1) The document describes the governing system and components of a steam turbine. It includes throttle controlled governing and discusses advantages like avoiding overspeeding and adjusting droop.

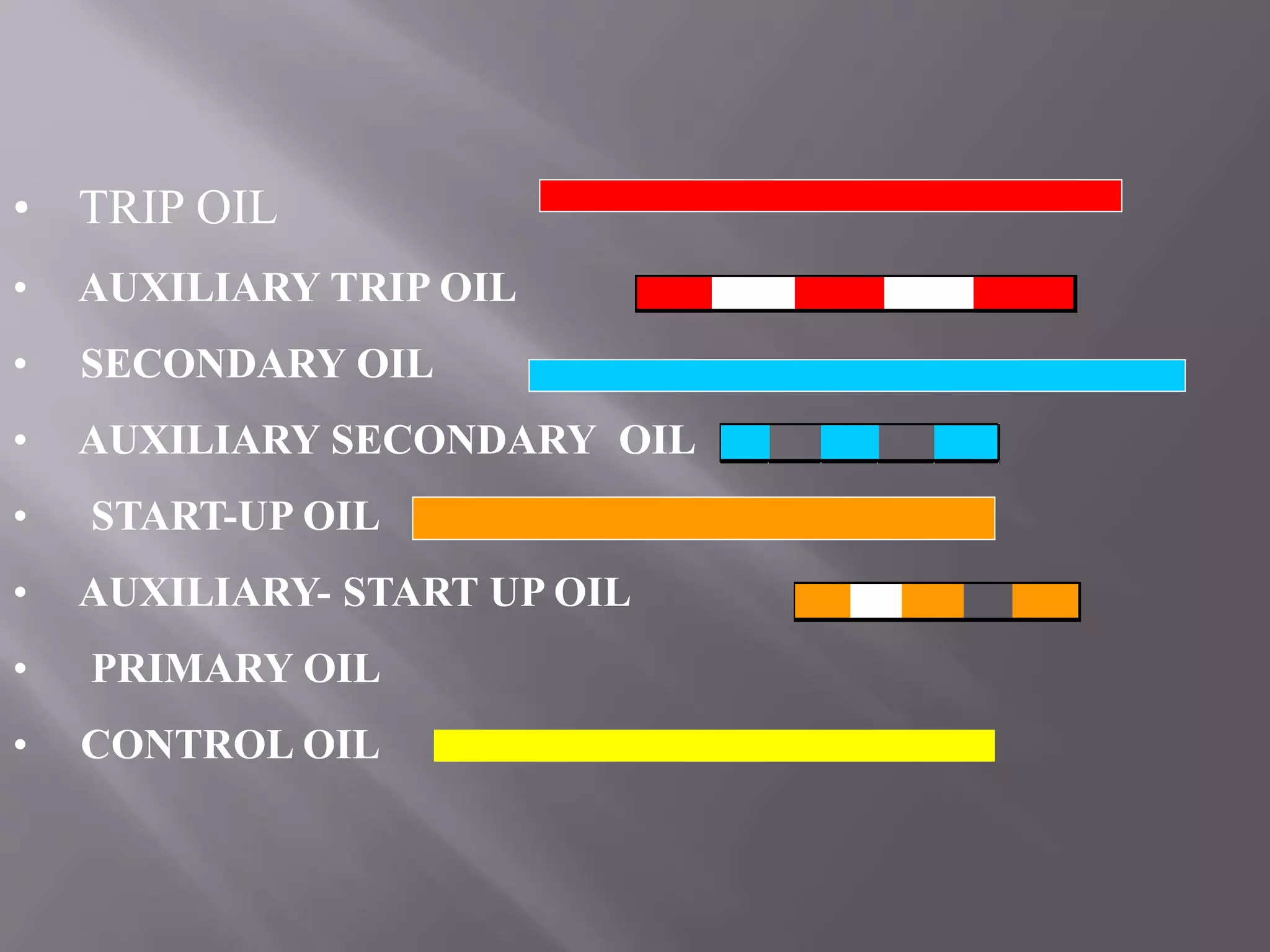

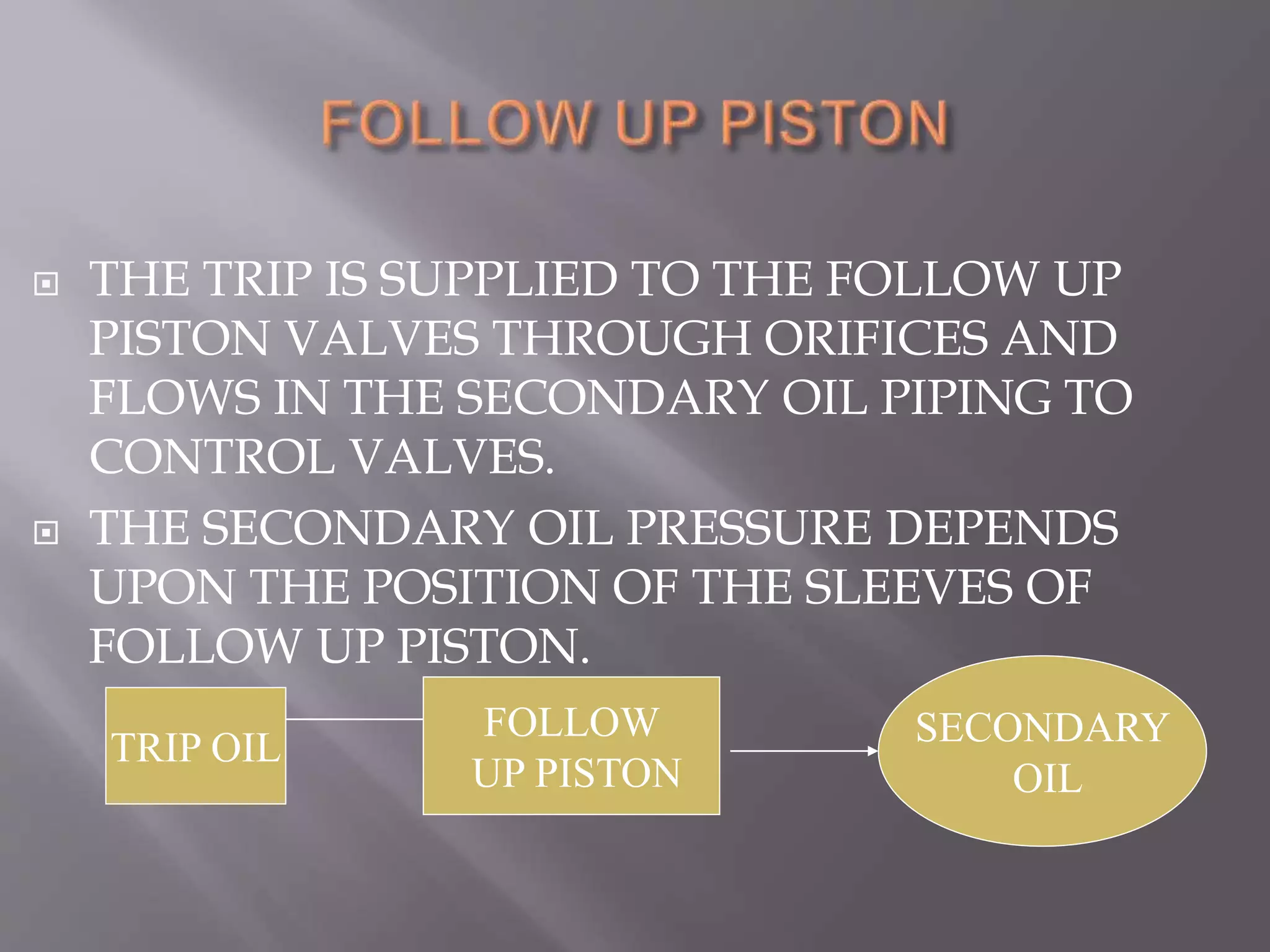

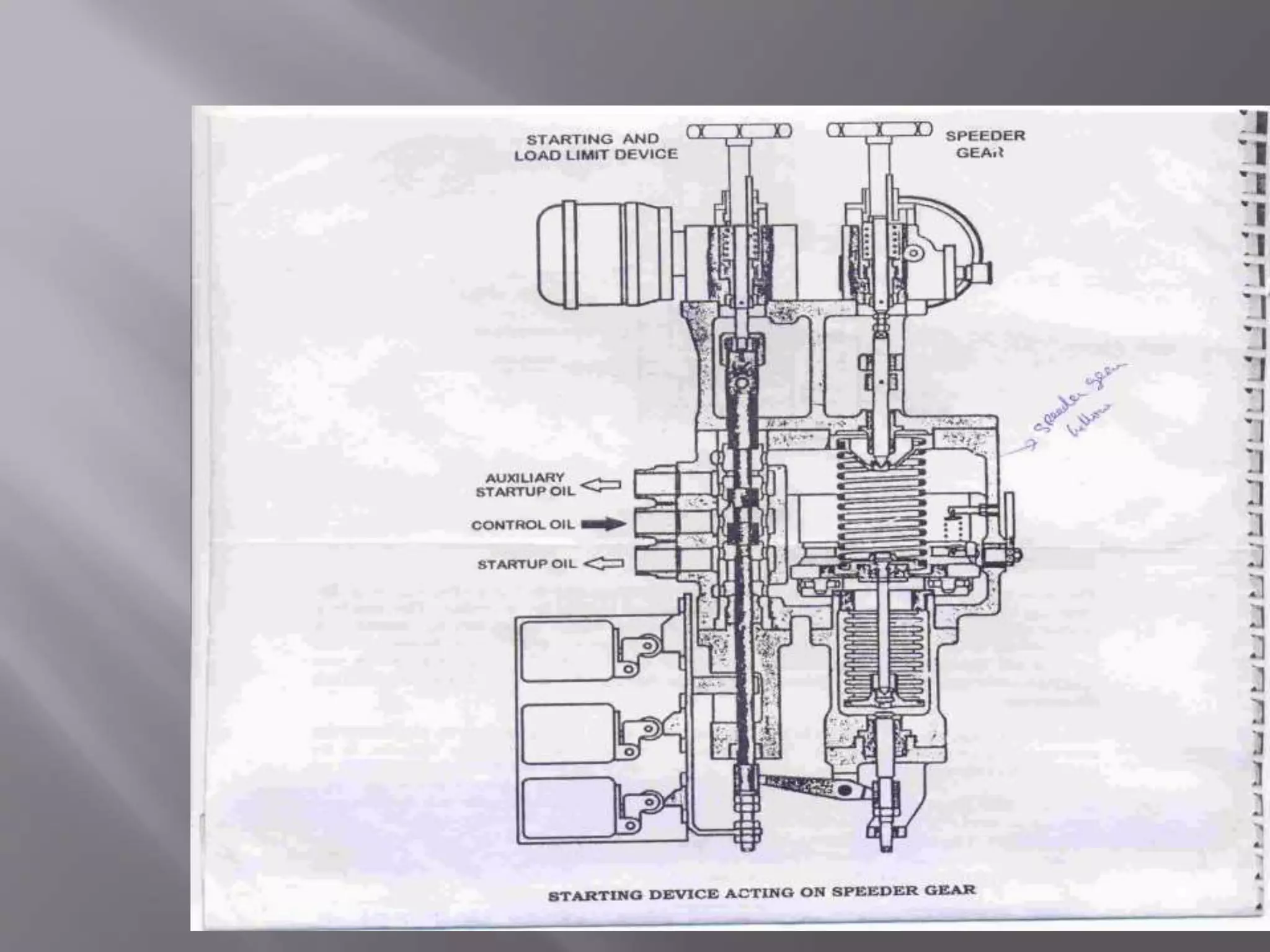

2) It lists the different oils used like trip oil, auxiliary trip oil, and control oil and describes what each oil is used for like tripping the stop valve or hydraulic governing.

