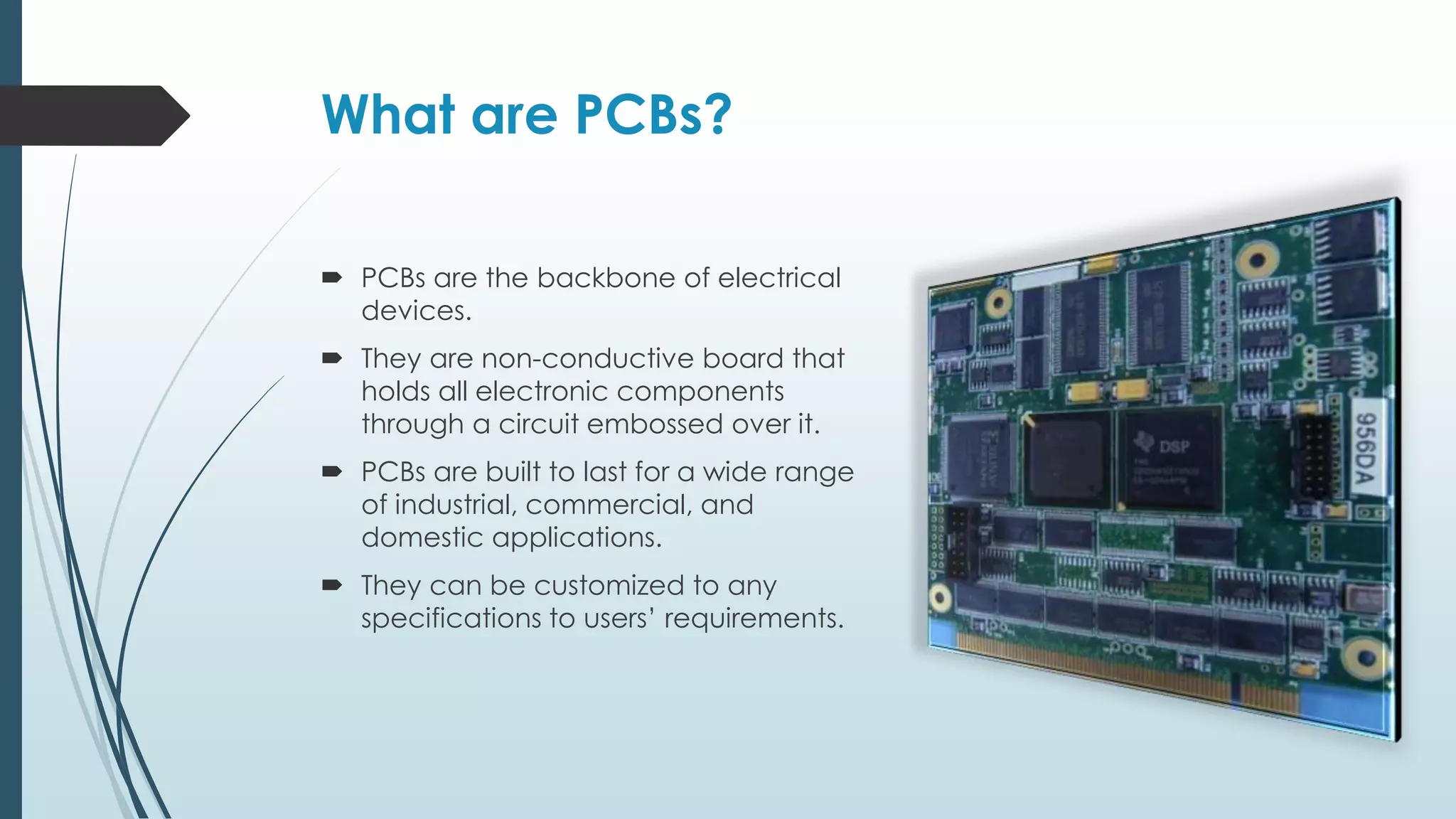

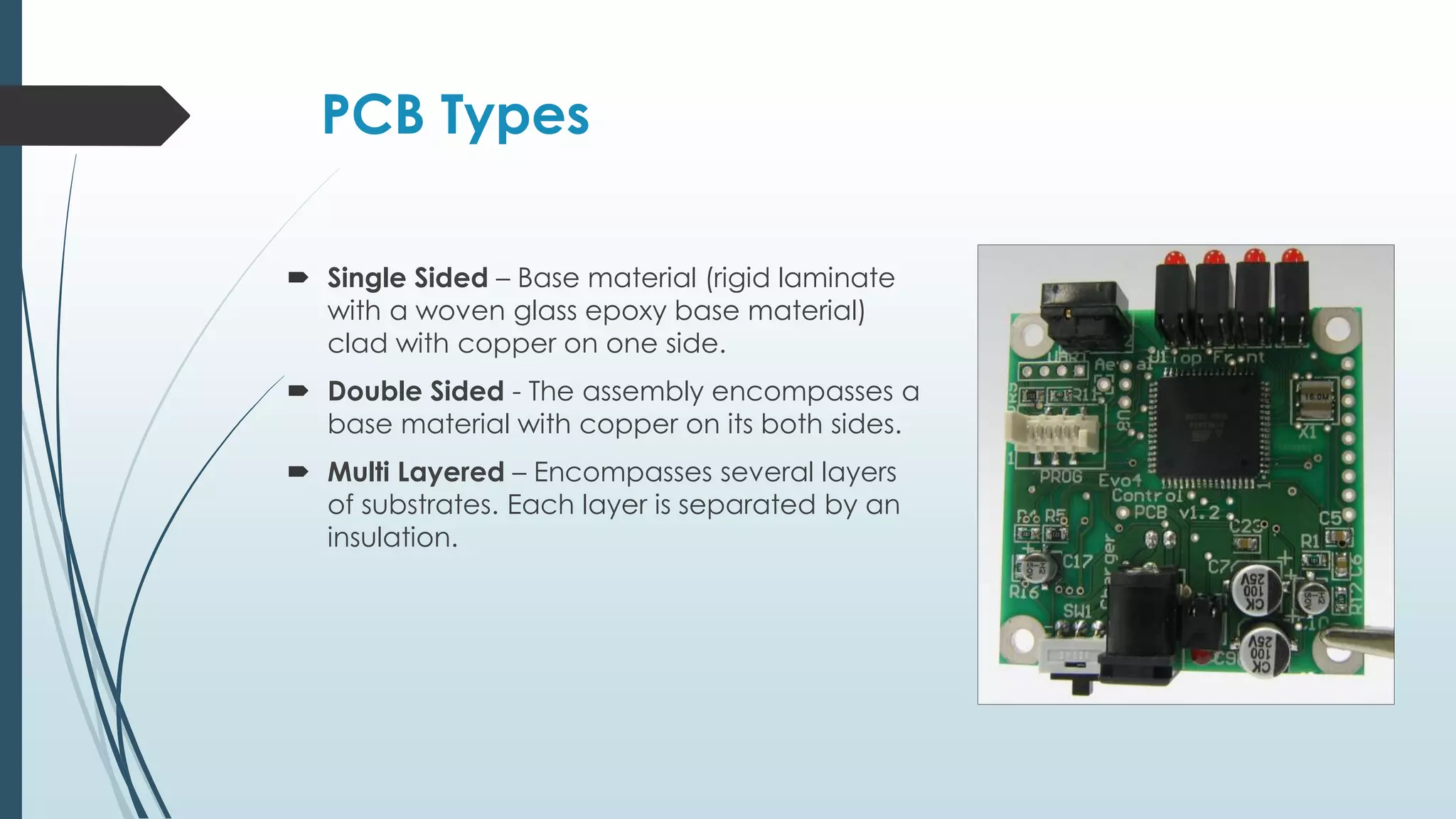

Printed circuit boards (PCBs) are essential components made of non-conductive material that hold electronic elements through a custom circuit. They have evolved since their first creation for military use during World War II and come in various types, including single-sided, double-sided, and multi-layer designs. PCBs are used in a wide range of applications such as medical devices, military systems, telecommunications, automotive, and consumer electronics.