The document discusses concepts related to tension testing of materials including:

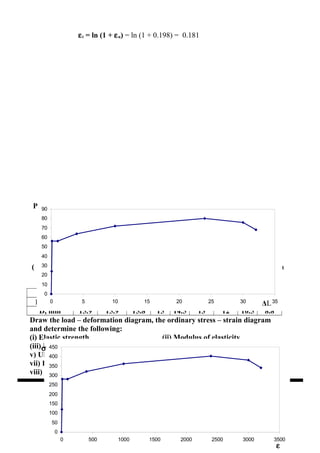

- Stress-strain diagrams and key points like proportional limit, yield point, ultimate tensile strength

- Ductile and brittle material behaviors

- Calculations of properties from test data like modulus of elasticity, resilience, toughness

- Effects of factors like carbon content, temperature, specimen geometry

Worked examples are provided to calculate properties from given tension test load-extension data.