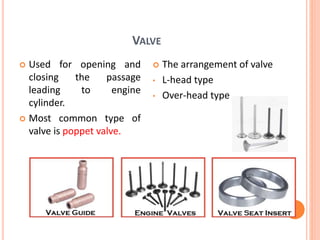

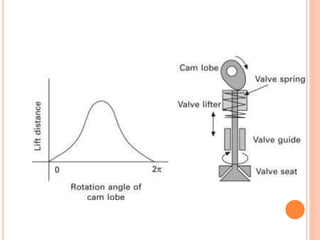

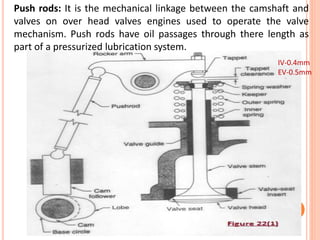

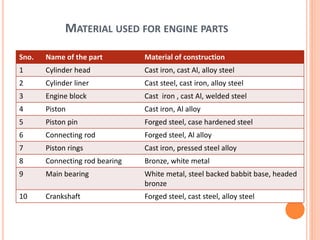

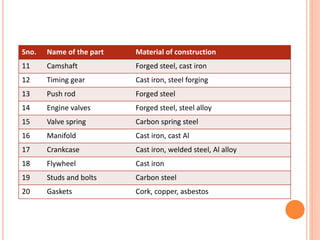

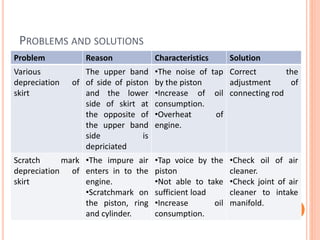

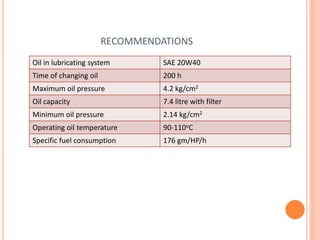

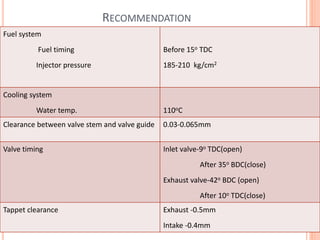

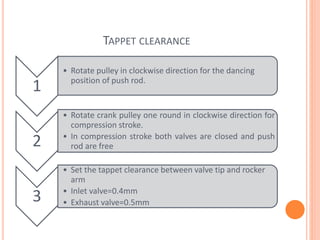

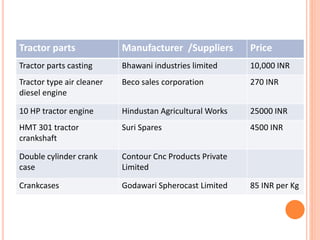

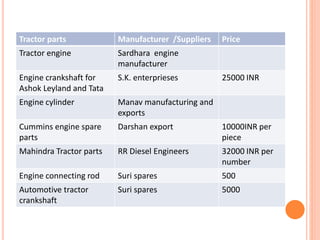

This document provides an overview of the key components of an internal combustion engine. It describes the purpose and basic design of major engine parts including the cylinder, piston, connecting rod, crankshaft, camshaft, valves, manifolds, and others. It also discusses common engine materials, recommended specifications for things like oil pressure and temperature, and lists local manufacturers and prices for tractor engine parts in India.