1. The beam is a cantilever 1.2 m long made of steel tube with an external diameter of 6 cm and internal diameter of 5 cm.

2. A concentrated load W is applied at the free end of the cantilever beam.

3. The maximum bending stress in the beam is not to exceed 1. The value of the load W that satisfies this condition is required.

![Mmax

Y

I π

/64

x (7)4

X

Pp.l

. L3

48 ∆p.l

. I

3.6 x (60)3

48 x 0.3 x π

/64

(7)4

0

100

200

300

400

500

600

700

800

0 5 10 15 20 25 30 35 40 45

P

Δ

I = 1

/12

[2.5(5)3

] Y = 5/2 = 2.5

L = 90 cm M =

PL

4

W

2.5 cm

5cm

Modulus of rupture = = = 2.49 ton/cm2

Modulus of elasticity E = = = 458 ton/cm2

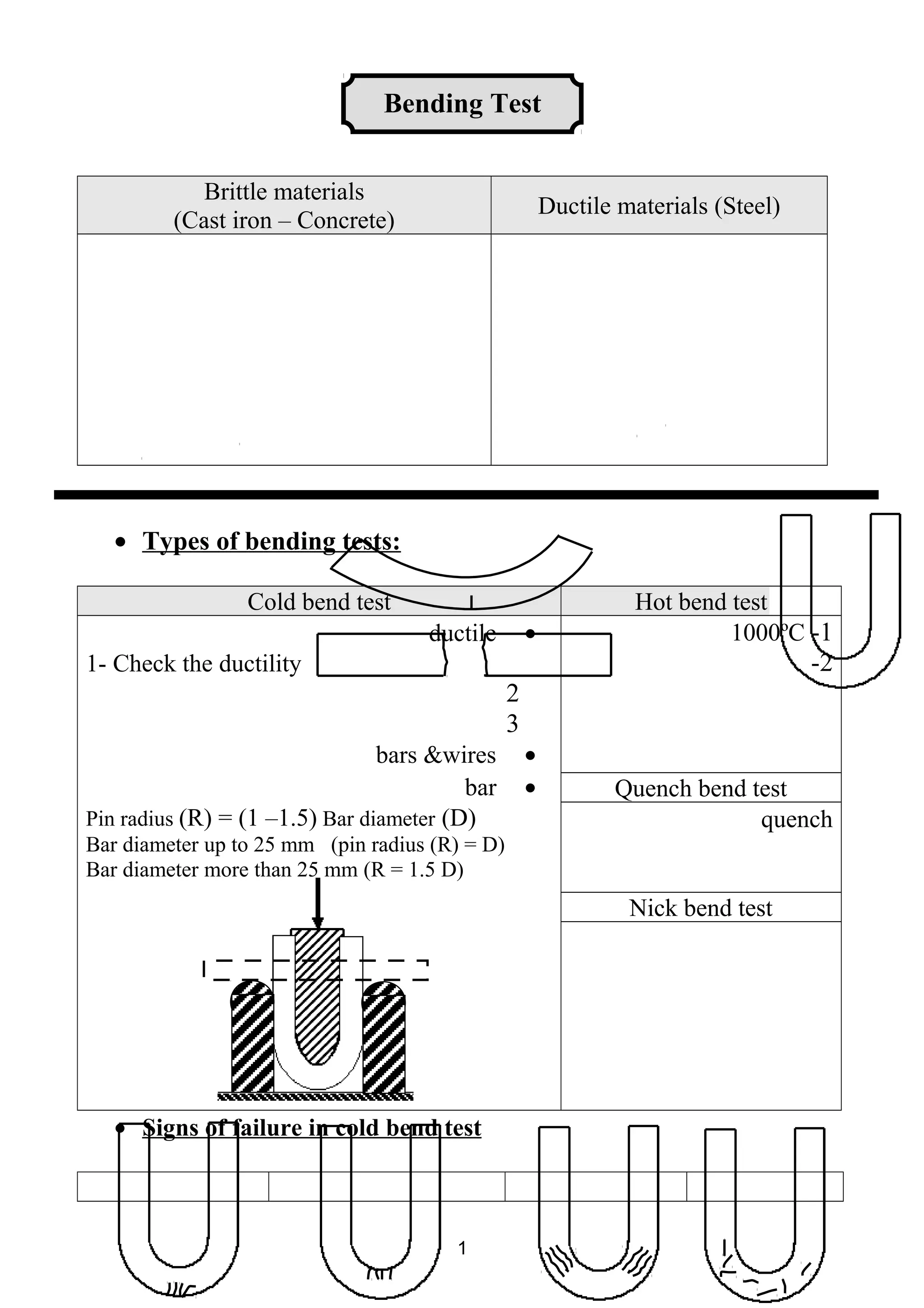

Fracture Shape

( ) A timber beam was centrally loaded; the distance between supports being 90

cm, the cross section of the beam was 2.5 cm breadth and 5 cm depth. If the

loads and corresponding deflections are as follows:

Load ( Kg) 100 200 300 400 500 600 700 750

Deflection (mm)

4.75 9.52 14.3 19.02

23.8

6

27.2

36.