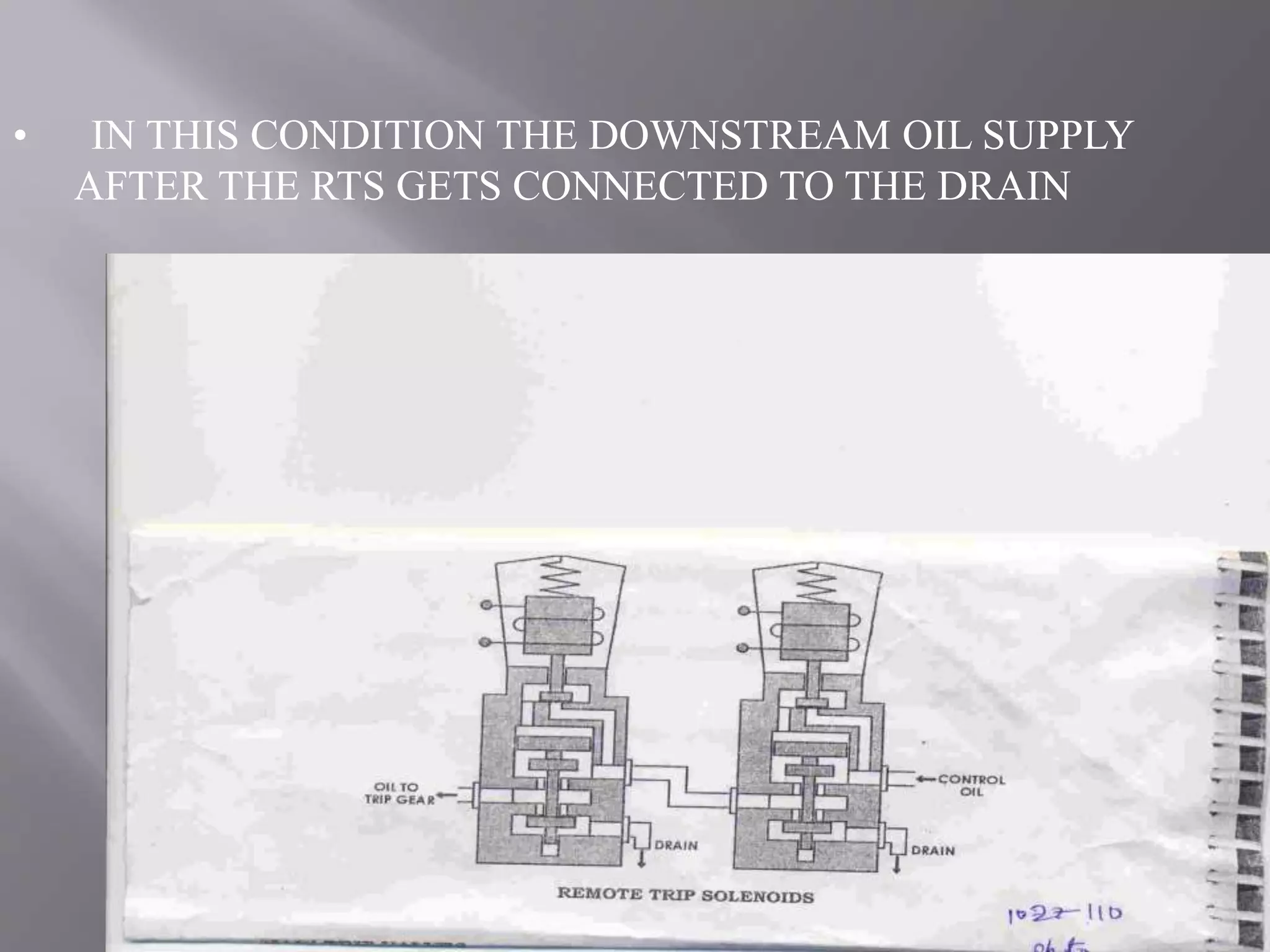

3) The main elements of the governing system are described including remote trip solenoids, main trip valve, speeder gear, and follow-up piston valves that control steam flow and turbine speed.