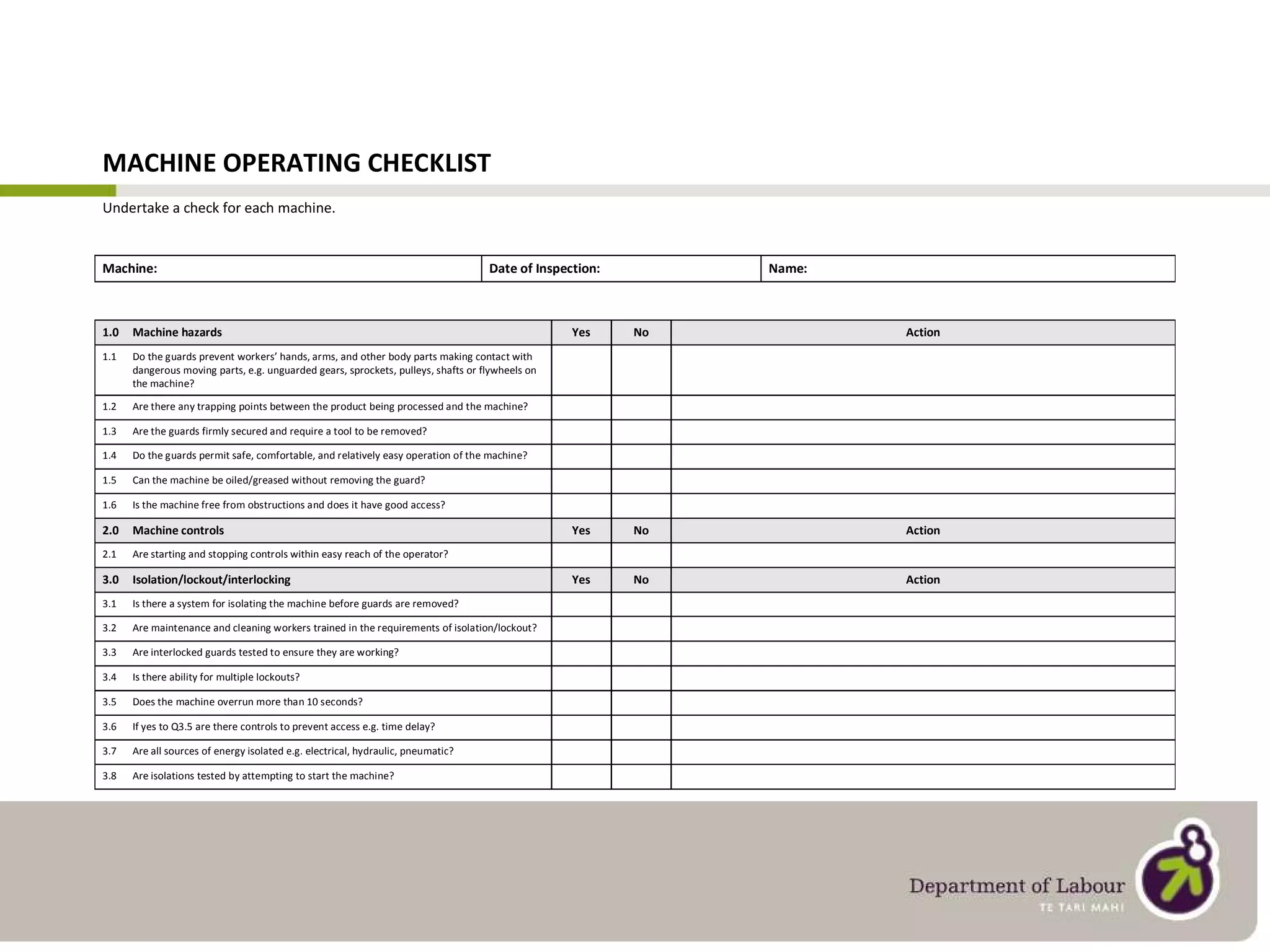

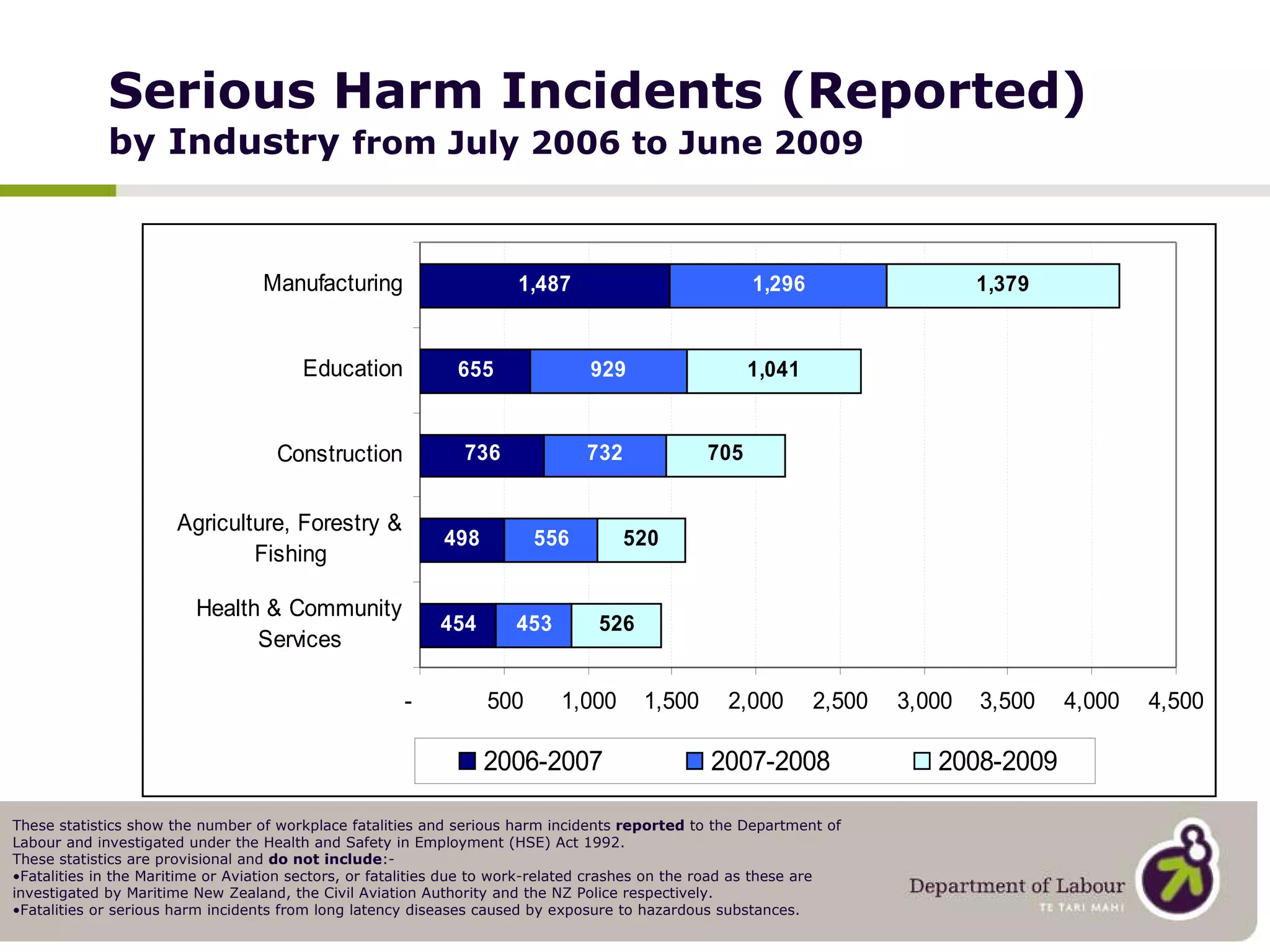

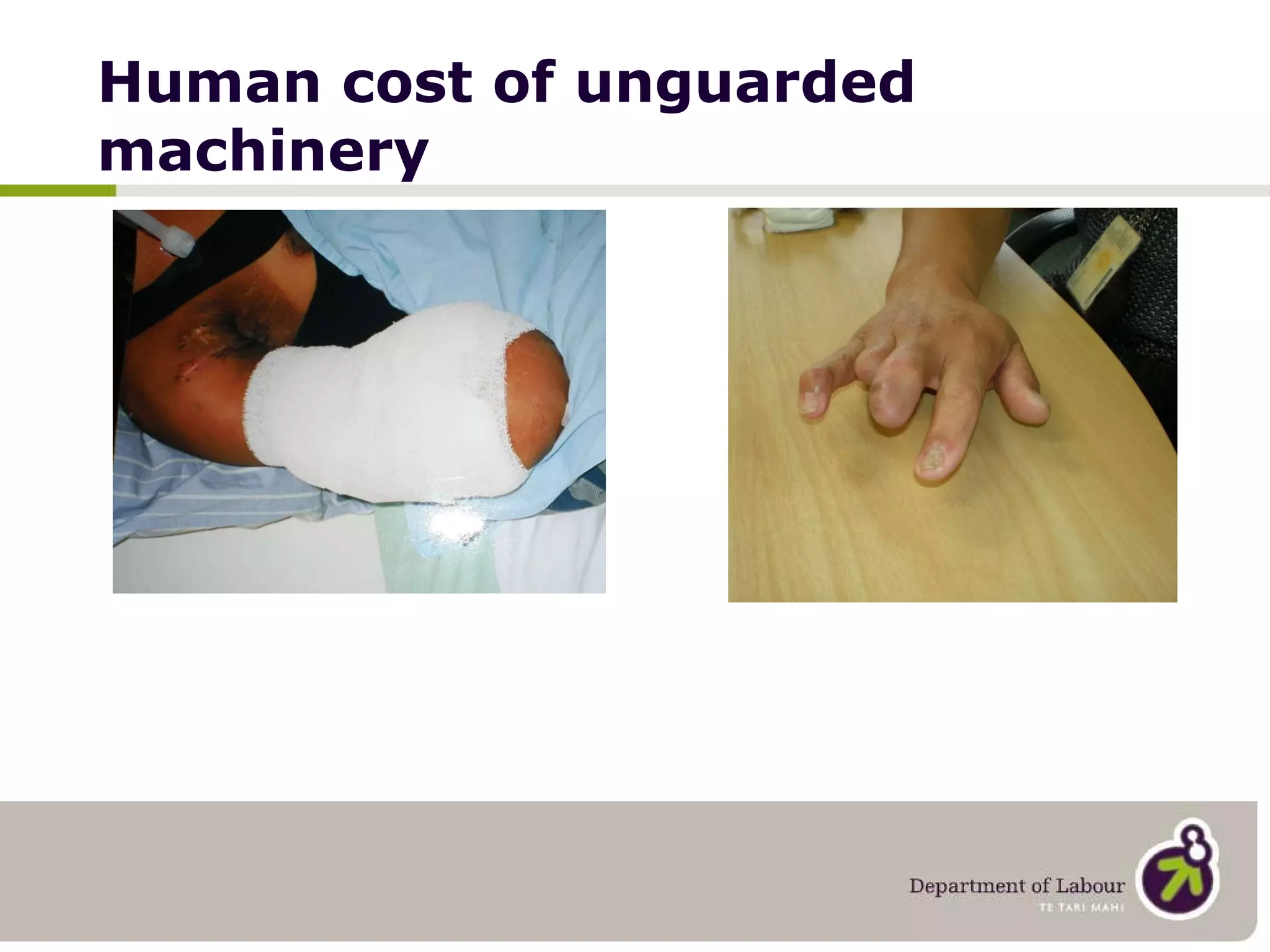

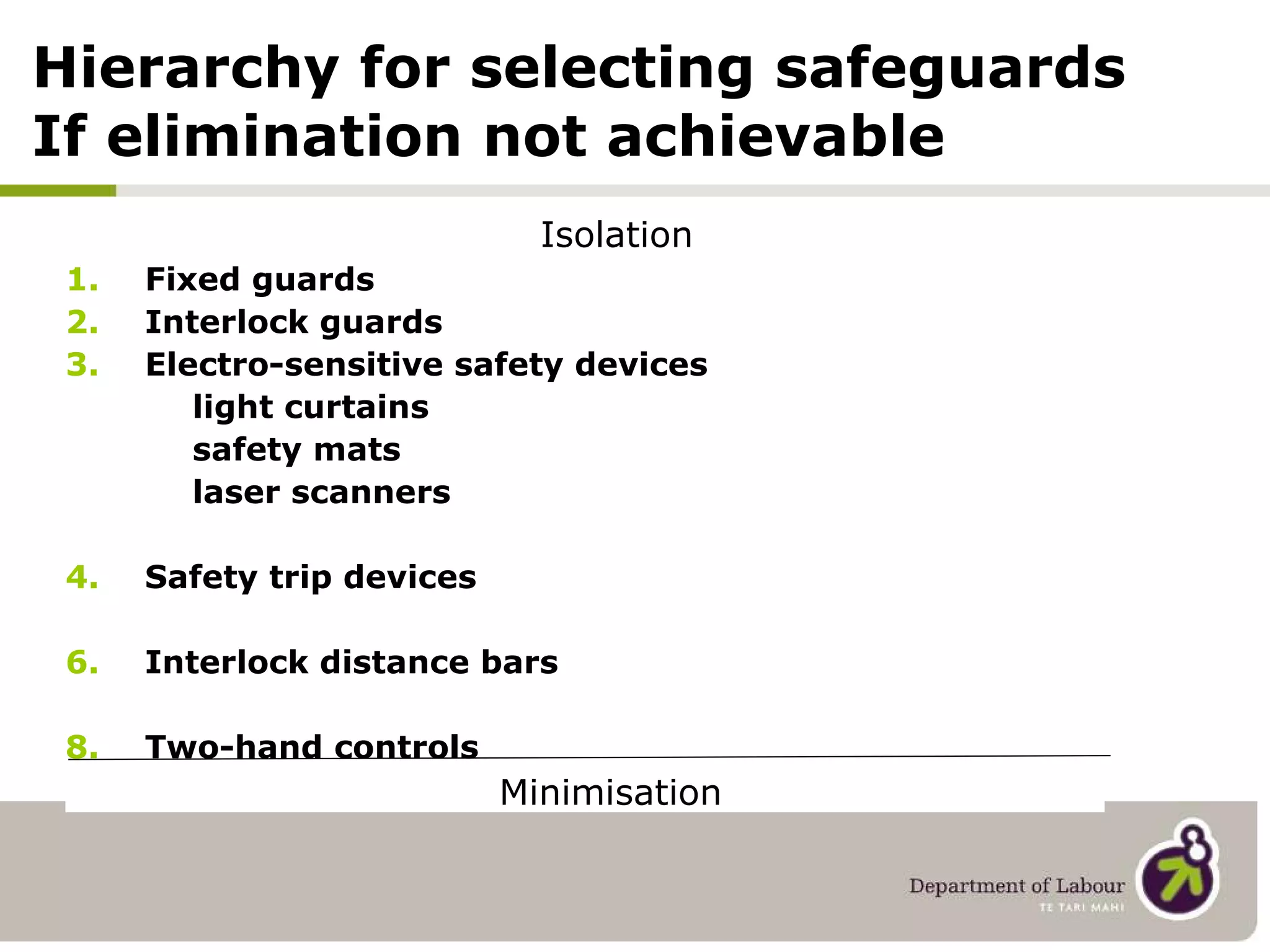

