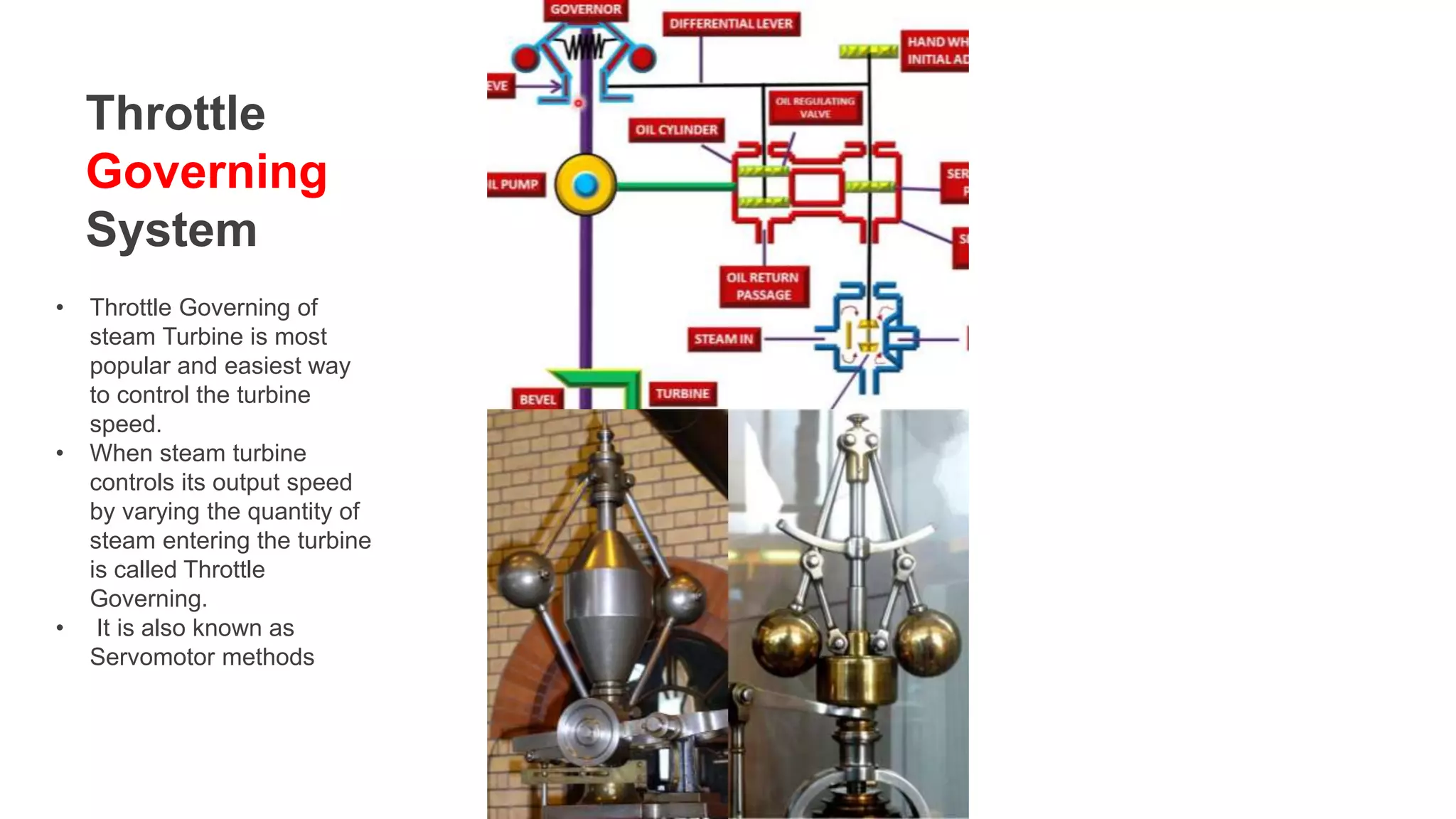

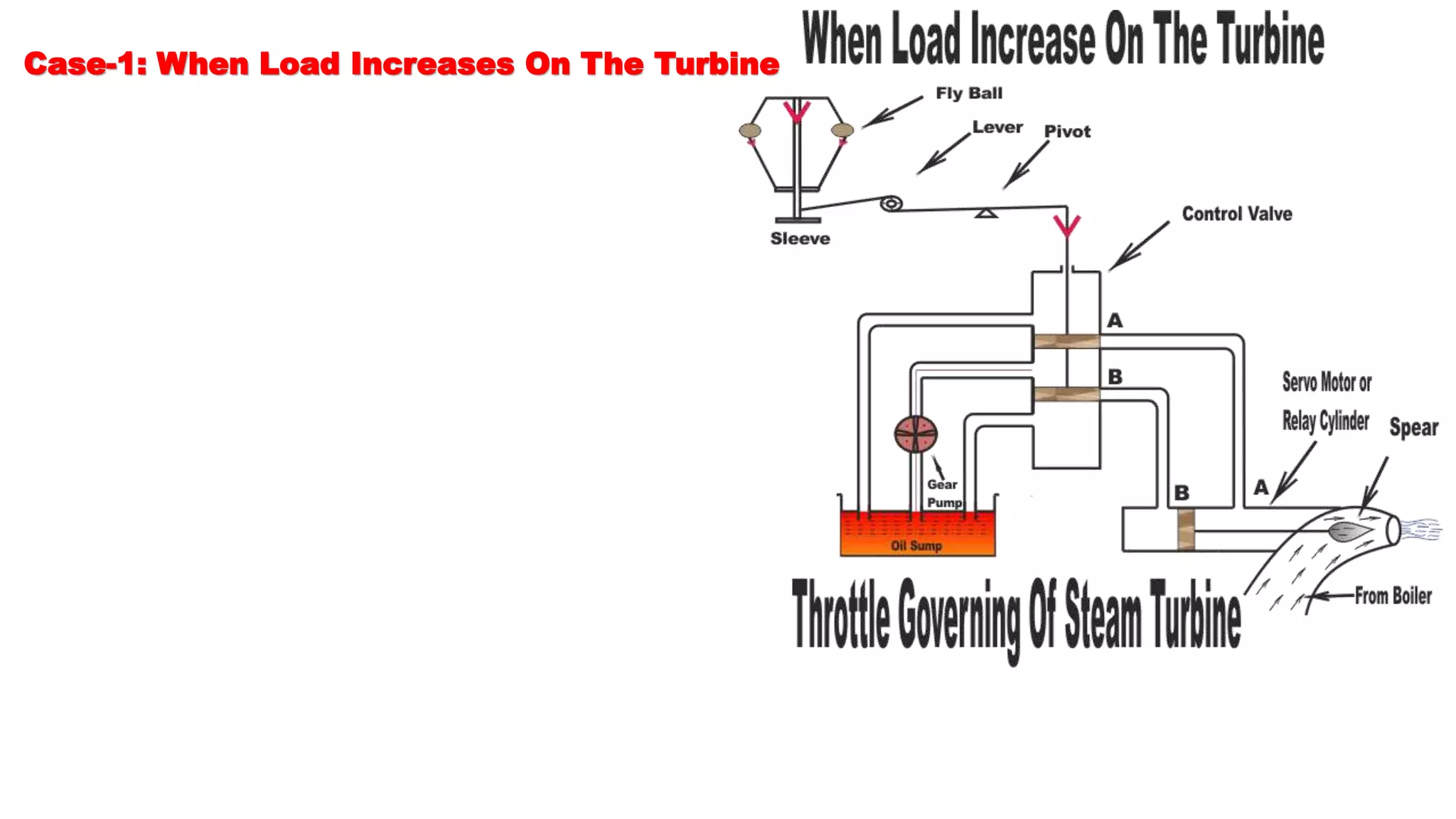

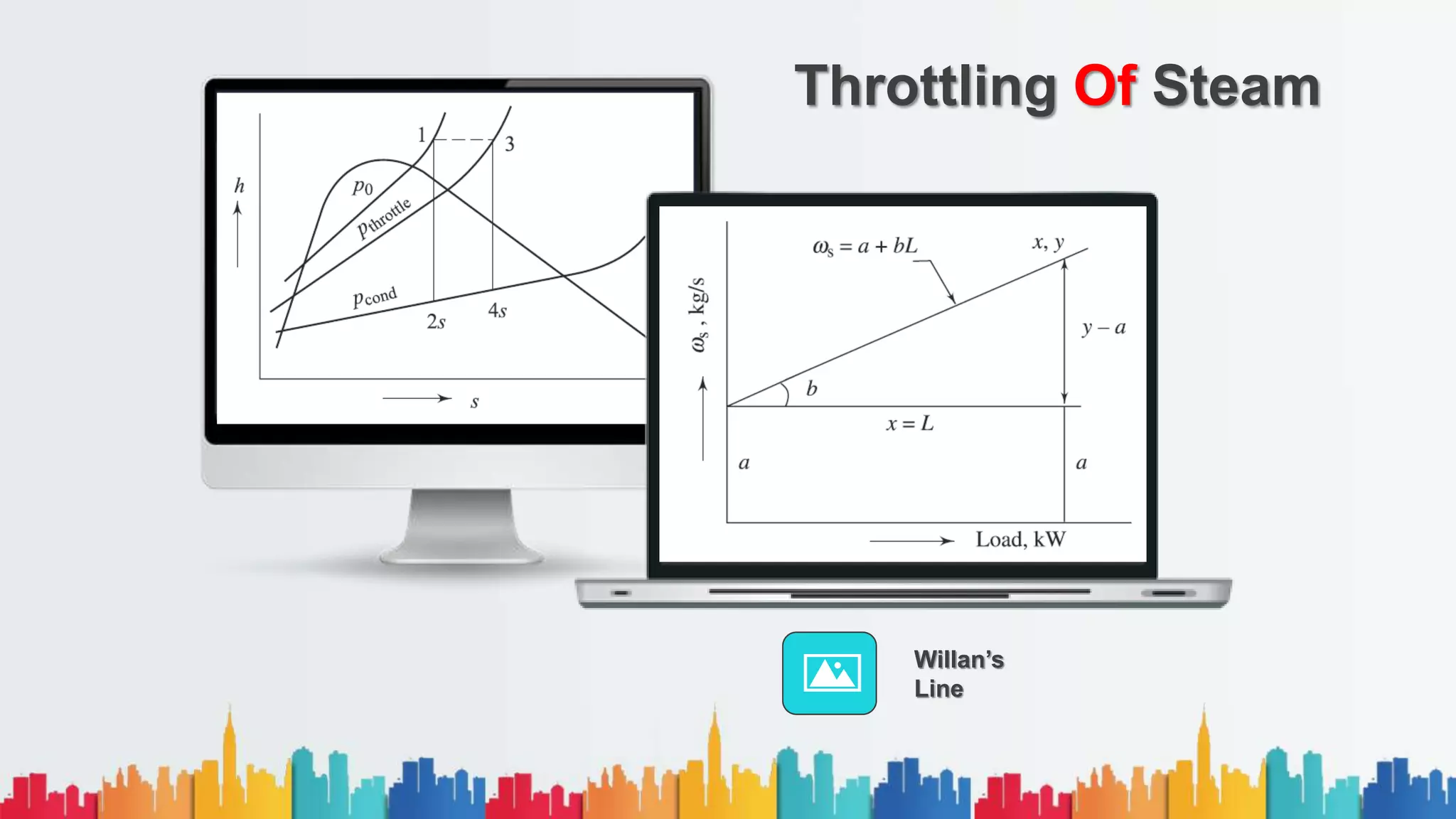

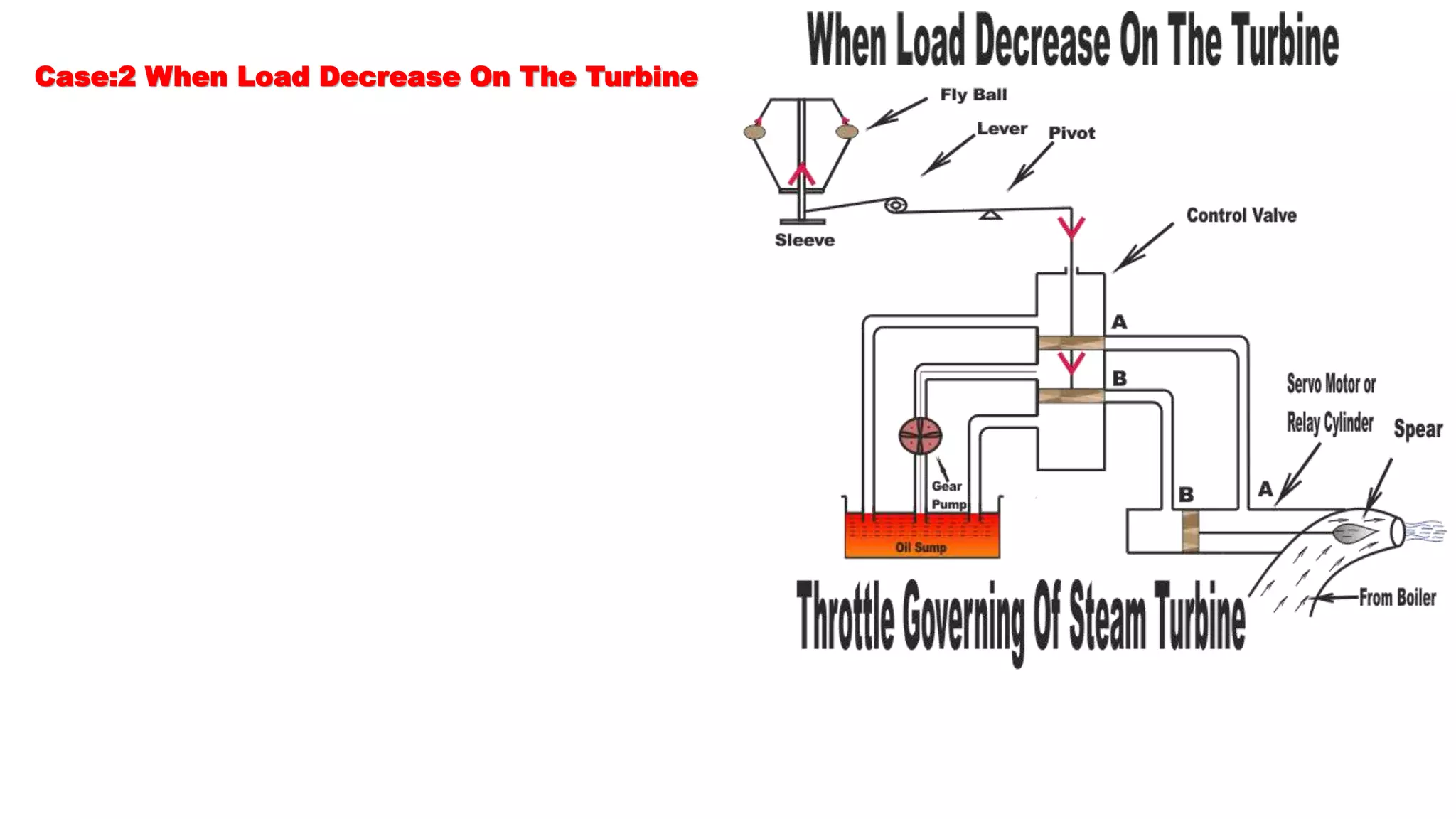

