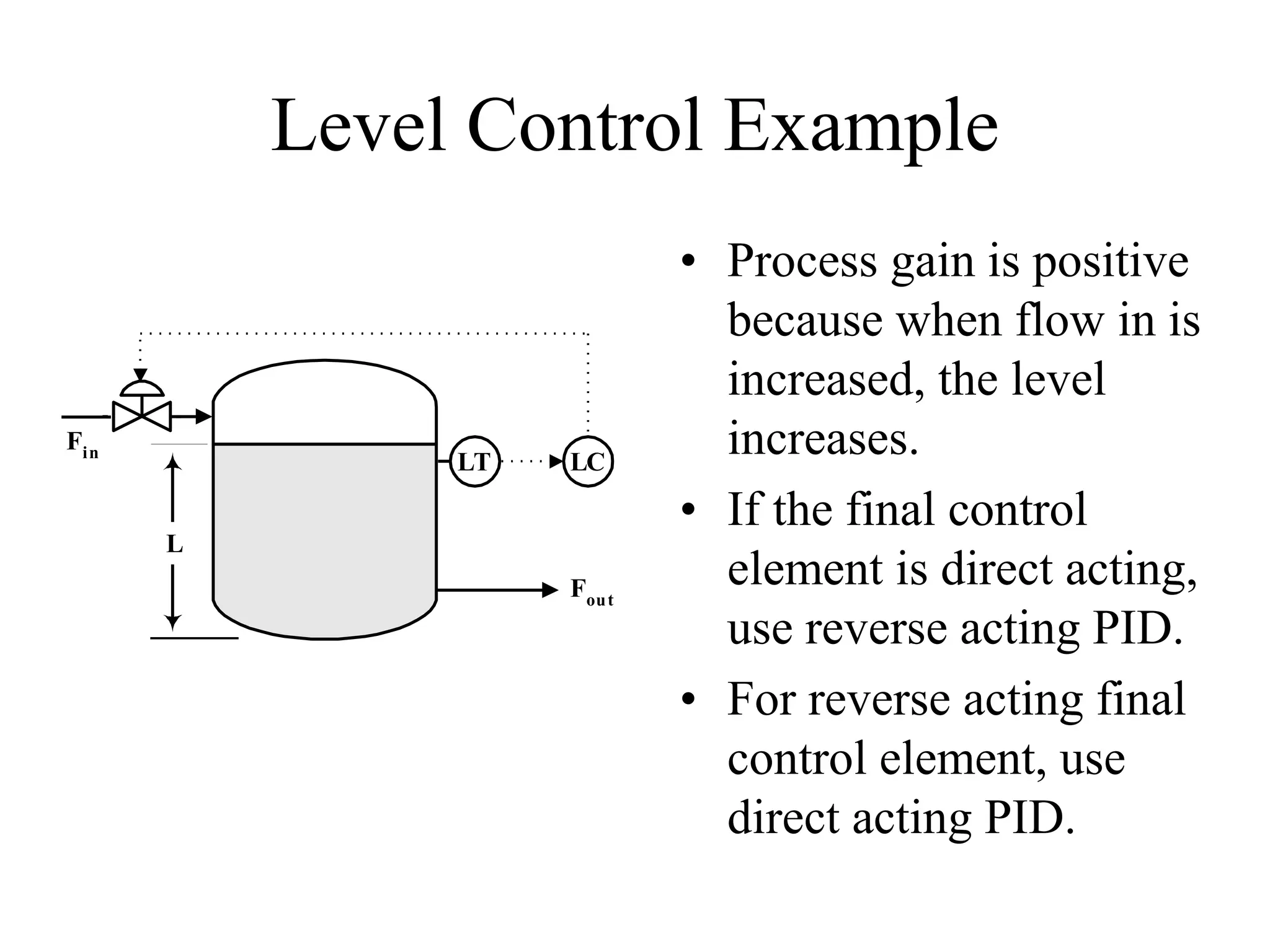

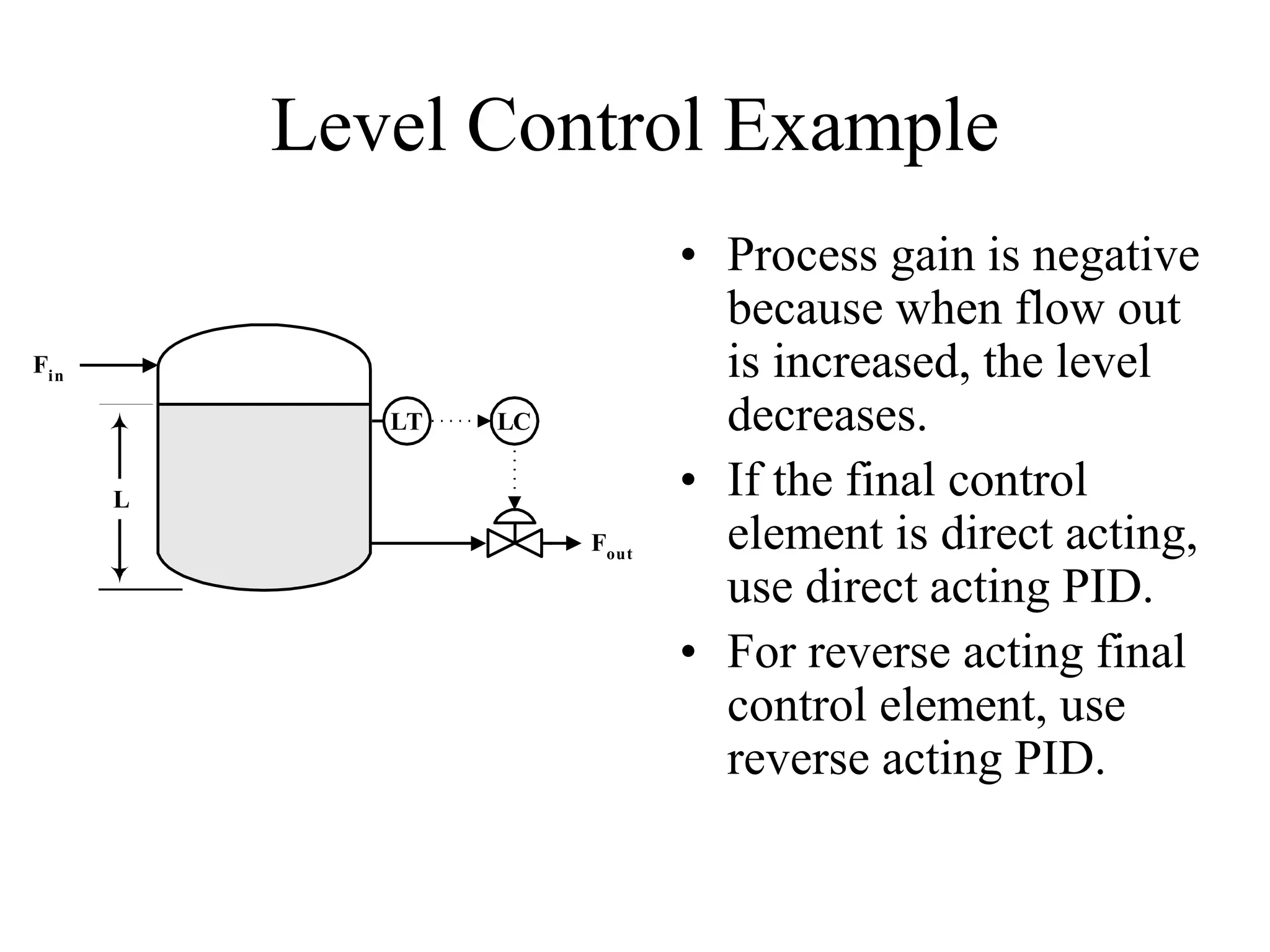

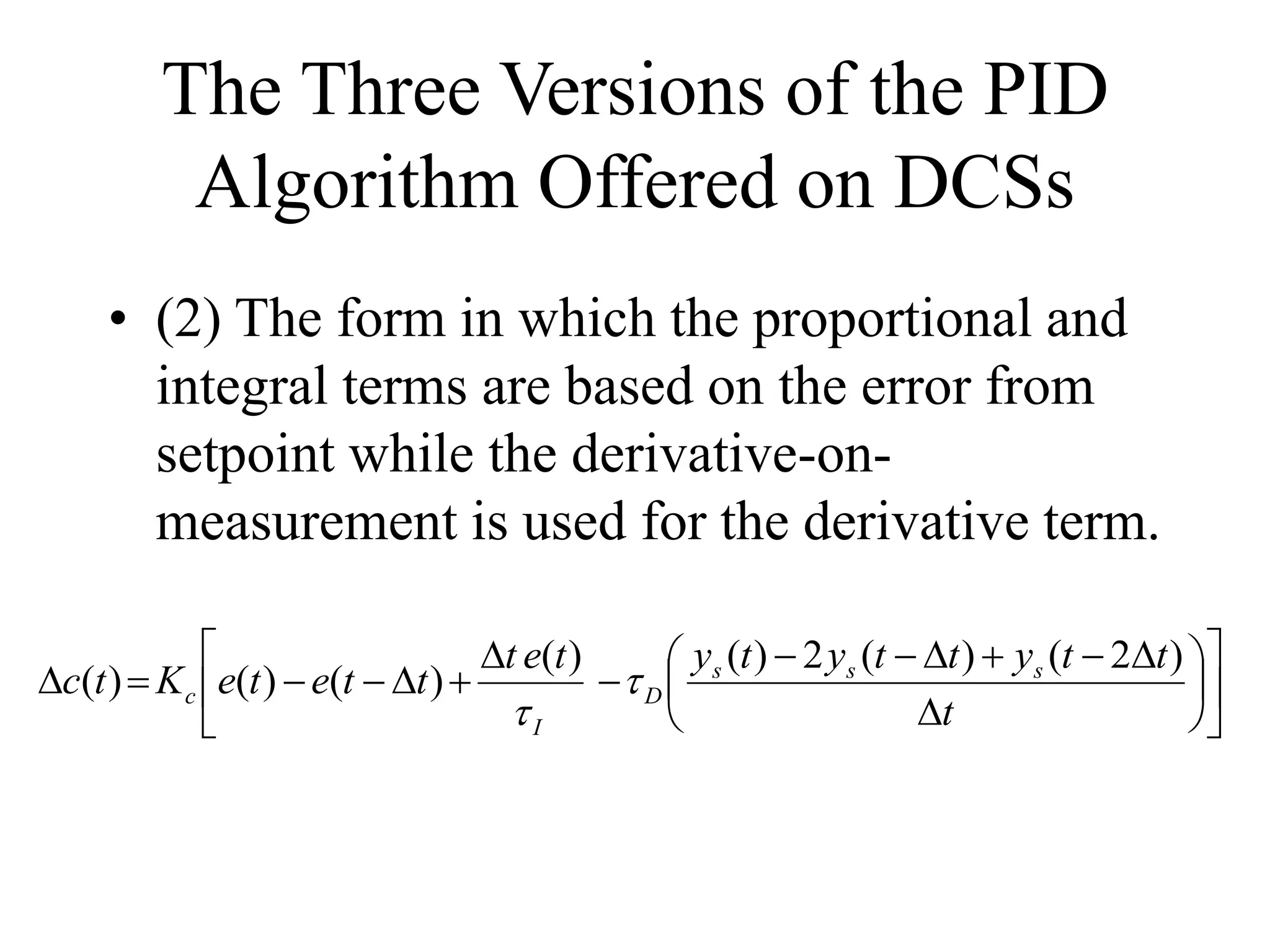

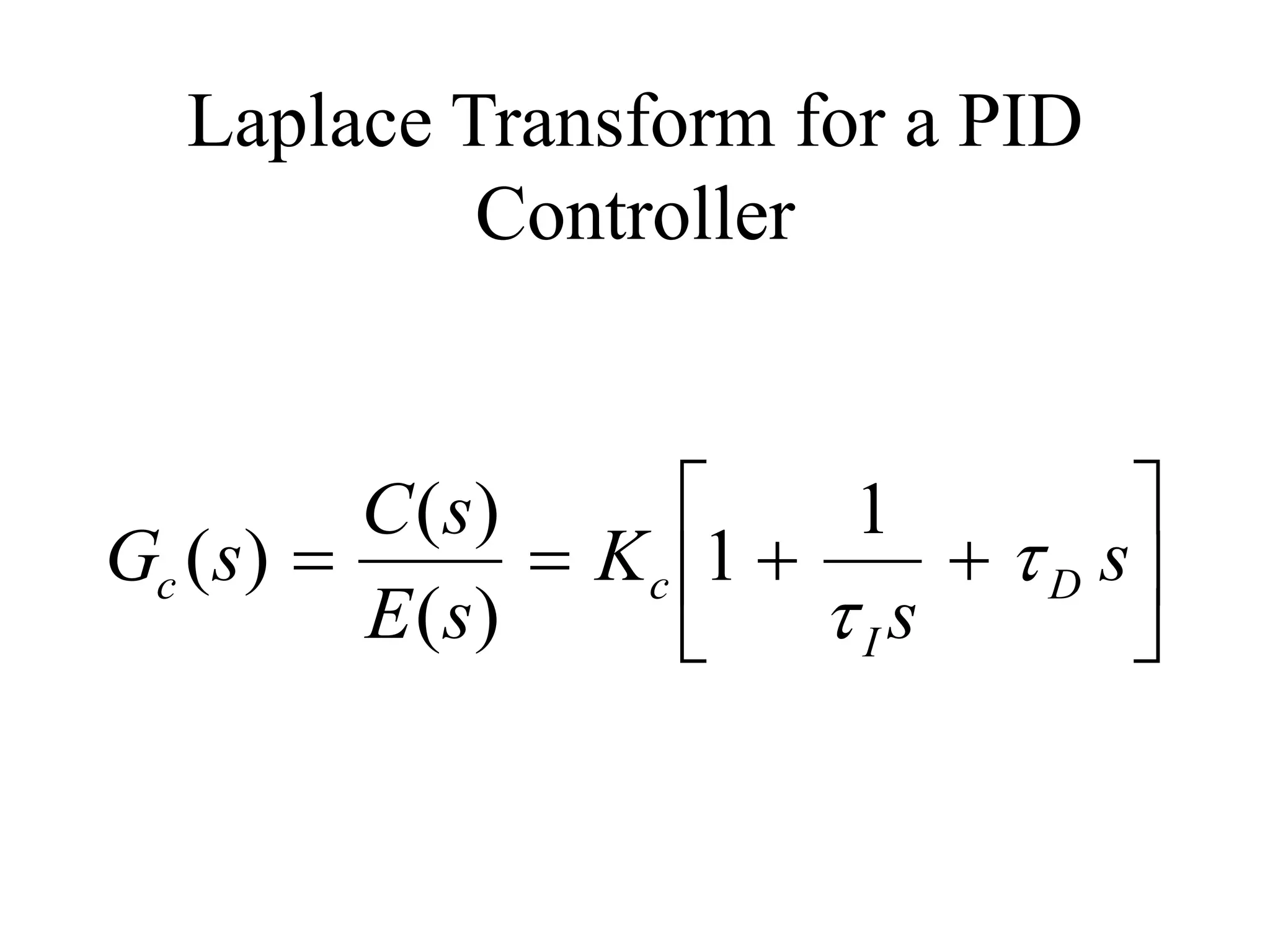

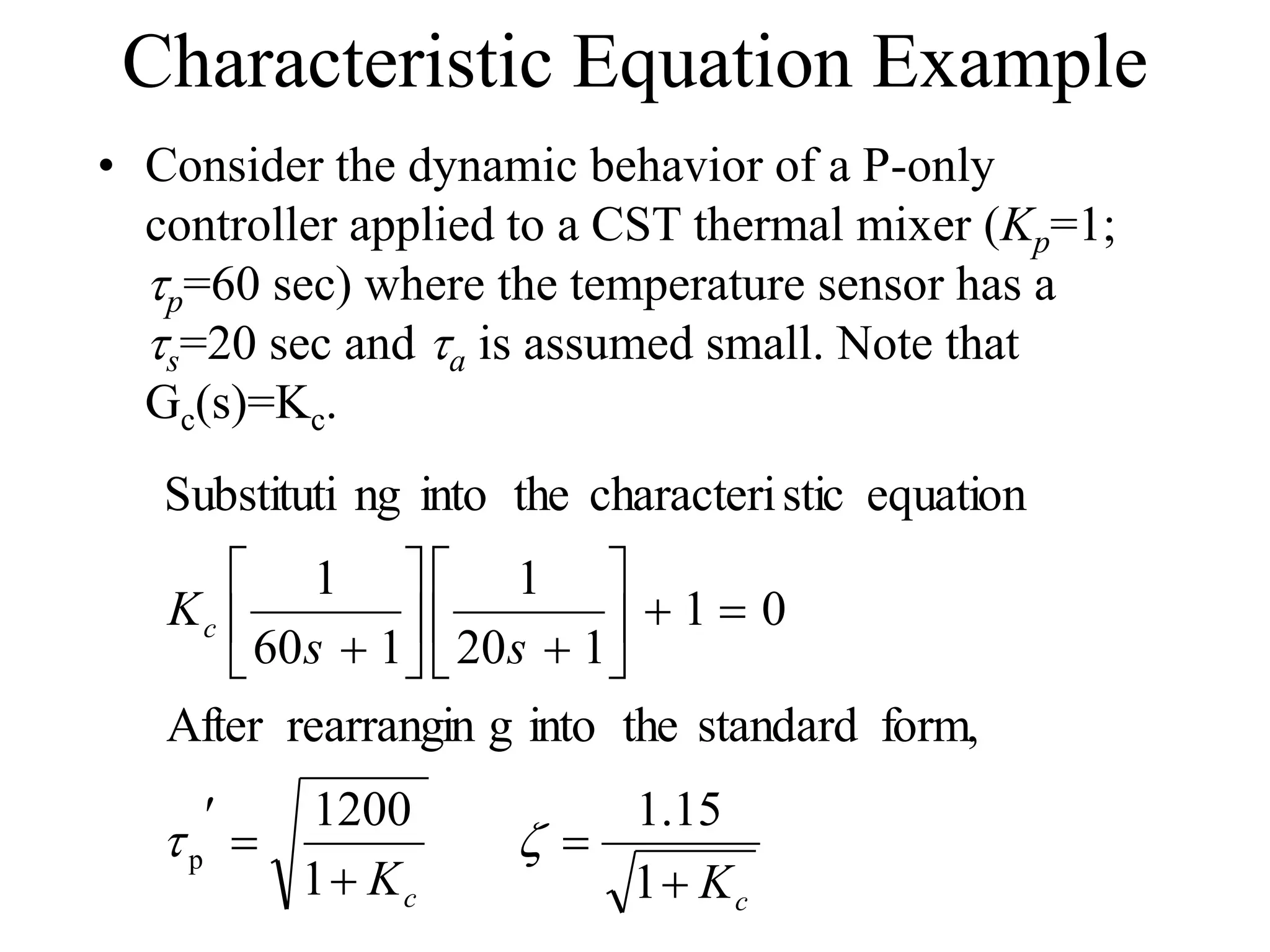