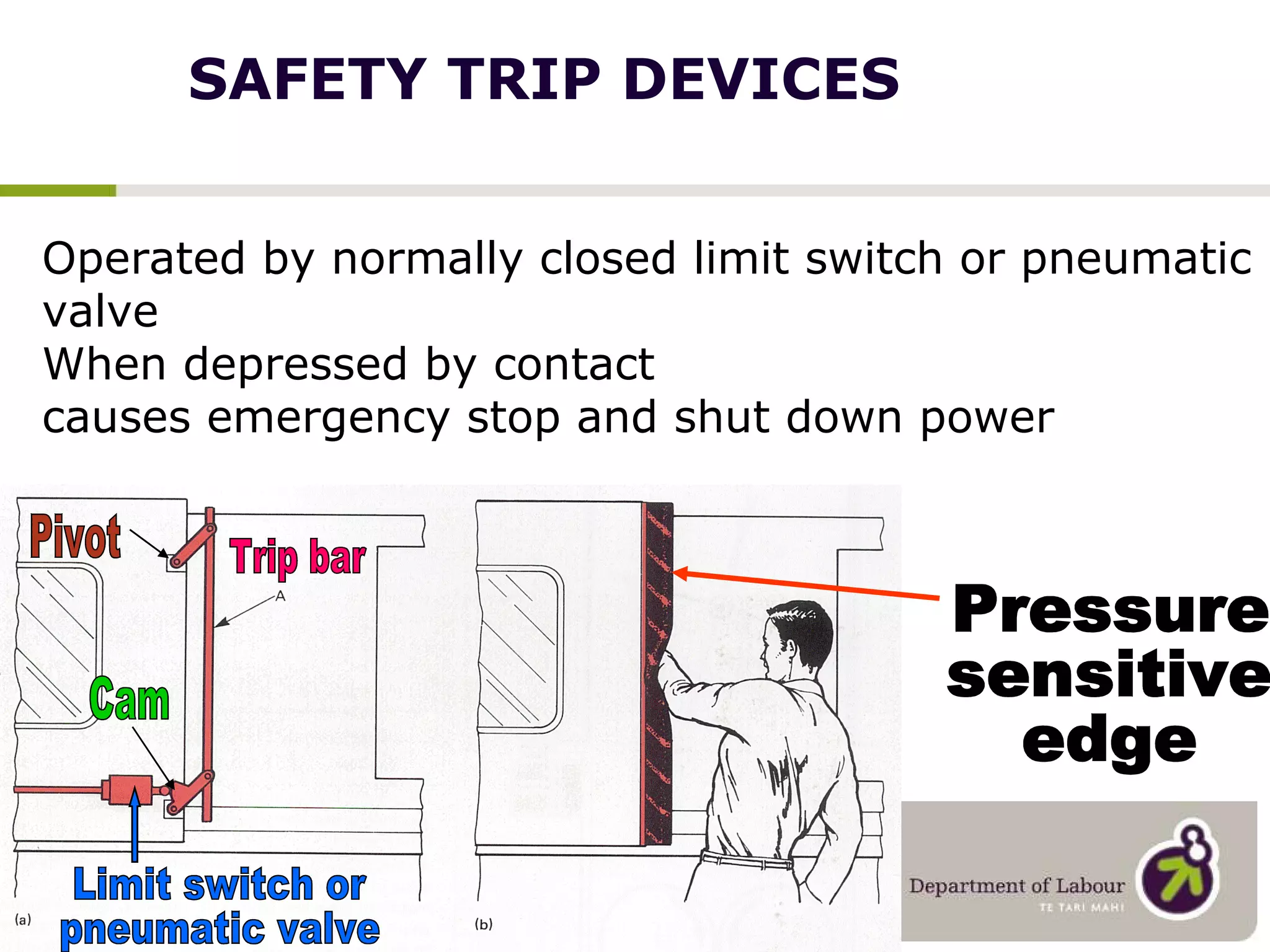

The document outlines a national machine guarding project initiated by the Department of Labour aimed at reducing fatalities and serious injuries caused by unsafe machinery in workplaces. It details compliance with machine guarding standards, responsibilities of employers and workers, and proactive assessment processes alongside guidelines to ensure safety measures are effectively implemented. Furthermore, it highlights the significance of collaboration between inspectors and employers, as demonstrated by the Northland District Health Board's engagement in adhering to safety standards.