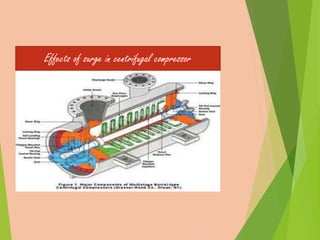

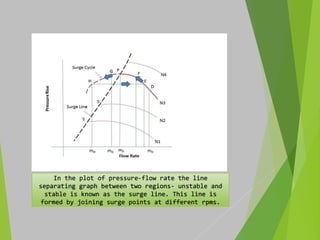

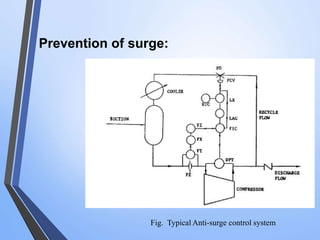

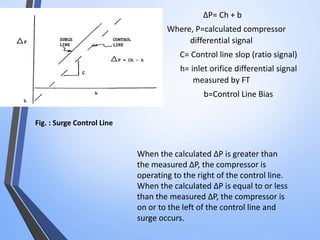

Surge is a phenomenon seen in gas turbine engines where there is a sudden decrease in the supply pressure to the compressor inlet. This causes air to flow in the reverse direction through the compressor, creating vibrations throughout the engine. Surge can be generated by diffuser vanes retarding the airflow or rotating stall causing breakdowns of the air flow between compressor blades. Repeated surging can damage components like rotor seals, bearings, and the compressor driver through high vibrations and temperature increases. Anti-surge systems aim to prevent surge by maintaining a minimum air flow through the compressor.

![Surge VS Stall

STALL

LOCAL PHENOMENON

CAUSED BY FLOW SEPARATION

TEMPORARY INSTABILITY

ROTATING IN NATURE

MAY LEAD TO SURGE

MECHANICAL DAMAGE MAY OR

MAY NOT OCCUR

SURGE

GLOBAL PHENOMENON

CAUSED BY FLOW REVERSAL

PERMANENT INSTABILITY

AXIAL IN NATURE

STALL MAY BE THE CAUSE, [TOTAL

FLOW BREAK DOWN]

DAMAGE TO THE COMPRESSOR /

TURBNE INESCAPABLE](https://image.slidesharecdn.com/surge-140915125420-phpapp02/85/Surge-in-compressor-31-320.jpg)