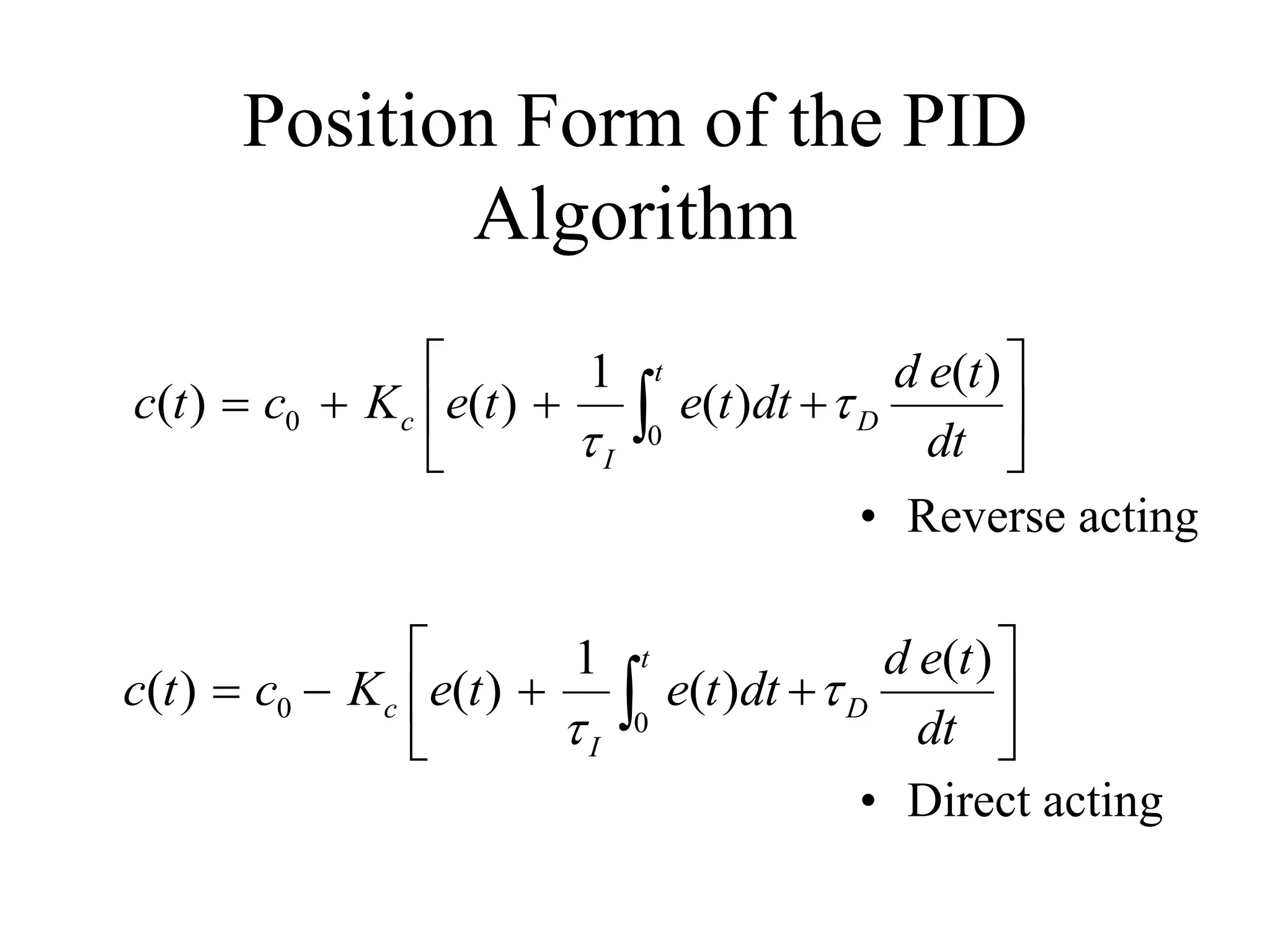

This document discusses PID control. It begins by explaining that PID controllers are the most common type used in process industries. It then provides the general feedback control loop model and shows how to derive the closed-loop transfer functions. Next, it defines the characteristic equation and provides an example using a P-only controller. The document continues by presenting the position and velocity forms of the PID algorithm as well as digital equivalents. It concludes by discussing different PID configurations available in distributed control systems.

![Definition of Terms

• e(t)- the error from setpoint [e(t)=ysp-ys].

• Kc- the controller gain is a tuning parameter

and largely determines the controller

aggressiveness.

• tI- the reset time is a tuning parameter and

determines the amount of integral action.

• tD- the derivative time is a tuning

parameter and determines the amount of

derivative action.](https://image.slidesharecdn.com/269836960-pid-control-240401143556-cf55b4a2/75/PID-Control_automation_Engineering_chapter6-ppt-9-2048.jpg)