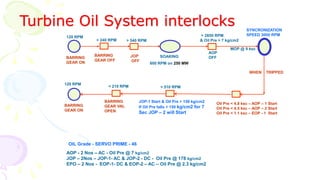

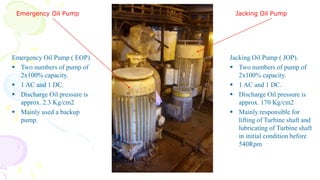

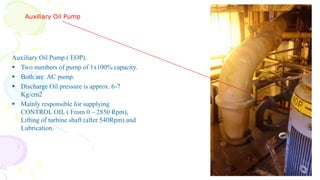

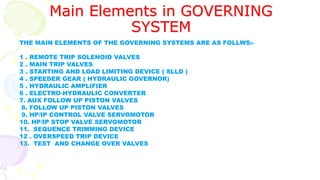

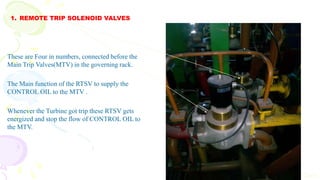

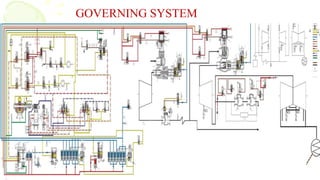

The document provides an introduction and overview of governing systems for steam turbines. It defines a governing system as a control mechanism that regulates steam turbine parameters like inlet pressure and steam flow rate to enable stable power production. It describes the main types as nozzle and throttle governing and notes most LMW turbines use nozzle while KWU turbines use throttle governing. It outlines the key components of KWU turbine governing systems including control valves, pumps, speeders and more. It provides details on operating parameters and functions of different elements.