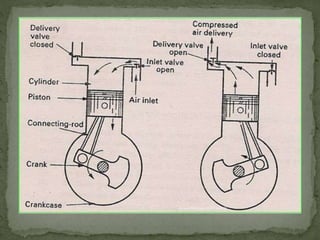

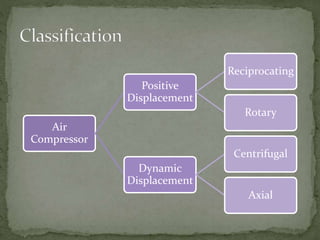

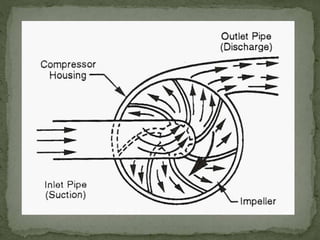

The document discusses centrifugal compressors. It begins with an introduction to air compressors in general, then describes the two main types: positive-displacement and dynamic-displacement. It focuses on centrifugal compressors, which use a rotating impeller to impart kinetic energy to air and compress it. The key components of a centrifugal compressor are the inlet, impeller, diffuser, and collector. Centrifugal compressors are commonly used in applications like gas turbines, turbochargers, pipelines, and HVAC due to benefits like fewer parts and higher efficiency compared to reciprocating compressors. However, they have a lower maximum compression ratio than reciprocating compressors.