1

Failure

Draw the load-deflection diagram and determine:

a) Extreme fiber stress at limit of proportionality

b) Modulus of rupture

c) Modulus of resilience

d) Modulus of toughness

e) Stiffness of material

9

0

1

2

3

4

5

6

0 2 4 6 8 10 12

P

Δ

4

5.6 x 60

2

7](https://image.slidesharecdn.com/3-bendingtest-161027220430/75/3-bending-test-9-2048.jpg)

![W

D cm

L = 80 mm I = π

/64

(D)4

Y = D/2M =

PL

4

1000

1200P

Stress at proportional limit = = = 1.08 ton/cm2

Modulus of rupture = = = 1.62 ton/cm2

Modulus of resilience = = = 0.53 x 10-3

ton/cm2

Modulus of toughness = = = 1.87 x 10-3

ton/cm2

Modulus of elasticity E = = = 122 ton/cm2

( ) A cast iron beam of circular cross-section was tested in bending under a

central load and on support 80 mm apart. If the modulus of resilience of this

grade of cast iron equals 0.196 Kg/cm2

and the loads and corresponding

deflections measured during the test are as follows:

Load ( Kg)

150 300 450 600 750

90

0

1050 1100

Deflection (mm) 1.05 2.1 3.15 4.2 5.25 6.8 8.88 Failure

Draw the load-deflection diagram and determine:

a) Diameter of cross section

b) Modulus of rupture

10

½ Pp.l

X ∆p.l

Ao

Lo

⅔ Pmax

X ∆max

Ao

Lo

Mp.l

Y

I 1

/12

[2.5(5)3

]

4

0.5 x

2

5

X

Mmax

Y

I 1

/12

[2.5(5)3

]

4

0.75 x

2

5

X

½ x 0.5 x 2.386

2.5 x 5 x 90

⅔ x 0.75 x 4.2

2.5 x 5 x 90

Pp.l

. L3

48 ∆p.l

. I

0.5 x (90)3

48 x 2.386 x 1

/12

[2.5(5)3

]](https://image.slidesharecdn.com/3-bendingtest-161027220430/75/3-bending-test-10-2048.jpg)

![0

200

400

600

800

0 1 2 3 4 5 6 7 8 9 10

Δ

c) Modulus of elasticity

Modulus of resilience = = = 1.96 x 10-3

kg/mm2

D = 126 mm

Modulus of rupture = = = 0.112 kg/mm2

Modulus of elasticity E = = = 0.123 kg/mm2

( ) A simply supported cast iron beam of square cross-section 12cm x 12cm was

centrally loaded by 24 tons, if the bending strength of the beam is 25

kg/mm2

. Calculate the span of the beam.

= = 25 kg/mm2

L = 1200 mm

11

Mmax

Y

I π

/64

x (126)4

4

1100 x 80

2

126

X

½ Pp.l

X ∆p.l

Ao

Lo

½ x 750 x 5.25

π

/4

(D)2

x 80

Pp.l

. L3

48 ∆p.l

. I

750 x (80)3

48 x 5.25 x π

/64

(126)4

I = 1

/12

[120(120)3

] Y = 120/2 = 60mm

L =??? M =

PL

4

P

12 cm

12cm

1

/12

[120(120)3

]

4

24000 L

2

120

XM . Y

I

σ =](https://image.slidesharecdn.com/3-bendingtest-161027220430/75/3-bending-test-11-2048.jpg)

![( ) A cantilever 1.2 m consisting of a steel tube with external and internal

diameters of 6 and 5 cm respectively, carries a concentrated load of W (Kg)

at the free end. Neglecting the weight of the tube, it is required to find the

value of W if the maximum bending stress is not to exceed 1.3 ton/cm2

.

= = 1.3 ton/cm2

W = 0.119 ton = 119 kg

12

π

/64

[(6)4

- (5)4

]

W x 120 x 3M .Y

I

σ =

M = P L

P

L = 120 cm I = π

/64

[(6)4

- (5)4

] Y = D/2 = 6/2 = 3 cm

6

5](https://image.slidesharecdn.com/3-bendingtest-161027220430/75/3-bending-test-12-2048.jpg)

![I = 1

/12

[10(15)3

] Y = 15/2 = 7.5cm

L = 240 cm

M =

W L

4

=

240W

4

I = 1

/12

[10(h)3

] Y = h/2

M =

W x 0.6 x 100

2

=

( ) A simply supported beam of 2.4 m span

has a constant width of 10 cm throughout

its length with varying depth of 15 cm at

the centre to minimum at the ends as

shown in fig. the beam is carrying a point

load W at its mid span. Find the

minimum depth of the beam at a section

0.6 m from the left hand support. Such that the maximum bending stress at

this section is equal to that at the mid span of the beam.

At mid span

= = 0.16 W

At 0.6 m from left support

30 W

13

2.4m

W

BCA

10

15

W

W/2W/2

0.6 m

10

10

15

1

/12

[10(15)3

]

4

240 W

2

15

XM . Y

I

σ1

=](https://image.slidesharecdn.com/3-bendingtest-161027220430/75/3-bending-test-13-2048.jpg)

![2 = =

σ1 = σ2

0.16 W = 18 W / h2

h = 10.61 cm

14

h

10

1

/12

[10(h)3

]

30 W XM . Y

I

σ = 2

h

h2

18W](https://image.slidesharecdn.com/3-bendingtest-161027220430/75/3-bending-test-14-2048.jpg)