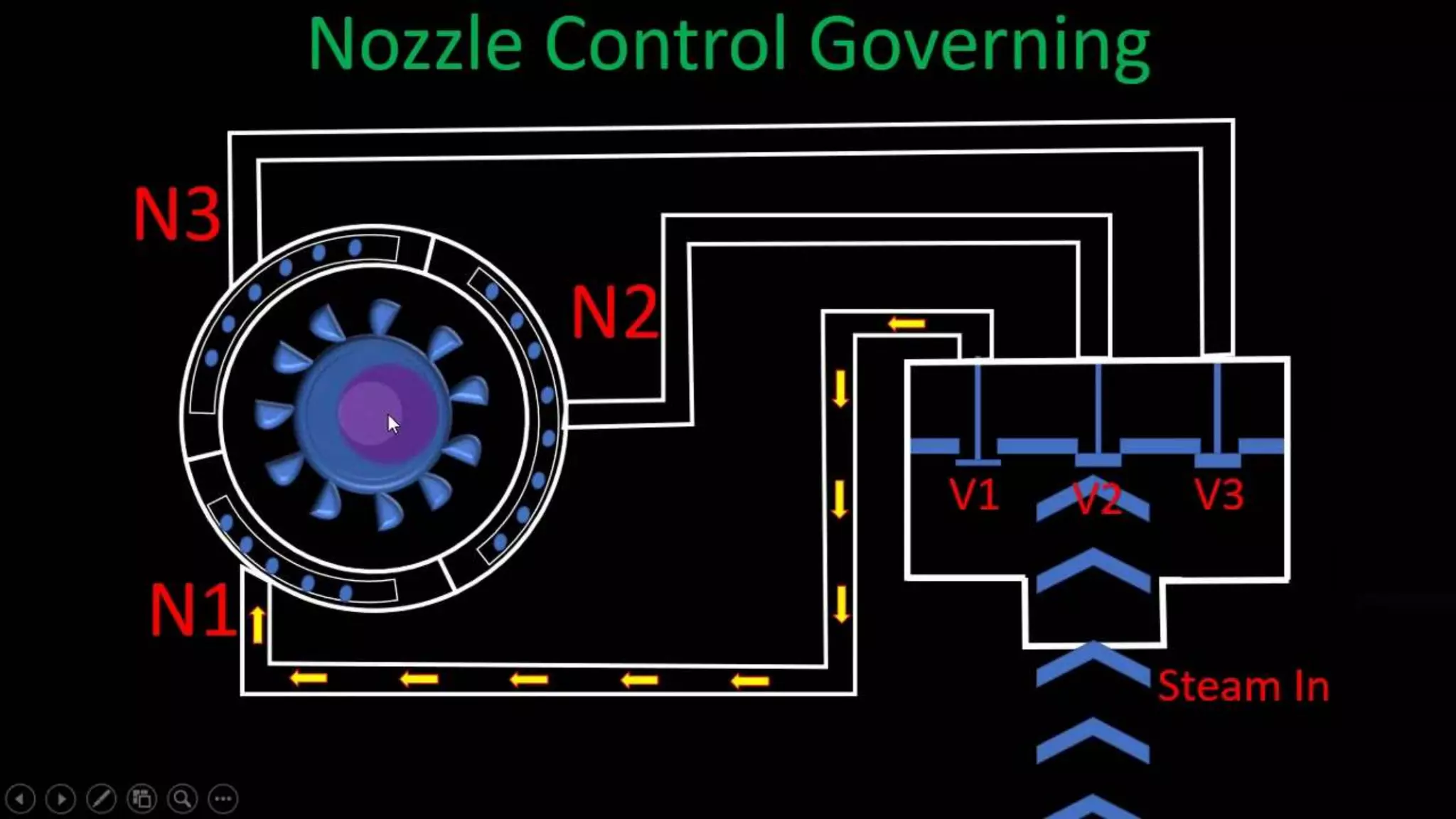

The document discusses throttle and nozzle governing systems for steam turbines. The throttle governing system controls turbine speed by varying the quantity of steam entering the turbine. When load increases, the centrifugal governor decreases its amplitude, lowering the control valve rod and increasing steam flow to bring the turbine back up to normal speed. When load decreases, the opposite occurs to reduce steam flow. The nozzle governing system controls steam flow to individual nozzle groups to regulate turbine speed during part-load operation. Only some nozzles remain open depending on the load demand.